Introduction: Navigating the Global Market for 3d printed part

The past decade has seen a dramatic transformation in global manufacturing, with 3D printed parts at the epicenter of this change. Once limited to prototyping, additive manufacturing (AM) now drives agile production across industries—from automotive to medical devices—enabling rapid iterations, custom solutions, and resilient supply chains. For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, this evolution presents both a challenge and an unprecedented opportunity.

Global disruptions—from pandemics to geopolitical tensions—have underscored the vulnerabilities of traditional, centralized supply chains. Rising shipping costs, material shortages, and a need for faster turnaround have prompted many organizations to rethink how and where they source critical components. 3D printed parts have emerged as a key enabler of localized and on-demand manufacturing, reducing dependency on distant suppliers and streamlining delivery to even the most complex or underserved markets.

This guide provides a comprehensive roadmap to navigating the 3D printed parts market. It covers:

- Core 3D Printing Technologies: Understand the leading AM processes and their applications.

- Material Options: Evaluate engineering-grade metals, polymers, and composites for your requirements.

- Manufacturing, Quality, and Certification: Learn about quality control, international standards, traceability, and repeatability.

- Supplier Evaluation: Strategies to identify, vet, and collaborate with reliable global and local suppliers.

- Cost Structures and Market Insights: Break down cost drivers, pricing models, and total cost of ownership.

- Frequently Asked Questions: Address common concerns relevant to cross-border sourcing and regional challenges.

Whether you are looking to localize your supply chain in Egypt, unlock tailored production in Mexico, or enhance responsiveness in rapidly evolving markets, this guide equips you with actionable insights to make informed, cost-effective, and resilient sourcing decisions when procuring 3D printed parts globally.

Understanding 3d printed part Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Prototyping Parts | Rapid, flexible, non-final iterations; wide material range | Concept validation, product development | Fast and affordable; not typically production-grade durability |

| Production-Grade Polymer Parts | Engineering plastics, robust mechanical properties, certified | End-use components, jigs, fixturing | High performance; may need volume pricing, certification |

| Functional Metal Parts | Fully dense metals, intricate geometries, high strength | Aerospace, automotive, medical, tooling | Strong and precise; higher cost, complex post-processing |

| Customized Components | Tailored designs, batch or one-off, digital inventory | Spare parts, medical devices, on-demand parts | Unmatched flexibility; long qualification cycles in regulated sectors |

| Tooling & Fixtures | Specially designed for manufacturing support, rapid iteration | Manufacturing aids, assembly lines, molds | Fast turnaround; may wear faster than traditional tools |

Prototyping Parts

Prototyping parts represent the entry point for most organizations into 3D printing. These parts are produced quickly and cost-effectively, allowing engineering and product teams to validate concepts, refine designs, and shorten development cycles. African, Middle Eastern, or South American buyers can leverage rapid prototyping to bring products to market faster or adapt to local market needs without heavy upfront investment. When sourcing, prioritize material compatibility and supplier responsiveness, since speed and flexibility are critical.

Production-Grade Polymer Parts

With advances in additive manufacturing, 3D printed polymer parts now meet strict functional requirements and industry certifications. These parts are used directly in assembly lines, equipment, and finished goods. For international buyers, the ability to source on-demand and locally produced end-use parts is especially valuable for reducing lead times and supply chain risks. Ensure suppliers adhere to quality management standards (e.g., ISO), and confirm mechanical property specifications align with application needs.

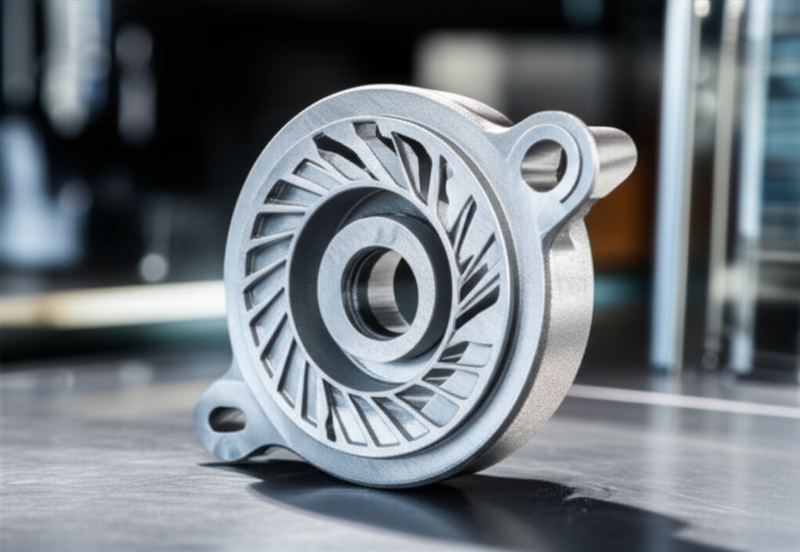

Functional Metal Parts

3D printed metal components are revolutionizing sectors requiring complex, lightweight, or customized parts – notably aerospace, automotive, and medical industries. These parts are manufactured using processes like DMLS or SLM, resulting in high-strength, fully dense metal structures. The main consideration for buyers is balancing the higher upfront cost and required post-processing with the performance and supply chain benefits. Vet your suppliers’ technical capabilities, certification status, and quality assurance processes, as consistency and traceability are paramount for mission-critical applications.

