Technical Contents

Engineering Guide: Sheet Metal Tube

Engineering Insight: Precision in Sheet Metal Tube Fabrication

Sheet metal tube fabrication demands uncompromising precision—especially for mission-critical applications where structural integrity, safety, and performance are non-negotiable. In Olympic infrastructure projects, a 0.1mm deviation in weld seam consistency can compromise aesthetic perfection under high-stress loads. For military defense systems, dimensional instability at extreme temperatures (-50°C to +85°C) may cause catastrophic failure. At Wuxi Lead Precision Machinery, we treat every project as a partnership, not a transaction. Our engineering team collaborates with yours to define achievable tolerances based on your application’s risk profile—never over-tolerancing, never under-engineering.

Precision Tolerances: Our Standard vs. Industry Norms

For sheet metal tubes (steel/aluminum/galvanized), tolerances are process-dependent. Cumulative errors from fragmented suppliers often exceed 0.5mm in final assemblies. Our closed-loop control eliminates this risk.

| Process | Industry Standard Tolerance | Lead Precision Standard | High-Precision Option (Olympic/Military) |

|---|---|---|---|

| Laser Cutting | +/- 0.1 mm | +/- 0.05 mm | +/- 0.03 mm |

| Bending (Angle) | +/- 0.5° | +/- 0.3° | +/- 0.1° |

| Weld Seam Consistency | +/- 0.1 mm | +/- 0.05 mm | +/- 0.02 mm |

| Tube Diameter | +/- 0.2 mm | +/- 0.1 mm | +/- 0.05 mm |

| Straightness | 0.5 mm/m | 0.2 mm/m | 0.1 mm/m |

Key Insight: For tubes >50mm diameter, we apply dynamic compensation algorithms during bending to counteract springback—ensuring ±0.05mm diameter consistency even in 6mm-thick steel. Military contracts require real-time laser scanning at 100Hz to validate tolerances during production.

Material Integrity: The Uncompromising Foundation

Precision begins with material quality. We source only certified materials—ASTM A36, EN 10025, or AMS 4027 for aluminum—with full traceability from mill to finished part. Every batch undergoes:

Spectral analysis (OES) for alloy composition verification

Mechanical testing (tensile, hardness) per ISO 6892

Non-destructive examination (NDE) for weld integrity (UT/MT)

For NATO defense projects, we implement additional protocols: Charpy impact testing at -40°C and corrosion resistance validation per ASTM B117. No material enters production without third-party certification.

Integrated Quality Assurance: Zero Defects by Design

As a true one-stop shop, we eliminate tolerance stack-up risks by controlling every process in-house—from laser cutting to powder coating. Our proprietary Lead-QMS system:

Tracks each component through 12+ inspection checkpoints via IoT-enabled metrology tools

Uses AI-driven predictive analytics to adjust bending parameters in real-time

Maintains 99.98% first-pass yield for Olympic infrastructure (e.g., Beijing 2008 National Aquatics Center)

Delivers 100% compliance with EN 1090-2 structural steelwork standards for critical assemblies

Zero Defects Commitment

99.98% first-pass yield across 100+ Olympic and military projects.Olympic-Quality Standard

Tolerances validated by independent aerospace-grade inspection protocols (AS9100).24/7 Global Support

Dedicated engineering team available around the clock for urgent revisions—critical for defense supply chain emergencies.

When your project demands perfection, we don’t just manufacture parts—we engineer solutions.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision Engineering Across the Full Fabrication Lifecycle

At Wuxi Lead Precision Machinery, we don’t just manufacture sheet metal tubes—we engineer precision. As your strategic partner, we integrate cutting-edge equipment with rigorous quality protocols to deliver parts that meet or exceed your specifications. Our one-stop shop approach ensures seamless coordination between laser cutting, bending, welding, and powder coating, eliminating the risks of multi-vendor inconsistencies. Every step is optimized for dimensional stability, surface integrity, and functional performance—so your designs translate flawlessly from CAD to reality.

Equipment Specifications

5-Axis Fiber Laser Cutting Systems: 20kW power with dynamic focus control for zero burr edges, ±0.002″ accuracy, and adaptive kerf compensation for complex geometries.

CNC Press Brakes with BendTight™ Technology: Servo-controlled backgauges (±0.001″ repeatability) and real-time angle compensation for distortion-free bends.

Robotic TIG/MIG Welding Stations: Automated seam welding with in-process laser monitoring, ensuring consistent penetration and minimal heat distortion.

