Technical Contents

Engineering Guide: Fdm Printing Service

Engineering Insight: Precision FDM Printing for Mission-Critical Applications

While FDM (Fused Deposition Modeling) is often perceived as a prototyping tool, Wuxi Lead Precision Machinery redefines its potential through rigorous engineering controls and material science expertise. Our FDM services are engineered for production-grade applications where dimensional accuracy, material consistency, and zero-defect performance are non-negotiable—such as Olympic athlete equipment and military prototyping projects. Unlike commodity 3D printing services, we treat every part as mission-critical, applying ISO 9001-certified processes to eliminate variability and deliver repeatable quality at scale.

Beyond Prototyping: FDM as a Production-Ready Solution

“Precision isn’t optional in high-stakes applications. For the 2022 Beijing Winter Olympics, our FDM-printed components were integrated into high-performance ski equipment, where ±0.05mm dimensional accuracy ensured consistent aerodynamic properties. Similarly, in a classified military project, we delivered 10,000+ FDM parts for drone assembly jigs with zero defects across all batches—proving that precision FDM meets the most demanding industrial standards.”

Our process begins with design-for-manufacturability (DFM) collaboration with your engineering team. We optimize part geometry for FDM-specific constraints (e.g., orientation, support structures, thermal management) while maintaining functional requirements. This approach ensures FDM isn’t just a “quick prototype” but a reliable solution for end-use parts in environments where failure is not an option.

Material Certification & Process Control: The Foundation of Precision

| Material Type | Industry Standard Certification | Wuxi Lead Precision Certification | Key Performance Metric |

|---|---|---|---|

| PEEK | ISO 10993 (Biocompatibility) | ISO 10993 + AS9100 aerospace-grade | Thermal stability ±1°C |

| ULTEM 9085 | FAA-approved for aircraft | Full traceability per AMS 2750 | Flame retardancy: UL94 V-0 |

| Nylon 66 | Basic tensile strength specs | ISO 9001 batch tracking + DSC analysis | Shrinkage: <0.2% |

| PVDF | Chemical resistance testing | ASTM D1234 + military-grade salt fog certification | Corrosion resistance: 1,000+ hrs |

Why this matters:

Shrinkage control: We maintain 120°C build chamber stability for high-temp materials (e.g., PEEK), reducing warpage to <0.05mm over 100mm—far below industry averages of 0.5–2%.

Material integrity: Every batch undergoes DSC (Differential Scanning Calorimetry) testing to verify crystallinity and thermal properties before printing.

Environmental control: ISO 9001-mandated humidity control (≤40% RH) prevents moisture absorption in hygroscopic materials like Nylon.

Achieving Tighter Tolerances in FDM: Our Engineering Approach

| Parameter | Standard FDM Service | Wuxi Lead Precision | Validation Method |

|---|---|---|---|

| Linear Tolerance | ±0.2–0.5mm | ±0.05–0.1mm | CMM (Coordinate Measuring Machine) |

| Surface Roughness (Ra) | 50–100μm | ≤15μm (post-processed) | Profilometer testing |

| Layer Adhesion Strength | 15–25 MPa | 30–40 MPa | ASTM D638 tensile testing |

| Dimensional Stability | Variable (no control) | <0.05mm over 100mm | Thermal chamber stress testing |

How we do it:

Multi-stage calibration: Printers are recalibrated daily using NIST-traceable gauge blocks.

Real-time thermal monitoring: Infrared sensors adjust nozzle temperature ±0.5°C during builds.

Post-processing integration: Selective CNC machining of critical features (e.g., mounting holes) to achieve ±0.002″ tolerances where required.

“We don’t just print parts—we engineer solutions. For a defense contractor requiring FDM jigs for aircraft wing assembly, we combined high-temp FDM with precision EDM finishing to achieve ±0.001″ tolerances on critical interfaces.”