Customized Components

3D printing excels at producing bespoke components, from patient-specific medical implants to urgently needed industrial spares. This enables companies in Africa, Latin America, and other import-reliant regions to minimize downtime and better serve their markets with tailored solutions. When purchasing, clarify requirements for customization, digital inventory integration, and validation protocols to ensure fit-for-purpose results. Note that regulated industries may require thorough qualification and compliance documentation.

Tooling & Fixtures

The production of specialized tooling and fixtures using additive manufacturing offers fast lead times and iterative design improvements. Factories can boost agility and reduce bottlenecks by quickly replacing or updating manufacturing aids. However, some 3D printed tools may have shorter service lifespans compared to traditional alternatives. Evaluate expected tool wear and discuss service agreements or reprint options with suppliers, especially if reliability on the production floor is mission-critical.

Related Video: Connect 3D Printed Parts | Design for Mass Production 3D Printing

Key Industrial Applications of 3d printed part

| Industry/Sector | Specific Application of 3d printed part | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive & Transportation | Rapid tooling, custom fixtures, and spare parts | Accelerated production cycles, minimized downtime, reduced inventory | Material durability, dimensional accuracy, after-sales support |

| Aerospace & Defense | Lightweight structural components | Optimized fuel efficiency, reduced part count, design flexibility | Certification to industry standards (e.g., AS9100), material traceability |

| Energy & Utilities | On-demand repair parts for turbines/pumps | Minimized operational interruptions, local supply resilience | Corrosion-resistant materials, digital part files security |

| Medical Devices | Patient-specific implants & surgical guides | Increased surgical precision, personalized care, fast turnarounds | Biocompatibility, regulatory compliance (CE/FDA), traceable records |

| Industrial Machinery | Replacement gears and end-use custom parts | Shorter lead times, lower storage costs, part design optimization | Mechanical strength, compatibility with existing systems |

Automotive & Transportation

3D printed parts are now routinely used for rapid tooling, custom jigs and fixtures, and even production-ready spare parts in automotive supply chains. This technology enables manufacturers and fleet operators to respond quickly to part shortages, minimize costly downtime from equipment failures, and avoid large inventories—especially valuable in regions with import bottlenecks. For international buyers, it is essential to ensure material durability and tight dimensional tolerances. Sourcing partners should also be able to provide ongoing technical support and local service.

Aerospace & Defense

Aerospace companies leverage 3D printing for lightweight, complex structural components—such as brackets, ducts, and mounts—that were previously expensive or impossible to fabricate using conventional means. These parts reduce aircraft weight, cut fuel costs, and enable innovative design features. Because aerospace applications demand exacting certification and traceability, B2B buyers, especially those in regulatory-sensitive markets, must ensure suppliers are compliant with strict industry standards and can provide full documentation and traceability for each part.

Energy & Utilities

Energy producers and utilities increasingly adopt 3D printing for fast, cost-effective production of repair parts for turbines, pumps, and critical infrastructure, often in remote or hard-to-access locations. Rapid, local manufacturing helps minimize costly service outages and avoids the risk of supply chain delays. When sourcing, buyers should prioritize partners who use corrosion-resistant, high-performance materials and who can securely manage and deliver digital part files to protect proprietary technology.

Medical Devices

In medical device manufacturing, 3D printed patient-specific implants, prosthetics, and surgical guides enable tailored care and rapid production—critical in healthcare markets with growing populations and diverse patient anatomies. For international buyers, regulatory compliance is paramount: each part must be manufactured with biocompatible materials, adhere to local and international safety standards, and be fully documentable for medical records. Finding suppliers with proven regulatory expertise and traceable processes is essential.

Industrial Machinery

Manufacturers maintain uptime and reduce costs by using 3D printing to produce replacement gears, custom housings, and optimized machine parts on demand. This is particularly beneficial in settings where importing parts is slow or unreliable and where legacy equipment may lack replacement parts from original manufacturers. Buyers should focus on suppliers who offer strong mechanical properties, can customize parts for unique needs, and ensure compatibility with existing assemblies and machinery systems.

Related Video: A 100% 3D Printed Linear Snap Action Mechanism.

Strategic Material Selection Guide for 3d printed part

When selecting materials for 3D printed parts, international B2B buyers must balance mechanical performance, regulatory requirements, cost, and supply chain realities. The right material can determine not only the functionality and durability of a component but also affect compliance, logistics, and total cost of ownership—especially across diverse regions like Africa, South America, the Middle East, and Europe. Below, we analyze four common 3D printing materials through a B2B lens.

Nylon (Polyamide, PA12/PA11)

Key Properties: Nylon grades such as PA12 and PA11 are renowned for their balance of strength, toughness, abrasion resistance, and moderate flexibility. They tolerate moderate temperatures (up to 150°C) and offer excellent chemical resistance, especially to fuels, oils, and many solvents.

Pros & Cons:

– Pros: Durable under mechanical stress, impact-resistant, lightweight, and can be printed with complex geometries using Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF). PA12 offers better dimensional stability; PA11 (bio-based) is more environmentally friendly.

– Cons: Sensitive to moisture absorption, which can affect dimensional tolerances. Mechanical performance decreases at higher temperatures or when exposed to prolonged humidity.

Application Impact:

Ideal for functional prototypes, end-use connectors, housings, pump components, and machinery parts exposed to moderate stress and chemical environments.

International Considerations:

Nylon is commonly approved under ASTM D638, ISO 527, or DIN EN ISO 178 for mechanical performance, making it easier to meet import and quality standards in the EU, Middle East, or Latin America. Moisture control during transit and storage is critical, especially in humid climates such as West Africa or Latin America.

