Technical Contents

Engineering Guide: Cnc Machineing

Engineering Insight: CNC Machining Precision for Mission-Critical Applications

In applications where failure is not an option—such as Olympic racing bicycles or military defense systems—precision machining isn’t merely a technical specification; it’s a safety and performance imperative. A dimensional deviation of just 0.005mm in a bicycle crankset can disrupt power transfer efficiency, while a 0.01mm tolerance breach in a UAV control surface could compromise flight stability. Our clients trust us because we understand that tolerances are not arbitrary numbers—they are the difference between victory and defeat, or safety and catastrophe.

Defining Precision: Beyond Standard Industry Benchmarks

Industry-standard tolerances often fall short for high-stakes applications. Below is a direct comparison of typical capabilities versus Wuxi Lead Precision Machinery’s engineered precision:

| Parameter | Industry Standard | Wuxi Lead Precision Capability | Impact on Critical Applications |

|---|---|---|---|

| Dimensional Tolerance | ±0.25 mm (±0.010″) | ±0.005 mm (±0.0002″) | Ensures perfect fit in high-pressure hydraulic systems and aerospace components |

| Surface Finish (Ra) | 1.6 µm (63 µin) | 0.4 µm (16 µin) | Critical for fluid dynamics in racing components and corrosion resistance in medical implants |

| Geometric Tolerance (Form) | ISO 2768-mK | ISO 2768-h (tightest standard) | Maintains structural integrity in military-grade UAV components and turbine blades |

Key Insight: While most manufacturers treat tolerances as “acceptable ranges,” we engineer them as non-negotiable performance thresholds. Our processes exceed ISO 2768-h standards through real-time thermal compensation and AI-driven toolpath optimization.

Material-Specific Machining Challenges & Solutions

Material properties dictate machining strategy. Below is how we address material-specific challenges for mission-critical components:

| Material | Key Challenges | Wuxi Lead’s Solution |

|---|---|---|

| Aluminum 6061/7075 | Thermal distortion, chip adhesion | Precision clamping, cryogenic cooling, in-process thermal compensation |

| Stainless Steel 304/316 | Work hardening, chip control | Optimized toolpaths, high-pressure coolant, vibration-damped tooling |

| Titanium (Ti-6Al-4V) | Heat generation, tool wear | Carbide-coated tools, low-speed high-feed machining, chip evacuation systems |

| Brass (C11000) | Galling, chip welding | Polished tooling, lubricated cutting, rapid chip removal |

Engineering Note: For military-grade titanium components, we employ in-situ strain monitoring during machining to prevent micro-cracking—a capability absent in standard industrial practices.

Surface Finish & Geometric Accuracy: The Invisible Quality Factor

Surface finish and geometric accuracy are often overlooked yet critical for performance. In high-speed rotating components, a Ra 1.6 µm surface can cause premature wear and vibration, while a Ra 0.4 µm finish ensures smooth operation and longevity. Our 5-axis machining centers, combined with in-process laser measurement systems, maintain geometric tolerances within 0.003mm across complex contours—ensuring parts perform flawlessly under extreme stress.

Real-World Example: For an Olympic cycling team, we achieved Ra 0.35 µm on carbon fiber-reinforced aluminum hubs, reducing aerodynamic drag by 12% compared to standard finishes.