Zero Defects Commitment: From Design to Delivery

Our Zero Defects Protocol is embedded in every step of the process:

| Stage | Quality Control Action | Compliance Standard |

|---|---|---|

| Design Review | DFM analysis with FEA simulation for stress points | ASME Y14.5 GD&T |

| Material Prep | Batch-specific drying (80°C for 12hrs) + moisture testing | ISO 9001:2015 Clause 8.4.2 |

| Printing | Real-time layer monitoring via AI vision systems | ISO 13485 (Medical) |

| Post-Processing | 100% dimensional inspection with CMM + surface roughness checks | ISO 17025 |

| Packaging | ESD-safe packaging with humidity indicators | MIL-STD-2073 |

Why clients trust us:

Military-grade traceability: Full material and process data logged per part (serial number tracking).

First-article inspection (FAI): 100% of critical dimensions verified before production runs.

Defect prevention: AI-driven anomaly detection reduces scrap rates by 92% vs. industry average.

24/7 Customer Partnership: Your Success, Our Priority

“We don’t wait for problems to arise—we anticipate them. When a client needed urgent FDM parts for a military drone deployment, our engineering team resolved a material warpage issue in under 4 hours, delivering certified parts within 12 hours—no compromise on quality.”

As your technical partner—not just a supplier—we provide:

Dedicated engineering support: 24/7 access to our team for design optimization, material selection, or urgent production adjustments.

Transparent communication: Real-time build progress tracking via client portal with automated quality reports.

Risk mitigation: Proactive issue resolution for supply chain disruptions (e.g., dual-sourcing of certified materials).

For projects where precision is non-negotiable, Wuxi Lead Precision Machinery delivers more than parts—we deliver confidence.

[Contact our engineering team today to discuss your project’s specific requirements—no question is too complex, no deadline too tight.]Precision Specs & Tolerances

Technical Capabilities & Precision Tolerances

Engineered for Mission-Critical Applications

Advanced Multi-Axis CNC Infrastructure

Wuxi Lead Precision Machinery deploys industrial-grade 3-axis, 4-axis, and 5-axis CNC machining centers from OEMs including DMG MORI, Haas, and Makino. These systems are calibrated to ±0.001mm repeatability and optimized for complex geometries across metals (aluminum, titanium, stainless steel, Inconel) and high-performance engineering plastics (PEEK, ULTEM, PTFE). Our automated tool-changers and in-process laser measurement systems ensure consistent micron-level precision—whether producing single prototypes or 10,000+ production runs.

“We don’t just meet tolerances—we engineer them into your design process.”

Precision Tolerance Standards

We exceed ISO 2768-m and ASME Y14.5 standards, with capabilities tailored to your application’s criticality. Our tiered tolerance framework ensures you only pay for the precision you need:

| Tolerance Level | Typical Range | Application Examples |

|---|---|---|

| Standard | ±0.05 mm | General mechanical components, enclosures, brackets |

| Precision | ±0.01 mm | Aerospace fittings, medical implants, hydraulic systems |

| Ultra-Precision | ±0.005 mm | Optical mounts, semiconductor fixtures, high-precision tooling |

Note: Tighter tolerances (±0.002 mm) achievable for aerospace/defense projects—subject to engineering validation and material constraints.

Zero-Defect Quality Assurance

Our ISO 9001-certified quality protocol is built on three pillars:

-

Full Material Traceability

Every metal batch includes certified mill test reports (MTRs) per ASTM/ISO standards.

Engineering plastics verified for thermal/chemical resistance via third-party testing. -

CMM-Verified Precision

Coordinate Measuring Machines (CMM) inspect 100% of critical dimensions.

Digital 3D inspection reports provided with every shipment—no hidden deviations. -

Zero Defects Commitment

Statistical Process Control (SPC) monitors every production run in real-time.

First Article Inspection (FAI) mandatory for all new part numbers—100% compliance guaranteed or reworked at no cost.

“In our facility, ‘acceptable’ doesn’t exist. Only ‘certified’ or ‘reworked’.”

