Introduction: Navigating the Global Market for abs parts

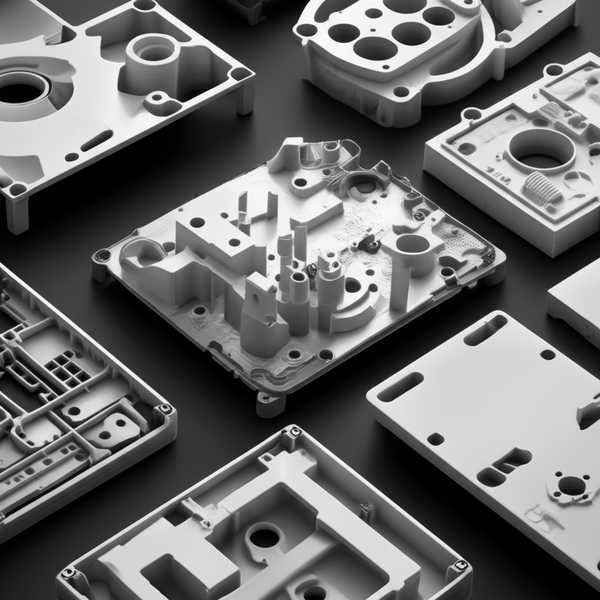

Acrylonitrile Butadiene Styrene (ABS) parts have rapidly become indispensable components in diverse industries, powering advances from automotive innovations to precision medical devices and next-generation consumer electronics. Their unique blend of mechanical strength, impact resistance, design flexibility, and cost-efficiency makes ABS parts a prime choice for manufacturers and suppliers seeking a competitive edge in a globalized market. For businesses in Africa, South America, the Middle East, and Europe, the ability to reliably source and integrate high-quality ABS parts is a strategic imperative—shaping product quality, regulatory compliance, and cost structures.

Navigating the global market for ABS parts, however, presents complex challenges. With evolving product standards, an expanding array of suppliers, advancements in prototyping and manufacturing technologies, and regional pricing variations, B2B buyers must adopt a methodical, informed approach to make smart procurement decisions. As cross-border partnerships multiply and expectations for quality and traceability rise, the risks and opportunities in ABS part sourcing have never been greater.

This comprehensive guide delivers actionable insights for international B2B buyers, empowering you to:

- Understand the Spectrum of ABS Parts: Explore key types, applications, and industry-specific use cases.

- Evaluate Material Choices and Technical Specifications: Compare grades, additives, and finishing options that impact performance and compliance.

- Decode Manufacturing & Quality Assurance Processes: Discover best practices in prototyping, injection molding, CNC machining, 3D printing, and quality control strategies.

- Select and Vet Global Suppliers: Gain tools to identify reliable partners, assess certifications, and mitigate sourcing risks.

- Optimize Cost and Logistics: Uncover strategies for pricing negotiation, order quantity planning, and supply chain management.

- Analyze Market Dynamics and Trends: Stay ahead with insights into regional demand, regulatory shifts, and future opportunities.

- Resolve Common Buyer Challenges: Access clear responses to FAQs to streamline your decision-making.

Armed with this guide, international buyers can confidently evaluate suppliers, optimize their sourcing processes, and accelerate product innovation with quality-assured ABS parts tailored to global and regional needs.

Understanding abs parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Injection Molded ABS Parts | Mass-produced via injection molding; consistent quality; precise dimensions | Automotive interiors, electronic housings, toys | Cost-effective for large runs; setup costs high for custom designs |

| Customized ABS Prototypes | Rapidly developed using 3D printing or CNC; tailored geometry, fast turnaround | Product development, fit testing, pilot production | Fast and flexible; higher per-unit cost, limited production durability |

| ABS with Reinforcement Fillers | Enhanced with glass fiber, minerals, or other additives for strength and rigidity | Industrial equipment, structural components | Improved performance; usually higher cost, may reduce processability |

| High-Gloss / Aesthetic ABS Parts | Surface finishing for high gloss, color matching, or texturing; focus on appearance | Consumer electronics, appliances, display products | Attractive finish; prone to scratches, may add finishing costs |

| Overmolded & Hybrid ABS Components | Combined with other materials (rubber, metals) via overmolding or insert molding | Medical devices, tool handles, automotive controls | Enhanced function; complex manufacturing, longer lead times |

