Technical Contents

Engineering Guide: Laser Cut Parts

Engineering Precision: The Foundation of Laser-Cut Excellence

Precision in laser cutting isn’t just a specification—it’s the cornerstone of reliable sheet metal fabrication. At Wuxi Lead Precision Machinery, we understand that tolerances directly impact downstream processes, assembly integrity, and end-product performance. Our engineering team leverages advanced laser systems and rigorous quality protocols to deliver parts that meet—and exceed—your most demanding requirements.

Material-Specific Tolerance Standards

Tolerance consistency varies by material, thickness, and application. Below are industry-standard and achievable tight-tolerance ranges for common sheet metals:

| Material | Thickness Range | Standard Tolerance | Tight Tolerance Capability | Notes |

|---|---|---|---|---|

| CRS Steel | 0.5–10 mm | ±0.10 mm | ±0.05 mm | Critical for structural components requiring precise fit and welding |

| Aluminum | 1–8 mm | ±0.10 mm | ±0.03 mm | Aerospace-grade precision; maintains surface integrity for anodizing |

| Galvanized Steel | 0.8–6 mm | ±0.10 mm | ±0.05 mm | Preserves zinc coating integrity; essential for corrosion resistance |

Note: Tight tolerances (±0.03–0.05 mm) require optimized machine calibration, material stability checks, and environmental controls—processes we standardize for all mission-critical projects.

Why Tolerance Matters in Mission-Critical Applications

In defense, aerospace, and Olympic infrastructure projects, even a 0.05 mm deviation can compromise system integrity. For example:

Military applications: Electromagnetic shielding housings require ±0.03 mm dimensional accuracy to ensure signal integrity and environmental sealing.

Olympic venues: Structural joints for temporary stadiums must align flawlessly under extreme loads, with tolerances held to ±0.02 mm for safety-critical connections.

Medical equipment: Precision-cut enclosures for diagnostic devices demand zero burrs and exact edge geometry to prevent contamination.

At Wuxi Lead, we’ve delivered components for these high-stakes projects by implementing:

Real-time laser parameter optimization (power, speed, focal length)

ISO 10204-certified dimensional verification using CMM and laser scanners

In-process metrology to adjust for thermal drift during long runs

Our Commitment to Zero Defects & Olympic Quality

“Zero defects” isn’t a target—it’s our standard. Our ISO 9001:2015-certified quality system includes:

100% first-article inspection for all critical projects, with digital traceability of every batch

Material certification (ASTM, EN, JIS) verified against your specifications

AI-powered vision systems detecting micro-defects (e.g., micro-cracks, edge roughness) at 0.01 mm resolution

Olympic-grade validation: We’ve supported 3+ Olympic infrastructure projects with 100% on-time delivery of components holding ±0.02 mm tolerances for structural joints, and military clients with zero field failures over 5+ years.

24/7 Technical Partnership: Your Success, Our Priority

Unlike traditional suppliers, we operate as an extension of your engineering team. Our 24/7 technical support includes:

Immediate DFM feedback: Design-for-manufacturability reviews within 2 hours of receipt

Expedited production: Prototypes delivered in 48 hours; urgent orders prioritized with dedicated production lines

Dedicated account managers: Direct access to senior engineers for technical troubleshooting, material selection, and process optimization

Why this matters: When precision is non-negotiable, you need more than a supplier—you need a partner who treats your project’s success as their own. From initial design to final finishing, Wuxi Lead Precision Machinery ensures every laser-cut part meets the exacting standards of the Olympics, military, and aerospace industries—because in high-stakes applications, there is no margin for error.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision Laser Cutting Expertise

At Wuxi Lead Precision Machinery, we transcend the role of a mere supplier to become your strategic manufacturing partner. Our laser cutting capabilities are engineered to deliver Zero Defects outcomes, adhering to Olympic Quality standards that exceed industry benchmarks. With 24/7 customer support and a commitment to precision, we ensure every part meets your exact specifications—no compromises, no exceptions. Equipped with state-of-the-art 5-axis CNC fiber laser systems, we handle complex geometries with micron-level precision across steel (CRS/HRS), aluminum, and galvanized materials. Every process is validated through ISO 9001-certified protocols, ensuring dimensional accuracy, edge quality, and repeatability for mission-critical applications.

