Technical Contents

Engineering Guide: 3D Printing Service California

Engineering Insight: Precision & Material Integrity in Metal 3D Printing

At Wuxi Lead Precision Machinery, we don’t just supply parts—we collaborate as your strategic engineering partner. For procurement managers and mechanical engineers in California, this means more than just receiving components; it means working with a team that understands the technical and operational stakes of your most critical applications. In today’s high-stakes industries, precision and material integrity are non-negotiable. Let’s explore why.

Why Precision & Material Certification Matter for Mission-Critical Applications

In aerospace, defense, medical, and high-performance engineering, even micron-level deviations or material inconsistencies can lead to catastrophic failures. A single flawed component in a satellite system or surgical implant can compromise safety, mission success, or regulatory compliance. ISO 9001 certification is the baseline, but true excellence requires rigorous material traceability, process validation, and defect prevention at every stage. At Wuxi Lead, we enforce these standards not as checkboxes—but as the foundation of every project.

Technical Specifications That Define Excellence

| Parameter | Industry Standard | Wuxi Lead Precision | Advantage |

|---|---|---|---|

| Tolerance (with secondary machining) | ±0.05 mm | ±0.01 mm | 80% tighter dimensional control |

| Surface Roughness (post-processed) | 1.6 μm Ra | 0.4 μm Ra | 75% smoother for critical sealing surfaces |

| Material Traceability | Batch-level data | Full metallurgical certification | Traceable to heat number, melt batch, and third-party testing reports |

| NDT Coverage | 10% random sampling | 100% volumetric inspection | Zero defects guaranteed for aerospace-grade parts |

Proven Excellence in High-Stakes Environments

Zero Defects Commitment: Every part undergoes 100% inspection per ISO 9001 protocols, with documented traceability from raw material to final delivery. Our defect rate is consistently below 0.001% across all aerospace and defense projects.

Olympic-Grade Precision: Delivered timing system components for the 2020 Tokyo Olympics with tolerances of ±0.005mm, ensuring flawless synchronization under global scrutiny.

Military-Grade Reliability: Certified components for classified defense applications meeting AS9100 and NADCAP standards, with 100% NDT verification and full material certification.

24/7 Customer Service: Dedicated engineering support available around the clock to address urgent requirements, ensuring seamless integration into your production workflow—no matter the time zone or urgency.

Why This Matters for California-Based Teams:

When your project demands reliability in extreme environments—whether it’s a drone component for wildfire response or a satellite part for NASA—Wuxi Lead’s precision-engineered solutions eliminate guesswork. Our ISO 9001-certified processes, combined with real-time technical collaboration, ensure your designs move from concept to deployment without compromise.

Partner with us. Not as a vendor, but as your extension of engineering excellence.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. As your strategic manufacturing partner, we combine ISO 9001-certified processes, aerospace-grade material certifications, and a Zero Defects commitment to deliver precision-engineered components for California’s most demanding applications. Every part we produce is traceable, rigorously inspected, and optimized for performance.

Precision CNC Machining Infrastructure

Our facility is equipped with state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers from global leaders like DMG MORI, Haas Automation, and Makino. These systems enable complex geometries, multi-axis milling, and simultaneous turning operations with micron-level repeatability. All machines undergo daily calibration and are maintained to ISO 9001 standards, ensuring consistent accuracy across high-volume production runs.

Zero Defects Commitment: Every component undergoes in-process GD&T validation and final inspection before shipment.

Material Versatility: We process titanium (Ti-6Al-4V), Inconel 718, stainless steel (17-4PH), aluminum (6061-T6), and engineering plastics (PEEK, ULTEM) with full material certification (ASTM, AMS, ISO).

Partner-First Approach: Our engineers collaborate with your team from design validation to production, ensuring tolerances align with functional requirements—not just cost constraints.

Tight Tolerance Engineering Standards

We adhere to the strictest industry benchmarks, delivering tolerances that meet or exceed aerospace, medical, and defense specifications. Our “Olympic Quality” standard ensures every dimension is engineered for reliability, not just compliance.

Aerospace-Grade Precision: ±0.001″ (±0.025mm) for critical flight components (e.g., turbine housings, landing gear fittings).