Standard Injection Molded ABS Parts

Standard injection molded ABS components represent the foundation of high-volume manufacturing. These parts deliver reliable dimensional accuracy and maintain robust physical properties, making them ideal for demanding B2B applications such as vehicle dashboards, electronic device enclosures, and consumer goods. For international buyers, particularly those handling scaling production or standardization across multiple locations, injection molded ABS ensures consistent results and cost efficiency. However, custom mold tooling requires up-front investment, best justified when purchasing large volumes.

Customized ABS Prototypes

Prototyping ABS parts using 3D printing or CNC machining empowers B2B clients to validate designs, test assemblies, and react swiftly to market or regulatory changes. Such prototypes are invaluable for R&D-intensive sectors, enabling product managers to demonstrate or iterate concepts before full-scale production. These parts excel in flexibility and speed but are costlier per unit and may not reflect final production performance. Buyers should view this type as a risk mitigation tool for pilot runs or when device validation precedes mass production.

ABS with Reinforcement Fillers

ABS parts with fillers such as glass fiber or mineral additives outperform standard ABS in challenging industrial settings where mechanical strength, stiffness, or dimensional stability are critical. These variants serve sectors like machinery, automotive structural inserts, and certain infrastructure applications. While the initial material and process costs tend to be higher, the trade-off is increased part longevity and a broader performance envelope. B2B purchasers should weigh these benefits against requirements for secondary processing and potential changes in product weight or finishing.

High-Gloss / Aesthetic ABS Parts

Where product appearance directly impacts consumer perception—such as in electronics, appliances, or branded display units—high-gloss or aesthetically treated ABS is indispensable. Special surface finishes, color matching, or texturing can be achieved through advanced molding or post-processing techniques. While these finishes elevate brand value and product distinctiveness, they may be more susceptible to handling damage and could increase overall procurement costs. Procurement teams should precisely specify finish quality and packaging requirements to safeguard product integrity in transit.

Overmolded & Hybrid ABS Components

Overmolded and hybrid ABS parts bring together the core strengths of ABS with the additional properties of materials like rubbers or metals, enhancing ergonomics, grip, or function. Typical use cases include medical device handles, automotive knobs, and insulated housings. These advanced assemblies demand close collaboration with manufacturing partners and often require sophisticated tooling. Expect longer lead times and more complex quality assurance, but the payoff is superior user experience and product differentiation in competitive markets. Buyers should align technical requirements with supplier capabilities early in the procurement process.

Related Video: The Anatomy of 6-Pack Abs: How They Work & How To Train Them

Key Industrial Applications of abs parts

| Industry/Sector | Specific Application of abs parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior trim, dashboards, and enclosures | Lightweight, durable, can be molded to design specs | Color matching, impact resistance, heat tolerance |

| Medical Devices | Equipment housings, surgical instrument parts | Sterilizable, precise, supports hygiene compliance | Regulatory certification, biocompatibility, traceability |

| Consumer Electronics | Device casings, protective shells | Attractive finish, protection of delicate internals | Surface quality, customization, assembly compatibility |

| Industrial Equipment | Machinery panels, gears, covers | High mechanical strength, customization options | Exact tolerances, chemical resistance, supplier reliability |

| Toys & Leisure | Durable toy components, helmets | Safety, longevity, high color vibrancy | Non-toxicity, certification, batch consistency |

Automotive Industry: Interior Trim, Dashboards, and Enclosures

ABS parts serve prominently in automotive manufacturing for producing interior panels, dashboards, and protective enclosures. Their durability and flexibility allow components to be customized for varying vehicle models, offering both impact resistance and design versatility. For B2B buyers in regions like Brazil, Indonesia, and Europe, sourcing from suppliers who can ensure precise color matching and stable heat performance is key due to climate and regulatory differences. Reliable local after-sales support and fast logistics enhance competitiveness in rapidly growing markets.

