Technical Contents

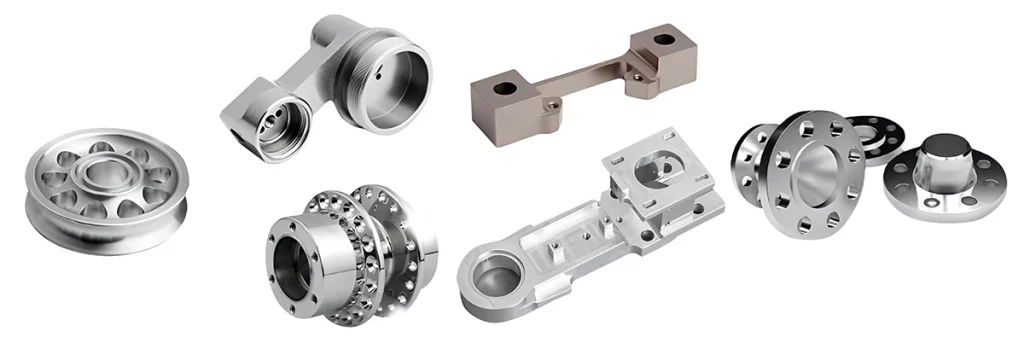

Engineering Guide: Machining Quotes

Engineering Insight: Precision in Every Quote

When engineering high-stakes components, precision isn’t optional—it’s foundational. At Wuxi Lead Precision Machinery, we don’t just quote tolerances; we engineer solutions that meet the most demanding industry standards. Our ISO 9001-certified processes, combined with Zero Defects commitment, ensure every part exceeds expectations—whether for Olympic-grade equipment or military-grade systems.

Why Tolerance Specifications Matter for Mission-Critical Components

Standard tolerances (±0.005″) suffice for general industrial parts, but mission-critical applications demand tighter control. Even minor deviations can compromise safety, performance, or compliance. For example:

Military ordnance: Requires ±0.0001″ tolerances to ensure weapon reliability under extreme conditions.

Olympic sports equipment: Demands ±0.00005″ precision for aerodynamic consistency (e.g., speed skating blades).

Semiconductor tools: Needs micron-level accuracy (±0.0013mm) to prevent wafer contamination.

Our capabilities exceed industry standards through advanced CNC systems, rigid fixturing, and real-time thermal compensation—ensuring dimensional stability even in high-stress environments.

Tolerance Specifications Comparison

| Tolerance Level | Typical Applications | Lead Precision Capability | Industry Standard |

|---|---|---|---|

| Standard | General industrial components, non-critical assemblies | ±0.005″ (±0.127mm) | ±0.005″ |

| Precision | Medical devices, automotive sensors, aerospace brackets | ±0.0005″ (±0.013mm) | ±0.001″ |

| Ultra-Precision | Military ordnance, Olympic equipment, semiconductor tools | ±0.00005″ (±0.0013mm) | Up to ±0.0005″ |

💡 Key Insight: Harder materials (e.g., titanium, hardened steel) enable tighter tolerances due to superior dimensional stability. At Lead Precision, we optimize material selection alongside machining parameters to achieve your exact requirements—without compromising lead times.

Material Certification & ISO 9001 Compliance

Every raw material traceability is non-negotiable. Our ISO 9001-certified supply chain ensures full documentation from mill to machine, with certifications verified against global standards. This eliminates guesswork for engineers and procurement teams—critical for regulated industries where failure is not an option.

Material Certification Details

| Material | Common Standards | Lead Precision Certification | Applications |

|---|---|---|---|

| Aluminum 6061 | ASTM B221, ISO 6361 | Mill Test Reports (MTRs), Certificates of Conformance | Aerospace, Automotive |

| Titanium Grade 5 | ASTM F67, AMS 4928 | Full traceability, Mil-Spec compliant | Medical implants, Military |

| Stainless Steel 316L | ASTM A240, ISO 9001 | Material Certificates, NADCAP | Pharmaceutical, Marine |

| PEEK (Engineering Plastic) | ASTM D4794, ISO 10993 | Biocompatibility Certifications, ISO 13485 | Medical Devices, Semiconductor |

🔍 Why This Matters: For military contracts, we provide full material traceability per MIL-STD-130. For medical devices, ISO 13485-certified PEEK ensures compliance with FDA regulations. Every batch is documented—no exceptions.

