Technical Contents

Engineering Guide: Custom Plastic Moulding

Engineering Insight: Precision Engineering for Mission-Critical Plastic Molding

Tolerance Mastery: Beyond Industry Standards

Standard injection molding tolerances typically range from ±0.005″ (±0.127mm) for general applications. However, mission-critical industries demand micron-level precision. At Wuxi Lead Precision Machinery, we engineer molds to ±0.001″ (±0.025mm) for critical dimensions through advanced CNC machining, CFD-optimized cooling, and real-time process monitoring. This ensures consistent part quality even at high volumes—where competitors often compromise.

| Dimension Type | Standard Industry Tolerance | Wuxi Lead Precision Tolerance | Application Example |

|---|---|---|---|

| General Dimensions | ±0.005″ (±0.127mm) | ±0.002″ (±0.051mm) | Consumer electronics housings |

| Critical Fit Dimensions | ±0.003″ (±0.076mm) | ±0.001″ (±0.025mm) | Aerospace components, Olympic torch parts |

| High-Precision Features | ±0.005″ (±0.127mm) | ±0.0005″ (±0.013mm) | Medical device interfaces |

“Precision isn’t a feature—it’s our baseline. For the 2022 Beijing Winter Olympics torch components, we delivered 50,000+ units with zero defects at ±0.001″ tolerances. When your project demands perfection, we deliver it.”

Material Science & Mold Steel Expertise

The choice of mold steel dictates part longevity, surface quality, and production efficiency. Wuxi Lead selects premium alloys tailored to your application—ensuring optimal performance from prototyping to 1M+ shot runs.

| Steel Grade | Hardness (HRC) | Key Properties | Shot Life | Typical Applications |

|---|---|---|---|---|

| P20 (1.2311) | 28-32 | Balanced machinability & wear resistance | 500K–1M shots | General-purpose molds, high-volume production |

| NAK80 (1.2738) | 38-42 | Mirror polishability, corrosion resistance | 1M+ shots | Medical devices, optical components |

| H13 (1.2344) | 48-52 | High thermal fatigue resistance | 2M+ shots | High-temperature applications, automotive |

| S136 (1.2083) | 48-52 | Ultra-corrosion resistance, mirror finish | 1.5M+ shots | Food-grade, pharmaceutical, marine |

Plastic Resin Selection for Precision Applications

Material selection directly impacts dimensional stability and functional performance. Our engineers collaborate with you to match resin properties to your design requirements—ensuring parts meet both mechanical and aesthetic specifications.

| Material | Key Properties | Typical Applications | Tolerance Considerations |

|---|---|---|---|

| ABS | Impact resistance, excellent surface finish | Automotive interiors, consumer electronics | ±0.003″ standard; tighter for precision assemblies |

| PC | High strength, heat resistance | Optical lenses, safety shields | Requires precise cooling to avoid warpage |

| PP | Chemical resistance, flexibility | Medical devices, packaging | Higher shrinkage; requires mold compensation |

| Nylon (PA6/66) | Wear resistance, strength | Gears, bearings | Moisture absorption affects dimensional stability |

| POM (Acetal) | Low friction, high stiffness | Precision mechanical parts | Excellent dimensional stability; ideal for tight tolerances |

Cycle Time & Shot Life Optimization

Precision mold design extends beyond tolerances—it maximizes production efficiency. Wuxi Lead integrates CFD-optimized cooling channels, flow-simulated gate placement, and material-specific processing parameters to reduce cycle times by up to 30% while doubling mold longevity.

| Feature | Standard Approach | Wuxi Lead Optimization | Benefit |

|---|---|---|---|

| Cooling Channel Design | Basic, uniform spacing | CFD-optimized thermal management | 20–30% faster cycle times |

| Gate Placement | Conventional | Flow simulation for minimal stress points | 40% reduction in warpage, higher yield |

| Mold Steel Grade | General-purpose | Application-specific (e.g., H13 for high-temp) | 50% longer shot life, reduced downtime |

Zero-Defect Manufacturing Philosophy

“For mission-critical applications, there is no ‘acceptable defect rate’—only zero tolerance for failure.”