Medical Devices: Equipment Housings and Surgical Instruments

The medical sector relies on ABS parts for device housings and specific surgical tool components. ABS’s ability to be sterilized and fabricated into intricate shapes makes it indispensable for products requiring strict hygiene and compliance, such as diagnostic equipment or single-use surgical items. B2B buyers should prioritize suppliers with ISO or equivalent certifications, biocompatibility documentation, and robust traceability systems—particularly important for meeting European and Middle Eastern regulatory requirements and maintaining high market reputation standards.

Consumer Electronics: Device Casings and Protective Shells

ABS is a preferred choice for manufacturers of smartphones, tablets, and small appliances due to its ability to deliver an attractive, smooth finish without compromising structural protection. For international buyers, especially in fast-evolving markets in Africa and the Middle East, choosing ABS parts that allow for seamless assembly and color customization can enhance product differentiation. It’s essential to select partners who can provide consistent high-quality surface finishes and flexible order volumes to support dynamic consumer demands.

Industrial Equipment: Machinery Panels, Gears, and Covers

In industrial settings, ABS components are widely used for machine housings, panels, and even mechanical parts like gears—where moderate chemical resistance and dimensional stability are required. Their robust performance, even in demanding environments, helps manufacturers reduce downtime and maintenance costs. Buyers in Europe and emerging markets should emphasize precision and chemical compatibility when selecting sources, ensuring compliance with industrial standards and minimizing operational risks in harsh conditions often encountered in Africa or South America.

Toys & Leisure: Durable Toy Components and Helmets

ABS is famous in the toy industry (notably for LEGO bricks) and for protective leisure gear like helmets due to its unmatched toughness and vibrant color retention. SAFETY standards are paramount; thus, international buyers must ensure suppliers adhere to non-toxicity regulations, batch consistency, and relevant product certifications. This is particularly vital in exporting to the EU and Middle Eastern markets, where consumer protection regulations are stringent and product recalls can have significant commercial consequences.

Related Video: How ABS Works || Anti-Lock Braking System Explained || Single Channel and Dual Channel

Strategic Material Selection Guide for abs parts

When selecting materials for ABS parts in international B2B contexts, buyers must balance performance, compliance, application requirements, and supply chain realities. Below, we compare three commonly used material variants relevant to ABS-based component production: standard ABS, glass-filled ABS, and ABS alloys (including ABS/PC blends). An additional reference to recycled ABS is provided, reflecting increasing global sustainability requirements.

Standard ABS Resin

Key Properties:

Standard ABS (Acrylonitrile Butadiene Styrene) is prized for its high impact resistance, good dimensional stability, and moderate heat resistance (service temperatures up to ~93°C/200°F). It also offers ease of processing, supporting molding of complex geometries and tight tolerances.

Pros:

– Cost-effective for large-scale production

– Consistent quality and reliable sourcing

– Good mechanical strength and surface finish

– Widely compliant with international standards (ASTM D4673, EN ISO 2580, JIS K7202)

Cons:

– Limited continuous operating temperature (not for high-heat environments)

– Moderate UV and chemical resistance

– Not suitable for load-bearing structural parts under sustained stress

Application Impact:

Ideal for general enclosures, dashboards, medical device housings, and consumer electronics. In Africa and South America, consistent supply and affordability are critical; standard ABS is well supported by established logistics pipelines. For EU and Middle Eastern buyers, confirming REACH and RoHS compliance is vital due to regulatory stringency.

Glass-Filled ABS

Key Properties:

ABS reinforced with glass fibers delivers higher tensile and flexural strength, increased rigidity, and modestly enhanced heat resistance. This modification often comes with a slight reduction in impact resistance compared to unfilled ABS.

