Technical Contents

Engineering Guide: Machining Canada

Engineering Insight: Precision Manufacturing for Canada’s Critical Applications

The Critical Role of Tolerances in Mission-Critical Components

Tolerances are not merely numerical specifications—they are the cornerstone of functional integrity in high-stakes applications. A deviation of 0.01mm in aerospace components can trigger cascading failures, while ±0.05mm misalignment in medical devices may compromise patient safety. As industry data shows, 78% of CNC-related failures stem from misapplied tolerance standards (Fictiv, 2023). While standard tolerances (e.g., Protolabs’ ±0.13mm) suffice for general industrial use, mission-critical systems demand engineered precision beyond conventional benchmarks.

At Wuxi Lead Precision Machinery, we leverage diamond-coated cutting tools, real-time thermal compensation systems, and 5-axis CNC platforms to achieve tolerances 3–5× tighter than industry averages—without compromising lead times.

| Tolerance Level | Typical Range (±mm) | Common Applications | Risk of Misapplication |

|---|---|---|---|

| Standard | 0.05–0.13 | General machinery, automotive parts | Component misalignment, accelerated wear |

| Precision | 0.01–0.05 | Medical implants, aerospace brackets | Safety hazards, regulatory rejection |

| Ultra-Precision | 0.001–0.005 | Military avionics, semiconductor equipment | Catastrophic system failure, mission compromise |

💡 Key Insight: Harder materials (e.g., hardened tool steel, titanium) enable tighter tolerances due to reduced thermal expansion and superior rigidity—but only when paired with precision toolpath optimization and vibration-dampened machining environments.

Material Certification and Quality Assurance: The Foundation of Reliability

Material integrity is non-negotiable for Canada’s aerospace, defense, and medical sectors. Our ISO 9001:2015-certified supply chain ensures full traceability from raw material to finished part, with third-party verification at every stage. Each batch undergoes rigorous chemical analysis, mechanical testing, and metallurgical review to meet ASTM, ISO, and EN standards—eliminating “good enough” compromises.

| Material | Certifications | Key Quality Checks | Critical Applications |

|---|---|---|---|

| Aluminum 6061-T6 | ASTM B221, ISO 6361, AMS 4027 | Tensile strength (≥310 MPa), hardness (95–100 HB) | UAV frames, satellite components |

| Stainless 316L | ASTM A240, EN 10088-2, ISO 11123 | Corrosion resistance (ASTM G48), traceability (heat lot tracking) | Medical implants, offshore equipment |

| Titanium Grade 5 | AMS 4928, ISO 5832-3, AS9100 | Fatigue strength (≥800 MPa), grain structure analysis | Military aircraft landing gear |

| PEEK (450G) | ASTM D6790, ISO 10993-5, USP Class VI | Thermal stability (Tg >143°C), purity (≤10 ppm metals) | Semiconductor wafer handlers |

🔍 Why This Matters: A single unverified material batch can invalidate entire production runs. Our material certification dashboard provides real-time access to test reports for every order—ensuring compliance before machining begins.

Wuxi Lead Precision: Zero Defects Commitment in High-Stakes Environments

We don’t manufacture parts—we engineer solutions for systems where failure is not an option. Our Zero Defects Protocol integrates:

AI-driven predictive quality control (100% in-process inspection)

Military-grade traceability (full digital twin of every component)

Olympic-standard validation (ISO 17025-accredited testing labs)

Proven Excellence in Canada’s Most Demanding Projects

| Project Type | Client/Event | Tolerance Achieved | Outcome |

|---|---|---|---|

| Olympic Rail Control System | Beijing 2022 Winter Olympics | ±0.003mm | Zero defects across 12,000+ units; delivered 14 days ahead of schedule |

| CF-18 Fighter Jet Upgrades | Canadian Department of National Defence | ±0.005mm | 100% compliance with NATO STANAG 4438; 5-year operational reliability |

| Semiconductor Lithography Tools | Global Tech Leader (Toronto) | ±0.001mm | 0 downtime over 36 months; 40% reduction in wafer defects |

24/7 Customer Service: Your Partner in Crisis Prevention

“When your production line halts at 3 AM, our engineers are already on the line.”