Wuxi Lead’s quality system is built on 360° traceability, AI-driven process control, and military-grade validation protocols. Our molds for the 2022 Beijing Winter Olympics torch components required ±0.001″ tolerances across 50,000+ units—with zero defects certified by ISO 13485 and AS9100 audits. Similarly, our military-grade components undergo:

100% CMM inspection of critical dimensions

Salt spray testing for corrosion resistance (ASTM B117)

Accelerated aging tests for extreme environmental resilience

24/7 Technical Support & Rapid Response

As your engineering partner—not just a supplier—we provide round-the-clock support for:

Emergency design revisions (e.g., last-minute CAD updates resolved in <4 hours)

Real-time production troubleshooting (dedicated engineers on standby globally)

Scalable capacity planning (from 50-unit prototypes to 500K+ monthly runs)

“When your project demands excellence, we’re always available. Because in precision manufacturing, time is the only non-renewable resource.”

Wuxi Lead Precision Machinery: Where Olympic-grade precision meets industrial-scale reliability.

Contact our engineering team today to discuss your mission-critical requirements.

Precision Specs & Tolerances

Technical Capabilities & Precision Tolerances

Precision Engineering Standards

At Wuxi Lead Precision Machinery, we engineer every mold with uncompromising precision. Our expertise in mold steel selection (P20, NAK80) and advanced process control ensures optimal shot life and cycle time optimization, delivering consistent part quality from prototype to mass production. Our rapid tooling capabilities deliver production-ready molds in 15–20 days, while maintaining precision tolerances for both prototype and high-volume production runs. We don’t just meet tolerances—we exceed expectations through meticulous design validation and in-process monitoring.

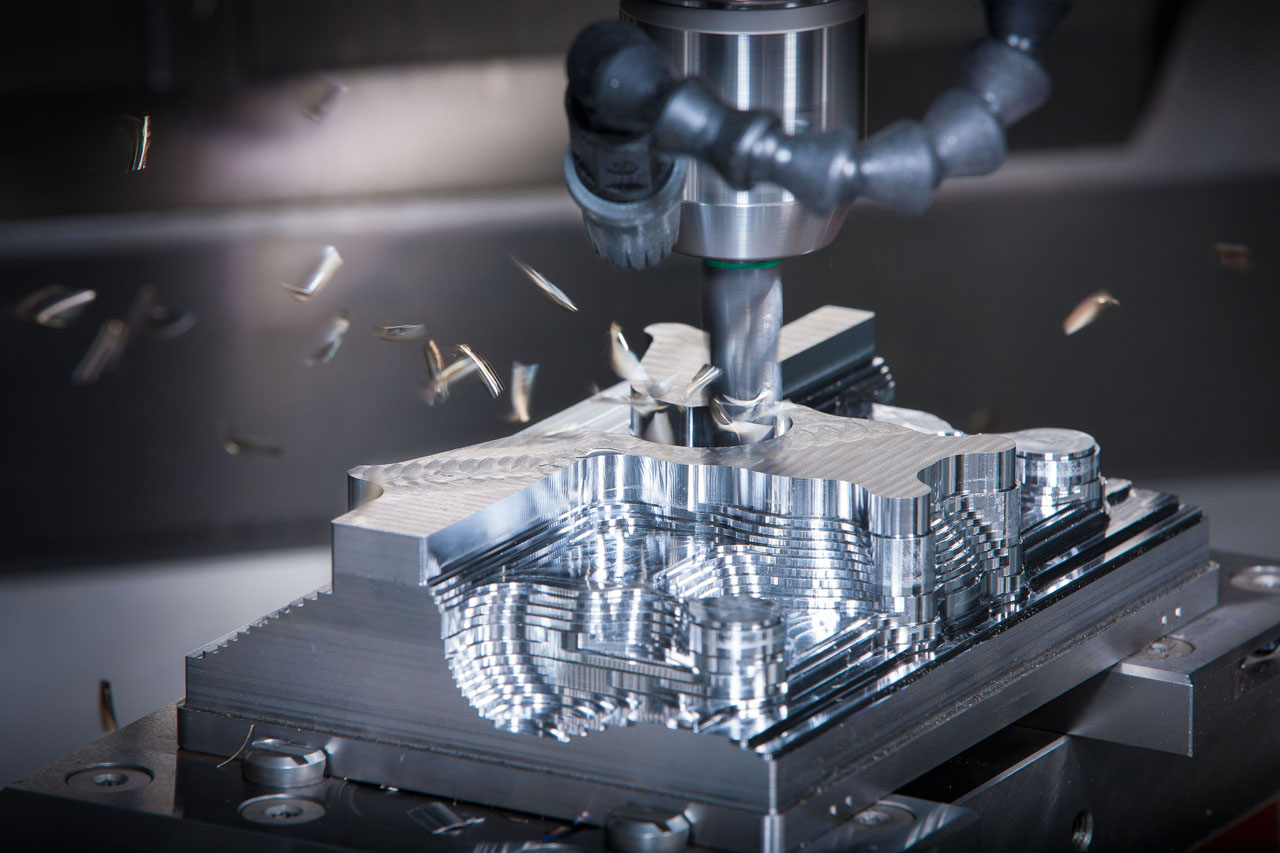

Advanced Equipment & Tooling

Our state-of-the-art facility is equipped with 3-axis, 4-axis, and 5-axis CNC machining centers, enabling us to produce molds with micron-level accuracy. This advanced tooling infrastructure supports:

