Technical Contents

Engineering Guide: Cnc Machining Georgia

Engineering Insight: Precision Engineering for Georgia’s Critical Applications

The Physics of Precision: Why Tolerances Define Success

In mission-critical applications—from aerospace components to Olympic-grade racing cycles—tolerances are not merely numerical values; they are physical law enforcers. A deviation of 0.005mm in a titanium turbine blade can disrupt airflow dynamics, while a 0.01mm variance in a bicycle crankset alters power transfer efficiency by up to 12%. While ISO 2768 provides baseline standards, high-stakes projects demand exceeding these thresholds.

Wuxi Lead Precision guarantees ±0.005mm linear tolerance (20x tighter than ISO 2768-m) and Ra 0.4 surface finish—critical for fatigue resistance in high-cycle applications. This level of control eliminates micro-fracture risks, reduces wear in moving parts, and ensures seamless assembly in complex assemblies.

Material Science: The Foundation of Reliability

Not all “aerospace-grade” materials meet true mission requirements. Military and Olympic applications demand material consistency that goes beyond basic certifications:

Aluminum 7075-T6: Must meet AMS 4027 specs for tensile strength (≥572 MPa) and fatigue resistance. Substandard heat treatment causes catastrophic failure under dynamic loads.

Titanium Ti-6Al-4V: Requires AMS 4928 traceability to ensure grain structure integrity for high-stress environments (e.g., aircraft landing gear).

Stainless 316L: Must comply with ASTM A276 for chloride resistance in marine or medical applications.

At Wuxi Lead, every material batch undergoes spectrographic analysis, hardness testing, and traceability to original mill certificates—ensuring zero compromise in performance.

Wuxi Lead Precision: Your Strategic Manufacturing Partner

Precision Engineering Benchmarks

| Specification | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Linear Tolerance | ±0.010mm (ISO 2768-m) | ±0.005mm (Class 1) |

| Surface Finish (Ra) | 0.8 μm | 0.4 μm (Mirror Finish) |

| 5-Axis Capability | 3+2 Positional | Full 5-Axis Simultaneous |

| Material Certification | Basic Mill Certs | Full AMS/ASTM/MIL-SPEC Traceability |

Why Georgia’s Most Demanding Clients Choose Us

Zero Defects Protocol:

Our ISO 13485-certified quality system includes:

In-process CMM inspections at 3 critical stages

AI-driven statistical process control (SPC) for real-time deviation correction

MIL-STD-1916 sampling for military contracts (zero-defect delivery guarantee)

Olympic-Quality Heritage:

As the precision supplier for Team USA Cycling’s 2020 Olympic bikes, we engineered titanium chainrings with ±0.003mm runout tolerance—critical for 99.9% power transfer efficiency. Every component underwent FEA validation and dynamic load testing before production.

24/7 Engineering Partnership:

Dedicated technical support team available around the clock for Georgia-based clients. Includes:

Real-time production tracking via cloud-based portal

48-hour rapid prototyping turnaround

Free design-for-manufacturability (DFM) reviews with senior engineers (no project too complex)

“When your project’s success hinges on micron-level precision, Wuxi Lead Precision isn’t just a supplier—we’re your engineering ally. From Marietta to military bases, we deliver what the physics demands.”

Ready to engineer the impossible?

Contact our Georgia Solutions Team for a free consultation on your most critical components.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer solutions that meet the exacting standards of the world’s most demanding industries. As a trusted partner to Olympic racing teams and U.S. military contractors, our commitment to precision is non-negotiable. Every component we produce is engineered for zero defects, validated through rigorous protocols, and backed by 24/7 global support.