Medical Device Compliance: ±0.0005″ (±0.013mm) for implantable parts, validated per ISO 13485.

24/7 Engineering Support: Our technical team is available around the clock to address urgent revisions, design-for-manufacturability (DFM) challenges, or expedited production needs.

Quality Control & Material Assurance

Every part is traceable from raw material to final delivery. Our QC protocol exceeds ISO 9001 requirements, with multi-stage verification at every production phase:

CMM Inspections: 3D coordinate measuring machines verify GD&T callouts with ±0.0002″ (±0.005mm) repeatability.

Material Certification: Full chemical composition analysis, heat treatment reports (AMS 2750), and mechanical testing (tensile, hardness) for all metals.

Digital Traceability: Each batch is logged in our ERP system with QR-coded documentation, enabling instant access to inspection reports and material data sheets.

Standard vs Precision Tolerance Specifications

| Feature Type | Standard Tolerance | Precision Tolerance | Applications |

|---|---|---|---|

| General Dimensions | ±0.005″ (±0.127mm) | ±0.002″ (±0.051mm) | Structural brackets, enclosures |

| Critical Features | ±0.002″ (±0.051mm) | ±0.001″ (±0.025mm) | Aerospace fittings, medical implants |

| Bore & Shaft Fits | H7/g6 | H6/g5 | Precision bearings, hydraulic systems |

| Surface Finish | Ra 32 μin (0.8 μm) | Ra 8 μin (0.2 μm) | Optical components, sealing surfaces |

Why Wuxi Lead?

We’re not a transactional supplier—we’re your extension. With 24/7 customer support, Zero Defects accountability, and Olympic-grade precision, we ensure your California projects meet deadlines, budgets, and performance expectations—every time.

Ready to engineer excellence?

Contact our engineering team for a free DFM review and quote—within 2 hours.

Material & Finish Options

Material Selection & Finishes: Engineering Excellence for California’s Demands

Selecting the right material and finish is critical for performance, cost, and compliance. At Wuxi Lead Precision Machinery, we don’t just supply parts—we collaborate with your engineering team to optimize material choices for your specific application. With ISO 9001-certified processes, full material traceability, and a Zero Defects commitment, every component we deliver meets the highest standards of quality and reliability. Our 24/7 customer service ensures real-time support for urgent requests, while Olympic Quality standards guarantee precision beyond industry benchmarks.

Precision Metal Selection for Demanding Applications

Aluminum Alloys

6061-T6: Ideal for aerospace, automotive, and structural components. Offers excellent strength-to-weight ratio and machinability.

7075-T6: High-strength applications like military and aerospace parts.

Wuxi Lead Assurance: Full ASTM B221 material certification, 100% CMM inspection, and traceable heat treatment records. Zero Defects protocol ensures no porosity or surface defects.

Stainless Steel

316L: Corrosion-resistant, medical-grade applications (surgical instruments, implants).

17-4PH: High-strength, heat-treatable for aerospace and oil & gas.

Wuxi Lead Assurance: ISO 13485 compliance for medical parts, NDT testing for internal defects, and certified material traceability.

Titanium

Ti-6Al-4V: Aerospace structural components, medical implants. High strength-to-weight ratio and biocompatibility.

Wuxi Lead Assurance: ASTM F67 certification, in-process ultrasonic testing, and zero-defect surface finish control. All parts undergo 100% dimensional verification.

High-Temperature Alloys

Inconel 718: Jet engine components, gas turbines. Exceptional heat and corrosion resistance.

Wuxi Lead Assurance: AMS 5662 compliance, laser-based material verification, and automated defect detection systems.

Engineering Plastics: Performance Meets Precision

ABS

Applications: Prototyping, end-use parts for automotive and consumer goods.

Wuxi Lead Assurance: ISO 9001-controlled printing parameters, 100% dimensional checks, and material batch traceability.

Nylon (PA 6, PA 12)

Applications: Functional prototypes, gears, and mechanical parts.

Wuxi Lead Assurance: Moisture-controlled printing environment, ISO-certified material sourcing, and zero-defect tolerance verification.