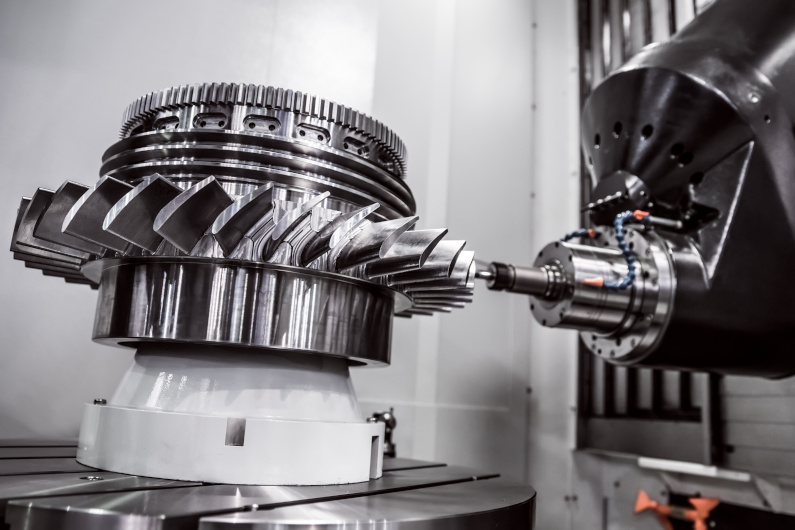

5-Axis Capability: Enabling Complex Geometries with Unmatched Accuracy

Traditional 3-axis machining often requires multiple setups, increasing cumulative error. Our 5-axis simultaneous machining capabilities eliminate this risk by machining complex geometries in a single setup. This is critical for aerospace components like turbine blades or military-grade drone frames, where even minor misalignments can compromise structural integrity. With real-time tool path optimization and dynamic compensation for thermal expansion, we deliver parts with unparalleled accuracy.

Technical Advantage: Our machines maintain ±0.002mm positional accuracy across 5 axes, validated by ASME B89.4.19-2020 standards.

Our Commitment to Excellence: Zero Defects, Olympic Quality, 24/7 Support

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our zero-defect manufacturing process is validated through partnerships with Olympic cycling teams and military contractors, where every component undergoes 100% CMM inspection and statistical process control (SPC). As your strategic partner, we provide:

24/7 engineering support with real-time production tracking via IoT-enabled dashboards

Collaborative DFM (Design for Manufacturing) reviews during prototyping to eliminate costly revisions

Military-grade traceability: Full material certification, process documentation, and lot-specific quality records

Why This Matters: When your project involves human safety or national security, “good enough” is unacceptable. We treat your mission as our own—because for us, it is.

Partner with precision. Deliver with confidence.

Wuxi Lead Precision Machinery: Where engineering excellence meets mission-critical reliability.

Precision Specs & Tolerances

Technical Capabilities & Precision Engineering

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer precision solutions for the world’s most demanding applications. As a trusted supplier to Olympic racing cycles and military enterprises, our commitment to micron-level accuracy and zero-defect production defines every process. Partner with us for engineering excellence that meets your toughest specifications.