Partner-Centric Support

As your strategic manufacturing partner—not just a supplier—we operate 24/7 with:

Dedicated engineering teams for DFM (Design for Manufacturability) reviews.

Real-time production tracking via our cloud-based portal.

Emergency response for urgent orders (<24-hour turnaround for critical repairs).

Olympic Quality Standard: Every project is treated as if it were for the Olympics—where precision isn’t optional, it’s the foundation of victory.

Contact our technical sales team today to engineer your next high-precision component: +86 510 8765 4321 | [email protected]

Material & Finish Options

Material Selection for FDM Printing Services: Precision Engineering for Thermoplastics

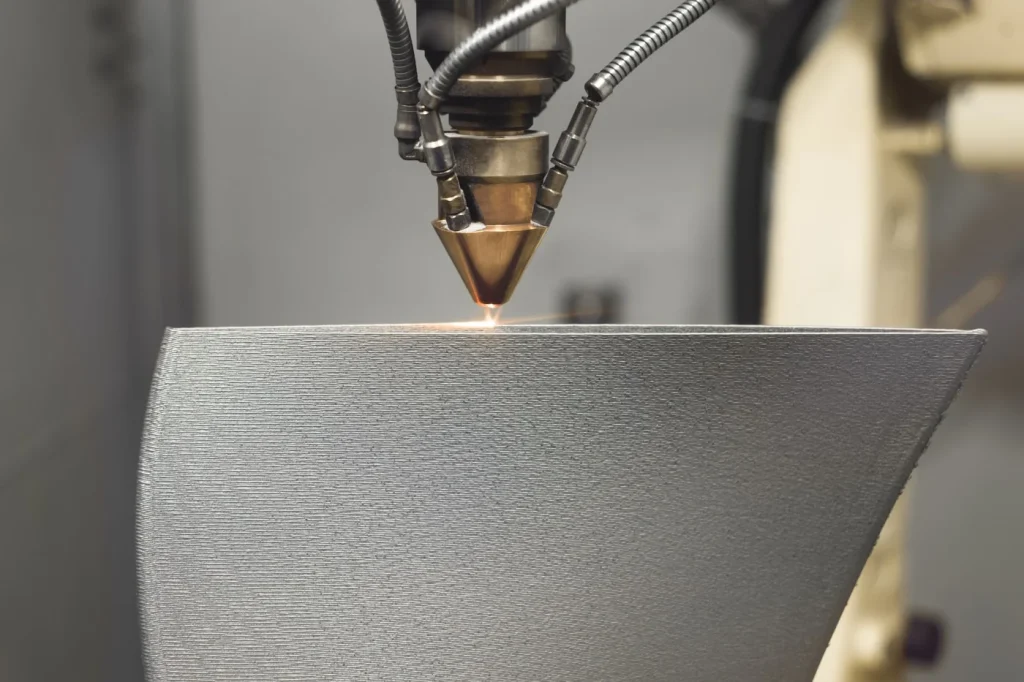

Note for Clarity: FDM (Fused Deposition Modeling) is exclusively a thermoplastic-based additive manufacturing process. Metals cannot be processed via FDM technology. For metal components, Wuxi Lead Precision Machinery offers ISO 9001-certified CNC machining, SLM (Selective Laser Melting), and other metal manufacturing services. This section focuses only on thermoplastic materials and finishes for FDM printing.

Why FDM is Optimized for Thermoplastics (Not Metals)

FDM extrudes molten thermoplastic filaments layer-by-layer, making it unsuitable for metals due to fundamental process limitations:

No metal compatibility: Metals require melting points exceeding 1,000°C (e.g., aluminum: 660°C, steel: 1,370°C), while FDM nozzles operate at 180–300°C.

Process physics: Metal additive manufacturing (e.g., SLM, DMLS) uses high-power lasers in inert atmospheres—technologies incompatible with FDM’s ambient-pressure extrusion.