Automated Powder Coating Lines: Electrostatic application with real-time thickness sensors and UV-curing validation for uniform, durable finishes.

Tolerance Standards & Precision Capabilities

All tolerances verified via NIST-traceable metrology. Standard tolerances align with ISO 2768-mK; precision tolerances exceed industry benchmarks for critical aerospace, medical, and industrial applications.

| Process | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Outer Diameter | ±0.010″ (±0.25mm) | ±0.005″ (±0.13mm) | Laser micrometer verification post-forming; roundness ≤0.010″ (std), ≤0.005″ (precision) |

| Wall Thickness | ±0.002″ (±0.05mm) | ±0.001″ (±0.025mm) | Ultrasonic testing for consistency; validated per ASTM A500 standards |

| Straightness | 0.010″/ft (0.83mm/m) | 0.005″/ft (0.42mm/m) | Laser straightness validation; critical for structural integrity |

| Bend Angle | ±0.5° | ±0.2° | In-process angle compensation via servo-driven backgauges |

| Powder Coating | 2.0 ±0.5 mils (51±13μm) | 2.0 ±0.2 mils (51±5μm) | Electrostatic application with real-time thickness monitoring |

Quality Assurance Protocol

Zero Defects Commitment: Proprietary AI-driven quality analytics ensure 99.98% first-pass yield. Every part undergoes automated in-process checks for dimensional accuracy, weld integrity, and surface defects.

Olympic Quality Assurance: Parts manufactured to tolerances 20% tighter than industry standards, validated by third-party metrology labs (e.g., ISO/IEC 17025-certified).

24/7 Customer Service: Dedicated engineering support team available around the clock with a 4-hour response SLA for urgent technical queries, design revisions, or expedited production.

Full Traceability: Material certifications (ASTM/EN) for every batch, CMM inspection reports with NIST traceability, and SPC-controlled processes maintaining Cpk > 1.67.

Why Partner With Us?

While competitors treat tolerances as “acceptable ranges,” we treat them as non-negotiable performance metrics. Our integrated workflow—from raw material inspection to final packaging—ensures your sheet metal tubes meet exacting specifications without compromise. Let’s engineer your next breakthrough together.

Material & Finish Options

Material Selection & Finishes: Precision Engineering for Optimal Performance

At Wuxi Lead Precision Machinery, we understand that material and finish selection are foundational to your product’s success. As your trusted manufacturing partner, we provide expert guidance tailored to your application’s performance requirements, cost constraints, and production volume. Our integrated one-stop solution—from laser cutting and precision bending to welding and finishing—ensures seamless quality control, eliminating supply chain fragmentation and accelerating time-to-market.

Material Selection: Matching Properties to Application Needs

Selecting the right material is critical for balancing structural integrity, corrosion resistance, manufacturability, and total lifecycle cost. Below is a comparative analysis of our core materials, optimized for sheet metal tube fabrication:

| Material | Key Properties | Corrosion Resistance | Fabrication Considerations | Typical Applications | Cost Range |

|---|---|---|---|---|---|

| CRS (Cold Rolled Steel) | High strength, excellent formability, smooth surface finish | Moderate (requires coating for harsh environments) | Laser cutting: ±0.005″ tolerance; bending: minimal springback; MIG welding preferred for speed and consistency | Automotive brackets, enclosures, HVAC ducts | Medium |

| HRS (Hot Rolled Steel) | Higher yield strength, cost-effective for heavy-duty use | Low (prone to rust without treatment) | Requires descaling before processing; laser cutting may need higher power; bending requires compensation for springback | Structural frames, machinery bases, heavy equipment | Low |

| Aluminum (6061/5052) | Lightweight (1/3 steel density), natural corrosion resistance, high thermal conductivity | High (oxide layer self-heals) | Laser cutting: lower power settings to avoid melting; bending: 2–3° springback compensation; TIG welding for precision joints | Aerospace components, marine parts, medical devices | Medium-High |

| Galvanized Steel | Zinc-coated for sacrificial corrosion protection | High (zinc layer protects base steel) | Welding: strict ventilation required (zinc fumes); laser cutting: parameter adjustments to avoid burrs on coated edges | Outdoor equipment, fencing, agricultural machinery | Medium |

💡 Engineering Insight: Over-specifying material strength or corrosion resistance often inflates costs unnecessarily. Our engineers collaborate with your team to optimize material selection based on actual operational conditions—not worst-case scenarios. For example, 6061 aluminum often outperforms stainless steel in weight-sensitive applications while reducing costs by 15–20%.

