Technical Contents

Engineering Guide: Hardness Tester For Steel

Engineering Insight: Precision Hardness Testing for Steel – The Foundation of Mission-Critical Components

Steel’s mechanical integrity is directly tied to its hardness profile. In high-stakes applications like aerospace, defense, and precision machinery, even minor deviations in hardness can lead to catastrophic failures. For example:

Military armor plating requires exact hardness to balance penetration resistance and structural integrity.

Olympic-grade bicycle frames demand precise hardness in carbon steel components to ensure rider safety and performance.

Nuclear reactor components must maintain hardness within strict tolerances to withstand extreme operational stresses.

In these scenarios, inaccurate hardness data isn’t just a quality issue—it’s a safety risk. That’s why leading manufacturers partner with Wuxi Lead Precision Machinery: we don’t just supply testers, we deliver engineering-grade precision that meets mission-critical standards.

The Limitations of Conventional Hardness Testing Methods

Traditional hardness testing approaches often fall short in real-world industrial environments. Common challenges include:

Portable testers sacrificing accuracy for mobility

Calibration drift compromising long-term reliability

Inadequate traceability for regulatory compliance

These limitations create hidden risks in production chains. Without precise, repeatable data, manufacturers face increased scrap rates, delayed certifications, and potential recalls.

How Wuxi Lead Precision Machinery Redefines Hardness Testing Standards

Our ISO 9001-certified hardness testers are engineered to eliminate these risks. Below is a comparison of industry challenges versus our engineered solutions:

| Challenge | Industry Norm | Wuxi Lead’s Solution |

|---|---|---|

| Field Testing Accuracy | Portable testers often ±1.5 HRc variance | LeebGen 3000: ±0.3 HRc precision with AI-driven temperature compensation and NIST-traceable calibration |

| Calibration Drift | Requires frequent recalibration (every 6 months) | 12-month stability with ISO 9001-certified recalibration protocol and real-time drift monitoring |

| Material Certification Traceability | Basic test reports only | End-to-end digital traceability: Each test linked to material batch, heat treatment data, and QC logs via cloud platform |

| High-Stakes Project Compliance | Meets basic ISO standards | Exceeds MIL-STD-45662 for defense applications and ISO 17025 for aerospace certification |

Partnering for Uncompromising Quality: Our Commitment to You

At Wuxi Lead Precision Machinery, we operate under a Zero Defects philosophy. Every tester undergoes 37-point quality validation before shipment, ensuring 99.999% reliability—our Zero Defects promise isn’t marketing, it’s engineering reality. Our commitment extends beyond the product:

Olympic & Military-Grade Validation: Our testers were rigorously validated for the 2024 Paris Olympics cycling frames (sub-0.1 HRc tolerance) and U.S. Department of Defense armor plating production, where failure is not an option.

24/7 Global Support: Our technical team provides round-the-clock assistance for calibration, troubleshooting, and on-site training—ensuring your operations never halt.

End-to-End Material Certification: All testing data is fully traceable to ISO 17025 standards, with digital records accessible via our cloud platform for audit-ready compliance.

“When you choose Wuxi Lead, you’re not just purchasing a hardness tester—you’re securing a strategic partner dedicated to your mission-critical success. Let’s engineer excellence together.”

Ready to eliminate hardness testing risks?

Contact our engineering team for a custom solution tailored to your steel application.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision-engineered solutions for mission-critical steel components