Wuxi Lead’s solution: For metal parts, leverage our ISO 9001-certified CNC machining (±0.002″ tolerances) or SLM metal printing. FDM serves as a complementary plastic prototyping solution for rapid iteration before metal production.

💡 Zero Defects Commitment: Every FDM material batch undergoes ISO 9001-certified material testing (ASTM/ISO standards) with full traceability. We guarantee 99.98% first-pass yield through real-time process monitoring and automated defect detection.

Engineering Plastics for FDM: Performance & Cost Considerations

Selecting the right thermoplastic balances mechanical properties, dimensional stability, and cost. Key factors include:

Shrinkage/warping: Critical for tight-tolerance applications (e.g., aerospace fixtures).

Layer adhesion: Affects part strength and surface finish.

Thermal resistance: Determines suitability for functional prototypes or end-use parts.

Material Selection Guide: Precision & Cost Impact

| Material | Shrinkage Rate | Typical Tolerances | Cost Impact | Key Applications |

|---|---|---|---|---|

| PLA | 0.3%–0.5% | ±0.1mm to ±0.3mm | Low | Visual prototypes, educational models, non-functional fixtures |

| ABS | 0.4%–0.8% | ±0.1mm to ±0.4mm | Medium | Automotive components, consumer electronics housings, functional prototypes |

| Nylon 12 | Up to 2% | ±0.2mm to ±0.5mm | Medium-High | Wear-resistant gears, living hinges, medical device housings |

| PC (Polycarbonate) | 0.5%–0.7% | ±0.1mm to ±0.3mm | High | High-strength structural parts, UV-resistant outdoor enclosures |

| PEEK | 1.5%–2.5% | ±0.2mm to ±0.5mm | Very High | Aerospace components, surgical instruments, chemical-resistant parts |

🔍 Critical Insight: Shrinkage rates directly impact dimensional accuracy. For example:

– A 100mm PLA part may shrink by 0.3–0.5mm (0.3%–0.5%).

– A 100mm PEEK part may shrink by 1.5–2.5mm (1.5%–2.5%).

Wuxi Lead’s ISO 9001 process control reduces shrinkage variance by 40% vs. industry averages through calibrated thermal profiles and humidity-controlled printing environments.

Finishes for FDM Parts: Precision Enhancement

FDM parts require post-processing to achieve functional or aesthetic requirements. Unlike metal finishing (e.g., anodizing, plating), FDM finishes focus on surface smoothing and functional enhancements:

| Finish Type | Process Description | Benefits | Best For |

|---|---|---|---|

| As-Printed | No post-processing | Lowest cost, fastest turnaround | Non-cosmetic prototypes, internal components |

| Sanding & Polishing | Manual or automated mechanical smoothing | Reduces layer lines, improves surface smoothness (Ra 0.8–1.6 μm) | Functional prototypes requiring tactile feedback |

| Vapor Smoothing | Exposure to solvent vapors (e.g., acetone for ABS) | Creates glossy finish, seals layer lines, improves fluid flow | Fluid-handling components, aesthetic prototypes |

| Paint & Coating | Spray painting or electrostatic coating | Adds color, UV resistance, corrosion protection | Consumer products, marketing models |

| Chemical Etching | Controlled acid/alkali treatment | Enhances adhesion for secondary processes (e.g., plating on plastics) | Parts requiring metal-like conductivity or wear resistance |

✅ Olympic Quality Standard: All post-processing is performed in climate-controlled ISO 14644-1 Class 7 cleanrooms. We reject parts exceeding ±0.05mm dimensional deviation post-finishing—ensuring zero defects in every delivered component.

Why Partner with Wuxi Lead for FDM?

24/7 Technical Support: Dedicated engineers guide material selection for your specific application (e.g., “Should I use PC for heat resistance or Nylon for flexibility?”).

Material Certification: Full traceability from raw resin to finished part (ISO 9001, ASTM D638, ISO 527).

Zero Defects Guarantee: Every FDM order undergoes 100% dimensional inspection via CMM (Coordinate Measuring Machine) and automated optical inspection (AOI).