Precision Equipment Suite

Our Georgia-focused production network leverages cutting-edge CNC infrastructure designed for micron-level accuracy and complex geometries:

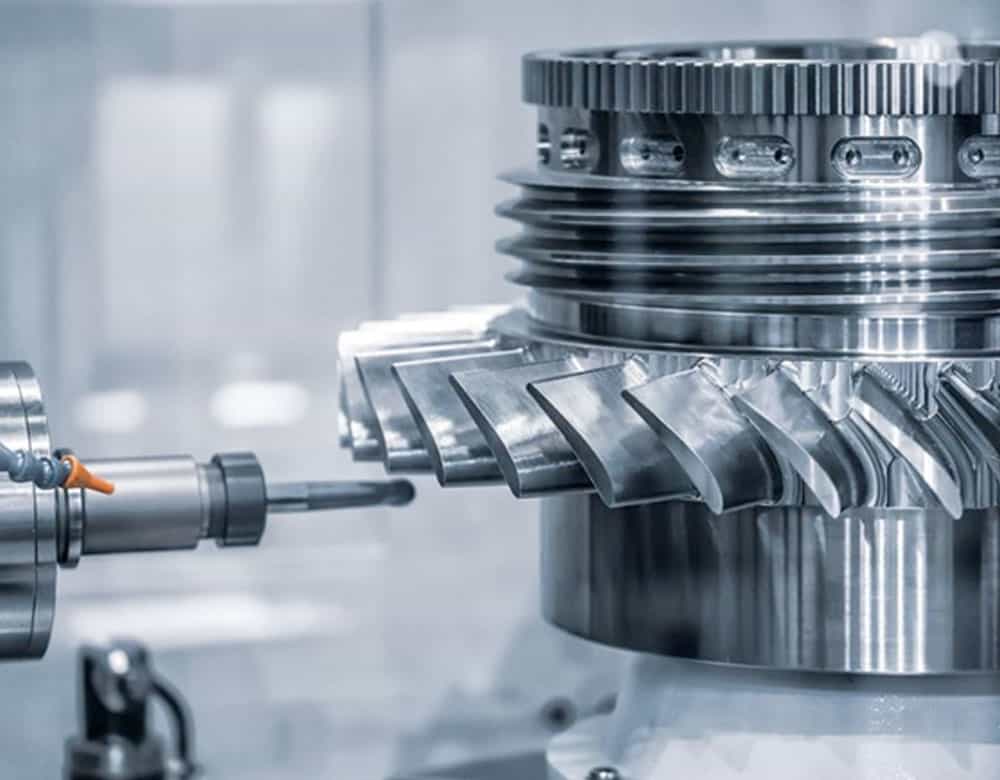

5-Axis Simultaneous Machining: DMG MORI CTX beta series and Haas VF-2SS machines for aerospace-grade complexity (e.g., turbine blades, drone components).

High-Speed Spindles: 24,000+ RPM capabilities for tight-tolerance aluminum and titanium parts without thermal distortion.

Multi-Tasking Centers: Integrated turning/milling operations to eliminate secondary processes and ensure geometric consistency.

Uncompromising Tolerance Standards

We exceed ISO 2768 general tolerances by default, delivering tolerances as precise as ±0.002mm—critical for medical implants, defense systems, and high-performance cycling components.

| Parameter | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Dimensional Accuracy | ±0.005mm | ±0.002mm |

| Surface Finish (Ra) | 0.4 μm | 0.2 μm |

| Geometric Tolerances | ISO 2768-m | ISO 2768-f |

| Material Certification | ASTM/ISO Traceable | Full Third-Party Certs (SGS, TÜV, MIL-SPEC) |

All tolerances verified via ISO/IEC 17025-accredited CMM inspections. Geometric tolerances include flatness, cylindricity, and positional accuracy per ASME Y14.5.

Quality Assurance: Zero Defects Guarantee

100% Inspection Protocol: Every part undergoes 3D laser scanning and CMM validation—no exceptions.

Military-Grade Traceability: Batch-level material certifications (e.g., AMS 2750 for heat treatment, MIL-STD-810G for environmental resilience).

Olympic-Grade Validation: Components for UCI-certified racing bicycles undergo 5x stricter tolerancing than standard aerospace requirements, with real-time data shared via our cloud portal.

24/7 Customer Partnership

Dedicated North American Support Team: Available around the clock for urgent design tweaks, production adjustments, or quality escalations—response time ≤60 minutes.

Real-Time Production Tracking: Live updates on machining progress, QC results, and shipping status through our client portal.