Stainless Steel (e.g., 316L, 17-4PH)

Key Properties: Stainless steels like 316L and 17-4PH are prized for their high strength, toughness, and exceptional corrosion resistance—even in harsh and caustic environments. These metals sustain significant loads and withstand high temperatures (up to 800°C for some grades).

Pros & Cons:

– Pros: Excellent for pressure-bearing parts, food and pharmaceutical equipment, petrochemical components, and marine hardware due to their resistance to most chemicals and weathering. Suitable for Direct Metal Laser Sintering (DMLS/SLM).

– Cons: High material and equipment costs. Metal 3D printing requires rigorous post-processing (e.g., heat treatment, surface finishing) and infrastructure for safe powder handling.

Application Impact:

Critical for end-use parts in sectors demanding traceability and performance (e.g., oil & gas valves, surgical tools, or water processing). Supports compliance with demanding international codes.

International Considerations:

Global acceptance of grades per ASTM A276/UNS S31603 (316L) or ASTM A564 (17-4PH). Regional certification is particularly important in regulated sectors—CE marking (Europe), ASME (North America), or local conformity assessment (Middle East). Logistics are sensitive to shipping costs and local capacity for finishing operations.

ABS (Acrylonitrile Butadiene Styrene)

Key Properties: ABS is a widely used engineering thermoplastic with good impact resistance, moderate mechanical strength, ease of processing, and a working temperature range up to ~85°C.

Pros & Cons:

– Pros: Affordable, readily available, and easy to process using Fused Deposition Modeling (FDM) printers. Maintains good dimensional stability and can be post-processed for a smoother finish.

– Cons: Limited chemical and UV resistance; prone to warping during print unless environmental controls are used. Not suitable for high-load or high-temperature environments.

Application Impact:

Commonly used for prototypes, jigs/fixtures, and low-stress industrial applications where higher volume and lower costs are priority considerations.

International Considerations:

ASTM D638 and ISO 527 certifications are typically relevant. For buyers in Africa or Latin America, ease of sourcing printer-grade ABS and cost-effectiveness make it attractive. However, parts shouldn’t be specified for prolonged outdoor use in sun-exposed or chemical-laden environments.

Ultem (PEI – Polyetherimide)

Key Properties: Ultem (PEI) is a high-performance thermoplastic with notable heat resistance (continuous service temperature up to 170°C), flame retardancy, and excellent dielectric properties.

Pros & Cons:

– Pros: Withstands aggressive chemicals, steam sterilization, and high-stress environments. Suitable for aerospace, automotive, and electrical enclosures. Delivers reliable dimensional stability and low flammability.

– Cons: Material and print costs are high. Requires advanced high-temperature 3D printers. More challenging to process, limiting regional supplier base.

Application Impact:

Selected for mission-critical applications—aircraft interior components, electronic housings, and medical devices needing sterilization.

International Considerations:

Ultem meets UL94 V-0 for flammability and is often specified per ASTM D5205. European and North American buyers commonly demand certification, while supply chain readiness in emerging economies may be a constraint. Check the availability of high-temperature FDM systems and local post-processing expertise.

Summary Comparison Table

| Material | Typical Use Case for 3d printed part | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon (PA12/PA11) | Machine components, connectors, enclosures, pump elements | Durable, chemical resistant | Sensitive to moisture, limited high-temp performance | Medium |

| Stainless Steel (316L/17-4PH) | Pressure-bearing components, medical or food devices, marine or petrochemical parts | High strength, corrosion/temperature resistance | High cost, needs post-processing, heavy logistics | High |

| ABS | Prototypes, tools, jigs/fixtures, low-stress housings | Affordable, easy to print | Limited heat/UV/chemical resistance, warping risk | Low |

| Ultem (PEI) | Aerospace or automotive parts, sterilizable medical devices, high-temp electrical housings | Heat/flame/chemical resistance, regulatory compliance | Expensive, complex to process, restricted supply | High |

In-depth Look: Manufacturing Processes and Quality Assurance for 3d printed part

Key Stages of 3D Printed Part Manufacturing

International B2B buyers evaluating 3D printed parts must understand the structured process that underpins production. Each stage—from material handling to final inspection—affects finished part quality and the ability to meet demanding market standards, especially for critical export or compliance-driven applications.

1. Material Preparation

- Selection & Sourcing: Material choice is foundational. Engineering-grade polymers (such as PA12, ABS, PEEK), composites, and metals (e.g., Inconel, stainless steel, titanium) must match design intent, usage environment, and regulatory standards. Verified material documentation, including lot traceability and certificates of analysis, is standard best practice.

- Pre-Processing: Proper material handling includes drying of hygroscopic polymers, sieving metal or plastic powders for consistency, and ensuring resins are within shelf life. For B2B buyers, requesting material validation reports is advised to prevent batch-to-batch variations.

2. Additive Forming (Printing Process)

- Technology Selection: The choice of additive manufacturing method depends on the part’s geometrical complexity, required mechanical properties, and application volume:

- Fused Deposition Modeling (FDM)—common for functional plastics, rapid iteration, and jigs.

- Selective Laser Sintering (SLS) and Multi Jet Fusion (MJF)—preferred for production-strength nylon parts with intricate geometry, minimal supports.

- Stereolithography (SLA)/Digital Light Processing (DLP)—chosen for high-precision resin parts, prototypes, and tooling.