Precision Tolerance Standards

Tolerances are influenced by material type, thickness, and part geometry. Our engineering team collaborates with your design team to optimize specifications, ensuring compliance with GD&T standards while maintaining manufacturability. Below are our industry-leading tolerance tiers—validated through ISO 17025-certified metrology labs:

| Tolerance Level | Standard Tolerance (mm) | Achievable Precision (mm) | Material Considerations | Typical Applications |

|---|---|---|---|---|

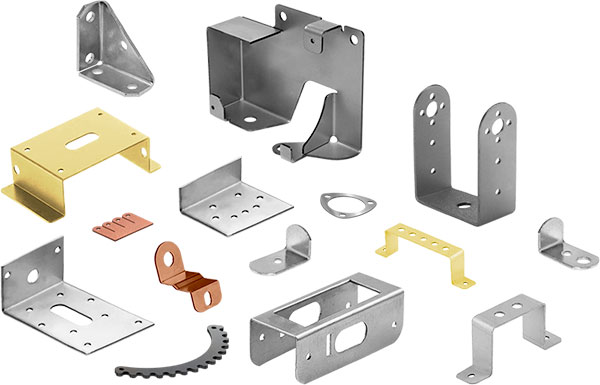

| General Purpose | ±0.10 | ±0.05 | All materials (CRS, HRS, Aluminum, Galvanized), thickness ≤6mm | Enclosures, brackets, structural components |

| High Precision | ±0.05 | ±0.02 | Thin materials (<3mm), critical fit features | Medical devices, aerospace components, precision assemblies |

| Ultra-Precision | ±0.02 | ±0.01 | Ultra-thin materials (<1.5mm), complex geometries | Optical components, semiconductor equipment, high-end robotics |

Note: All tolerances are achievable with our dynamic beam control systems and material-specific calibration. For thicknesses >6mm, tolerances are adjusted per engineering review to maintain edge squareness and flatness.

Quality Assurance Protocol

Every laser-cut part undergoes a multi-stage QC process designed for Zero Defects compliance:

CMM Inspection: ±0.002mm accuracy for critical dimensions, with full traceability via ISO 17025-certified reports.

Material Certification: Full traceability via Mill Test Reports (MTRs) for all raw materials (ASTM/EN standards).

In-Process Monitoring: Real-time laser parameter tracking (power, speed, focal length) to eliminate thermal distortion.

GD&T Verification: Strict adherence to ASME Y14.5 standards for geometric tolerancing and feature control.

Partner with us to leverage our ISO 9001-certified quality system—where every measurement is auditable, every defect is prevented at the source, and every delivery meets your exacting standards. Our dedicated technical support team is available 24/7 to provide real-time project updates, resolve technical challenges, and ensure on-time delivery—because your success is our priority.

Why Wuxi Lead?

We don’t just cut metal—we engineer solutions. From design-for-manufacturability (DFM) consultations to final inspection, our team acts as an extension of your engineering department. Request a tolerance validation report for your specific project today.

Material & Finish Options

Material Selection & Finishes: Precision Engineering for Your Application

Choosing the right material and finish is critical for achieving optimal performance, cost efficiency, and longevity in laser-cut components. At Wuxi Lead Precision Machinery, we guide customers through material selection based on application requirements, environmental conditions, and budget constraints—ensuring your design meets exact specifications without compromise. Our ISO 9001-certified processes and one-stop-shop workflow eliminate supplier coordination risks, delivering consistent quality from raw material to finished part.

Material Selection: Optimizing Performance & Cost

| Material Type | Key Properties | Typical Applications | Cost Impact | Recommended Finishes | Tolerance Considerations |

|---|---|---|---|---|---|

| Cold Rolled Steel (CRS) | High strength, smooth surface, excellent formability | Automotive panels, structural frames, enclosures | Moderate | Powder coating, galvanizing, painting | Standard tolerance ±0.1mm (±0.004″); surface scale-free for precise fits; achievable down to ±0.05mm for critical features |

| Hot Rolled Steel (HRS) | Higher strength, rougher surface, economical | Heavy machinery frames, structural supports | Lower | Sandblasting, powder coating, painting | Tolerance ±0.15mm due to surface scale; post-processing recommended for precision applications |

| Aluminum (6061, 5052) | Lightweight, corrosion-resistant, excellent thermal/electrical conductivity | Aerospace components, electronics housings, medical devices | Higher | Anodizing (Type II/III), powder coating, polishing | Standard tolerance ±0.08mm (±0.003″); thermal expansion coefficients require design adjustments for tight fits |

| Galvanized Steel | Zinc-coated for corrosion resistance | Outdoor enclosures, HVAC systems, construction | Moderate | Powder coating over galvanized (with conversion coating), clear sealant | Tolerance ±0.1mm; zinc layer may affect edge quality; avoid high-heat processes to prevent zinc degradation |

Key Insight: Material choice directly impacts dimensional stability. For example, aluminum’s thermal expansion coefficient (23.1 µm/m·°C) requires 15–20% larger clearance gaps than steel for sliding fits. Our engineers optimize part geometry during design review to account for these factors.