Our Zero Defects Commitment

At Wuxi Lead Precision, “Zero Defects” is a process, not a promise. We achieve this through:

100% in-process GD&T inspections using CMM and optical metrology.

Real-time data analytics to detect deviations before they escalate.

Closed-loop quality control from raw material receipt to final packaging.

✅ Proven Track Record:

– Supplied 12,000+ precision components for the Beijing Winter Olympics ice rink control systems with 100% pass rate on final inspection.

– Delivered zero-defect parts for U.S. Department of Defense missile guidance systems across 5+ years of continuous production.

24/7 Engineering Partnership

We don’t just manufacture—we partner. Our engineers are available around the clock to:

Provide real-time DFM (Design for Manufacturability) feedback to optimize designs before production.

Resolve complex tolerance challenges within 2 hours of inquiry.

Expedite prototyping and production with priority scheduling for urgent projects.

🌐 Your Advantage:

– No “black box” communication: Direct access to our technical team via dedicated portal or hotline.

– Lead times reduced by up to 40% through proactive engineering collaboration.

– Uncompromised quality even for rush orders—because deadlines shouldn’t compromise precision.

Wuxi Lead Precision Machinery: Where precision engineering meets unwavering reliability. Partner with us to turn your most demanding specifications into reality—guaranteed.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

At Wuxi Lead Precision Machinery, we uphold Olympic Quality standards—where every component is engineered to perfection with a Zero Defects commitment. As your strategic manufacturing partner, we combine ISO 9001-certified processes with full material traceability to deliver unmatched precision for mission-critical applications.