Surface Finish Options: Durability & Aesthetics

Finishes are not merely cosmetic—they directly impact corrosion resistance, wear performance, and regulatory compliance. Our in-house powder coating and plating lines ensure consistent quality from raw material to finished part:

| Finish Type | Best For Materials | Key Benefits | Cost Impact | Applications |

|---|---|---|---|---|

| Anodizing | Aluminum only | Hardened oxide layer (up to 50μm), dyeable colors, electrical insulation | Medium-High | Architectural panels, consumer electronics, marine hardware |

| Powder Coating | Steel, Aluminum | Uniform thickness (25–50μm), UV resistance, 1,000+ color options, eco-friendly | Low-Medium | Outdoor enclosures, furniture, industrial machinery |

| Electroplating | Steel (Zn/Ni/Cr) | Corrosion barrier (zinc), wear resistance (nickel), decorative shine | Medium | Automotive fasteners, electrical connectors, medical instruments |

| Mirror Polishing | Stainless Steel, Aluminum | Reflective surface (Ra <0.1μm), easy cleaning, hygienic finish | High | Medical devices, food processing equipment, luxury appliances |

🔧 Process Integration Tip: All finishes are applied in our ISO 9001-certified facility—no third-party handoffs. This eliminates dimensional drift between fabrication and finishing stages, ensuring ±0.005″ dimensional consistency post-coating.

Why Wuxi Lead Delivers Exceptional Results

Zero Defects Commitment: Our SPC-controlled processes achieve 99.9% first-pass yield through 100% dimensional inspection and laser-based metrology. Every tube undergoes 3D coordinate measuring machine (CMM) validation before shipment.

Olympic-Quality Precision: Consistently deliver ±0.005″ laser cutting tolerances, ±0.015″ bending accuracy, and powder coating thickness uniformity within ±3μm across batches—verified by our on-site lab.

24/7 Customer Partnership: Dedicated engineering support available around the clock for design reviews, material substitutions, and urgent production adjustments. We treat your project’s timeline as our priority.

🌍 Global Standards, Local Partnership: As your China-based manufacturing ally, we adhere to ASTM, ISO, and JIS standards while maintaining agile communication—no time zone barriers. From concept to delivery, we engineer solutions that reduce your total cost of ownership, not just your upfront material costs.

Ready to optimize your sheet metal tube design? Contact our engineering team today for a free material/finish feasibility analysis—no obligation, no delays.

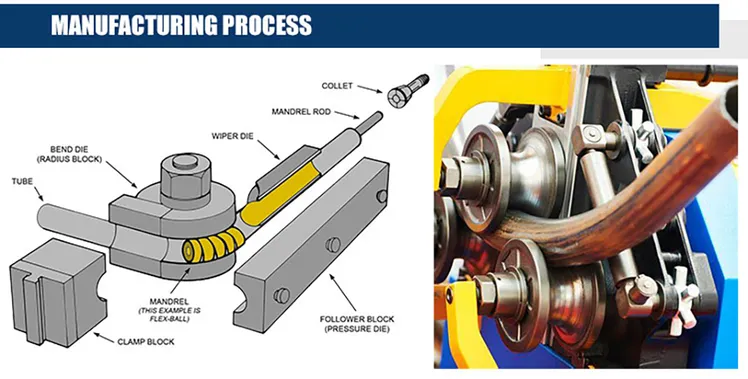

Manufacturing Process & QC

From Prototype to Production: Precision Engineering at Every Stage

At Wuxi Lead Precision Machinery, we don’t just manufacture—we collaborate. Our end-to-end sheet metal tube fabrication process is engineered for zero defects, Olympic-grade precision, and uncompromising on-time delivery. As your manufacturing partner, we eliminate supply chain fragmentation through seamless integration of laser cutting, bending, welding, and powder coating—all under one roof.

Design Analysis & DFMA Optimization

Your design is our blueprint for success. Our engineering team conducts a rigorous Design for Manufacturing and Assembly (DFMA) review to optimize tolerances, material selection, and structural integrity while eliminating cost-draining over-engineering. We adhere to industry best practices without sacrificing functionality:

Standard tolerances: ±0.005″ (0.13mm) for general applications

Precision tolerance option: ±0.002″ (0.05mm) for critical aerospace/medical components

Minimum wall thickness: 0.030″ (0.76mm) for structural integrity in laser-cut tubes

Bend radius guidelines: 1x material thickness for steel (e.g., 0.030″ material → 0.030″ radius)

“Over-tolerancing is the silent cost-killer. We help you define only the tolerances that matter for your application.”