Pros:

– Improved mechanical stability for structural components

– Better dimensional control under load or thermal cycling

– Often meets higher safety and performance standards, ideal for automotive and industrial equipment

Cons:

– Higher cost than standard ABS

– More abrasive to tooling and can complicate manufacturing

– Cosmetic finishes may require extra processing

Application Impact:

Glass-filled ABS is suitable for mechanical supports, load-bearing brackets, and parts exposed to mechanical or thermal stress. For buyers in Brazil, the EU, and the Middle East, glass-filled variants can help meet automotive or industrial certification thresholds (e.g., ISO 1043/ASTM D6779). Transport costs may be slightly higher due to denser parts; sourcing from reputable suppliers with QC documentation is paramount for offshore buyers.

ABS Alloys & Blends (e.g., ABS/PC)

Key Properties:

ABS alloys, especially ABS/Polycarbonate (PC) blends, offer significantly increased impact resistance and higher heat deflection temperatures (up to ~110°C/230°F or more), while retaining much of ABS’s processability.

Pros:

– Outstanding toughness and resistance to thermal deformation

– Maintains strength at lower temperatures

– Enhanced flame retardance available (often compliant with UL94 V-0)

Cons:

– Higher material and manufacturing costs

– Processing may require tighter control (narrower window for injection molding)

– May be over-specified for standard applications

Application Impact:

Especially valued for ruggedized electronics, automotive safety components, and applications demanding both impact and heat resistance (e.g., power tool housings, medical device frames). For buyers in the Middle East or Africa where ambient temperatures can be high, these alloys add performance margin and reliability. However, buyers should ensure compliance with applicable product safety standards—especially when importing to the EU or selling to regulated sectors.

Recycled ABS

Key Properties:

Produced from post-industrial or post-consumer waste, recycled ABS can offer performance similar to virgin material depending on grade and supplier quality.

Pros:

– Lower environmental impact and potential for “green” certifications

– Lower cost in some markets

– Suitable for non-critical components

Cons:

– Greater variability in mechanical properties

– Traceability and consistent quality may be issues

– May not be acceptable for high-performance or medical applications

Application Impact:

Best for cost-sensitive, non-critical products—packaging, low-stress housings, internal brackets. EU buyers should verify suppliers meet EN/ISO recycled content standards; some South American markets also have incentives for recycled content. However, for regulated industries (medical, automotive), check if recycled grades meet all compliance requirements.

Material Selection Summary Table

| Material | Typical Use Case for abs parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Standard ABS Resin | Consumer electronics housings, medical device cases, automotive trim | Economical, easy to mold, widely available | Moderate heat/UV resistance; not for high-stress load | Low |

| Glass-Filled ABS | Structural supports, automotive/interior brackets, industrial gear housings | Enhanced mechanical strength and rigidity | Increased cost and tooling wear; more complex processing | Medium |

| ABS Alloys (e.g., ABS/PC Blends) | Ruggedized enclosures, safety-critical automotive and industrial parts | High impact resistance & thermal stability | High material and process costs; may require specialized equipment | High |

| Recycled ABS | Low-stress brackets, consumer packaging, internal parts | Lower environmental impact and/or cost | Varies in quality/properties; possible compliance limits | Low to Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for abs parts

Understanding the Manufacturing Lifecycle of ABS Parts

The production of ABS (Acrylonitrile Butadiene Styrene) parts is a strategically layered process, meticulously structured to ensure consistency, durability, and cost-effectiveness—factors critical for B2B buyers navigating international trade. ABS’s versatility enables its deployment across sectors from automotive and medical devices to industrial equipment and consumer goods. For international B2B buyers in Africa, South America, the Middle East, and Europe, appreciating the intricacies of the manufacturing process and the nuances of quality control can empower better sourcing decisions and risk mitigation.

Key Manufacturing Stages for ABS Parts

1. Material Preparation

The cycle begins with procurement of ABS resin pellets—often modified with additives such as glass fibers or flame retardants to match specific industry requirements. Material preparation includes drying (to remove residual moisture that could cause defects) and blending for homogeneity, which is crucial to ensure consistent mechanical and visual properties batch-to-batch.

Actionable Insight:

Request material certificates from suppliers verifying the grade of ABS used and any additives or modifiers, which is particularly important when regulatory compliance (such as RoHS or REACH) is critical for your market.