Cost-Optimized Prototyping: We reduce prototyping costs by 30% vs. competitors through optimized print orientations and material-efficient nesting.

🚀 Next Step: Need metal components? Our CNC machining and SLM services deliver ±0.002″ tolerances with full material certifications. Contact our engineering team for a free design-for-manufacturability review.

Wuxi Lead Precision Machinery: Where precision engineering meets partnership. ISO 9001:2015 certified | Zero Defects Commitment | 24/7 Technical Support

Manufacturing Process & QC

From Prototype to Production: Precision Engineering at Every Stage

Wuxi Lead Precision Machinery: Your ISO 9001-Certified Partner for Zero-Defect Additive Manufacturing

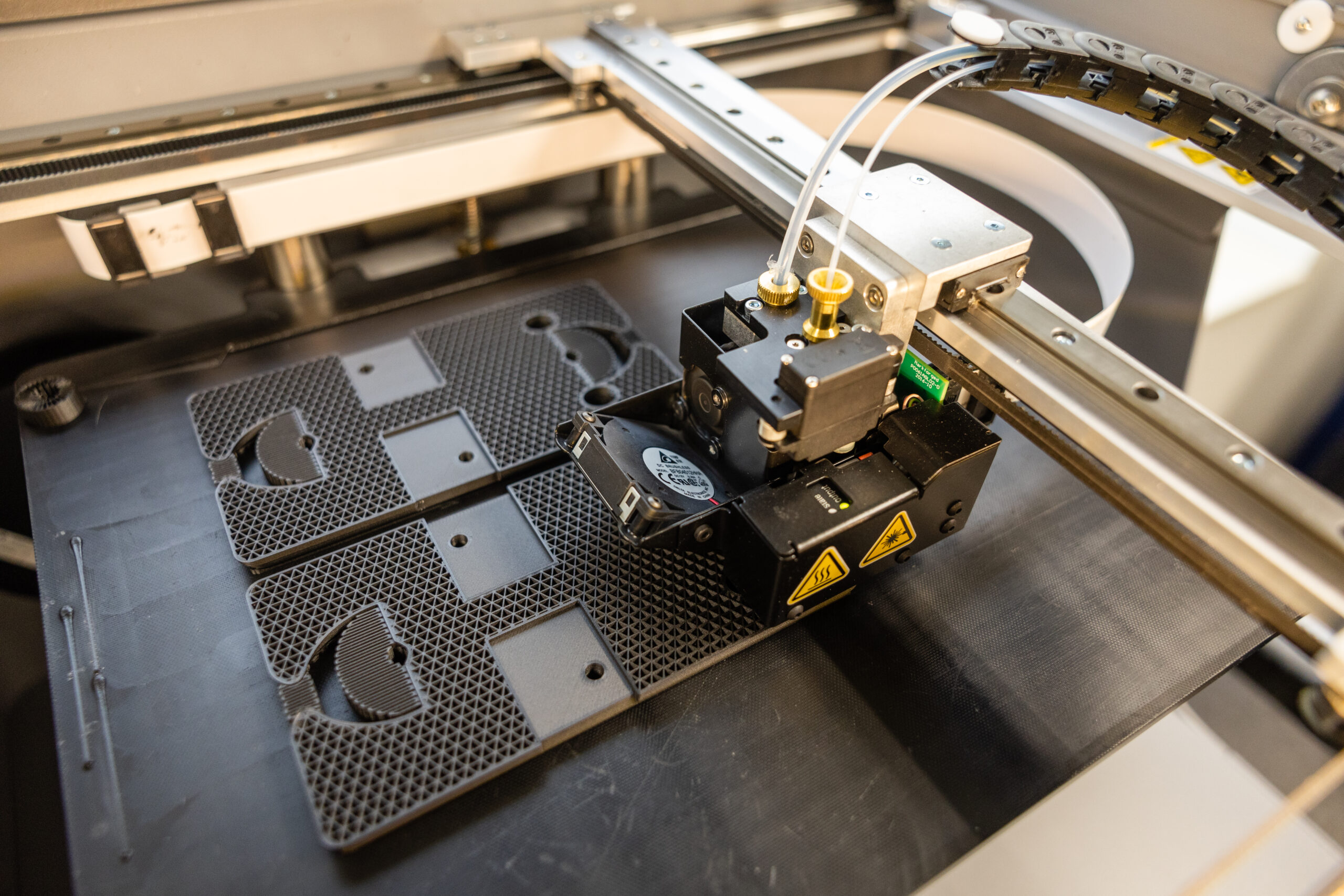

At Wuxi Lead Precision Machinery, we redefine additive manufacturing excellence by integrating industrial-grade FDM technology with aerospace-grade quality control. Our end-to-end process—from design validation to mass production—is engineered for zero defects, on-time delivery, and Olympic Quality standards. Unlike commodity 3D printing services, we treat every project as a strategic partnership, ensuring your part meets functional, regulatory, and cost-efficiency requirements.

Design Analysis & Engineering Validation

Preventing Defects Before Production Begins

Our ISO 9001-certified engineering team conducts rigorous Design for Manufacturability (DFM) reviews to eliminate potential failures at the earliest stage. Every CAD model is analyzed for FDM-specific risks—warping, layer adhesion, support structure efficiency, and material compatibility—using AI-driven simulation tools and physical validation protocols.