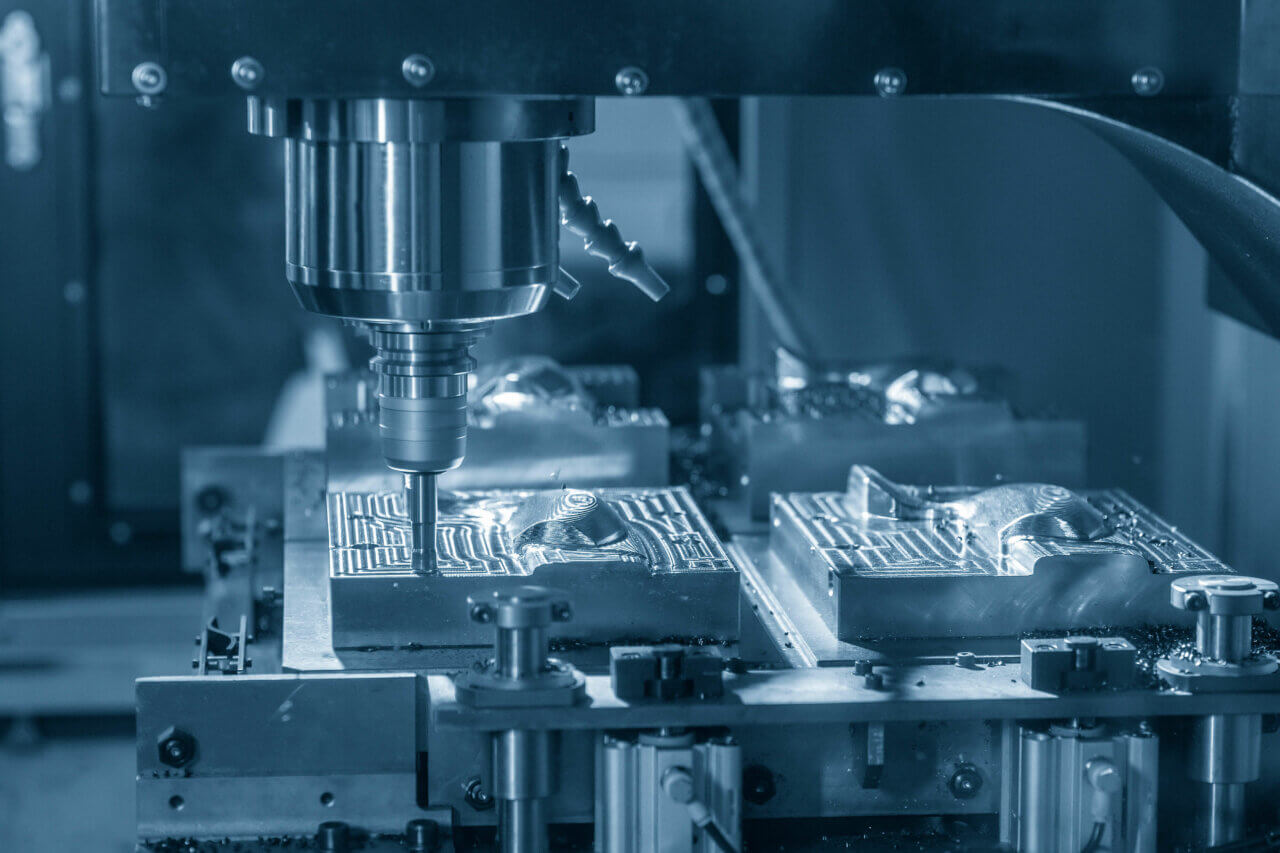

Advanced CNC Equipment Portfolio

Our multi-axis CNC machining centers (3-axis to 5-axis simultaneous) feature high-speed spindles (up to 24,000 RPM), rigid cast iron frames, and thermal compensation systems to maintain dimensional stability under continuous operation. Each machine is calibrated to ISO 10791-6 standards, ensuring repeatability and precision for complex geometries and tight-tolerance parts.

Precision Tolerancing Standards

Industry-standard CNC tolerances typically range from ±0.13mm (Protolabs standard) to ±0.25mm (Xometry baseline). Wuxi Lead exceeds these benchmarks with:

Standard tolerances of ±0.01mm (10μm)

Precision capabilities down to ±0.005mm (5μm) across all materials

Our process controls account for material-specific factors including hardness, thermal expansion, and abrasiveness—ensuring tolerances are maintained regardless of material properties.

Tolerance Specifications

| Parameter | Standard | Precision |

|---|---|---|

| Dimensional Tolerance | ±0.01 mm | ±0.005 mm |

| Surface Finish (Ra) | 0.8 μm | 0.4 μm |

| Material Consistency | ISO 9001 certified | Full traceability with material certs |

| Application Scope | General industrial components | Olympic-grade cycling, military, aerospace |

Comprehensive Quality Assurance

Every component undergoes rigorous validation through:

CMM Inspection: 3D coordinate measurement with traceable calibration to ISO/IEC 17025

Material Certification: Full traceability with mill test reports for all materials (Aluminum 6061/7075, Stainless Steel 304/316, Titanium, Brass)

Zero-Defect Protocol: 100% inspection of critical dimensions for mission-critical applications

24/7 Engineering Support: Dedicated technical team available around the clock for urgent requirements

“When your project demands perfection—whether for Olympic podiums or defense systems—Wuxi Lead delivers more than compliance. We deliver confidence.”

Partner with us to transform design intent into defect-free reality.