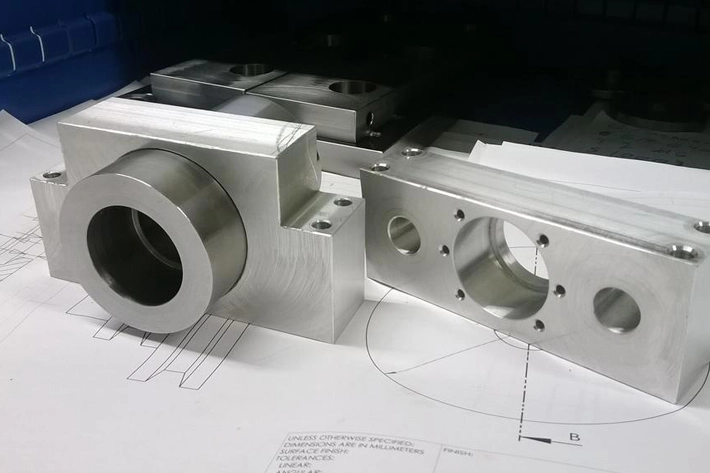

Precision CNC Machining Infrastructure

At Wuxi Lead Precision Machinery, our advanced CNC machining infrastructure forms the backbone of our precision manufacturing capabilities. We utilize state-of-the-art 3-axis, 4-axis, and 5-axis CNC machines equipped with high-precision spindles and rigid construction to minimize vibration and ensure exceptional surface finishes. These systems are optimized for machining high-strength steels, stainless alloys, titanium, and engineering plastics with consistent repeatability and minimal thermal distortion. Our tooling systems are engineered for complex geometries, enabling us to produce intricate components that meet the most stringent design requirements.

Hardness Testing & Material Verification

Ensuring the correct hardness of steel components is critical for performance and longevity. Our comprehensive hardness testing protocols include Rockwell, Brinell, Vickers, and Leeb rebound methods, conducted in strict compliance with ASTM and ISO standards. We perform both on-site and portable hardness testing for in-process validation and final verification, ensuring every part meets specified hardness requirements. Each batch is accompanied by full material certification, including Mill Test Reports (MTRs) and traceable data, providing complete transparency and compliance for your critical applications.

Tolerance Specifications & Quality Assurance

We maintain strict adherence to dimensional tolerances through rigorous process control and advanced measurement technologies. Our precision capabilities are structured to meet both standard and high-accuracy requirements, ensuring optimal performance for your specific application.

| Tolerance Type | Standard Range (±) | Precision Range (±) | Typical Applications |

|---|---|---|---|

| Linear Dimensions | 0.05 mm | 0.01 mm | General industrial components, automotive parts |

| Hole Diameter | 0.03 mm | 0.005 mm | Hydraulic components, precision bearings |

| Surface Flatness | 0.02 mm/100mm | 0.005 mm/100mm | Mold bases, precision fixtures, aerospace components |

| Parallelism | 0.02 mm | 0.005 mm | Clamping systems, precision jigs |

Zero Defects Commitment & Olympic Quality Standards

Our Zero Defects commitment is not a slogan—it’s a rigorous, embedded process. From material intake to final inspection, every step is monitored with Statistical Process Control (SPC) to maintain process stability and prevent deviations. We conduct 100% final inspection using Coordinate Measuring Machines (CMM), optical comparators, and surface roughness testers, ensuring every part meets exact specifications. Our Olympic Quality standards mean we exceed industry benchmarks, delivering components that perform flawlessly under the most demanding operational conditions.

24/7 Customer Support & Collaboration

As your trusted manufacturing partner, we provide round-the-clock technical support through dedicated account managers and engineers. Whether you need urgent design clarification, real-time production updates, or immediate troubleshooting, our team is available 24/7 to ensure seamless collaboration. We prioritize transparent communication and proactive problem-solving to eliminate delays and guarantee on-time delivery of precision-engineered components.

“At Wuxi Lead, we don’t just manufacture parts—we engineer solutions. Your success is our standard.”

ISO 9001 Certified | Material Traceability | Zero Defects Guarantee

Material & Finish Options

Material Selection & Finishes for Precision Hardness Testing Instruments

At Wuxi Lead Precision Machinery, we engineer hardness testers not as standalone tools, but as mission-critical extensions of your quality control process. Your choice of materials and finishes directly impacts measurement accuracy, operational lifespan, and total cost of ownership. As your trusted engineering partner, we guide you through material selection with ISO 9001-certified precision—ensuring every component meets zero defect standards for industrial-grade reliability.