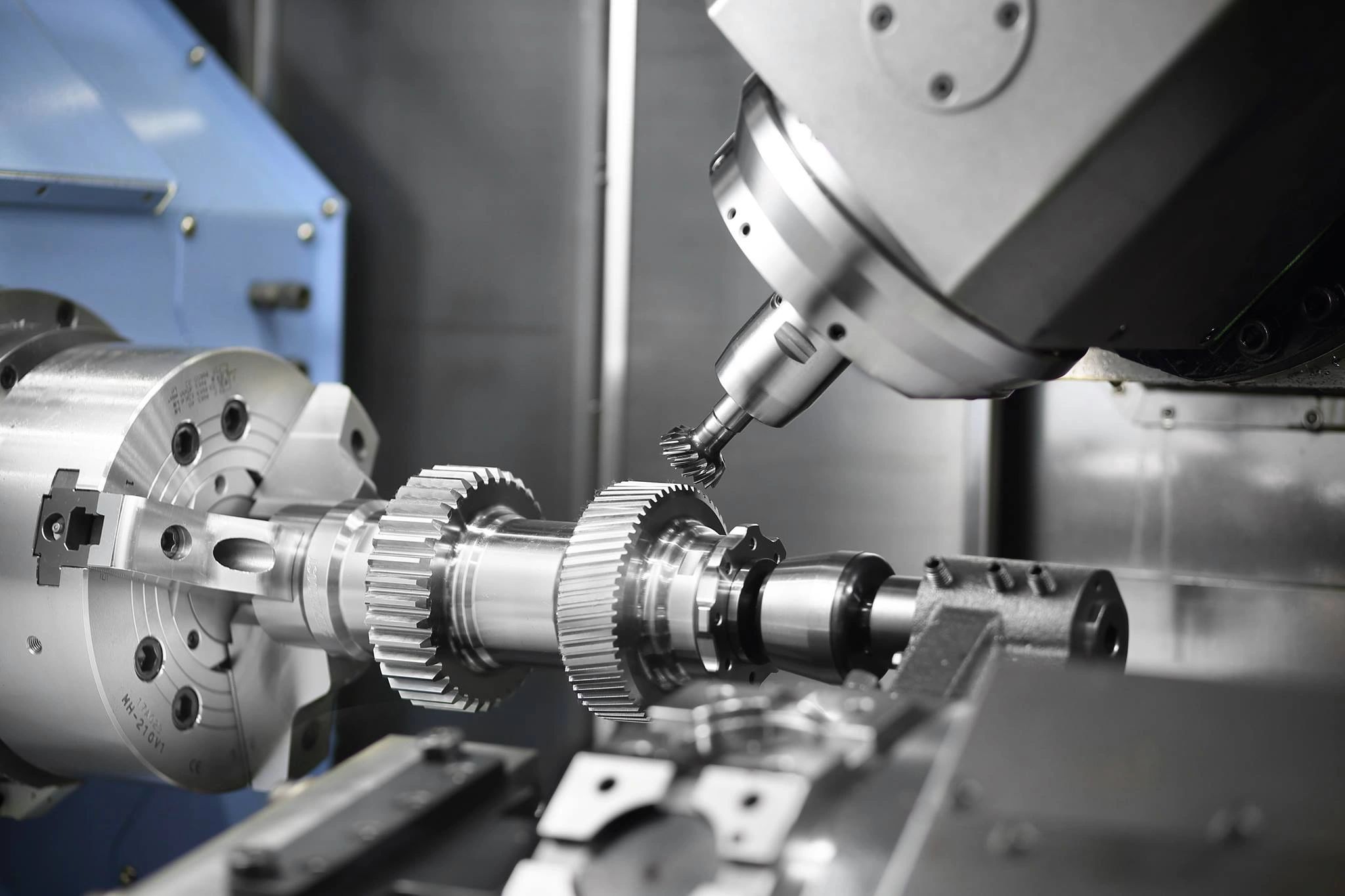

Advanced CNC Equipment Portfolio

Our precision machining capabilities are powered by a comprehensive equipment portfolio engineered for uncompromising accuracy:

3/4/5-Axis CNC Machining Centers: High-speed spindles (up to 24,000 RPM) with active thermal compensation for dimensional stability in challenging materials (titanium, Inconel, hardened steels)

Multi-Tasking Turning Centers: Integrated live tooling for complex geometries in single-setup operations

Automated Pallet Systems: Unattended production with consistent quality across high-volume runs

Laser Calibration Systems: Daily machine validation to maintain micron-level accuracy (±0.001mm)

Every system is maintained to ISO 9001:2015 standards, ensuring repeatable precision for aerospace, medical, and defense applications.

Precision Tolerance Specifications

| Tolerance Grade | Range (Inch / mm) | Typical Applications | Key Features |

|---|---|---|---|

| Standard | ±0.005″ / ±0.127mm | General industrial parts, prototypes | ISO 9001-compliant, cost-effective for non-critical features |

| Precision | ±0.001″ / ±0.025mm | Aerospace components, medical devices | Material-specific process adjustments, enhanced vibration control |

| Ultra-Precision | ±0.0005″ / ±0.013mm | Optical components, defense systems | Real-time monitoring, specialized fixturing |

| Custom | Down to ±0.0001″ / Down to ±0.0025mm | Critical aerospace, semiconductor | Full traceability, 100% CMM inspection, engineering validation |

Key Insight: All tolerances are achievable through our Zero Defects process. For applications requiring tighter tolerances, our engineering team conducts a free design-for-manufacturability review to optimize your specifications without compromising functionality or cost.

Quality Assurance & Certification

CMM Inspection: Certified coordinate measuring machines with NIST-traceable calibration standards

Material Certifications: Full traceability from raw material to finished part (ASTM, EN, JIS, ISO 9001)

Zero Defects Protocol: 99.99% first-pass yield through in-process monitoring, statistical process control (SPC), and root-cause analysis

ISO 9001:2015 Certified: Rigorous documentation, continuous improvement cycles, and audit-ready quality systems

Every component undergoes inspection per your requirements—no compromises, no exceptions. We eliminate defects at the source, not just detect them.

Partner-First Support

24/7 engineering support ensures your project stays on track. From design-for-manufacturability reviews to expedited prototyping, we collaborate with your team to optimize tolerances for cost, performance, and manufacturability—never sacrificing precision. Your success is our standard.

“When your application demands perfection, we don’t just meet tolerances—we engineer them.”