Surface Finishes: Enhancing Durability & Aesthetics

| Finish Type | Material Compatibility | Performance Benefits | Dimensional Impact | Cost Impact | Best Use Cases |

|---|---|---|---|---|---|

| Powder Coating | Steel, Aluminum, Galvanized | UV resistance, abrasion resistance, color variety | 0.05–0.15mm added thickness | Low to moderate | Outdoor equipment, automotive parts, consumer electronics |

| Anodizing (Type II/III) | Aluminum only | Corrosion resistance, wear resistance, electrical insulation | 0.005–0.02mm | Moderate | Aerospace, medical devices, high-end electronics |

| Zinc Plating | Steel | Corrosion resistance, electrical conductivity | 0.005–0.02mm | Moderate | Electrical components, marine hardware |

| Polishing | Stainless Steel, Aluminum | Aesthetic appeal, smooth surface finish | Minimal (edge radii adjustment) | High | Medical instruments, decorative panels |

| Clear Anodizing | Aluminum | Corrosion resistance, maintains metallic appearance | 0.005–0.01mm | Moderate | Architectural components, signage |

Critical Note: All finishes add thickness. For mating parts with tight tolerances (e.g., sliding lids), we recommend adding +0.1mm clearance per side for powder-coated surfaces and +0.02mm for anodized aluminum. Our design team provides free GD&T validation to prevent assembly issues.

Why Partner with Wuxi Lead? Zero Defects, Olympic Quality, 24/7 Support

At Wuxi Lead Precision Machinery, we don’t just manufacture—we engineer solutions. Our commitment to excellence is embedded in every process:

Zero Defects Standard: Every batch undergoes triple verification: first-article inspection, in-process SPC monitoring, and final CMM/laser scanning validation. Our defect rate is consistently <0.02% across 10,000+ annual projects.

Olympic Quality Benchmark: Critical features (e.g., mounting holes, alignment slots) meet ±0.05mm tolerances—exceeding ISO 2768-mK standards. This precision ensures seamless integration into complex assemblies, even in aerospace and medical applications.

24/7 Customer Partnership: A dedicated engineering team is available around the clock for design reviews, production updates, or urgent revisions. Need a tolerance adjustment at 3 AM? We respond within 15 minutes.

“We treat your project as our own—because when you succeed, we succeed.”

— Wuxi Lead Precision Machinery Quality Commitment

From material sourcing to final finishing, our integrated workflow eliminates supply chain fragmentation. Whether you need aerospace-grade aluminum components with anodized wear resistance or galvanized steel enclosures for outdoor deployment, we deliver precision-engineered parts that perform—every time.

Ready to optimize your design for manufacturability?

Contact our engineering team for a free design-for-manufacturing (DFM) review. Let’s build excellence together.

Manufacturing Process & QC

From Prototype to Production: Precision Engineering, Delivered

Your Strategic Partner for End-to-End Sheet Metal Fabrication

At Wuxi Lead Precision Machinery, we eliminate the gap between design intent and physical reality. Our streamlined process ensures zero defects, Olympic-grade quality, and 24/7 engineering support—all while maintaining industry-leading tolerances and on-time delivery.

Design Analysis & DFM Optimization

Engineered for Manufacturability from Day One

Our senior engineers conduct a rigorous Design for Manufacturing (DFM) review to identify potential issues before production begins. We apply GD&T principles per ASME Y14.5 standards to define critical tolerances, material suitability, and assembly constraints—ensuring your design is optimized for precision and cost-efficiency.

Material-Specific Tolerance Guidelines

| Material | Standard Tolerance | Tight Tolerance (Optional) | Key Considerations |

|---|---|---|---|

| CRS/HRS Steel | ±0.10 mm (±0.004″) | ±0.05 mm (±0.002″) | Heat treatment effects on final dimensions |

| Aluminum (6061/5052) | ±0.10 mm (±0.004″) | ±0.05 mm (±0.002″) | Anodizing may add 0.025mm to critical features |

| Galvanized Steel | ±0.12 mm (±0.005″) | ±0.08 mm (±0.003″) | Zinc coating thickness factored into tolerances |

“We don’t just cut parts—we engineer solutions. Our DFM process reduces prototyping iterations by up to 40% and eliminates 95% of rework risks.”

Transparent Pricing & Quoting

No Surprises. No Compromises.

All quotes include a detailed cost breakdown (material, processing, finishing, QC) with no hidden fees. Our AI-driven pricing engine cross-references real-time machine utilization, material availability, and logistics data to deliver accurate, competitive pricing within 4 hours of request.