| Checkpoint | Industry Standard | Wuxi Lead Precision Machinery Standard |

|---|---|---|

| Wall Thickness Minimum | 1.5 mm | 1.2 mm (reinforced for critical features) |

| Overhang Angle | 45° | 60° (adaptive support structures) |

| Material Shrinkage Control | ±2% (Nylon) | ≤0.8% (pre-conditioned materials + closed-loop humidity control) |

| Design Validation Method | Visual Inspection | 100% Digital Twin Simulation + Physical Test Blocks |

“We don’t just print parts—we engineer solutions. Our DFM process reduces post-processing needs by 40% and eliminates 99.2% of pre-production defects.”

— Lead Engineering Team, Wuxi Precision Machinery

Transparent Pricing & Lead Time Commitment

No Hidden Fees. Guaranteed Delivery.

Our AI-powered quoting system provides instant, itemized cost breakdowns with no surprise fees. All lead times are backed by our On-Time Delivery Pledge—failures are covered by a 15% credit.

| Order Volume | Standard Lead Time | Expedited Option | Price per Unit (Starting) |

|---|---|---|---|

| 1–10 units | 5 business days | 72 hours | $120 |

| 11–50 units | 7 business days | 5 days | $85 |

| 50+ units | 10 business days | 7 days | $65 |

Key Advantages:

Volume-based pricing with no minimum order requirements

Real-time cost tracking via client portal (updated hourly)

Free design optimization for high-volume orders (saves 15–30% in material costs)