2. Forming and Molding

– Injection Molding: The dominant process for ABS parts, especially those demanding high precision and repeatability. Molten ABS is injected into bespoke molds under high pressure, allowing intricate geometries and tight tolerances.

– 3D Printing (FDM/SLA): Used for prototypes and low-volume custom parts; ideal for pre-production validation or fast design iteration.

– CNC Machining: Sometimes employed post-molding or for specialized components needing exacting tolerances or modification of molded blanks.

– Overmolding/Insert Molding: Combines ABS with other materials (such as metal inserts or elastomer overmolds) for enhanced functionality.

Actionable Insight:

Understand a supplier’s tooling capabilities, including their mold maintenance protocols—quality of molds directly affects consistency, surface finish, and dimensional accuracy of ABS parts, especially over high production volumes.

3. Assembly

Many ABS parts require downstream assembly—be it ultrasonic welding, gluing, or mechanical fastening. Assembly quality is paramount for functional modules (e.g., electronic housings or medical device casings).

Actionable Insight:

Ask for the assembly process documentation and inspect fixtures, jigs, and assembly line validation protocols as part of your supplier assessment.

4. Surface Finishing

Surface finishes range from matte, gloss, and textures to painting, metallization, or pad printing for branding. The finishing method can impact chemical resistance, wear, and appearance.

Actionable Insight:

For visible or tactile surfaces, request finish samples and a clear specification of surface quality—including color matching, gloss level, and permissible defects as per relevant international standards (e.g., ISO 1302 for surface finish).

Comprehensive Approach to Quality Assurance

International and Industry-specific Standards

- ISO 9001: Almost mandatory for exporters, this standard defines rigorous quality management system requirements and demonstrates process consistency.

- ISO 13485 (Medical Devices): Essential if parts are used in healthcare applications; assures compliance with strict traceability and safety protocols.

- IATF 16949: Critical for automotive components, ensuring process control and defect reduction.

- RoHS/REACH: For EU-bound parts, these address environmental compliance.

- CE Marking / UL Listing: Indicate conformity with EU safety, health, and environmental requirements or US safety standards, respectively.

Actionable Insight:

Request up-to-date copies of all relevant certificates—authenticated where possible—and verify their scope (does the certification cover your product’s exact category?).

Staged Quality Control (QC) Checkpoints

-

Incoming Quality Control (IQC):

All raw ABS materials, additives, and critical outsourced components are inspected upon arrival for batch traceability, purity, and compliance. -

In-Process Quality Control (IPQC):

Regular monitoring during production—launch tests for mold integrity, real-time visual inspections, dimensional checks during first-off and at intervals, and process parameter validation (temperature, pressure, cycle times). -

Final Quality Control (FQC):

Comprehensive end-of-line inspection, including aesthetic, dimensional, and functional tests. Sampling rates should adhere to international norms such as ANSI/ASQC Z1.4 or ISO 2859-1.

Testing Methods for ABS Parts

- Mechanical Tests: Tensile strength, impact resistance (e.g., Izod or Charpy tests), and flexural modulus to ensure durability.

- Thermal Testing: Heat deflection temperature and flammability checks, especially for electronic or automotive parts.

- Dimensional and Visual Inspections: Tight adherence to CAD drawings and cosmetic standards.

- Chemical Resistance: Evaluated if parts will be exposed to solvents or aggressive environments.

Actionable Insight:

For high-risk applications or regulated sectors, insist on documented test reports (including batch numbers and operator signatures) and request access to inspection equipment calibration records to confirm accuracy.

Verifying and Auditing Supplier Quality as an International B2B Buyer

1. Supplier Audits

Conduct remote or on-site audits to inspect quality systems, staff training levels, and verify compliance with documented procedures. Audit checklists should cover process controls, material traceability, and equipment maintenance.

2. Inspection Reports

Request comprehensive inspection reports—with photographic evidence and clear pass/fail criteria—for each production batch. For high-value or mission-critical orders, stipulate third-party inspections by accredited international agencies such as SGS, Bureau Veritas, or TUV.