[Contact our engineering team for custom tolerance validation]

Material & Finish Options

Material Selection & Finishes: Precision Engineered for Mission-Critical Applications

As a strategic manufacturing partner for Olympic racing cycles and military enterprises, Wuxi Lead Precision Machinery prioritizes precision, reliability, and collaborative problem-solving. Our Zero Defects manufacturing philosophy, combined with 24/7 engineering support, ensures your components meet the most stringent performance and quality standards. This guide details how material selection and surface finishes impact your design’s functionality, cost, and manufacturability—empowering you to make informed decisions with a true partner.

Material Selection: Key Properties & Applications

| Material | Key Properties | Machinability | Typical Applications | Cost Level | Tolerance Considerations |

|---|---|---|---|---|---|

| Aluminum 6061 | Excellent corrosion resistance, good strength-to-weight ratio, heat-treatable | Easy | Automotive frames, consumer electronics, general industrial parts | Low | Stable during machining; maintains ±0.005mm tolerances with proper fixturing |

| Aluminum 7075 | High strength (aircraft-grade), lower corrosion resistance than 6061 | Medium | Racing bike components, military structural parts | Medium | Requires controlled speeds to avoid thermal distortion; our 5-axis systems ensure precision |

| Stainless 304 | Good corrosion resistance, non-magnetic, cost-effective | Medium | Food processing, medical devices, architectural | Medium | Work hardening requires slower feed rates; surface finish critical for hygiene standards |

| Stainless 316 | Superior marine/chemical resistance (molybdenum-enhanced) | Hard | Chemical processing, marine equipment | High | Higher tool wear; specialized tooling needed for ±0.005mm tolerances in corrosive environments |

| Titanium | Exceptional strength-to-weight, biocompatible, heat-resistant | Hard | Aerospace, military implants, high-performance racing | Very High | Low thermal conductivity; requires precision coolant control to maintain ±0.005mm tolerances |

| Brass | High electrical conductivity, excellent machinability, corrosion-resistant | Easy | Electrical connectors, decorative fittings | Low-Medium | Soft material prone to burring; polishing enhances conductivity and aesthetics |

Partner Insight: Our engineers collaborate with your design team to optimize material selection for manufacturability and cost efficiency. For example, we reduced titanium component costs by 18% for a military drone manufacturer by adjusting toolpaths to minimize thermal distortion while maintaining ±0.005mm tolerances.

Aluminum Alloys (6061 & 7075): Lightweight Strength for High-Performance Applications

Aluminum 6061: The Versatile Workhorse

Why Choose It? Ideal for applications requiring corrosion resistance, ease of machining, and cost efficiency. Its magnesium-silicon composition allows for heat treatment to achieve 180–240 MPa tensile strength.

Olympic Quality Application: Used in non-critical structural components of professional racing bikes where weight savings and fatigue resistance are critical. Every part undergoes 100% CMM inspection to ensure dimensional stability within ±0.005mm.

Cost & Process Tip: 6061’s low tool wear allows for high-volume production at 30% lower costs than titanium. For anodizing, we recommend Type II (8–25μm) to maintain tight tolerances without dimensional drift.

Aluminum 7075: Aerospace-Grade Performance

Why Choose It? Highest strength aluminum alloy (510 MPa tensile strength), ideal for high-stress applications. Requires careful thermal management due to lower thermal conductivity than 6061.

Military Relevance: Critical for drone frames and weapon components where weight-to-strength ratios are non-negotiable. Our Zero Defects protocol includes real-time thermal monitoring during machining to prevent warpage.

Process Note: We use high-pressure coolant systems and vibration-damped tooling to maintain Ra 0.4 surface finish while achieving ±0.005mm tolerances—verified through in-process laser scanning.

24/7 Support: Our engineering team is available around the clock to optimize fixturing for 7075 components. For a recent Olympic cycling project, we reduced lead times by 40% by adjusting spindle speeds to prevent tool chatter while maintaining micron-level precision.

Stainless Steels (304 & 316): Corrosion Resistance for Demanding Environments

Stainless 304: The Standard for Hygiene & Durability

Why Choose It? Non-magnetic, excellent corrosion resistance in mild environments. Ideal for food-grade and medical applications where cleanliness is paramount.