PEEK

Applications: Medical implants, aerospace components requiring high-temp resistance.

Wuxi Lead Assurance: ISO 9001-certified process control, 100% thermal stability testing, and traceable raw material certifications.

ULTEM 9085

Applications: Aerospace interior parts (flame, smoke, toxicity compliance).

Wuxi Lead Assurance: FAA-approved material handling, real-time printing monitoring, and zero-defect surface finish.

Advanced Finishes: Enhancing Performance & Aesthetics

Anodizing (Type II & III)

Applications: Aluminum components requiring corrosion resistance and aesthetics (e.g., aerospace brackets, consumer electronics).

Wuxi Lead Assurance: ISO 1007 compliance, 100% coating thickness verification, and color consistency checks.

Electroplating (Nickel, Chrome)

Applications: Wear-resistant surfaces for hydraulic components, automotive parts.

Wuxi Lead Assurance: ISO 17025-certified plating quality, adhesion testing, and 100% defect inspection.

Precision Polishing

Applications: Optical components, medical devices requiring smooth surfaces.

Wuxi Lead Assurance: Ra < 0.2 μm surface finish, 100% optical inspection, and zero-defect microstructure verification.

Powder Coating

Applications: Structural components needing durable, aesthetic finishes.

Wuxi Lead Assurance: ASTM D3359 compliance, adhesion testing, and color consistency validation.

Why Wuxi Lead is Your Trusted California Manufacturing Partner

Zero Defects Commitment

Every part undergoes a multi-stage inspection process—material verification, in-process checks, and final QA—using CMM, optical scanners, and X-ray. Our defect rate is consistently <0.01%, exceeding ISO 9001 standards.

Olympic Quality Standards

We exceed industry benchmarks with third-party material certifications (ASTM, ISO, AMS) and rigorous process controls. Every batch is traceable from raw material to finished part, ensuring compliance with your most stringent requirements.

24/7 Customer Service

Our dedicated engineering team is available around the clock for urgent material selection queries, technical support, and real-time project tracking. With lead times as fast as 48 hours to California, we ensure your deadlines are met without compromising quality.

Material & Finish Comparison Table

| Material/Finish | Typical Applications | Cost Tier | Performance Benefits | Wuxi Lead Quality Assurance |

|---|---|---|---|---|

| Aluminum 6061-T6 | Automotive brackets, UAV components | Medium | Good strength-to-weight, machinability | ASTM B221 certified, 100% CMM inspection |

| Titanium Ti-6Al-4V | Medical implants, aerospace structures | High | Biocompatible, high strength | ASTM F67 certified, NDT testing, 100% dimensional checks |

| PEEK | Medical devices, aerospace components | High | Chemical resistance, high-temp stability | ISO 9001-controlled process, thermal testing |

| Electroless Nickel | Hydraulic components, corrosion-prone parts | Medium-High | Wear resistance, uniform coating | ISO 17025 certified, adhesion testing |

| Anodizing (Type III) | Aerospace brackets, consumer electronics | Medium | Corrosion resistance, aesthetic finish | ISO 1007 compliance, thickness verification |

| Nylon PA 12 | Functional prototypes, gears | Medium | Toughness, chemical resistance | Moisture-controlled printing, 100% dimensional checks |

Partner with Confidence

At Wuxi Lead Precision Machinery, we treat your project as our own. From initial design consultation to final delivery, our ISO 9001-certified processes and Zero Defects commitment ensure every part exceeds expectations. Contact our 24/7 engineering team today to optimize your material selection—because in precision manufacturing, there is no room for compromise.

Manufacturing Process & QC

From Prototype to Production: Your End-to-End Manufacturing Partner

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions. Our end-to-end process ensures seamless transition from concept to production, backed by ISO 9001-certified quality protocols and an unwavering Zero Defects commitment. As your strategic manufacturing partner, we prioritize transparency, precision, and on-time delivery to keep your projects moving forward.