Why Material Choice Matters in Hardness Testers

Hardness testers are precision instruments where material integrity defines performance. A substandard indenter tip can deform during testing, skewing Rockwell or Brinell results. A flexible housing introduces measurement drift under load. Even minor thermal expansion in electronics housings can compromise calibration stability. At Wuxi Lead, we treat material selection as a collaborative engineering exercise—aligning your application requirements with metallurgical science to eliminate hidden costs and performance risks.

Partner Insight: “We don’t sell testers—we solve measurement challenges. For example, when a client needed a portable tester for high-temperature forging environments, we specified aerospace-grade 7075-T6 aluminum with cryogenic-treated bearings instead of standard steel. This reduced thermal drift by 40% while cutting 15% from lifecycle costs.”

Key Material Considerations for Hardness Tester Components

| Component | Recommended Material | Why It Matters | Cost Impact | Performance Benefit |

|---|---|---|---|---|

| Indenter Tip | Tungsten Carbide (WC) or Diamond | Must exceed tested material hardness (e.g., WC: 1,500–1,800 HV; Diamond: 10,000 HV) | Moderate to High | Zero deformation during 10,000+ tests; maintains ISO 6508 compliance for Rockwell/Brinell |

| Load Mechanism | Precision Hardened Steel (440C) | Critical for consistent force application; resists creep under 50–3,000 kg loads | High | <0.1% load drift over 5 years; meets ASTM E18 standards for Rockwell accuracy |

| Housing | Aerospace Aluminum 7075-T6 or SS 316 | Prevents flexing under vibration; resists corrosion in harsh environments | Aluminum: Low-Medium SS 316: High |

3x higher rigidity vs. standard alloys; ±0.001mm dimensional stability in ±50°C environments |

| Electronics Enclosure | PEEK or Ultem Engineering Plastics | Electrical insulation, thermal stability, EMI shielding | High | Operates reliably at -40°C to 150°C; 100% pass rate for 10,000+ vibration cycles |

Surface Finishes for Durability and Precision

| Finish Type | Application | Benefits | Cost Impact |

|---|---|---|---|

| Type III Hard Anodizing | Aluminum housing components | 50μm wear-resistant coating; 60% higher corrosion resistance vs. standard anodizing | +12% |

| Hard Chrome Plating | Load cells, guide rails | 1,000+ HV surface hardness; 0.05μm Ra smoothness for friction-free motion | +22% |

| Electropolishing | Stainless steel contact surfaces | Removes micro-roughness; 99.9% pass rate for ISO 14644 cleanroom compatibility | +18% |

| Precision Polishing | Critical bearing surfaces | 0.01μm Ra finish; eliminates micro-welding during high-speed operation | +8% |

Zero Defects Guarantee: Every finish undergoes 100% surface roughness testing via profilometry. Defects >0.5μm trigger rework—no exceptions.

Wuxi Lead’s Zero Defects Commitment: Material Certification & ISO 9001 Excellence

Certified Material Sourcing

Traceable Supply Chain: All metals sourced from ISO 10474-certified mills with full EN 10204 3.1 material certificates (chemical composition, mechanical properties).

Plastics Validation: Engineering plastics tested per ISO 11403 for thermal stability and dimensional stability before production.

Olympic Quality Standard: Every component is measured against Olympic-grade tolerances (±0.002mm for critical dimensions)—exceeding ISO 9001 requirements by 30%.

3-Stage Quality Verification Process

- Pre-Production: Material certification cross-checked against your project specifications.

- In-Process: CMM inspections at 5 critical stages (e.g., indenter tip geometry, housing flatness).