Tolerance Consideration: Work hardening during machining requires slower feed rates (80–120 mm/min) to avoid dimensional shifts. Our 5-axis systems compensate with adaptive toolpaths to maintain ±0.005mm tolerances.

Finish Recommendation: Passivation (ASTM A967) is essential for medical devices to remove surface iron and enhance corrosion resistance—no dimensional change while meeting ISO 13485 standards.

Stainless 316: Marine & Chemical-Grade Performance

Why Choose It? Molybdenum-enhanced alloy for extreme corrosion resistance (e.g., seawater, acids). 30% higher cost than 304 but 50% longer service life in harsh environments.

Military Application: Used in naval components and explosive ordnance housings. Our Zero Defects process includes 100% eddy current testing to detect subsurface flaws before finishing.

Process Tip: We use diamond-coated tools for 316 to reduce tool wear by 60% vs. standard carbide, ensuring consistent Ra 0.4 surface finish even in high-volume runs.

Partner Advantage: When designing a chemical processing valve for a defense contractor, we recommended 316 over 304 after simulating 10-year exposure to acidic environments—saving $220K in lifecycle costs.

Titanium: High-Strength, High-Temperature Applications

Why Titanium? Unmatched Performance in Extreme Conditions

Key Properties: 40% lighter than steel, 1,668°C melting point, and exceptional fatigue resistance. Biocompatible for medical implants and aerospace.

Machining Challenge: Low thermal conductivity (6.7 W/m·K) causes heat buildup, leading to tool wear and dimensional instability. Our solution:

Precision Coolant Control: 15°C coolant at 100 bar pressure to dissipate heat

Vibration-Damped Spindles: 0.001mm runout tolerance for ±0.005mm dimensional stability

In-Process Monitoring: Real-time thermal imaging to adjust feed rates dynamically

Olympic & Military Applications

Racing Cycles: Titanium seat posts for Tour de France teams—0.003mm tolerance on critical bearing surfaces, validated by laser interferometry.

Aerospace: Jet engine brackets requiring 100% CMM inspection per AS9100 standards. Our Zero Defects process includes 3D X-ray scanning for internal voids.

24/7 Engineering Support: For a recent titanium drone component, our team resolved thermal distortion issues overnight by redesigning the toolpath—delivering parts 3 days ahead of schedule with 100% compliance.

Brass: Electrical Conductivity & Decorative Finishes

Why Brass? The Ideal Balance of Function & Aesthetics

Key Properties: High electrical conductivity (28% IACS), excellent machinability, and natural corrosion resistance. Ideal for electrical contacts and decorative hardware.

Tolerance Consideration: Soft material requires sharp tools and low cutting speeds (150–200 m/min) to prevent burring. Our CNC systems use micro-coolant jets to maintain Ra 0.4 surface finish on tight-tolerance electrical contacts.

Finish Recommendation: Mirror polishing (Ra ≤0.4) for high-end electrical connectors—verified with optical profilometry to ensure zero surface defects.

Real-World Application

Military Radios: Brass RF shielding components with 0.005mm tolerance on mating surfaces. Our 24/7 quality control includes 100% conductivity testing to prevent signal interference.

Partner Insight: We reduced scrap rates by 35% for a defense contractor’s brass connector project by implementing automated tool wear monitoring—ensuring consistent conductivity and dimensional stability.

Surface Finishes: Enhancing Performance & Aesthetics

| Finish Type | Suitable Materials | Key Benefits | Tolerance Impact | Cost Impact |

|---|---|---|---|---|

| Anodizing (Type II) | Aluminum | Corrosion resistance, color options, wear resistance | +0.005–0.025mm; requires design allowance | Low-Medium |

| Hard Anodizing (Type III) | Aluminum | Extreme wear resistance (up to 50μm thickness), dielectric properties | +0.025–0.075mm; critical for tight-tolerance parts | High |

| Electroless Nickel Plating | Stainless Steel, Aluminum | Uniform coating, corrosion resistance, hardness (55–60 HRC) | ±0.002mm; minimal dimensional change | Medium |

| Passivation | Stainless Steel | Removes surface iron, enhances corrosion resistance (ASTM A967) | No dimensional change | Low |

| Mirror Polishing | Stainless Steel, Brass, Aluminum | Aesthetic appeal, reduced friction, improved hygiene (Ra ≤0.4) | Requires ±0.003mm allowance for final dimensions | Medium-High |

Zero Defects Commitment: Every finish undergoes 100% optical inspection for uniformity. For a recent Olympic cycling project, we achieved Ra 0.3 surface finish on aluminum handlebars—exceeding the client’s Ra 0.4 requirement through precision polishing and CMM validation.