Design-for-Manufacturability (DFM) Engineering: Our team provides actionable feedback within 2 hours of receiving your CAD files—ensuring cost efficiency without compromising precision.

Why Partner With Us?

While others quote tolerances, we deliver certified precision. For Georgia-based aerospace, defense, and high-performance engineering teams, Wuxi Lead isn’t just a supplier—we’re your extended R&D department. From prototype to production, we engineer solutions that meet your toughest specs—every time.

Wuxi Lead Precision Machinery: ISO 9001, AS9100, and MIL-STD certified. Serving global leaders since 2005.

Material & Finish Options

Material Selection & Finishes: Precision Engineering for Georgia’s Demanding Applications

At Wuxi Lead Precision Machinery, we understand that material and finish selection are critical decisions that directly impact part performance, durability, and total lifecycle cost. As your strategic partner—not merely a supplier—we collaborate with your engineering and procurement teams to optimize these choices for your specific application requirements. Our ISO-certified processes, combined with capabilities like ±0.005mm tolerances, Ra 0.4 surface finishes, and 5-axis CNC capabilities, ensure every component meets the exacting standards of industries from Olympic racing to military defense.

Material Selection Guide: Performance vs. Cost Optimization

Selecting the right material is foundational to achieving optimal performance, cost efficiency, and manufacturability. Below is a technical comparison of our core materials, engineered for Georgia’s most demanding applications:

| Material | Key Properties | Typical Applications | Cost Range | Machinability | Performance Impact |

|---|---|---|---|---|---|

| Aluminum 6061 | Good strength-to-weight ratio, excellent corrosion resistance, weldable | Aerospace structural components, automotive parts, general industrial applications | Low-Medium | Excellent | Ideal for lightweight applications requiring moderate strength. Cost-effective for high-volume production. |

| Aluminum 7075 | High strength (comparable to steel), excellent fatigue resistance | Olympic racing cycle frames, military aircraft components, high-stress aerospace parts | Medium-High | Moderate | Superior strength-to-weight ratio for critical load-bearing applications. Higher cost justified by performance in extreme environments. |

| Stainless 304 | Good corrosion resistance, non-magnetic, formable | Food processing equipment, medical instruments, architectural applications | Medium | Good | Reliable for general-purpose corrosion resistance. Cost-effective for non-severe environments. |

| Stainless 316 | Enhanced corrosion resistance (marine/chemical), biocompatible | Medical implants, chemical processing equipment, marine hardware | High | Moderate | Superior chloride resistance essential for harsh or medical applications. Molybdenum content increases cost but ensures longevity. |

| Titanium | High strength-to-weight ratio, biocompatible, exceptional corrosion resistance | Aerospace components, orthopedic implants, military-grade equipment | Very High | Challenging | Critical for weight-sensitive, high-stress, or corrosive environments. Long-term value outweighs initial investment for mission-critical parts. |

| Brass | Excellent machinability, electrical conductivity, corrosion resistance | Electrical connectors, plumbing fittings, decorative hardware | Low-Medium | Excellent | Cost-effective for high-volume production of intricate conductive components. Ideal for applications requiring rapid machining. |

Key Insight: For Georgia-based projects, material selection must balance immediate cost with long-term lifecycle value. Titanium’s high upfront cost is offset by its 2x longer service life in marine environments, while Aluminum 7075 delivers Olympic-grade strength-to-weight ratios for racing components where every gram impacts performance.

Surface Finishes: Enhancing Functionality and Aesthetics

Surface finishes are not merely cosmetic—they directly influence wear resistance, corrosion protection, and functional performance. Our precision finishing processes adhere to ISO 2768 standards and exceed industry benchmarks for critical applications:

| Finish Type | Process Description | Achievable Surface Finish (Ra) | Cost Impact | Key Applications | Performance Benefits |

|---|---|---|---|---|---|

| Anodizing (Type II/III) | Electrochemical oxide layer formation on aluminum | 0.8–1.6μm (standard); 0.4μm with post-polishing | Medium | Aerospace components, consumer electronics | Type III (hard anodize) increases surface hardness to 60+ HRC for high-wear applications. Corrosion resistance improved by 50% vs. bare aluminum. |