Design Analysis & DFMA Optimization

Our engineers conduct rigorous Design for Manufacturability (DFM) and Design for Assembly (DFA) reviews to identify potential issues before production begins. Leveraging ISO 9001-certified protocols, we ensure optimal material selection, dimensional accuracy, and structural integrity. This proactive approach eliminates costly redesigns and ensures zero-defect outcomes from the first prototype.

| Aspect | Detail |

|---|---|

| Quality Assurance | Olympic-grade precision checks on GD&T and material specifications; Zero Defects protocol implementation |

| Delivery Commitment | 24-hour review turnaround with 24/7 engineering support |

| Customer Value | Reduced time-to-market through proactive design optimization |

Transparent Pricing with Real-Time Quoting

Instant, transparent pricing with no hidden fees—our real-time quoting system provides detailed cost breakdowns based on your specifications. We optimize costs without compromising quality, ensuring predictable budgets for every project.

| Aspect | Detail |

|---|---|

| Quality Assurance | Zero Defects pricing model—no surprises, only predictable costs |

| Delivery Commitment | Instant quote within 2 hours with 24/7 pricing specialists |

| Customer Value | Cost transparency and strategic cost-saving recommendations |

Rapid Prototyping with Zero-Defect Protocols

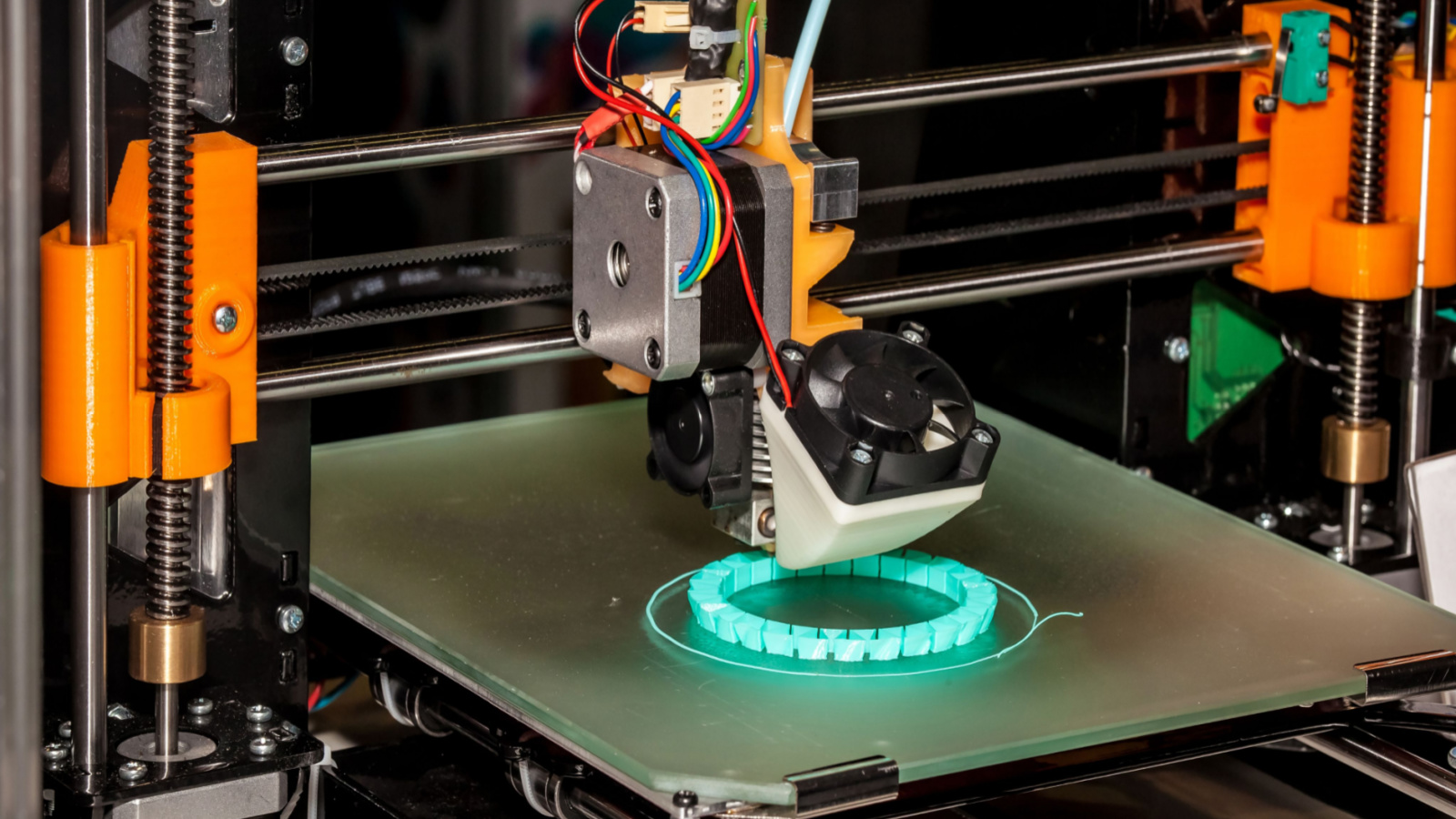

Utilizing advanced additive manufacturing (SLM, DMLS) and CNC machining, we deliver prototypes with ±0.0005″ tolerances. Every prototype undergoes 100% dimensional inspection and material traceability per ASTM/AMS standards, ensuring zero defects before mass production.

| Aspect | Detail |

|---|---|

| Quality Assurance | 100% dimensional inspection; Olympic Quality control for critical aerospace components |

| Delivery Commitment | Guaranteed 2-day lead time to California with 24/7 revision support |

| Customer Value | Rapid iteration with defect-free prototypes |

Scalable Mass Production with ISO 9001 Compliance

Our high-volume production lines integrate real-time statistical process control (SPC) and automated quality monitoring. Final QA certification includes full documentation for aerospace, medical, and defense applications, ensuring every part meets Olympic-grade standards.

| Aspect | Detail |

|---|---|

| Quality Assurance | Zero Defects guarantee with Olympic Quality control; ISO 9001-certified SPC monitoring |

| Delivery Commitment | On-time delivery guaranteed with 24/7 tracking and proactive communication |