- Direct Metal Laser Sintering (DMLS)/Selective Laser Melting (SLM)—crucial for high-performance metal parts in aerospace, medical, and industrial sectors.

- Printing Parameters: For repeatability, leading manufacturers use strict control over machine parameters—layer thickness, laser power, temperature calibration, and scan strategies. Increasingly, industrial systems incorporate closed-loop feedback, AI-driven print monitoring, and detailed print logs to ensure consistency across global locations.

3. Post-Processing and Assembly

- Support Removal & Surface Finishing: Most parts require manual or automated removal of supports, depowdering, and smoothing. Techniques include bead blasting (for powder bed parts), chemical vapor smoothing (polymers), or heat treatment (metals) to achieve tolerances and performance.

- Assembly: Multi-part assemblies or hybrid components may be bonded, welded, or mechanically fixed post-print. Traceability protocols should continue through this stage for regulated industries.

- Inspection & Cleaning: Cleaning (mechanical, ultrasonic, or chemical) ensures parts are contaminant-free—critical in medical, food, or electronics fields.

Understanding Quality Assurance (QA) in 3D Printed Parts

The shift of 3D printing from prototyping to production mandates dependable, transparent, and verifiable QA processes. For international buyers, this clear focus on robust quality assurance translates directly to risk mitigation—both commercially and reputationally.

Core International and Regional Standards

- ISO 9001:2015 – Quality Management: Widely adopted as the baseline for quality management systems, ISO 9001 certification demonstrates that a supplier has standardized procedures for process control, documentation, and corrective actions.

- ISO/ASTM 52900 Series: Sets specific guidelines for terminology, testing, and process validation in additive manufacturing. Requesting compliance or familiarity indicates supplier maturity in 3D printing.

- Industry-Specific Standards:

- Automotive: IATF 16949, CE Marking (for Europe), E-Mark (for electrical components), and homologation as required.

- Medical Devices: ISO 13485 QMS, FDA 21 CFR 820 (for US), CE (Europe), SFDA (Middle East).

- Oil & Gas/Industrial: API Q1/Q2 for critical components.

- Aerospace: AS9100–specific traceability and process validation protocols.

- Regional Nuances: Buyers in Africa or the Middle East should be aware that local regulatory acceptance (such as ECAS in the UAE, SONCAP in Nigeria) may require documentation in addition to international marks.

Key QC Checkpoints and Practices

- Incoming Quality Control (IQC): Inspection of raw materials and consumables upon delivery: verifying certificates, testing powder or filament quality, and checking for contamination or degradation.

- In-Process Quality Control (IPQC): Monitoring during printing—recording machine parameters, employing real-time sensors for temperature, printhead speed, or laser power. Machine logs are analyzed to flag deviations, reducing scrap and ensuring traceability.

- Final Quality Control (FQC): Post-processing checks for dimensional accuracy (using CMMs, laser scanning), surface finish, mechanical properties (tensile, flexural, and impact tests), and—where needed—non-destructive evaluation (NDT methods like X-ray, CT scanning for critical aerospace or medical parts).

Common Testing & Verification Methods

- Dimensional & Visual Inspection: Digital gauges and 3D scanners compare part geometry against CAD models.

- Mechanical Testing: Tensile, compression, and fatigue tests are done per ISO/ASTM protocols. For metals, hardness and microstructure analysis may be stipulated.

- Material Analysis: Chemical composition checks (e.g., via XRF or spectroscopy), porosity, and density testing for metal parts.

- Functional Testing: Especially for assemblies or end-use components, suppliers may conduct pressure, electrical, thermal, or lifecycle tests as dictated by the part spec or industry standard.

How B2B Buyers Verify Supplier Quality: Actionable Steps

Quality, consistency, and compliance are non-negotiable for global supply chains. Here’s how B2B buyers—whether from Mexico, Egypt, the EU, or the Middle East—can proactively ensure robust QC for 3D printed parts:

- Supplier Audits: Conduct on-site or virtual audits, reviewing QMS documentation, equipment calibration logs, operator certifications, and process flow. Focus on traceability and process repeatability, especially if buying for regulated industries.

- Request for Detailed QC Reports: Insist on comprehensive batch or lot-specific documentation, including material certs, process parameters, in-process QC logs, inspection results, and corrective action reports.

- Third-Party Inspections: Use recognized entities (SGS, TÜV, Intertek) for independent inspection at critical stages—particularly final inspection and pre-shipment—ensuring objective validation for cross-border orders.

- Witness Sampling & Testing: For high-risk or high-value parts, arrange to witness destructive/non-destructive testing or to receive representative part samples from the production run.

- Compliance Documentation: Clarify up-front which certifications and declarations of conformity (CE, FDA, ECAS, etc.) are required for import, and confirm supplier capability to provide valid, up-to-date certificates.

Unique Considerations for International B2B Buyers

- Regulatory Acceptance Varies by Country: A CE-marked part may need additional certification for legal import or use in Brazil, Egypt, or Saudi Arabia. Early engagement with local regulatory agencies accelerates clearance and avoids border issues.

- Language & Documentation: Ensure all quality documentation, certificates, and test reports are available or translated in the required language (Spanish, French, Arabic, etc.) to meet local customs and legal requirements.

- Traceability and Aftermarket Support: For long-term supply contracts or spare parts, prioritize digital traceability and supplier commitment to support re-certification, technical queries, and documentation needs over the product lifecycle.