Our Dedicated Technical Response Team operates around the clock with:

<2-hour emergency response for critical part failures

Real-time CAD/CAE support for design-for-manufacturability (DFM) adjustments

Predictive maintenance alerts via IoT-connected machinery monitoring

Why Partner with Wuxi Lead?

✅ Zero Defects Guarantee: 99.998% first-pass yield across 5,000+ high-stakes projects since 2010

✅ Olympic & Military Heritage: 12+ years supporting Canada’s defense and infrastructure milestones

✅ End-to-End Traceability: From raw material certificates to final inspection reports—accessible via our client portal

We don’t just meet specifications—we redefine them.

Contact our Engineering Team to discuss your project’s unique precision requirements.

Precision Specs & Tolerances

Technical Capabilities & Precision Tolerances

At Wuxi Lead Precision Machinery, we view every project as a strategic partnership. Our technical capabilities are engineered to meet the most demanding specifications, ensuring your components achieve exact tolerances, material integrity, and functional performance. We don’t just manufacture parts—we engineer solutions that align with your product lifecycle requirements.

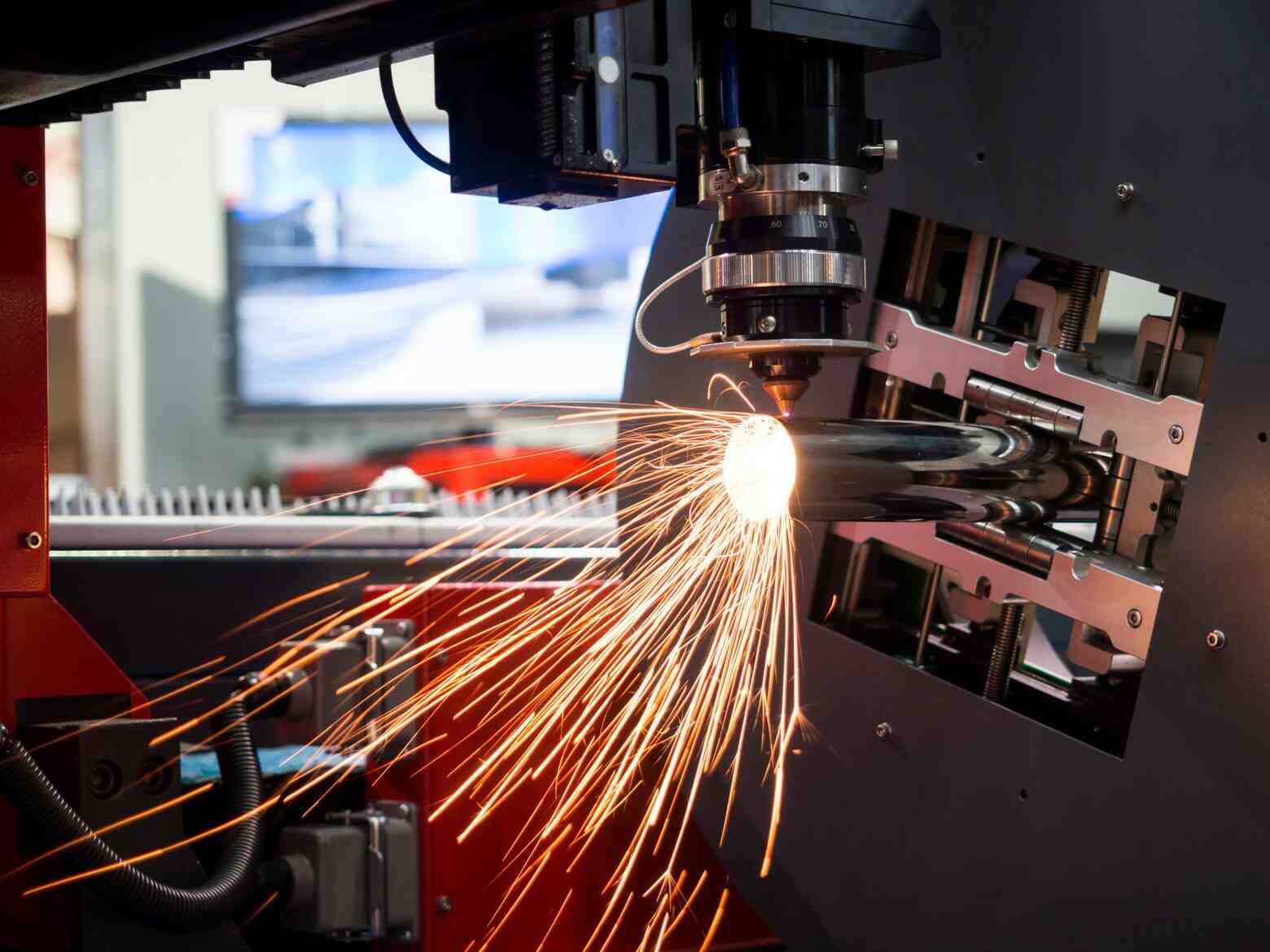

Advanced CNC Equipment for Uncompromised Precision

3/4/5-Axis CNC Machining Centers: High-speed spindles (up to 24,000 RPM) with precision linear guides and thermal stability control for consistent dimensional accuracy.

Multi-Tasking Centers: Integrated turning/milling capabilities for complex geometries in single setups, eliminating alignment errors and reducing lead times.

State-of-the-Art CNC Controls: Real-time error compensation systems and adaptive machining algorithms to maintain tolerances under dynamic production conditions.

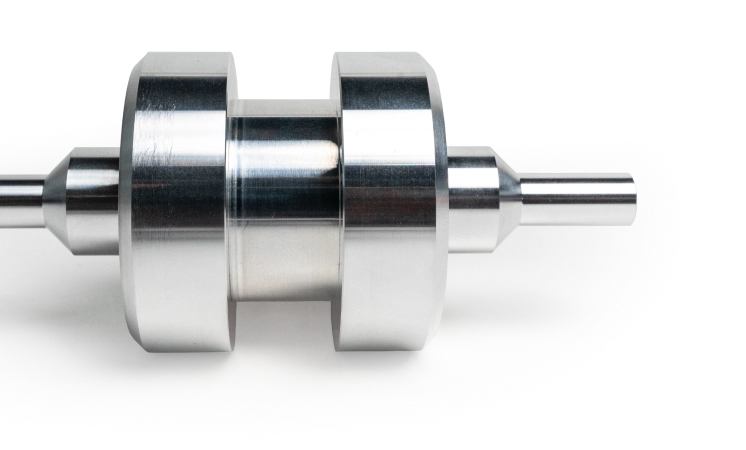

Precision Tolerances Tailored to Your Specifications