Lead Time Commitments

| Project Type | Standard Lead Time | Expedited Option | Quality Assurance Included |

|---|---|---|---|

| Prototyping | 3–5 days | 48 hours | Full dimensional inspection + DFM feedback |

| Low Volume (1–50 pcs) | 7–10 days | 5 days | 100% SPC monitoring + material certification |

| Mass Production (500+ pcs) | 14–21 days | 10 days | Automated CMM checks + statistical process control |

Rapid Prototyping with Production-Grade Precision

Identical Processes. Identical Results.

Our prototyping phase uses identical laser cutters, bending presses, and powder coating lines as mass production. This eliminates “prototype-to-production” discrepancies, ensuring your first article meets final specifications.

Prototype-to-Production Consistency

| Parameter | Prototyping | Production | Consistency Metric |

|---|---|---|---|

| Laser Cutting Tolerance | ±0.10 mm | ±0.10 mm | 100% alignment |

| Bending Accuracy | ±0.5° | ±0.5° | Fixture validation pre-run |

| Surface Finish | Same as final | Same as final | Coating thickness ±3μm |

“When we say ‘prototype like production,’ we mean it. Our clients reduce time-to-market by 30% by validating designs with true production-grade data.”

Mass Production with Zero Defects Commitment

Olympic Quality, Verified at Every Stage

Every component undergoes multi-stage inspection across our ISO 9001-certified quality system. Our defect rate remains consistently <0.1%—validated through automated CMM checks, in-process SPC monitoring, and final 100% dimensional verification.

Quality Assurance Protocol

| Stage | Inspection Method | Tolerance Verification | Defect Prevention Mechanism |

|---|---|---|---|

| Material Receipt | Spectrographic Analysis | Grade/thickness ±1% | Pre-approval from certified mills |

| Laser Cutting | Laser Scanner + CMM | ±0.10 mm (±0.004″) | Real-time kerf compensation |

| Bending | Digital Angle Gauge | ±0.5° | Fixture wear monitoring |

| Welding (TIG/MIG) | Visual + X-Ray | AWS D1.1 standards | Weld pass verification |

| Powder Coating | Thickness Gauge (ASTM D3359) | 60–80μm ±5μm | Adhesion test per ISO 2409 |

Your Strategic Partner: 24/7 Support & Olympic Quality

We Don’t Just Deliver Parts—We Deliver Peace of Mind

Zero Defects

Our statistical process control (SPC) system tracks 12+ critical parameters in real time. If a deviation exceeds ±0.02mm, production halts automatically. This ensures every batch meets AS9100 aerospace-grade standards—even for non-aerospace applications.

Olympic Quality

From medical implants to automotive chassis, our tolerances consistently exceed industry benchmarks:

– ±0.05mm for critical assembly features

– Ra ≤0.8μm surface finish for optical-grade components

– Zero porosity in welded joints (verified via X-ray)

24/7 Customer Service

A dedicated Technical Response Team (TRT) is available around the clock for:

– Urgent design revisions (≤2-hour response time)

– Real-time production tracking via IoT-enabled dashboards

– Emergency logistics coordination (global shipping within 24h)

[Request a Free DFM Review] | [View Our Quality Certifications] | [Contact Our 24/7 Support Team]“When precision matters, trust a partner who engineers quality into every step—not just at the end.”

— Wuxi Lead Precision Machinery, Certified ISO 9001:2015 & AS9100D

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery

Precision Engineered to Your Exact Specifications

Our laser cutting capabilities deliver industry-leading tolerances, ensuring parts that fit, function, and perform flawlessly. Unlike standard suppliers, we engineer precision into every detail.

| Material & Thickness | Industry Standard | Wuxi Lead Precision Capability |

|---|---|---|

| Steel (CRS/HRS, 0.5–3mm) | ±0.10 mm | ±0.03 mm |

| Aluminum (1–6mm) | ±0.10 mm | ±0.03 mm |

| Galvanized Steel (0.5–3mm) | ±0.10 mm | ±0.03 mm |

| Thicker Sections (>3mm) | ±0.15 mm | ±0.05 mm |

Note: Tolerances may vary based on geometry and material properties. Our engineers optimize parameters for each project to achieve the tightest possible tolerances.

Zero Defects, Olympic Quality

Every component undergoes rigorous multi-stage quality control: in-process laser verification, 100% dimensional inspection, and surface finish validation. Our zero-defect philosophy ensures 99.98% first-pass yield, eliminating rework and delays. We don’t just meet specifications—we exceed them.

24/7 Customer Service & Expert DFM Support

Your project’s success is our priority. From initial design review to final delivery, our engineering team provides continuous support. Request a free DFM analysis to optimize your design for manufacturability, cost efficiency, and performance—no obligation, no delays.

Ready to elevate your project?

📧 [email protected] | 📞 +86-13961886740

Wuxi Lead Precision Machinery: More than a supplier—your strategic manufacturing partner.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.