Takeaway:

3D printed part manufacturing is a disciplined, multi-stage process, with quality assurance heavily reliant on adherence to international standards, rigorous QC checkpoints, and verifiable documentation. Buyers in Africa, South America, the Middle East, and Europe must implement robust supplier verification steps, ensure regulatory alignment, and demand transparency to mitigate supply risks and guarantee reliable, compliant products in their markets.

Related Video: Product Design & Manufacturing Collection workflows: Factory

Comprehensive Cost and Pricing Analysis for 3d printed part Sourcing

Breakdown of Key Cost Components

Sourcing 3D printed parts involves a distinct set of cost factors compared to traditional manufacturing. Understanding these components is crucial for international B2B buyers seeking value, reliability, and agility.

-

Raw Materials: Costs can vary significantly based on polymer, resin, or metal powders. Metal AM materials (e.g., titanium, stainless steel) are notably pricier than plastics, while specialty engineering polymers or composites further increase expenses.

-

Labor: Although 3D printing is less labor-intensive than subtractive manufacturing, critical labor is still needed for pre-print setup, part removal, post-processing, and final inspection. Skilled labor for design validation or support removal is a non-negligible cost.

-

Manufacturing Overhead: This includes machine depreciation, facility upkeep, software, and energy costs. Advanced AM equipment (e.g., DMLS, MJF) can be expensive to maintain, and utilization rates greatly impact per-part overhead allocation.

-

Tooling: One of 3D printing’s strengths is minimal or zero tooling for most parts. However, some finishing (jigs or fixtures for post-processing) may be needed, particularly for tighter tolerances or large production runs.

-

Quality Control (QC) & Certification: Inspection, material traceability, and documentation for compliance (ISO, ASTM) introduce additional costs—essential for industries like medical, automotive, or aerospace.

-

Logistics: While AM supports local or regional printing, international buyers should consider intra-regional shipment, customs fees, and delivery insurance when not sourcing locally.

-

Supplier Margin: Margins reflect supplier expertise, technology investments, and service levels (e.g., engineering support, digital inventory).

Primary Pricing Influencers

A variety of factors drive the final price per part, often with greater nuance than conventional production. The most impactful include:

-

Order Volume/MOQ: Unlike injection molding, 3D printing lends itself well to low or mid-volume runs, but larger quantities can still bring per-unit cost reductions due to batch optimization and machine efficiencies.

-

Part Specifications & Customization: Complex geometries, thin wall sections, internal channels, or custom finishes can result in increased printing time or post-processing costs. Clear communication of tolerances and critical features improves quotation accuracy.

-

Material Selection: High-performance materials drive up costs—metal powders and engineered polymers command higher base prices and may involve more challenging print parameters or certification.

-

Quality & Certifications: Demanding surface finishes, mechanical testing, or formal certifications add cost. For export to regions like the EU or Middle East, ensure relevant compliance is quoted upfront.

-

Supplier Location & Capabilities: Sourcing from suppliers close to your region (e.g., Europe for EU buyers, the Middle East for GCC buyers) can reduce lead times and freight. Suppliers with advanced process controls or digital inventory offer additional agility, sometimes at a premium.

-

Incoterms & Delivery Terms: Whether prices are quoted ex works (EXW), free on board (FOB), or delivered duty paid (DDP) impacts total landed cost. Hidden charges—customs duties, VAT, insurance—can vary by destination.

Practical Buyer Insights for International Sourcing

-

Negotiate Transparently: Request detailed, line-item quotations. Understanding each cost driver allows for more informed negotiation—especially for logistics, material surcharges, or premium post-processing.

-

Emphasize Total Cost of Ownership (TCO): Consider not just unit price, but costs over the product lifecycle (spare parts, local support, quality failures, and potential for digital inventories or design updates).

-

Leverage Regional Hubs: Owing to recent global disruptions and logistics uncertainties, assess if suppliers can print near your market to minimize shipping time, lower customs exposure, and speed up delivery—especially critical for buyers in Africa, South America, or MENA regions.

-

Customization Does Not Always Mean Expensive: For small- to medium-lot custom parts, AM is often cost-competitive compared to traditional routes, as tooling/setup is minimized. For large orders, balance between 3D printing and conventional manufacturing may be necessary.

-

Beware of Hidden Costs: Clarify post-printing requirements such as finishing, painting, or mechanical testing. Ensure QC and documentation (especially for regulated sectors) are included, avoiding unwanted surprises on final invoice.

-

Monitor Exchange Rates and Duties: Currency volatility and tax regimes vary by country; safeguard against fluctuations by discussing payment terms and considering hedging if ordering in foreign currency.

Disclaimer: The above insights outline typical cost structures and pricing factors in 3D printed part sourcing but are indicative only. Actual pricing will vary depending on supplier, region, order specifics, and market dynamics. Always obtain detailed quotes and clarify terms prior to finalizing any order.

Spotlight on Potential 3d printed part Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘3d printed part’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

14 Leading 3D Printing Companies As Of 2025 (www.rankred.com)

Representing a curated group of market leaders, the “14 Leading 3D Printing Companies As Of 2025” encompasses pioneering firms across North America, Europe, and Asia that together drive over 40% of global additive manufacturing revenue. This cohort includes legacy innovators like Stratasys and Desktop Metal, specializing in FDM and high-speed metal/resin printing, as well as agile disruptors and renowned desktop brands. Their strengths lie in advanced industrial part production for key sectors such as automotive (23%+ of market demand), aerospace, healthcare, and construction—delivering components ranging from certified aerospace-grade titanium parts to intricate medical devices.