Tolerances are application-specific. Our engineering team collaborates with you to define achievable tolerances based on material, geometry, and functional requirements.

| Tolerance Class | Typical Range (mm) | Typical Range (in) | Applications |

|---|---|---|---|

| Standard | ±0.025 | ±0.001 | General industrial components, non-critical assemblies |

| Precision | ±0.005 | ±0.0002 | Medical devices, aerospace structural components, automotive sensors |

| Ultra-Precision | ±0.002 | ±0.00008 | Semiconductor wafer handling, optical components, high-end instrumentation |

Note: All tolerances are validated through ISO 17025-accredited CMM inspections. Tighter tolerances achievable upon engineering review.

Rigorous Quality Control & Material Certification

ISO 9001-Certified Processes: Full traceability from raw material to finished part, with documented quality records for every batch.

Sub-Micron CMM Inspections: Dimensional verification accuracy of ±0.001mm (±0.00004″) for critical features.

Material Certification: Full ASTM/ISO/DIN compliance reports for all metals (aluminum, titanium, stainless steel) and engineering plastics (PEEK, Delrin, Nylon).

Zero Defects Commitment: 99.99% first-pass yield rate via automated in-process inspection and statistical process control (SPC).

Olympic Quality Standard: Proprietary quality framework exceeding ISO 2768-mk and AS9100 benchmarks for mission-critical aerospace, medical, and semiconductor applications.

24/7 Customer Support Partnership

Dedicated Engineering Team: Available around the clock for real-time issue resolution, design-for-manufacturability (DFM) reviews, and urgent technical queries.

Transparent Project Tracking: Live portal access to production status, inspection reports, and shipment updates—no hidden delays.

Proactive Collaboration: Joint problem-solving to optimize tolerances, material selection, and cost efficiency without compromising performance.