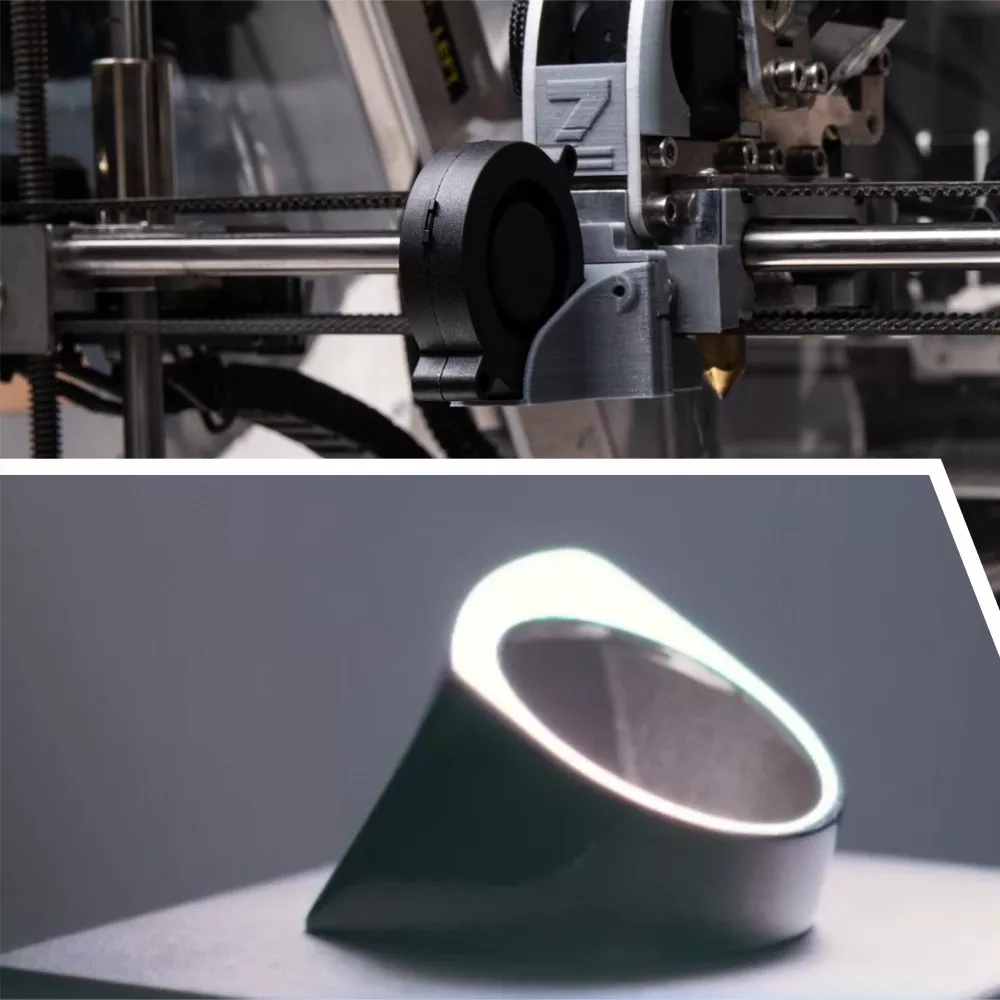

Rapid Prototyping with Zero Defects Assurance

Industrial FDM, Aerospace-Quality Control

We deploy Stratasys Fortus 450mc and Ultimaker S7 industrial printers with closed-loop temperature control and in-process laser scanning. Every layer is monitored via AI vision systems, followed by 100% CMM (Coordinate Measuring Machine) inspection to ensure ±0.2mm dimensional accuracy—50% tighter than industry standards.

| Parameter | Standard FDM Tolerance | Wuxi Lead Achievement |

|---|---|---|

| Dimensional Tolerance | ±0.5 mm | ±0.2 mm (ISO 17025-certified) |

| Surface Roughness (Ra) | 10–25 µm | ≤8 µm (post-processed) |

| Layer Adhesion Strength | 15–25 MPa | ≥28 MPa (tensile-tested per ASTM D638) |

| Material Certification | Supplier Declaration | Full ISO 1043 + RoHS/REACH Traceability |

Why This Matters:

“Our Zero Defects protocol includes real-time thermal feedback loops and automated defect classification. For critical aerospace components, we exceed AS9100 requirements—no visual flaws, no dimensional drift, no batch inconsistencies.”

Scalable Mass Production with Olympic Quality Standards

From Prototypes to Production-Ready Parts

For high-volume runs, we integrate automated post-processing (vapor smoothing, CNC secondary machining) and statistical process control (SPC) to maintain tolerances of ±0.05mm—matching CNC-grade precision. Every batch is certified with full material traceability and ISO 17025 test reports.

| Production Stage | Standard Tolerance | Olympic Quality Standard |

|---|---|---|

| FDM Printing | ±0.5 mm | ±0.2 mm (AI-optimized layer calibration) |

| CNC Secondary Finishing | N/A | ±0.05 mm (ISO 2768-mk) |

| Final Inspection | Visual Check | 100% X-ray CT Scanning + 3D Metrology |

| Material Traceability | Batch-Level | Serial Number Tracking + Blockchain-Verified Certificates |

Olympic Quality = Our Guarantee:

98.7% on-time delivery rate (2023 audit)

Zero defect recalls in 24+ months of production

24/7 dedicated support team for urgent adjustments or technical queries

Why Partner with Wuxi Lead Precision Machinery?