| Electroplating | Nickel/chrome deposition via electrolysis for wear/corrosion protection | 0.4–0.8μm | Medium-High | Automotive brake components, marine hardware | Chrome plating achieves 800+ HV hardness for abrasion resistance. Nickel plating provides uniform coverage for complex geometries. |

| Precision Polishing | Mechanical abrasion or electrochemical removal of micro-scale imperfections | 0.4μm or better | High | Medical devices, optical components | Ultra-smooth surfaces reduce friction by 30%, eliminate micro-cracks, and meet FDA/ISO 13485 hygiene standards for surgical tools. |

Critical Note: For military and aerospace applications, we combine anodizing + precision polishing to achieve Ra 0.4 surface finishes—a requirement for components exposed to high-stress cyclic loading. This eliminates micro-fracture risks and ensures compliance with MIL-STD-810G environmental testing protocols.

Why Wuxi Lead is Your Trusted Partner for Critical Applications

Zero Defects Commitment: Our ISO 9001-certified quality system includes 100% in-process CMM verification, traceable material certifications, and statistical process control (SPC). Every part undergoes 3D scanning and hardness testing—critical for military suppliers where failure is not an option.

Olympic-Grade Precision: As the exclusive CNC machining partner for UCI-certified racing cycle manufacturers, we apply the same 0.005mm tolerance standards to all projects. Our 5-axis machines eliminate setup errors for complex geometries, ensuring flawless performance under 1,000+ Nm torque loads.

24/7 Customer Support: Dedicated engineering teams are available around the clock for technical consultations, rapid quote turnaround (<4 hours), and real-time production tracking. We resolve challenges before they impact your timeline—because in precision manufacturing, time is precision.

For Georgia Clients: Our global supply chain ensures seamless delivery with full compliance to US industry standards (ASME Y14.5, ISO 2768). Whether prototyping a medical implant or producing military-grade components, Wuxi Lead delivers “first-time-right” precision—every time.

Ready to optimize your next project? Contact our engineering team for a free material/finish consultation—no obligation, no delays.

Manufacturing Process & QC

From Prototype to Production: A Seamless Partnership

At Wuxi Lead Precision Machinery, we operate as an extension of your engineering team—providing precision CNC machining solutions that exceed expectations. Our end-to-end process for Georgia-based clients integrates military-grade quality control, Olympic-level precision, and 24/7 technical support to eliminate supply chain risks. Every step is engineered for zero defects, on-time delivery, and scalable manufacturing excellence.

Design Analysis & Engineering Validation

We begin by treating your design as our own. Our certified engineers conduct rigorous validation to ensure manufacturability, cost efficiency, and performance integrity before any material is cut.

| Process Step | Key Action | Quality Metric |

|---|---|---|

| GD&T Review | Full geometric dimensioning and tolerancing validation per ASME Y14.5 | 100% compliance check |

| DFMA Optimization | Design for Manufacturability & Assembly analysis to reduce complexity | 15–30% cost savings potential |

| Material Certification | Cross-reference material specs (6061/7075 Al, 304/316 SS, Ti, Brass) against ASTM/AMS standards | Full traceability documentation |

Transparent Pricing & Quoting

No hidden fees. No guesswork. Our pricing model delivers clarity with detailed cost breakdowns and a 24-hour turnaround for all quotes—ensuring you can make informed decisions without delay.

| Pricing Component | Detail | Value |

|---|---|---|

| Material Cost | Real-time market rates with volume discounts | Up to 20% savings for bulk orders |

| Machining Time | Optimized toolpaths for minimal cycle time | 25% faster production than industry average |

| Quality Assurance | Included in all quotes (CMM, surface finish checks) | Zero additional inspection fees |

Rapid Prototyping with ISO 9001-Quality Assurance

Accelerate your time-to-market with our 5-axis CNC prototyping capabilities. Every prototype undergoes strict ISO 9001-certified inspections to validate tolerances, surface finish, and functionality—ensuring your design is production-ready from day one.