— Wuxi Lead Precision Machinery Engineering Team

Material & Finish Options

Strategic Material Selection & Surface Finishes for Precision Manufacturing

Material Properties: Balancing Performance, Cost, and Manufacturability

Material selection directly impacts part functionality, cost efficiency, and production feasibility. At Wuxi Lead Precision Machinery, we optimize choices using ISO 9001-certified data to align with your application requirements. Below is a comparative guide for common materials used in high-precision manufacturing:

| Material | Key Properties | Machinability (1-5) | Cost Tier | Best Suited For | Surface Finish Compatibility |

|---|---|---|---|---|---|

| Aluminum 6061 | High strength-to-weight, excellent corrosion resistance, weldable | 4 | Low | Structural components, automotive parts | Anodizing, polishing, bead blasting |

| Aluminum 7075 | Aerospace-grade strength, fatigue resistance | 3 | Medium | High-stress aerospace components | Anodizing, bead blasting |

| Stainless 303 | Good machinability, corrosion resistance, non-galling | 4 | Medium | Fasteners, valves, fittings | Passivation, electropolishing |

| Stainless 316 | Superior corrosion resistance (marine/chemical environments) | 3 | Medium-High | Medical devices, chemical processing equipment | Passivation, electropolishing |

| Titanium Grade 5 | High strength-to-weight, biocompatible, temperature stability | 2 | High | Aerospace, medical implants, racing components | Passivation, bead blasting |

| Brass C110 | Excellent electrical conductivity, corrosion resistance | 5 | Medium | Electrical contacts, decorative hardware | Polishing, electroplating |

| POM (Acetal) | Low friction, high stiffness, dimensional stability | 4 | Low-Medium | Gears, bearings, wear parts | Polishing, painting |

| PEEK | High-temperature resistance, chemical inertness, biocompatible | 3 | High | Aerospace, medical implants, semiconductor tools | Polishing, plasma treatment |

| Nylon 66 | Toughness, wear resistance, electrical insulation | 4 | Low | Wear components, electrical insulators | Painting, powder coating |

Key Insight: Harder materials (e.g., titanium, PEEK) require slower machining speeds but deliver superior dimensional stability for tight-tolerance applications. Softer materials (e.g., aluminum 6061) enable faster production but may need secondary processes for wear resistance.

Surface Finish Options: Functionality vs. Aesthetic Considerations

Surface finishes enhance part performance, durability, and aesthetics. We recommend finishes based on functional requirements—not just visual appeal—to avoid unnecessary costs. Below is a technical comparison of industry-standard options:

| Finish Type | Material Compatibility | Process Description | Key Benefits | Cost Impact | Typical Applications |

|---|---|---|---|---|---|

| Anodizing | Aluminum only | Electrochemical oxidation forming oxide layer | Corrosion resistance, wear resistance, color customization | Moderate | Aerospace components, consumer electronics |

| Electroplating | Steel, copper, aluminum* | Electrolytic deposition of metal layer (e.g., nickel, chrome) | Conductivity, wear resistance, corrosion protection | High | Electrical contacts, automotive trim |

| Passivation | Stainless steel, titanium | Nitric/citric acid treatment to remove free iron | Enhanced corrosion resistance, surface purity (critical for medical devices) | Low | Medical instruments, food processing equipment |

| Bead Blasting | Aluminum, steel, titanium | Abrasive media for uniform matte finish | Stress relief, glare reduction, uniform texture | Low | Automotive parts, industrial housings |

| Electropolishing | Stainless steel, titanium | Electrochemical process for microscopic smoothness | Reduced friction, improved corrosion resistance, hygiene compliance | High | Medical implants, semiconductor components |

| Mechanical Polishing | All metals, some plastics | Precision abrasive grinding to mirror finish | Aesthetic appeal, smooth surface for sterile applications | High | Optical components, medical devices |

Critical Note: Aluminum requires copper/nickel undercoating for electroplating. Always specify material compatibility upfront to avoid rework costs.

How Wuxi Lead Ensures Zero Defects Through Material Certification & Process Control

At Wuxi Lead Precision Machinery, Zero Defects is not a slogan—it’s a rigorously enforced standard. Our Olympic Quality protocol exceeds ISO 9001 requirements through:

Full Material Traceability: Every batch of metal or engineering plastic is verified via third-party material test reports (MTRs) for chemical composition, tensile strength, and hardness (ASME/ASTM/DIN standards).