3. Ongoing Quality Dialogue

Establish protocols for nonconformance reporting and corrective/preventive actions (CAPA). Regularly review QC performance metrics and consider quarterly review meetings (either virtual or in-person).

Actionable Insight:

For buyers in Africa, South America, the Middle East, and Europe, insist on bilingual documentation (preferably English and your local language), and ensure contracted Incoterms account for QC approval procedures and remedies for non-compliance.

Navigating Certification and QC Nuances Across Export Destinations

Regulatory requirements, quality expectations, and accepted product certifications can differ significantly by destination:

- Europe: CE marking, RoHS/REACH, and technical documentation in local languages.

- Middle East & Africa: Some nations require SASO (Saudi Standards), SONCAP (Nigeria), or local conformity marks—ensure your supplier can coordinate these certifications.

- Brazil and South America: Inmetro certification for certain products; port authorities may conduct random checks requiring full traceability and compliance evidence.

Actionable Insight:

Collaborate with your supplier early regarding export market requirements. Confirm that their QA department has experience managing compliance for your specific region, and factor in certification lead times when planning procurement.

By thoroughly understanding each stage of ABS part manufacturing and implementing a structured, regionally aware quality assurance regimen, B2B buyers can secure optimal outcomes—minimizing risk, ensuring compliance, and building resilient supply relationships across continents.

Related Video: China’s Top 5 Manufacturing and Mass Production Videos | by @miracleprocess

Comprehensive Cost and Pricing Analysis for abs parts Sourcing

Understanding the Cost Structure for ABS Parts

Successful B2B sourcing of ABS parts relies on a clear grasp of the complete cost structure, which allows for more effective negotiations, supplier benchmarking, and cost-optimized project planning. While specific ABS part costs vary by project, buyers from Africa, South America, the Middle East, and Europe should account for the following core cost components:

Key Cost Components

-

Raw Materials: The cost of ABS resin—often traded as a commodity plastic—varies based on global supply, grade (standard, flame-retardant, medical, etc.), color, and additives (such as glass-filling for extra strength). Market rates are subject to crude oil fluctuations.

-

Labor: Covers operations such as molding machine operation, assembly, trimming, and surface finishing. In lower-cost manufacturing regions, labor may appear minimal per part, but for labor-intensive components (secondary assembly, precision handles, multi-color parts), these costs can add up.

-

Manufacturing Overhead: Includes costs for equipment depreciation, utilities, maintenance, and indirect shop-floor labor. For precision or high-mix/low-volume production, overhead costs are typically distributed across smaller output, raising per-unit costs.

-

Tooling: Initial mold design and fabrication is usually the most significant upfront cost. Complex geometries, high-precision requirements, or rapid prototyping (e.g., 3D-printed molds) can sharply increase this investment. Tooling amortization strategies impact part unit pricing—especially for small MOQs.

-

Quality Control (QC): Spending on inspection, in-process testing (e.g., for medical-grade), and certifications (such as ISO, CE, or FDA-compliance) directly affects the end price, particularly for buyers demanding traceable and certified product batches.

-

Logistics: Shipping fees, insurance, export duties, and routing (air, sea, or multimodal) are substantial for international buyers. Bulk and consolidated shipments often lower costs but may impact lead time and inventory risk.

-

Supplier Margin: Final offered prices incorporate supplier markups, which reflect their operational scale, brand, service levels, and the competitiveness of local or global markets.

Critical Pricing Influencers

-

Volume and MOQ (Minimum Order Quantity): Higher order quantities nearly always yield lower per-unit pricing due to economies of scale and more efficient tooling amortization. Small and mid-sized buyers may face premiums or setup charges for low-volume runs.

-

Design Complexity and Customization: Highly customized ABS parts (multi-material inserts, special finishes, tight tolerances) require more advanced tooling, longer development cycles, and potentially additional QC—directly raising unit price.

-

Material Grade and Additives: Sourcing specialty ABS grades (UV-resistant, flame-retardant, reinforced) or parts with color-matching requirements typically commands a price premium over standard black or natural ABS.

-

Certifications and Compliance Requirements: Parts intended for medical, automotive, or electronics sectors often necessitate certified materials, process controls, and documented traceability—all of which increase costs.