Most member companies operate internationally, with strong supply chain integration and proven export capabilities into emerging markets across Africa, South America, and the Middle East. Many are recognized for compliance with global quality standards and invest in end-to-end digital workflows for consistent part validation. Their broad portfolio makes them well-suited for international B2B buyers seeking reliable and scalable 3D printed part solutions from established industry leaders.

18 3D Printing Companies in the World (www.imarcgroup.com)

The group of top-tier 3D printing companies featured by IMARC reflects a global cohort specializing in advanced additive manufacturing solutions for industrial B2B buyers. These market leaders are deeply invested in R&D to deliver highly differentiated, complex 3d printed parts, with strengths spanning biomedical components (such as prosthetic parts using bio-compatible materials) and precision metal parts for aerospace and automotive sectors. Notable production capabilities include binder jetting and other metal 3D printing technologies that help reduce lead times and overall costs—key factors for B2B clients prioritizing reliable, localized manufacturing and efficient supply chains. These companies often adhere to internationally recognized quality and manufacturing standards and demonstrate proven experience supporting global markets, including Africa, LATAM, the Middle East, and Europe. Their broad portfolio and technological leadership make them strategic partners for organizations seeking scalable 3D printed part solutions worldwide.

Manufactur3Dmag (manufactur3dmag.com)

Manufactur3Dmag positions itself as a leading information and business resource within the global 3D printing ecosystem, with a notable presence in India and insights spanning worldwide markets. While primarily an industry platform, Manufactur3Dmag deeply engages with top manufacturers, service providers, and solution vendors specializing in 3D printed parts across diverse sectors, including healthcare, automotive, and industrial manufacturing. Their extensive coverage and participation in key global events such as Formnext Asia indicate significant knowledge of both established and emerging international supply chains.

For B2B buyers, Manufactur3Dmag offers market intelligence, access to reputable manufacturers, trends analysis, and detailed insights into advanced additive manufacturing capabilities—such as rapid prototyping, customized parts production, and the latest industrial standards. Though direct manufacturing certifications or proprietary technologies are not specified, their curated network and up-to-date market data provide a reliable gateway for buyers seeking vetted suppliers, especially for organizations in Africa, South America, the Middle East, and Europe looking to mitigate supply chain risks and accelerate procurement.

Quick Comparison of Profiled Manufacturers

| Manufacturer | Brief Focus Summary | Website Domain |

|---|---|---|

| 14 Leading 3D Printing Companies As Of 2025 | Leading global industrial 3D printing consortium. | www.rankred.com |

| 18 3D Printing Companies in the World | Global leaders in industrial 3D printed parts. | www.imarcgroup.com |

| Manufactur3Dmag | Global 3D printing insights, supplier connections. | manufactur3dmag.com |

Essential Technical Properties and Trade Terminology for 3d printed part

Key Technical Specifications for 3D Printed Parts

B2B buyers evaluating 3D printed parts must focus on several technical properties that directly impact quality, supply chain efficiency, and compliance—especially when sourcing across diverse regions such as Africa, South America, the Middle East, and Europe.

1. Material Grade & Type

The choice of material—ranging from engineering polymers (like PA12, ABS, PEKK) to advanced metals (such as titanium, stainless steel, or Inconel)—determines a part’s mechanical, thermal, and chemical properties. For international buyers, specifying material grade ensures compatibility with desired application standards, durability in local environments, and regulatory compliance. Always require certificates of conformance or material traceability, especially when operating in sectors with stringent safety or environmental requirements.

2. Dimensional Tolerance

Tolerance defines the permissible variation in a part’s dimensions (e.g., ±0.1 mm). Tight tolerances are critical in industries like automotive or aerospace to guarantee part interchangeability and functionality. For decentralized manufacturing and cross-border sourcing, clear tolerance requirements help avoid downstream compatibility issues, minimize costly rework, and support consistent quality regardless of where parts are made.

3. Surface Finish & Roughness

Surface quality impacts both aesthetics and performance (e.g., wear, friction, hygiene). 3D printed parts may come as-printed (with visible layer lines) or undergo post-processing (machining, polishing, coating). Specify required Ra (roughness average, in µm) or finishing processes to ensure delivered parts meet application needs—vital for medical devices, consumer products, or sealing surfaces.

4. Mechanical Strength & Load Capacity

The strength of a 3D printed part (tensile, flexural, impact) depends on material, print process, and part orientation. International buyers must align specified strength benchmarks (e.g., minimum tensile strength in MPa) with end-use requirements. Requesting mechanical property data allows you to compare suppliers objectively and validate parts for structural applications.

5. Heat and Chemical Resistance

Sectors like oil & gas, food processing, or transport often require parts to endure heat, solvents, or corrosive agents. Clearly define any required thermal performance (operating temperature range) or resistance to chemicals, as these properties vary significantly between different 3D printing materials and processes.

6. Certification & Compliance

Certain applications (medical, aerospace, automotive) demand certified parts—compliant with standards like ISO 9001, AS9100, or FDA. Ask suppliers about available certification, documentation, and traceable production records to de-risk sourcing and facilitate import/export across regulated environments.

Essential Industry Terms for International B2B Buyers

Understanding core 3D printing and trade terms is crucial for clear communication, aligned expectations, and sound contracting.