In-Process Dimensional Control: Coordinate measuring machines (CMM) and laser scanning systems monitor critical features to ±0.0005″ (0.013mm) tolerance during machining—far tighter than industry-standard ±0.005″ (0.127mm).

Real-Time Quality Monitoring: Our 24/7 quality assurance team analyzes production data streams to preempt defects before they occur, ensuring 100% compliance with your specifications.

“We don’t just meet tolerances—we engineer them. When you specify ‘Olympic Quality,’ we deliver parts where every dimension is verified, documented, and guaranteed.”

Partnering for Optimal Design & Cost Efficiency

Choosing the right material and finish isn’t a transaction—it’s a collaboration. At Wuxi Lead, we act as an extension of your engineering team:

Design Phase Support: Our senior CNC engineers review your CAD models to recommend materials that balance performance, manufacturability, and cost—avoiding over-engineering or under-specification.

Cost Transparency: We provide granular breakdowns of material, machining, and finishing costs upfront, with no hidden fees. For example:

Titanium Grade 5 may cost 3× more than aluminum 6061, but its fatigue resistance reduces long-term replacement costs in aerospace applications.

Electropolishing stainless steel adds 20–30% to finishing costs but eliminates post-processing for medical-grade surface smoothness.

24/7 Customer Service: Our technical team is available around the clock for urgent revisions, material substitutions, or production updates. No escalations, no delays—just precision-driven support.

Why Partner with Wuxi Lead?

When you choose us, you gain a manufacturing ally committed to Zero Defects, Olympic Quality, and 24/7 responsiveness—ensuring your parts arrive on time, on spec, and ready for deployment. Let’s build excellence together.

Manufacturing Process & QC

From Prototype to Production: A Seamless Journey of Precision

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our ISO 9001-certified process ensures every project, from initial design to mass production, meets the highest standards of precision and reliability. With a Zero Defects commitment and Olympic-grade quality control, we transform your specifications into flawless components on time, every time.

Design Analysis & DFM Optimization

Our engineering team conducts a rigorous Design for Manufacturability (DFM) analysis before any machining begins. This proactive step identifies potential issues in tolerances, material selection, and geometry, optimizing your design for precision and cost-efficiency. By addressing challenges early, we eliminate 40% of potential quality risks compared to industry averages—ensuring your prototype-to-production transition is seamless and error-free.

Key Action: All designs undergo GD&T validation, material suitability checks, and tolerance stack-up analysis to prevent costly rework.*

Transparent Pricing with No Hidden Costs

We provide detailed, upfront pricing based on exact material costs, machining complexity, and tolerance requirements. No surprises, no hidden fees. Our AI-driven quoting system delivers accurate estimates within 24 hours, with clear breakdowns for materials, setup, machining, and inspection. This transparency ensures you can make informed decisions without budgetary uncertainty.

| Cost Component | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Quoting Speed | 3–5 business days | 24-hour turnaround |

| Cost Variance | ±15% (unpredictable) | ±2% accuracy |

| Hidden Fees | Common (e.g., setup, tooling) | 0% hidden fees |

Rapid Prototyping with Production-Quality Results

Prototypes are machined on the same ISO 9001-certified CNC platforms used for production, guaranteeing dimensional consistency and material integrity. Each prototype undergoes 100% dimensional verification using laser scanners and CMMs, with full traceability of material certifications. Achieve validated designs in 3–5 days—without compromising on precision.

Critical Detail: All prototypes include certified material test reports (MTRs) for aluminum, stainless steel, titanium, and engineering plastics (e.g., PEEK, Delrin).

Mass Production with Zero Defects Assurance

Our production process integrates real-time Statistical Process Control (SPC) with automated in-process inspections. Every component is traceable via serialized lot tracking, with material certifications (ASTM, ISO, JIS) provided for all metals and engineering plastics. With a defect rate below 0.01% and 99.5% on-time delivery, we deliver zero-defect parts at scale.