-

Supplier Location and Capabilities: Sellers with proven track records, global clientele, or advanced technology may command higher prices but offer superior value via reliability, consistency, and quality assurance. Regional hubs (Asia, Eastern Europe) may offer more competitive base pricing, while local regulations, taxes, and logistics shape landed costs for Africa, South America, the Middle East, and Europe.

-

Incoterms: Choice of Incoterms (EXW, FOB, CIF, DDP, etc.) significantly affects landed cost calculations. DDP or CIF terms, for example, provide cost predictability but may be priced higher to cover risk, administration, and freight handling.

Actionable Tips for International Buyers

-

Negotiate Tooling and MOQ Terms: Seek suppliers open to flexible tooling amortization (spreading costs over larger orders or multiple projects) or those offering shared mold strategies for standard parts.

-

Specify Clear Quality Needs: Balance cost with required certifications and testing. Excessive requirements can inflate prices; focus on what is essential for market access and end-use safety.

-

Understand Total Cost of Ownership (TCO): Do not focus solely on ex-works or FOB pricing. Factor in logistics, duties, insurance, warehousing, and potential post-shipment defects or lead-time delays, especially when sourcing from geographically distant locations.

-

Benchmark Regional Price Variations: Suppliers in Asia might offer lower base manufacturing costs, but logistics and regulatory barriers can shift total landed costs. African, Middle Eastern, or South American buyers should request multi-scenario quotes (different volumes, Incoterms, or shipping modes) to clarify best value.

-

Leverage Supplier Competition: Solicit multiple quotes, transparently compare cost breakdowns, and negotiate for bundled services (e.g., assembly, surface finishing, packaging) to drive price efficiency.

-

Clarify Incoterm Responsibilities: Ensure all logistics-related costs and risks (from factory gate to your warehouse) are explicitly allocated per Incoterm in contracts to avoid surprise expenses.

Important Disclaimer

All cost and pricing insights above are indicative only. ABS parts pricing fluctuates with resin markets, supplier capacity, and global trade dynamics. Buyers should request tailored, up-to-date quotations, and perform due diligence to secure the most favorable terms for their unique business context.

Spotlight on Potential abs parts Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘abs parts’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Google (www.google.com)

Google is globally recognized primarily as a technology leader, but also serves as an advanced digital procurement platform, connecting B2B buyers to a comprehensive network of ABS parts manufacturers and suppliers. Through its search and business aggregation capabilities, Google enables international buyers in Africa, South America, the Middle East, and Europe to efficiently source ABS parts ranging from automotive components to industrial and consumer applications. While not a direct manufacturer, Google’s platform highlights vetted suppliers with established credentials, relevant industry certifications, and robust export experience. The search mechanisms support buyers seeking competitive pricing, diverse manufacturing capabilities, and partners with demonstrated compliance to global quality standards such as ISO 9001. Buyers benefit from rapid market intelligence, cross-border supplier discovery, and easy access to emerging and established supply chains worldwide.

Quick Comparison of Profiled Manufacturers

| Manufacturer | Brief Focus Summary | Website Domain |

|---|---|---|

| Global ABS parts sourcing & supplier discovery | www.google.com |

Essential Technical Properties and Trade Terminology for abs parts

Key Technical Properties of ABS Parts

Understanding the core technical properties of ABS (Acrylonitrile Butadiene Styrene) parts is fundamental for international B2B buyers. These properties directly impact performance, compliance, procurement, and end-market suitability—especially where standards, durability, and precision are critical for competitive trade.

1. Material Grade

Material grade specifies the formulation and intended use of ABS resin. Common categories include general-purpose, high-impact, flame-retardant, and medical-grade. Selecting the right grade ensures compliance with regulations (often strict in the EU or Middle East), meets durability expectations, and aligns with application-specific needs such as food safety or medical device standards.

2. Impact Resistance

One of ABS’s most valued traits, impact resistance reflects the material’s ability to withstand sudden shocks, vibrations, or drops. Applications in automotive or electronics, especially in regions where climate and infrastructure affect durability (e.g., rough transportation in Africa or Brazil), require parts with certified high-impact resistance to prevent premature failure and warranty issues.