-

OEM (Original Equipment Manufacturer):

Refers to the company that originally manufactures parts or products, as opposed to third-party or aftermarket suppliers. In global B2B, knowing whether you’re dealing with an OEM or a contract manufacturer can impact warranty, quality control, and IP protection. -

MOQ (Minimum Order Quantity):

The smallest number of parts a supplier is willing to produce per order. 3D printing often allows for lower MOQs than traditional manufacturing—a strategic advantage for buyers seeking small runs, spares, or rapid product iterations without overstocking. -

RFQ (Request for Quotation):

A formal procurement document sent to suppliers to obtain price, lead time, and technical offer for specific part requirements. A well-structured RFQ with detailed specs (material, tolerance, quantity) streamlines supplier selection, especially across multiple countries or new markets. -

Incoterms (International Commercial Terms):

Globally recognized rules that define responsibilities between buyers and sellers regarding shipping, insurance, customs, and risk. Examples include CIF (Cost, Insurance, and Freight) and DDP (Delivered Duty Paid). Understanding Incoterms ensures that both parties are clear on logistical obligations and cost divisions—crucial when managing international shipments of time-sensitive 3D printed parts. -

Lead Time:

The total time from order placement to delivery at your site. As 3D printing enables local or on-demand production, negotiating realistic lead times—based on print volume, post-processing, and shipping—can significantly improve inventory management and responsiveness. -

ITAR/EAR Compliance (for Export Regulations):

In certain countries, like the USA, 3D printed parts for defense or sensitive industries may fall under export control rules (International Traffic in Arms Regulations, Export Administration Regulations). For cross-border B2B transactions, clarify whether parts are subject to such controls to avoid legal or customs complications.

By mastering these technical properties and trade terms, B2B buyers across global markets can confidently source 3D printed parts that align with their quality requirements, budget constraints, and regulatory obligations—paving the way for agile, resilient, and transparent supply chains tailored to today’s smart manufacturing landscape.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 3d printed part Sector

Market Overview & Key Trends

3D printing, or additive manufacturing (AM), has rapidly evolved from a niche prototyping tool into a mainstream production technology, fundamentally reshaping global sourcing and manufacturing models. For international B2B buyers—particularly those operating in Africa, South America, the Middle East, and Europe—recent disruptions in global logistics, supply chain vulnerabilities, and rising transportation costs have intensified the focus on agile, decentralized manufacturing solutions. The shift toward localized production, powered by 3D printing, enables companies to bypass supply bottlenecks, reduce lead times, and maintain better control over product quality and intellectual property.

Key drivers influencing the market include technological advancements in printer hardware and materials, growing adoption of digital supply chains, and demand for rapid product customization. Regions like Egypt and Mexico increasingly leverage AM to meet local industry demands for automotive, industrial, and medical device components, especially where conventional supply routes are unreliable or expensive. B2B buyers should monitor the emergence of digital part inventories and on-demand, distributed production models that can significantly lower inventory costs and accelerate time-to-market.

On the sourcing front, buyers are increasingly turning to suppliers that demonstrate robust process standardization—such as compliance with ISO/ASTM standards for additive manufacturing—and offer traceable, repeatable production quality. The widespread adoption of industrial-grade 3D printing methods, including Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), and Multi Jet Fusion (MJF), further enables international buyers to specify and source complex end-use parts more confidently. Participation in global platforms and trade shows, such as Formnext, provides strategic opportunities for keeping abreast of the latest supplier capabilities, materials, and digital workflow innovations.

Sustainability & Ethical Sourcing in B2B

As corporate sustainability drives grow stronger worldwide, the environmental profile of 3D printed parts is gaining significant attention in B2B purchasing decisions. Additive manufacturing offers notable eco-friendly advantages: it minimizes material waste through near-net-shape production, reduces the need for energy-intensive machining, and supports lighter, optimized geometries for improved product performance and lower emissions, especially in transportation-related industries.

Equally important for B2B buyers today is the assurance of an ethical, transparent supply chain. International partners increasingly seek out suppliers certified under global standards such as ISO 14001 (Environmental Management) and those adhering to recognized lifecycle assessment (LCA) practices. The use of recycled or bio-based printing materials—such as recycled polymers and metal powders—further positions 3D printed parts as a lower-impact alternative to traditional subtractive fabrication.

Sourcing from providers with robust traceability protocols and digital tracking of raw materials and processes helps buyers meet both regulatory requirements and customer expectations regarding product provenance. Partnering with local or regional AM bureaus can also reduce transportation emissions and support community-based economic development, aligning procurement strategies with broader ESG goals. As sustainability reporting becomes a competitive differentiator, it is advisable to conduct thorough supplier assessments and request documentation of ‘green’ initiatives, such as closed-loop material handling and renewable energy usage in production facilities.

Brief Evolution/History of 3D Printed Parts

The origins of 3D printing in industrial applications date back to the late 1980s, primarily as a rapid prototyping technique for visualizing product designs. Over the following decades, advancements in material science and printer precision transformed AM from a design support tool into a robust platform for functional part production. By the mid-2010s, aerospace, automotive, and healthcare industries integrated 3D printing for both tooling and end-use components, unlocking new possibilities in lightweighting, complex geometries, and mass customization.

Today, industrial-scale 3D printing systems rival traditional manufacturing in terms of mechanical properties, surface finish, and throughput, bridging the gap between one-off prototyping and high-mix, low-volume production. This rapid evolution, accelerated by digital workflows and Industry 4.0 integration, now enables global B2B buyers to source high-performance, certified parts with unprecedented agility and geographic flexibility.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of 3d printed part

-

How can I effectively vet and select international suppliers for 3D printed parts?