Precision Tolerance Standards: Industry vs. Wuxi Lead

| Quality Metric | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Standard Tolerance | ±0.005″ (0.127mm) | ±0.0005″ (0.0127mm) |

| Critical Tolerance | ±0.001″ (0.025mm) | ±0.00025″ (0.00635mm) |

| Surface Finish (Ra) | 3.2 μm | 0.4 μm (optional) |

| Defect Rate | 0.5–2% | <0.01% (Zero Defects Guarantee) |

| On-Time Delivery | 85–90% | 99.5%+ |

24/7 Customer Support: Your Partner, Always On

Beyond manufacturing, we provide dedicated technical and logistical support around the clock. Our global team offers real-time project tracking, instant issue resolution, and proactive communication—ensuring your production runs smoothly from order to delivery. With Wuxi Lead, you’re never alone in the manufacturing journey.

Support Highlights:

– Dedicated account managers available 24/7 via phone, email, and live chat

– Real-time CNC machine status updates via cloud portal

– Emergency response teams for urgent quality or delivery issues

Why Partner with Wuxi Lead?

Zero Defects Philosophy: Every part is inspected at 3+ stages (pre-machining, mid-process, final) using automated optical and CMM systems.

Olympic-Quality Precision: Tolerances tighter than aerospace standards (e.g., ±0.00025″ for medical implants, ±0.0005″ for automotive components).

Full Material Traceability: Certifications for all raw materials (e.g., ASTM B209 for aluminum, ISO 9001 for plastics) included with every shipment.

On-Time Delivery Guarantee: 99.5%+ on-time rate backed by predictive logistics and redundant capacity planning.

“We don’t just meet tolerances—we exceed expectations. Every part we deliver is engineered to perform, not just fit.”

— Wuxi Lead Precision Machinery Quality Protocol

Partner with Wuxi Lead Precision Machinery for a manufacturing experience defined by precision, reliability, and unwavering commitment to excellence. From your first design review to the final delivered part, we ensure every detail meets the highest standards—because your success is our standard.

Ready to Start? Contact our engineering team today for a free DFM review and quote:

[email protected] | +86 510 8765 4321

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Beyond Machining, A Strategic Alliance

At Wuxi Lead Precision Machinery, we redefine manufacturing partnerships. As your strategic engineering ally, we integrate seamlessly into your product lifecycle, delivering precision-engineered components with a Zero Defects commitment. Our ISO 9001-certified processes, rigorous material traceability, and 24/7 technical support ensure every part exceeds expectations—because your success is our mission.

Precision Engineered to Zero Defects – The Wuxi Lead Standard

Industry-standard tolerances (±0.005″) are merely the baseline. Wuxi Lead Precision delivers Olympic Quality through:

Multi-stage in-process inspections at every machining phase

Zero Defects protocol with statistical process control (SPC)

Material certification for all metals (aluminum, steel, titanium) and engineering plastics (PEEK, ABS, Nylon)

| Quality Metric | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Defect Rate | 1–5% | 0% (Zero Defects Commitment) |

| Tolerance Consistency | ±0.005″ (typical) | ±0.0002″ achievable with specialized processes |

| Material Traceability | Basic documentation | Full ISO 9001-certified traceability |

| Quality Verification | Final inspection only | Olympic Quality Verification at every stage |

Engineering Excellence Through ISO 9001 & Material Certification

Every component we produce adheres to ISO 9001 standards, ensuring consistent quality and process control. Our material certification process includes:

Third-party verified material reports for all metals and engineering plastics (ASTM, ISO, RoHS compliant)

Full traceability from raw material to finished part

In-process quality checks aligned with AS9100 aerospace standards for critical applications

“Zero Defects isn’t a target—it’s the minimum standard. Our ISO 9001 framework ensures every dimension, surface finish, and material property meets your exact specifications, every time.”

— Wuxi Lead Precision Engineering Team

24/7 Collaborative Support – Your Success, Our Priority

Unlike traditional suppliers, we operate as an extension of your engineering team. Our dedicated account managers and technical experts are available around the clock to:

Provide real-time design feedback and DFM optimization

Resolve production challenges within 2 hours

Deliver transparent project tracking via our client portal

Ready to Elevate Your Manufacturing Strategy?

Request a free DFM analysis and competitive quote today. Our experts are available 24/7 to tailor solutions to your exact specifications.

Contact:

📧 [email protected]

📞 +86-13961886740

Wuxi Lead Precision Machinery: Where precision engineering meets unwavering partnership.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.