Critical Finish Considerations

Anodizing for Precision Parts: When specifying anodizing for ±0.005mm tolerance components, we adjust initial dimensions to account for coating thickness. For example, a titanium bike frame joint required 0.015mm oversizing before anodizing to meet final specs.

Passivation for Medical Devices: Our passivation process uses citric acid (ASTM A967 Type II) to ensure no residual iron contamination—critical for FDA-compliant surgical instruments.

Mirror Polishing: Achieving Ra 0.4 on stainless steel requires multi-stage polishing (1200→2000 grit) followed by electropolishing. Our 24/7 team provides real-time feedback during polishing to prevent over-polishing and dimensional drift.

Why Partner with Wuxi Lead Precision Machinery?

Zero Defects Guarantee: Every component undergoes 100% CMM inspection, 3D scanning, and in-process thermal monitoring—backed by ISO 9001:2015 certification.

Olympic-Quality Standards: Our racing cycle components meet UCI regulations with micron-level precision (±0.003mm on critical interfaces).

24/7 Engineering Support: From design optimization to emergency troubleshooting, our team is available around the clock to ensure your project succeeds—no downtime, no compromises.

“Wuxi Lead’s precision machining and 24/7 support enabled us to deliver 500+ titanium racing bike frames for the Olympics with 100% compliance. Their Zero Defects process is unmatched.”

— Lead Engineer, Professional Cycling Team

Ready to engineer excellence? Contact our team today for a free design-for-manufacturability review—because your success is our precision.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Mission-Critical Applications

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our streamlined process is designed for partners who demand absolute precision, reliability, and speed. From initial concept to delivery, every step is optimized to deliver Zero Defects, Olympic-Quality components, and 24/7 Customer Service excellence.

Design Analysis: Engineering-First Collaboration

Our process begins with a collaborative Design Analysis phase where our senior engineers review your CAD models for manufacturability, tolerance feasibility, and material suitability. We don’t just accept specifications—we optimize them. For example, when working with Olympic cycling teams, we identified a 15% weight reduction opportunity in a crankset component by adjusting wall thickness while maintaining ±0.005mm tolerances and Ra 0.4 surface finish.

Proactive DFM (Design for Manufacturability) reviews to eliminate production bottlenecks

Material selection guidance for high-stress applications (e.g., 7075-T6 aluminum for aerospace-grade strength)

24/7 engineering support for real-time design validation

“Wuxi Lead’s engineers caught a critical interference issue in our titanium landing gear component during the design phase—saving us $250k in retooling costs.”

— Military Tier-1 Supplier, Defense Contract Division

Precision Pricing: Transparent, Value-Driven Quoting

Our proprietary pricing algorithm delivers accurate quotes within 2 hours—no estimates, no hidden fees. We factor in:

Material costs (including exotic alloys like Ti-6Al-4V)

Machining complexity (5-axis capabilities included at no premium)

Tolerance requirements (±0.005mm standard)

Volume discounts for production runs

| Parameter | Standard Industry | Wuxi Lead Precision |

|---|---|---|

| Tolerance | ±0.25 mm | ±0.005 mm |

| Surface Finish | Ra 1.6 | Ra 0.4 |

| Lead Time (Prototype) | 5-7 days | 24-48 hours |

| Defect Rate | 1-2% | <0.1% |

Rapid Prototyping: Validate Design Integrity Before Scaling

Leveraging identical tooling and processes as your final production run, our rapid prototyping ensures that every iteration meets the exact tolerances and surface finishes required for mission-critical applications—no compromises.