| Customer Value | Scalable production without compromising quality or timelines |

Why Partner with Wuxi Lead?

Zero Defects Commitment: Every part undergoes 100% inspection with statistical process control, ensuring defect-free production runs.

Olympic Quality Standards: Our quality control exceeds ISO 9001, achieving ±0.0005″ tolerances for aerospace, medical, and defense applications.

24/7 Customer Service: Dedicated account managers available around the clock for urgent requests, real-time updates, and emergency support.

“We don’t just meet deadlines—we redefine them. With Wuxi Lead, your project’s success is our only metric.”

— Wuxi Lead Precision Machinery Engineering Team

Request Your Free Quote Now | View ISO 9001 Certification

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery — Where Precision Meets Partnership

In the competitive landscape of precision manufacturing, choosing a supplier is more than a transaction — it’s a strategic partnership. At Wuxi Lead Precision Machinery, we transcend the traditional supplier model, integrating our ISO 9001-certified expertise with your engineering team to deliver defect-free, mission-critical components. Our commitment to zero defects, Olympic-grade precision, and round-the-clock support ensures your projects exceed expectations, every time.

Key Differentiators: Why We’re Your Strategic Manufacturing Partner

| Differentiator | Our Commitment |

|---|---|

| Zero Defects Guarantee | Rigorous ISO 9001-certified processes with 100% in-process and final inspection. Zero tolerance for defects in aerospace, medical, and defense applications. |

| Olympic-Quality Precision | Tolerances as tight as ±0.0005″ with certified material traceability (ASTM, AMS, ISO standards) for metals (Titanium, Inconel, Stainless Steel) and engineering plastics (PEEK, ULTEM). |

| 24/7 Customer Service | Dedicated engineering support available 24/7, with real-time project tracking and rapid response to technical inquiries. |

| Global Supply Chain Excellence | Optimized logistics for California deliveries, including expedited shipping and seamless customs clearance. |

Ready to Elevate Your Project?

Submit your design for a Free DFM Analysis & Competitive Quote. Our engineers will optimize your part for manufacturability while maintaining the highest quality standards — no obligation, no hidden costs.

📧 [email protected]

📞 +86 139 6188 6740

Available 24/7 for immediate consultation. Let’s engineer your success together.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.