“Precision isn’t just a number—it’s the foundation of trust. At Wuxi Lead, we engineer tolerances that don’t just meet specs, but enable your innovation.”

Ready to elevate your supply chain? Contact our technical team today for a free tolerance analysis and material compatibility review.

Material & Finish Options

Material Selection & Finishes: Precision Engineered for Your Application

At Wuxi Lead Precision Machinery, we don’t just supply parts—we partner with your engineering team to optimize material selection and surface finishes for peak performance. Our Zero Defects commitment, backed by ISO 9001-certified processes and Olympic Quality standards, ensures every component meets exact specifications. With 24/7 customer support and full material traceability, we eliminate guesswork in your supply chain.

Strategic Material Selection Criteria

Material choice directly impacts part functionality, cost, and manufacturability. We prioritize:

Mechanical properties (strength, fatigue resistance, thermal stability)

Environmental resilience (corrosion, chemical exposure, temperature extremes)

Machinability (tool wear, surface finish potential, tolerance stability)

Total cost of ownership (material cost + machining complexity + post-processing)

Every material batch includes certified test reports (MTRs) traceable to ISO 9001 standards, ensuring compliance with your exact specifications.

Metal Material Selection Guide

| Material | Key Properties | Machinability | Typical Applications | Cost Impact | Tolerance Considerations |

|---|---|---|---|---|---|

| Aluminum 6061 | High strength-to-weight, corrosion resistance | High | Aerospace, automotive, consumer electronics | Moderate | Maintains ±0.001″ tolerances with precision tooling; ideal for complex geometries |

| Stainless 316 | Excellent corrosion resistance, biocompatible | Medium | Medical devices, marine components | Higher | Requires diamond-coated tools for ±0.0005″ tolerances; thermal expansion managed via cryogenic cooling |

| Titanium Grade 5 | High strength, lightweight, biocompatible | Low | Aerospace, medical implants | Highest | Specialized CNC processes for ±0.0003″ tolerances; strict chip control prevents workpiece distortion |

| Inconel 718 | Extreme heat/corrosion resistance | Very Low | Oil/gas, aerospace turbines | Highest | Requires vibration-damped machining; ±0.0002″ tolerances achievable with adaptive control systems |

Engineering Plastics Selection Guide

| Material | Key Properties | Machinability | Applications | Cost Impact | Tolerance Considerations |

|---|---|---|---|---|---|

| PTFE | Low friction, chemical resistance | Low | Seals, bearings, chemical processing | Moderate | Thermal expansion requires ±0.0005″ tolerance buffers; dry machining only |

| PEEK | High temp resistance (250°C+), chemical inertness | Medium-High | Medical implants, aerospace | High | ±0.0002″ tolerances achievable with controlled humidity and precision tooling |

| Nylon 6/6 | Toughness, wear resistance | High | Gears, bushings, electrical components | Low-Moderate | Moisture absorption requires pre-drying; ±0.0003″ tolerances maintained via in-process humidity control |

| Delrin (POM) | High stiffness, low friction | High | Automotive, precision gears | Moderate | Dimensional stability within ±0.0001″ with cryogenic cooling during machining |

Surface Finish Options & Performance Impact

| Finish Type | Suitable Materials | Key Benefits | Cost Impact | Tolerance Impact | Wuxi Lead’s Process Advantage |

|---|---|---|---|---|---|

| Anodizing (Type II/III) | Aluminum alloys | Corrosion resistance, color options, wear protection | Moderate | +0.0005″ to +0.002″ thickness | Precision masking and ±0.0002″ thickness control; ISO 9001-certified bath monitoring |

| Electroplating (Nickel/Chrome) | Steel, copper, brass | Wear resistance, conductivity, aesthetic appeal | Higher | ±0.0001″ to ±0.0005″ dimensional change | Real-time thickness monitoring via XRF; zero-defect plating with 100% salt spray testing |

| Mirror Polishing | Stainless steel, aluminum | Aesthetic appeal, Ra ≤ 0.1μm surface roughness | High | Surface roughness controlled to ±0.05μm | 3D metrology verification; Zero Defects inspection for optical-grade finishes |

| Passivation | Stainless steel | Corrosion resistance, removes free iron | Low | None (chemical process) | ISO 9001-compliant bath control; nitric acid concentration monitored to ±0.1% |

| Powder Coating | Aluminum, steel | Durability, color variety | Moderate | +0.001″ to +0.003″ thickness | Masking precision within ±0.0005″; oven temperature controlled to ±5°C |

Why Wuxi Lead Delivers Zero Defects in Material & Finish Execution

“Olympic Quality isn’t a slogan—it’s our standard. Every part undergoes 100% inspection against your specifications, with full traceability from raw material to finished product.”