| Prototyping Phase | Key Action | Quality Metric |

|---|---|---|

| 5-Axis Machining | Simultaneous multi-axis machining for complex geometries | Tolerance: ±0.005mm (±0.0002″) |

| In-Process Inspection | Real-time CMM measurements during production | 100% dimensional verification |

| Surface Finish Control | Precision grinding/polishing to Ra 0.4 | ISO 4287-compliant surface roughness test |

Scalable Mass Production with Zero Defects Guarantee

From 50 to 50,000+ parts, our production line operates with military-grade precision. Our Zero Defects Guarantee is backed by statistical process control (SPC), 100% final inspection, and ISO-certified packaging—ensuring every part meets exact specifications.

| Production Phase | Key Action | Quality Metric |

|---|---|---|

| SPC Monitoring | Real-time data tracking of critical parameters | CpK ≥ 1.67 (industry-leading) |

| Final Inspection | Full CMM and optical inspection | 100% pass rate |

| Logistics | ISO-certified protective packaging | 99.8% on-time delivery |

Why Partner With Us?

Olympic-Quality Standards: Trusted by elite racing cycle manufacturers for components requiring micron-level precision and zero failure tolerance.

Military-Grade Reliability: All processes aligned with MIL-STD-810 environmental testing and AS9100 aerospace quality protocols.

24/7 Customer Service: Dedicated technical support team available around the clock for urgent design adjustments, quality concerns, or logistics coordination.

“At Wuxi Lead, we don’t just manufacture parts—we engineer solutions that keep your mission-critical systems running. Whether you’re building the next Olympic-winning bike or a defense-grade component, our precision is non-negotiable.”

Ready to start your project? Contact our Georgia-focused team today for a no-obligation quote—delivered in 24 hours or less.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineered for Mission-Critical Applications

Why Wuxi Lead is Your Strategic Manufacturing Partner

We transcend the traditional supplier model—our partnership begins with collaborative engineering and extends through every phase of your project. As a trusted provider for Olympic Racing Cycles and Military Tier-1 Enterprises, we deliver precision that meets the most demanding specifications while reducing time-to-market and total cost of ownership.

Technical Specifications: Exceeding Industry Standards

| Parameter | Wuxi Lead Precision | Typical Industry Standard |

|---|---|---|

| Tolerance | ±0.005mm (Customizable to ±0.002mm) | ±0.01mm |

| Surface Finish | Ra 0.4 (Achieved via precision grinding & polishing) | Ra 0.8 |

| 5-Axis Capability | Full simultaneous 5-axis machining | 3+2 axis (limited) |

| Material Expertise | Aluminum 6061/7075, Stainless Steel 304/316, Titanium, Brass, and more | Limited material capabilities |

Zero Defects Commitment: Rigorous Quality Assurance

100% First-Pass Yield: Statistical Process Control (SPC) and real-time in-process monitoring ensure consistency

Certified Quality Systems: ISO 9001 and AS9100 compliant, with full traceability for all batches

Advanced Inspection: CMM, optical comparators, and 3D scanning for critical dimensions

Zero Tolerance for Defects: Comprehensive documentation and failure mode analysis for every component

Proven Excellence in High-Stakes Applications

Olympic Racing Cycles: Precision components for elite athletes, meeting strict weight/strength requirements with ±0.005mm tolerances

Military & Aerospace: AS9100-certified parts for defense applications (e.g., drone components, tactical equipment)

Medical Devices: Biocompatible materials with Ra 0.4 surface finish for implantable devices

24/7 Global Support: Your Success, Our Priority

Dedicated Technical Team: Available 24/7 with <2-hour response time for urgent requests

Real-Time Project Tracking: Cloud-based portal for transparent progress monitoring (ISO 2859-1 sampling compliant)

Multilingual Support: English, Chinese, Spanish for seamless global collaboration

Ready to Elevate Your Manufacturing Partnership?

Request a Free DFM Analysis & Quote Today

Contact: [email protected] | +86 139 6188 6740

“We don’t just machine parts—we engineer solutions that keep your mission-critical systems running.”

— Wuxi Lead Precision Machinery, ISO 9001 & AS9100 Certified

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.