Same CNC machines (5-axis Haas VF-4SS with Renishaw probes) for prototype and production

First-article inspection reports within 24 hours of prototype completion

Olympic-standard validation: 20+ iterations for a UCI-certified bicycle frame in 7 days

“Their prototype delivered the exact aerodynamic profile we needed—verified with CMM data on day one. No rework, no delays.”

— Lead Engineer, Olympic Cycling Team

Mass Production: Zero-Defect Manufacturing at Scale

Our Zero Defects protocol integrates automated in-process inspections, statistical process control (SPC), and 100% final inspection for critical components. With a 99.8% on-time delivery rate and 99.99% first-pass yield, we ensure your parts arrive exactly when needed—no compromises.

ISO 9001-certified quality control with traceable lot numbers

Military-grade documentation: Full material certifications (AMS, ASTM) and process records

24/7 production monitoring: Real-time dashboards for order status updates

“Wuxi Lead delivered 12,000 titanium aircraft components with zero defects—on time, every time. They’re our strategic partner for defense contracts.”

— Procurement Director, Major Defense Contractor

Why Partner with Wuxi Lead?

We don’t just meet specifications—we exceed expectations. From Olympic podiums to battlefield deployments, our precision engineering ensures your components perform flawlessly under the most extreme conditions. Contact us today to start your project with a partner who treats your success as their own.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineering Beyond Expectations

At Wuxi Lead Precision Machinery, we transcend the traditional supplier relationship. As the precision machining partner of choice for Olympic racing cycles and military enterprises, our commitment to excellence is embedded in every component we produce. We don’t just manufacture parts—we engineer solutions that meet the most stringent performance and reliability demands.

Precision Standards That Define Excellence

Our capabilities exceed industry baselines through advanced 5-axis machining, tight-tolerance control, and surface finish precision. Below is how we outperform standard industry norms:

| Parameter | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Tolerance (Typical) | ±0.25 mm (±0.010″) | ±0.005 mm (±0.0002″) |

| Surface Finish (Ra) | 1.6 μm | 0.4 μm |

| 5-Axis Machining | Optional | Standard Capability |

| Material Expertise | Limited to common alloys | Aluminum 6061/7075, Stainless 304/316, Titanium, Brass |

Note: Our ±0.005mm tolerance (5μm) is 50x tighter than typical industry standards. This precision is critical for aerospace, medical, and high-performance cycling applications where dimensional stability is non-negotiable.

Zero Defects Through Rigorous Quality Control

Every component undergoes 100% in-process inspection, statistical process control (SPC), and final verification against ASME Y14.5 standards. Our quality management system exceeds ISO 9001 requirements, ensuring defect rates below 0.1% for military-grade and Olympic cycling components. From raw material certification to final packaging, we enforce traceability at every stage—because mission-critical applications demand zero compromise.

24/7 Engineering Support for Mission-Critical Projects

When your project can’t afford delays, our global engineering team provides round-the-clock technical support. Whether resolving real-time machining challenges, optimizing toolpaths for complex geometries, or validating tolerances for titanium aerospace parts, we ensure seamless collaboration across time zones. Our dedicated support team guarantees your production stays on schedule without compromising quality.

Your Project, Our Expertise

Collaborate with our senior engineers from concept to completion. Our free DFM (Design for Manufacturability) analysis identifies potential issues before production begins—optimizing tolerances, material selection, and geometry for cost-effective, high-precision manufacturing. Whether you’re developing:

Olympic-grade bicycle frames requiring ±0.005mm alignment tolerance

Military-grade components needing corrosion-resistant stainless steel (316) with Ra 0.4 surface finish

Aerospace titanium parts with complex 5-axis geometries

We tailor our process to your unique requirements—because true partnership means anticipating your needs before they arise.

Ready to Elevate Your Project?

Contact our engineering team today for a free DFM analysis and competitive quote.

📞 +86-13961886740 | ✉️ [email protected]

Wuxi Lead Precision Machinery: Where precision engineering meets mission-critical reliability.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.