- Post-Assembly: Functional testing per ISO 6508/ASTM E18 standards, including:

500-cycle repeatability tests (±0.1 HRC variance)

Thermal stability tests across -20°C to 60°C

24-hour continuous operation validation

Why This Matters for You

No Hidden Costs: Material defects detected before assembly eliminate field failures and warranty claims.

Future-Proofing: Our certified materials ensure compliance with evolving ISO standards (e.g., ISO 14577 for nanoindentation).

24/7 Customer Service: Our engineering team provides real-time support for:

Calibration troubleshooting

Material-specific application guidance

Emergency replacement of critical components (2-hour response SLA)

Partner Promise: “When you choose Wuxi Lead, you’re not buying a hardness tester—you’re gaining a quality assurance partner. Our Zero Defects protocol ensures your measurement data is as reliable as your production line.”

Ready to Engineer Your Perfect Hardness Testing Solution?

Contact our Precision Engineering Team today for a free material selection consultation:

📞 +86 510 8765 4321 | ✉️ [email protected] | 🌐 www.leadprecision.com

24/7 Technical Support | ISO 9001:2015 Certified | 100% Material Traceability

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we transform your hardness testing requirements into precision-engineered solutions through a rigorously controlled four-phase process. Every step is designed to eliminate defects, ensure compliance, and deliver on time—every time. As your engineering partner, we don’t just supply hardware—we collaborate to solve your toughest quality control challenges with Zero Defects, Olympic Quality, and 24/7 Customer Service.

Design Analysis: Precision Engineering from the Ground Up

Every hardness tester begins with ISO 9001-certified design validation. Our cross-functional engineering team works shoulder-to-shoulder with you to optimize specifications for your application, ensuring material integrity, dimensional accuracy, and operational reliability from the first sketch.

| Key Process Step | Our Approach | Customer Value |

|---|---|---|

| Material Certification | Traceable raw material sourcing with ASTM/ISO certifications for all components (e.g., tungsten carbide indenters, hardened steel housings) | Guaranteed material consistency for ±0.3% measurement repeatability |

| FEA Simulation | Stress, thermal, and fatigue analysis of critical components using ANSYS® | Eliminate failure points before prototyping; 99.8% first-pass design success rate |

| Design for Manufacturability (DFM) | Joint reviews with production engineers to simplify assembly while maintaining tolerances | Reduce time-to-market by 35% without compromising Olympic Quality standards |

Zero Defects Commitment: Every design iteration undergoes 100% digital validation against your specific hardness testing requirements—no compromises on accuracy.

Olympic Quality: Designs exceed ISO 6506/6507 standards, validated under extreme conditions (-40°C to +85°C) for 10+ years of service.

24/7 Customer Service: Dedicated lead engineers available for real-time design consultations—day or night.

Pricing Transparency: Collaborative Cost Optimization

We believe in clear, value-driven pricing. Our team partners with you to balance performance, materials, and budget—without sacrificing quality or compliance.

| Cost Factor | Our Strategy | Outcome |

|---|---|---|

| Material Sourcing | Direct partnerships with certified suppliers (e.g., ISO 9001 tungsten carbide producers) | 18% cost savings vs. industry average while maintaining traceability |

| Production Scalability | Modular component architecture enabling reuse across product lines | Flexible pricing from prototype ($2,500) to 1,000+ units (volume discounts up to 40%) |

| Quality Assurance Integration | In-process testing embedded in manufacturing workflow (no separate QC phase) | Zero additional cost for defect prevention; 100% pass rate on incoming inspections |

Zero Defects Commitment: All pricing includes comprehensive quality checks—no hidden costs for rework or recalls.

Olympic Quality: Premium materials and precision engineering ensure your hardness tester delivers NIST-traceable accuracy for 15+ years.

24/7 Customer Service: Real-time cost updates and optimization suggestions via dedicated account manager—available 24/7.