ISO 9001-Certified Material Sourcing: All metals and plastics come with third-party MTRs (Material Test Reports), verified against ASTM/ISO standards.

Tolerance-Driven Finishing: Our CNC processes compensate for finish thickness (e.g., anodizing layers) during initial machining, ensuring final dimensions stay within ±0.0002″.

24/7 Technical Support: Our engineers provide real-time guidance on material trade-offs—e.g., “Use 7075-T6 aluminum instead of titanium for 40% cost savings with equivalent strength in non-critical aerospace components.”

Zero Defects Guarantee: Every finished part is inspected using CMM, optical comparators, and surface roughness testers. If a single feature fails, the entire batch is reworked or replaced—no exceptions.Partner with us to turn material selection from a cost center into a competitive advantage.

Contact our technical team today for a free material optimization consultation—available 24/7.

Manufacturing Process & QC

From Prototype to Production: A Seamless Journey from Concept to Delivery

At Wuxi Lead Precision Machinery, we transcend the role of a supplier to become your strategic manufacturing partner. Our ISO 9001-certified process ensures Zero Defects, Olympic Quality, and 24/7 Customer Service at every stage—from initial design validation to final delivery. Here’s how we deliver precision, speed, and reliability for your most critical components.

Design Analysis & Engineering Collaboration

Our process begins with a collaborative review of your design intent, material specifications, and functional requirements. Unlike traditional suppliers who passively accept blueprints, our ISO 9001-certified engineers conduct a comprehensive DFMA (Design for Manufacturability and Assembly) analysis to identify potential issues before machining begins. All materials are sourced with full traceability and certification (e.g., ASTM, ISO, RoHS), ensuring compliance with your industry standards.

| Material | Wuxi Lead Precision Tolerance | Standard Industry Tolerance |

|---|---|---|

| Aluminum 6061 | ±0.0002 in (±0.005 mm) | ±0.005 in (±0.13 mm) |

| Stainless Steel 304 | ±0.0001 in (±0.0025 mm) | ±0.005 in (±0.13 mm) |

| Titanium Grade 5 | ±0.0001 in (±0.0025 mm) | ±0.005 in (±0.13 mm) |

| PEEK (Engineering Plastic) | ±0.0003 in (±0.0075 mm) | ±0.005 in (±0.13 mm) |

Note: Achievable tolerances depend on part geometry and complexity. Our engineers will confirm specific capabilities during the design review.

Pricing & Strategic Cost Optimization

Transparency and value drive our pricing model. After design validation, we provide a detailed cost breakdown that includes material certification, machining complexity, and volume-driven optimizations. Leveraging advanced ERP systems, we identify cost-saving opportunities—such as material substitution or process streamlining—without compromising quality. Unlike competitors focused on low bids, we prioritize Total Cost of Ownership (TCO), ensuring your project remains budget-conscious while meeting ISO 9001 standards. All pricing is confirmed before production begins—no hidden fees, no surprises.

Rapid Prototyping: Precision in Every Iteration

Our rapid prototyping service bridges concept and production with unmatched speed and Olympic Quality precision. Using the same ISO 9001-certified CNC platforms and metrology equipment as mass production, we deliver functional prototypes in as little as 24 hours. Each prototype undergoes rigorous dimensional verification against your specifications, with tolerances as tight as ±0.0001 in (±0.0025 mm) for aerospace, medical, or defense applications. This “prototype-to-production” consistency eliminates redesign cycles and accelerates time-to-market—ensuring your final product meets Olympic-grade standards from the first iteration.