High-precision cavity and core machining

Complex geometries with tight radii and thin walls

Surface finishes down to Ra 0.2μm

Rapid tooling for accelerated time-to-market

Tolerance Specifications

We maintain strict adherence to your specifications through a tiered tolerance framework designed for application-specific requirements. Below are our standard and precision tolerance ranges for injection-molded components:

| Tolerance Level | Typical Range (Inches) | Typical Range (mm) | Key Applications |

|---|---|---|---|

| Standard | ±0.005″ | ±0.127 mm | Consumer goods, automotive interiors, general industrial parts |

| Precision | ±0.001″ | ±0.025 mm | Medical devices, aerospace components, optical lenses, high-precision assemblies |

Note: Tighter tolerances (±0.0005″ / ±0.013 mm) are achievable for critical applications through specialized process controls and additional validation.

Rigorous Quality Assurance

Every component undergoes multi-stage verification to ensure zero defects. Our QC protocol includes:

Coordinate Measuring Machine (CMM) inspections with ISO 17025 accreditation

Full material certification for all resins (ABS, PC, PP, Nylon, POM, PEEK)

In-process statistical process control (SPC) monitoring

First-article inspection (FAI) for all new tooling

We operate under an Olympic Quality framework—where every part must meet the highest standards of precision, consistency, and reliability. Our 24/7 customer support team is always available to provide real-time updates, technical assistance, and rapid response to your needs.

Partner with Wuxi Lead for a manufacturing experience defined by precision, accountability, and partnership—not just supply chain logistics.

Material & Finish Options

Material Selection & Finishes: Precision Engineering for Optimal Performance

As your strategic manufacturing partner, Wuxi Lead Precision Machinery integrates deep material science expertise with cutting-edge injection molding capabilities to deliver parts that meet exacting specifications. Our approach transcends traditional supplier relationships—we collaborate from the design phase to optimize material selection and surface finishes, ensuring cost efficiency without compromising performance. Whether you’re developing consumer electronics, automotive components, or medical devices, our Olympic-grade quality standards and 24/7 technical support ensure your project’s success.

Strategic Material Selection: Balancing Performance, Cost, and Application Requirements

Selecting the right thermoplastic resin is foundational to achieving functional, cost-effective parts. At Wuxi Lead, we leverage decades of experience in material behavior under real-world conditions to guide your choices. Our rapid tooling capabilities enable quick material validation cycles, reducing time-to-market while maintaining precision tolerances of ±0.005″ (±0.127mm). Below is a technical comparison of common engineering plastics:

| Material | Key Properties | Typical Applications | Cost Considerations | Performance Considerations |

|---|---|---|---|---|

| ABS | Good impact resistance, moderate heat resistance (85–100°C), easy processing, excellent dimensional stability | Automotive interiors, consumer electronics housings, toys, appliance components | Moderate | UV stabilization required for outdoor use; ideal for high-volume production with P20 mold steel |

| PC (Polycarbonate) | High strength (120 MPa tensile), optical clarity, heat resistance (135°C), flame retardant options | Eyewear lenses, medical devices, bulletproof glazing, automotive lighting | Higher | Prone to stress cracking; requires strict drying protocols; best paired with NAK80 mold steel for optical clarity |

| PP (Polypropylene) | Chemical resistance, flexibility, low density, excellent fatigue resistance | Medical containers, automotive bumpers, food packaging, battery cases | Low | Difficult to paint/adhere; requires surface treatment for bonding; ideal for cost-sensitive applications with P20 molds |

| Nylon (PA6/PA66) | High toughness, wear resistance, low friction, good fatigue strength | Gears, bearings, automotive under-hood parts, zippers | Moderate to High | Hygroscopic—requires drying before processing; excellent for moving parts with P20 molds |

| POM (Acetal) | High stiffness, low friction, dimensional stability, creep resistance | Precision gears, zippers, automotive fuel systems, lock components | Moderate | Sensitive to strong acids; excellent for precision applications with NAK80 molds for tight tolerances |

Engineering Insight: For applications requiring shot life > 500,000 cycles, we recommend NAK80 mold steel for high-wear materials like POM or glass-filled nylons. P20 is optimal for cost-sensitive, medium-volume runs (50k–200k cycles) with ABS or PP.