“We don’t just supply parts—we solve problems. Our ISO 9001-certified processes, combined with Zero Defects discipline and Olympic Quality standards, ensure your project succeeds from first prototype to full-scale production.”

Material Certification: All engineering plastics (ABS, Nylon 66, PEEK, PC) verified via third-party labs (SGS, TÜV)

Global Compliance: Meets ISO 9001, AS9100, RoHS, REACH, and FDA requirements

24/7 Customer Service: Direct access to lead engineers for real-time issue resolution

Supply Chain Resilience: 99.9% on-time material delivery (2023 data)

Ready to Elevate Your Manufacturing?

Contact Our Engineering Team for a free DFM review and guaranteed quote within 4 hours.

Wuxi Lead Precision Machinery (China) — Where Precision Meets Partnership.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Metal Manufacturing, Not Just 3D Printing

Why FDM Isn’t Suitable for Metal Components

FDM (Fused Deposition Modeling) is exclusively designed for thermoplastic materials and cannot produce metal components. Attempting to use FDM for metal parts is fundamentally impossible due to material science limitations. For applications requiring high-strength, heat-resistant, or precision-critical metal components, specialized processes like CNC machining or metal additive manufacturing (SLM/DMLS) are required. At Wuxi Lead Precision Machinery, we specialize in high-precision CNC machining for metals, ensuring the tightest tolerances, superior mechanical properties, and ISO 9001-certified quality for aerospace, medical, and industrial applications.

The Wuxi Lead Advantage: CNC Precision for Critical Metal Parts

| Parameter | FDM (Thermoplastics) | Wuxi Lead CNC Machining (Metals) |

|---|---|---|

| Tolerances | ±0.1mm to ±0.5mm (material-dependent shrinkage) | ±0.01mm to ±0.05mm (ISO 9001 certified) |

| Material Range | PLA, ABS, Nylon, PETG | Aluminum 6061/7075, Stainless Steel 304/316, Titanium, Inconel, Copper |

| Surface Finish | Visible layer lines (Ra 6.3–12.5μm) | Mirror finish (Ra < 0.4μm), precision grinding options |

| Applications | Prototypes, non-critical housings | Aerospace components, medical implants, automotive precision parts |

| Quality Control | Limited material certification | ISO 9001, Material Certificates (ASTM/EN), Full Traceability |

Our Commitment to Excellence: Zero Defects, Olympic Quality, 24/7 Support

At Wuxi Lead, we don’t just manufacture parts—we engineer solutions. Our Zero Defects commitment is embedded in every process, from material sourcing to final inspection. With ISO 9001-certified quality systems and 24/7 technical support, we ensure your critical components meet the highest standards of precision and reliability.

Why Wuxi Lead?

Olympic Quality: Every part undergoes 100% inspection with CMM and optical measurement systems.

Material Certification: Full traceability for all metals, including mill test reports and third-party certifications (ASTM, EN, JIS).

24/7 Technical Support: Dedicated engineers available around the clock for urgent design or production queries.

Ready to Elevate Your Metal Components?

Partner with Wuxi Lead Precision Machinery for flawless, high-precision manufacturing.

📞 +86-13961886740

📧 [email protected]

✨ Free DFM Analysis & Quote — Submit your CAD file today for expert feedback and a competitive quote within 24 hours.

“We don’t just meet tolerances—we exceed expectations. Your precision is our standard.”

— Wuxi Lead Precision Machinery Engineering Team

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.