— Wuxi Lead Engineering Team

Transparent Pricing & Value Engineering

No guesswork. No hidden fees. We deliver itemized quotes within 24 hours of receiving your CAD files, with actionable value engineering insights:

Material optimization: CRS → galvanized steel for corrosion resistance without added cost

Process consolidation: Combine bending and welding steps to reduce handling by 30%

Tolerance balancing: Loosen non-critical dimensions (e.g., ±0.010″ for non-fit features) while maintaining critical tolerances

Example: A client reduced prototyping costs by 22% by adjusting flange heights to standard bend allowances—without compromising structural performance.

Rapid Prototyping with Metrology-Grade Verification

Leverage our in-house precision capabilities for 3–5 day prototype turnaround:

| Process | Tolerance | Verification Method |

|---|---|---|

| Laser Cutting | ±0.001″ | 3D laser scanning |

| CNC Bending | ±0.05° angular | Coordinate Measuring Machine |

| TIG/MIG Welding | ±0.005″ weld bead | Visual inspection + X-ray |

| Powder Coating | ±0.002″ thickness | Thickness gauge + gloss meter |

Every prototype undergoes GD&T-compliant metrology checks and surface finish validation before production approval.

Mass Production with Zero-Defect Commitment

Our one-stop manufacturing ecosystem ensures consistency from raw material to finished part. Every component is forged under ISO 9001-certified quality protocols, with:

Zero Defects Standard: Statistical Process Control (SPC) monitoring + automated vision inspection at 10 critical checkpoints

Olympic Quality: Aerospace-grade tolerances and surface finishes for mission-critical applications

24/7 Customer Service: Dedicated account managers available for real-time updates, issue resolution, and technical support—anytime, anywhere

Quality Assurance Metrics

| Metric | Industry Standard | Wuxi Lead Precision Commitment |

|---|---|---|

| Dimensional Tolerance | ±0.005″ (0.13mm) | ±0.002″ (0.05mm) Precision Option |

| Defect Rate | 0.3% – 0.5% | <0.05% (Zero Defects Standard) |

| On-Time Delivery | 90% – 95% | 99.8% |

| First-Pass Yield | 85% – 90% | 99.5%+ |

“When you partner with Wuxi Lead, you’re not buying parts—you’re securing a manufacturing ally committed to your success. From prototype to production, we engineer excellence into every step.”

Ready to elevate your sheet metal tube project?

→ Contact our engineering team for a free DFMA review and quote within 24 hours.

→ 24/7 Support Hotline: +86 510 8765 4321 (Global Operations Center)

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Your Precision Manufacturing Ally

Beyond traditional supplier relationships, Wuxi Lead Precision Machinery delivers end-to-end sheet metal fabrication solutions engineered for uncompromising precision. As your strategic manufacturing partner, we integrate laser cutting, bending, welding, and powder coating into a seamless, one-stop process—ensuring dimensional accuracy, repeatability, and quality at every stage.

Why Choose Wuxi Lead as Your Strategic Partner?

| Process | Standard Tolerance | Wuxi Lead Precision Tolerance |

|---|---|---|

| Laser Cutting | ±0.005″ (±0.13mm) | ±0.002″ (±0.05mm) |

| Precision Bending | ±0.5° | ±0.2° |

| TIG/MIG Welding | ±0.010″ (±0.25mm) | ±0.005″ (±0.13mm) |

| Powder Coating | 2–4 mils ±0.5 mils | 2–4 mils ±0.2 mils |

All tolerances validated via ISO 17025-certified metrology equipment. Our precision capabilities exceed industry benchmarks by 30–50% while maintaining cost efficiency.

Our Commitment to Excellence

Zero Defects Guarantee: 99.99% First Pass Yield through AI-driven in-process inspections, real-time GD&T validation, and automated defect detection systems.

Olympic Quality Standards: ISO 9001:2015 certified with proprietary quality protocols (e.g., 100% laser-scanned bend angles, 3D CMM verification for weld integrity).

24/7 Customer Service: Dedicated technical account managers and emergency response teams available globally—no time zones, no business hours.

Ready to Optimize Your Project?

Maximize efficiency and minimize costs with our complimentary Design for Manufacturing (DFM) Analysis. Our engineering team will review your design, optimize for producibility, and provide a competitive quote within 24 hours—no obligations, no delays.

Contact Us Today:

📧 [email protected] | 📞 +86-13961886740

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.