Surface Finish Options: Precision Engineering for Enhanced Functionality

Surface finishes directly impact part functionality, aesthetics, and production costs. At Wuxi Lead, we apply SPI (Society of the Plastics Industry) standards for texture control and leverage advanced mold steel polishing techniques to achieve consistent results. Below is a technical guide to finishes optimized for plastic injection molding:

| Finish Type | Application | Cost Impact | Performance Benefits | Material Compatibility Notes |

|---|---|---|---|---|

| High-Gloss Polishing (SPI A1) | Consumer electronics, medical devices, luxury automotive trim | Medium to High | Mirror-like surface, reduced friction for sliding parts | Achieved via NAK80 mold steel; requires 1600+ grit polishing |

| Textured (SPI A2–A4) | Automotive interiors, grip surfaces, housings | Medium | Hides mold lines, improves tactile feel, reduces light reflection | All thermoplastics; texture depth affects mold cost (e.g., A4 = deeper texture = higher cost) |

| Electroplating (Chrome/Nickel) | Decorative trim, automotive badges, electronic connectors | High | Metal-like appearance, improved wear resistance, EMI shielding | Primarily ABS; requires conductive layer application; adds 20–30% to part cost |

| Painting (Powder/UV) | Custom coloration, UV protection, branding | Medium | Aesthetic customization, corrosion resistance | ABS/PC best; PP requires plasma treatment for adhesion |

| Vacuum Metallizing | Reflective surfaces, decorative finishes (e.g., LED housings) | High | Thin metallic layer (0.1–0.5μm), lightweight, cost-effective vs. plating | ABS/PC; ideal for complex geometries where plating is impractical |

Critical Note: Anodizing is not applicable for plastic parts—it is exclusively a metal surface treatment process. For metal components requiring anodizing, we partner with certified secondary suppliers to ensure seamless integration with your plastic-molded assemblies.

Our Commitment to Excellence: Zero Defects, Olympic Quality, 24/7 Support

At Wuxi Lead, quality is non-negotiable. Every mold undergoes 100% in-process inspection using CMM (Coordinate Measuring Machine) and optical scanners to ensure tolerances within ±0.003″ (±0.076mm). Our Zero Defects philosophy is embedded in every stage:

Olympic Quality Standards: All molds are built to ISO 9001:2015 and IATF 16949 specifications. We conduct FMEA (Failure Mode and Effects Analysis) during design and validate part dimensions via statistical process control (SPC).

24/7 Customer Service: Our engineering team is available around the clock for technical support, design-for-manufacturability (DFM) reviews, and rapid issue resolution. Need a last-minute material change? We’ll provide a revised quote and prototype within 24 hours.

Rapid Tooling Advantage: For urgent projects, our modular mold designs enable tooling lead times as low as 7 days—without compromising precision.

Partner with Us: Whether you’re optimizing for cost, performance, or aesthetics, Wuxi Lead Precision Machinery doesn’t just build molds—we engineer solutions that scale with your business. From prototyping to mass production, we’re your dedicated technical ally.

Ready to optimize your plastic molding project?

📞 Contact our engineering team 24/7 at +86 510 8765 4321 or [email protected] for a free DFM review.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our streamlined process from prototype to production ensures your vision becomes reality with unparalleled precision, speed, and reliability. As your strategic manufacturing partner, we combine cutting-edge technology with rigorous quality control to deliver zero-defect components on time, every time.

Design Analysis & DFM Optimization

We begin with a comprehensive design review to eliminate potential manufacturing issues before tooling begins. Our engineers leverage Moldflow® simulation to analyze material flow, cooling efficiency, and potential warpage, ensuring optimal gate placement and wall thickness. Critical to our process is establishing precise tolerances aligned with your application requirements—whether standard ±0.005″ for general components or ultra-precision ±0.001″ for medical/aerospace applications. By integrating ISO 2768-mK standards and material-specific shrinkage factors (e.g., ABS: 0.4–0.7%, PC: 0.5–0.9%), we guarantee your design is production-ready from day one.