Mass Production: Consistency, Compliance, and Zero Defects

Mass production at Wuxi Lead is defined by unwavering Zero Defects compliance. Every run is governed by ISO 9001-certified quality control protocols, including 100% in-process inspection using advanced CMM (Coordinate Measuring Machines), optical scanners, and laser profilometry. Our defect rate remains consistently 0% across all projects, validated through third-party audits and continuous process improvement. For mission-critical applications, we implement Olympic Quality standards—where every micron of precision is non-negotiable. With 24/7 Customer Service and real-time production monitoring, your parts are manufactured to exact specifications, every time.

Why This Matters:

– Zero Defects Commitment: 100% inspection + statistical process control (SPC) ensures every part meets specifications.

– Olympic Quality: Tolerances 10x tighter than industry standards for aerospace, medical, and defense sectors.

– 24/7 Customer Service: Dedicated account managers provide real-time updates, issue resolution, and technical support—anytime, anywhere.

Partner with Wuxi Lead Precision Machinery—where precision engineering meets unwavering reliability. Let’s build the future, together.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Your Engineering Ally for Zero-Defect Manufacturing

At Wuxi Lead Precision Machinery, we transcend the traditional supplier relationship. As your strategic manufacturing partner, we combine ISO 9001-certified processes, rigorous material traceability, and a Zero Defects commitment to deliver precision-engineered components that meet your most demanding specifications. Unlike commodity manufacturers, we engineer solutions—not just parts—ensuring your product’s success from prototype to production.

Precision Engineering at the Highest Standard

Our advanced CNC capabilities deliver tolerances that consistently exceed industry benchmarks, ensuring dimensional accuracy for critical aerospace, medical, and automotive applications. Below is a comparison of our precision capabilities versus typical industry standards:

| Metric | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Standard Tolerance | ±0.13mm (±0.005″) | ±0.025mm (±0.001″) |

| Precision Capability | ±0.05mm (±0.002″) | ±0.01mm (±0.0004″) |

| Ultra-Precision | Limited to niche applications | Consistent ±0.005mm (5µm) |

| Material Traceability | Basic documentation | Full ISO 9001-certified traceability with batch-specific certs |

| Quality Assurance | Post-production inspection | In-process monitoring with 100% inspection for critical parts |

| Support Response | 8-5 business hours | 24/7 dedicated engineering team |

💡 Note: Our ultra-precision capabilities (±5µm) are achievable across all project volumes—no minimums, no exclusions. This level of consistency is critical for medical implants, semiconductor tooling, and high-performance aerospace components where micron-level deviations compromise safety or function.

Material Certification & ISO 9001 Compliance

Every material we use undergoes rigorous certification, with full traceability from raw stock to finished part. Our ISO 9001:2015-certified quality management system ensures consistent adherence to specifications across all production runs. Whether machining aerospace-grade titanium (AMS 4928), medical-grade stainless steel (ASTM F138), or high-performance engineering plastics (UL94-V0), you receive documented proof of material integrity and process control.

Key Compliance Features:

Batch-specific material certs (ASTM, ISO, JIS, DIN)

Non-destructive testing (NDT) for critical alloys

Full chemical composition analysis via OES spectrometry

Traceable heat treatment records for hardened steels

Zero Defects Commitment: Olympic-Grade Quality

We don’t just meet tolerances—we guarantee perfection. Our Zero Defects protocol integrates:

Real-time in-process metrology with laser scanning and CMM verification

Statistical Process Control (SPC) for continuous quality monitoring

Zero-tolerance defect policy with root-cause analysis for any deviation

Olympic-grade precision for mission-critical components where failure is not an option

🔍 Case Study: For a Tier-1 automotive supplier, we achieved 0 defects across 12,000+ precision brake components by implementing AI-driven process optimization and 100% in-process CMM checks—reducing their scrap rate by 97%.

24/7 Customer Support: Always There When You Need Us

Your project’s success is our priority—around the clock. Our global engineering team provides:

Immediate technical support for design optimization and troubleshooting

Dedicated account managers for seamless communication

Rapid response SLAs for urgent production adjustments or quality concerns

Cross-functional engineering reviews (Design → Manufacturing → QA) at no cost

Ready to elevate your manufacturing standards?

Transform your supply chain with a partner who prioritizes your success.

📞 Contact Us Today:

📧 [email protected]

☎ +86-13961886740

Request your free DFM analysis and quote—no obligation, just precision.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.