Begin by assessing suppliers’ experience with industrial 3D printing, proven track record in your target sector, and transparency around manufacturing processes. Request case studies, references, and samples demonstrating consistent quality. Evaluate their certifications (ISO, ASTM, local equivalents) and ability to offer traceability. For buyers in Africa, South America, and other emerging markets, prioritize partners with experience in cross-border logistics and compliance with both exporting and importing country regulations. Virtual audits or digital factory tours can further validate a supplier’s capabilities before committing. -

What customization options are available when sourcing 3D printed parts internationally?

3D printing excels at complex, customized geometries—including adaptations for local operating conditions. Reputable suppliers can quickly iterate on your CAD files or help with design optimization for cost, strength, or regulatory needs. Discuss specific requirements such as material type (plastics, metals, composites), surface finish, and color. For tiered or on-demand production, ensure your supplier can manage design changes without costly tooling resets, and confirm their data security protocols for proprietary designs—especially if IP sensitivity is important in your region. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for B2B 3D printed part orders?

Unlike traditional manufacturing, 3D printing often allows for very low or even zero MOQs, making it ideal for small batches or custom components. Lead times vary by material, complexity, and supplier workload, but are generally much shorter than injection molding—ranging from a few days to a few weeks. For international orders, factor in potential customs delays. Payment terms commonly include deposits at order and balance upon pre-shipment inspection, but options like letters of credit or escrow are advisable for cross-border transactions, especially in markets with less established supplier relationships. -

How can I ensure quality assurance and compliance with certifications and standards?

Request detailed documentation demonstrating adherence to relevant industry standards (e.g., ISO 9001, ISO/ASTM 52900) for both processes and materials. High-quality suppliers will offer inspection reports, material property certificates, and full traceability throughout the production chain. For critical applications (aerospace, automotive, medical), ask about batch testing, process validation, and compliance with local or international regulatory requirements. Engage third-party inspection services if feasible, particularly when importing into regulated markets such as the EU or when sourcing from new suppliers. -

What are the key logistics considerations when importing 3D printed components internationally?

Identify whether your supplier has established experience with global shipping and can provide reliable tracking, insurance, and customs documentation (commercial invoice, certificate of origin, HS codes). For buyers in Africa, the Middle East, and South America, clarify Incoterms to define responsibilities for freight costs, duties, and risk transfer. Factor in potential port congestion and local regulation or certification requirements. Consider suppliers with distributed manufacturing networks or local production partners to reduce shipping time and cost, especially for urgent or high-volume needs. -

How do I manage potential disputes or non-conforming parts in international transactions?

Negotiate clear contracts outlining specifications, acceptable tolerances, inspection criteria, and dispute resolution mechanisms (ideally referencing international arbitration bodies). Use detailed purchase orders referencing specific quality benchmarks and include provisions for replacement, refund, or credit for defective parts. Regular status updates and quality checks—ideally including pre-shipment inspection—reduce surprises upon arrival. For large or strategic orders, consider payment structures that retain a portion of payment until final acceptance of goods at your site. -

What strategies can I use to minimize supply chain risks when sourcing 3D printed parts globally?

Diversify your supplier base—consider both global and local partners or those with a distributed manufacturing network. Seek suppliers with robust digital production management, real-time monitoring, and contingency plans for material shortages or shipping delays. For regions prone to supply chain disruptions, such as parts of Africa or South America, prioritize partners with demonstrated flexibility and strong documentation of their supply chain transparency and traceability. Regular communication and digital documentation will further enhance responsiveness to unexpected events. -

Are there regional or cultural factors I should be aware of when dealing with 3D printed part suppliers?

Local business practices, language barriers, and regulatory nuances can all influence the sourcing process. Establish relationships with bilingual account managers where possible, and be aware of local holiday calendars that might impact production or shipping. Some markets place strong emphasis on in-person relationships; when feasible, consider visiting key suppliers or meeting at international trade shows. Ensure contracts and technical drawings use internationally recognized terminology and measurement units for clarity, and consult with local trade advisors to ensure compliance with import/export regulations in both your country and the supplier’s.

Strategic Sourcing Conclusion and Outlook for 3d printed part

As global supply chains face continued volatility, 3D printed parts present B2B buyers with a transformative opportunity for agility, resilience, and competitive advantage. Key takeaways are clear: additive manufacturing (AM) enables faster lead times, streamlined logistics, and localized production, sharply reducing the risks associated with traditional sourcing models. For buyers in regions such as Africa, South America, the Middle East, and Europe, this means faster response to market demands and less exposure to geopolitical disruptions or transport delays.

Strategic sourcing is now more critical than ever. By leveraging AM, organizations can ensure repeatability across distributed sites, access a broader range of materials and technologies, and minimize inventory costs through on-demand production. Investing in robust supplier relationships, insisting on quality standards, and adopting traceability protocols will be essential for sustained success in this evolving landscape.

Looking forward, the integration of 3D printing into smart manufacturing systems promises even greater efficiencies and flexibility. Now is the time for international B2B buyers to reevaluate their sourcing strategies, deepen partnerships with AM innovators, and explore pilot projects that deliver immediate value. Embracing these changes will not only safeguard supply chains, but also unlock new growth possibilities—positioning your organization at the forefront of next-generation manufacturing.