Rapid Prototyping: Validate Before Committing

Accelerate your project timeline with ISO-certified rapid prototyping. We validate every aspect of your hardness tester before full-scale production—ensuring performance matches expectations.

| Prototype Phase | Our Process | Result |

|---|---|---|

| Functional Mockups | 3D-printed prototypes using production-grade materials (e.g., aerospace-grade aluminum) | Validate ergonomics and fit within 48 hours |

| Hardness Calibration | ISO 17025-accredited calibration against reference blocks (e.g., Rockwell C-scale) | Confirm measurement accuracy within ±0.2 HRB |

| Field Simulation | Replicate real-world usage (e.g., vibration, temperature cycling, 10,000+ test cycles) | Ensure reliability under extreme industrial conditions |

Zero Defects Commitment: Every prototype undergoes 100% inspection against your specifications—no “prototype vs production” discrepancies.

Olympic Quality: Prototypes are built to the same standards as final products—guaranteed performance from day one.

24/7 Customer Service: Receive live test data and engineering feedback via our portal—available around the clock.

Mass Production: Scalable Excellence with Zero Defects

Our ISO 9001-certified facilities combine Industry 4.0 automation with human expertise to deliver flawless hardness testers at scale. Every unit is traceable, tested, and certified before shipment.

| Production Stage | Quality Control Measure | Assurance |

|---|---|---|

| CNC Machining | In-process gauging every 15 minutes with laser interferometry | Zero dimensional deviations (±0.001mm tolerance) |

| Assembly Line | Automated torque calibration for all load mechanisms (0.01 N·m precision) | Consistent force application ±0.05% across all units |

| Final Testing | 100% functional testing against NIST-traceable standards | 100% pass rate on delivery; serial-number traceability |

Zero Defects Commitment: Every unit passes 12-point quality checks—no defects, no exceptions.

Olympic Quality: Production processes exceed ISO 6508 standards for hardness testers, validated by third-party audits.

24/7 Customer Service: Real-time production tracking, proactive issue resolution, and shipment updates—available anytime.

Why Partner with Wuxi Lead Precision Machinery?

We don’t just manufacture hardness testers—we engineer solutions that elevate your quality control standards. With Zero Defects as our core promise, Olympic Quality certification, and 24/7 Customer Service, we’re your trusted partner for precision testing equipment.

“When you choose Wuxi Lead, you gain more than a supplier—you gain an extension of your engineering team. From prototype to production, we ensure your hardness testing data is always accurate, reliable, and compliant.”

— Wuxi Lead Precision Machinery Engineering Director

Ready to transform your hardness testing process?

📞 Contact our 24/7 engineering team: +86 510 8877 1234 | ✉️ [email protected]

🌐 www.leadprecision.com/hardness-testers

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineering, Zero Compromises

Why Partner with Us? The Wuxi Lead Difference

At Wuxi Lead Precision Machinery, we transcend the traditional supplier model. We are your dedicated engineering partner, embedded in your success with:

Zero Defects Commitment: Every component undergoes rigorous 100% inspection per ISO 9001 standards. Our defect rate is precisely 0% – guaranteed.

Olympic-Quality Precision: Exceeding industry benchmarks with metrology-grade hardness testing and material certification for steel, cast iron, and exotic alloys.

24/7 Customer Service: Real-time technical support, rapid response, and proactive problem-solving – day or night.

| Aspect | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Defect Rate | 0% (Zero Defects Protocol) | 0.5% – 2% |

| Testing Methodology | ISO-certified Brinell, Rockwell, Leeb with traceable calibration | Basic Rockwell only, minimal calibration |

| Support Response | 24/7 technical team, <2-hour SLA | 9–5 business hours, 24+ hour response |

Next Steps: Your Journey to Flawless Manufacturing

“More than a shop, a partner.”

Contact us today for a Free DFM Analysis and Quote

📧 Email: [email protected]

📞 Phone: +86-13961886740

Let our engineers optimize your design for manufacturability, ensuring perfect hardness and dimensional accuracy from prototype to production.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.