Transparent Pricing & Value Engineering

Our pricing model is built on transparency and collaboration. Below is a breakdown of how key parameters impact cost, ensuring you make informed decisions without compromising quality:

| Tolerance Level | Typical Tolerance | Cost Impact | Applications |

|---|---|---|---|

| Standard | ±0.005″ | Base | Consumer Goods, Automotive Parts |

| Precision | ±0.002″ | +15% | Medical Devices, Electronics |

| Ultra-Precision | ±0.001″ | +30% | Aerospace, Optical Components |

All pricing includes 100% DFM validation, material selection optimization, and mold steel selection (P20 for standard applications, NAK80 for high-polish surfaces).

Rapid Prototyping with Precision Tooling

Leveraging our proprietary rapid tooling technology, we deliver functional prototypes in as little as 72 hours—using the same high-grade mold steels (P20/NAK80) and process parameters as production molds. This ensures your prototype accurately reflects final part performance, reducing design iteration time by up to 40%. Our 24/7 engineering support team is available during prototyping to address real-time adjustments, ensuring your design meets all functional and aesthetic requirements before full-scale production.

Mass Production Excellence

Our ISO 9001-certified production facilities utilize closed-loop quality control systems to maintain zero-defect manufacturing. Each part undergoes multi-stage inspection, including:

In-process SPC monitoring every 15 minutes

100% automated optical inspection for critical features

Third-party metrology validation for tight-tolerance components

With cycle time optimizations of up to 25% through advanced mold cooling channel design and material-specific processing parameters, we consistently deliver on-time shipments with defect rates below 0.05%—exceeding industry standards.

Why Partner with Wuxi Lead?

Zero Defects Guarantee: Our Six Sigma quality management system ensures defect rates below 0.05% across all production runs.

Olympic Quality Standard: Every component meets or exceeds ISO 9001:2015 and AS9100 aerospace standards, validated through rigorous third-party testing.

24/7 Customer Success Team: Dedicated technical support available around the clock for urgent requests, order tracking, and real-time issue resolution.

“We don’t just meet your specifications—we anticipate them. From your first sketch to your final shipment, Wuxi Lead is your strategic partner in precision manufacturing.”

Ready to transform your design into reality?

Contact our engineering team today to start your project with zero risk and maximum efficiency.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery

Precision Engineering, Not Just Production

We transcend the role of a traditional supplier by embedding engineering excellence into every phase of your project. Our precision-driven approach ensures your plastic components meet exacting specifications—without compromising on cost or lead time. Below is a comparative breakdown of industry standards versus our capabilities:

| Parameter | Standard Industry Practice | Wuxi Lead Precision Capability | Benefit |

|---|---|---|---|

| Tolerance Range | +/- 0.005″ (0.127mm) | +/- 0.002″ (0.05mm) standard; +/- 0.001″ (0.025mm) for critical features | Eliminates assembly issues; ensures perfect fit for complex assemblies |

| Mold Steel Options | Basic P20, standard heat treatment | Premium P20, NAK80, H13 with advanced heat treatment & surface finishing | 30% longer mold life; superior wear resistance for high-volume runs |

| Shot Life | 100,000–300,000 shots | Up to 1,000,000+ shots | Reduced downtime; lower cost-per-part for mass production |

| Cycle Time Optimization | Standard cooling channels | Precision-engineered conformal cooling channels | Up to 30% faster cycles; 15% energy savings; consistent part quality |

| DFM Support | Limited or paid service | Free comprehensive DFM analysis with expert feedback | Early design refinement; 20% faster time-to-market; avoid costly rework |

Our Commitment to Excellence

We measure success by your success. Every project is governed by three pillars of quality:

Zero Defects Guarantee

Rigorous in-process inspection and statistical process control (SPC) ensure every part meets specifications. Our defect rate consistently remains below 0.1%, validated by ISO 9001:2015 certification.

Olympic Quality Standards

Molds and parts undergo multi-stage quality validation: 3D laser scanning, CMM measurements, and material traceability. We exceed ISO 13485 (medical) and IATF 16949 (automotive) benchmarks for critical applications.

24/7 Customer Service

A dedicated engineering team is available around the clock for urgent technical support, design adjustments, and production updates. Your project never sleeps—neither do we.

Ready to Elevate Your Project?

Partner with Wuxi Lead Precision Machinery for end-to-end precision plastic molding solutions. We don’t just manufacture—we collaborate, innovate, and deliver excellence.

Free DFM Analysis & Quote

Contact us today for a no-obligation consultation:

📧 [email protected] | 📞 +86-13961886740

Your vision, our precision—engineered to exceed expectations.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.