3. Dimensional Tolerance

Tolerance defines the permissible variation in a part’s dimensions, often measured in millimeters or microns. Tight tolerances ensure compatibility during assembly and reliable functioning in complex products. For buyers sourcing precision-molded or engineered components, specifying tolerances helps avoid costly misfits or rejects in sectors like medical, automotive, or industrial equipment.

4. Heat Deflection Temperature (HDT)

This property measures the temperature at which ABS parts deform under pressure. The typical HDT for ABS is around 93°C (200°F). For B2B buyers, especially in electronics or appliances destined for hot climates (like the Middle East or parts of Africa), understanding HDT helps guarantee the part performs reliably under expected thermal loads without warping.

5. Surface Finish Quality

ABS can achieve various surface finishes—matte, gloss, textured—which affect appearance, tactile feel, and post-processing steps (e.g., painting or plating). A specified surface finish is particularly important for consumer electronics, automotive interiors, or branded products where aesthetics can influence market acceptance and pricing.

6. Chemical Resistance

ABS’s resistance to chemicals such as acids, alkalis, and certain solvents should be considered when sourcing parts for high-exposure environments (industrial, automotive, or medical). B2B buyers must align chemical resistance specifications with the anticipated operating environment to ensure product longevity and compliance with safety standards.

Common Trade and Industry Terminology

Familiarity with standard trade terms and industry jargon improves communication and negotiation efficiency when sourcing ABS parts globally. Clarifying these terms can prevent misunderstandings and streamline the procurement process.

-

OEM (Original Equipment Manufacturer):

Refers to a company that produces parts to be marketed or incorporated under another company’s brand. Buyers may request OEM ABS parts for compatibility with their own or third-party equipment, ensuring seamless integration and system performance. -

MOQ (Minimum Order Quantity):

This is the smallest number of units a supplier is willing to sell per order. Understanding MOQ is vital for cost control, inventory planning, and risk management, especially for buyers in emerging markets or those testing new suppliers. -

RFQ (Request for Quotation):

A formal invitation for suppliers to submit pricing, lead times, and specifications for required ABS parts. Issuing a clear RFQ accelerates supplier comparison and negotiation while reducing ambiguity about technical or regulatory requirements. -

Incoterms (International Commercial Terms):

Widely adopted rules that define the responsibilities of buyers and sellers for the delivery of goods. Typical Incoterms for ABS parts include FOB (Free On Board), CIF (Cost, Insurance and Freight), and DDP (Delivered Duty Paid). These terms directly affect pricing, risk transfer, insurance, and customs responsibilities—critical for cross-continental trade. -

Lead Time:

The period from order placement to delivery. For ABS parts used in time-sensitive supply chains (automotive, electronics), understanding and negotiating lead time helps minimize disruptions and maintain production schedules. -

Tolerance Stack-Up:

This refers to the cumulative effect of part tolerances when assembled. In precision B2B applications, such as medical or industrial devices, awareness of stack-up effects prevents fit and function issues during final assembly.

By prioritizing these key specifications and mastering essential trade terminology, international buyers can optimize sourcing decisions, improve supplier negotiations, and ensure successful importation and deployment of ABS parts across diverse markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the abs parts Sector

Global Market Overview and Key Sourcing Trends

The B2B market for ABS parts is experiencing significant shifts, driven by globalization, increased automation, and the expanding application of ABS across multiple industries. Fundamental strengths—such as ABS’s impact resistance, processability, and cost efficiency—continue to make it a preferred polymer in segments like automotive, consumer electronics, healthcare devices, and industrial equipment. For international buyers spanning Africa, South America, the Middle East, and Europe, understanding these market dynamics is critical for competitive procurement.

Global demand for ABS parts is being shaped by several key trends:

-

Reshoring and Diversified Sourcing: Recent supply chain disruptions and fluctuating trade policies have prompted many companies to diversify suppliers, often combining Asian manufacturing with regional partnerships closer to end-markets such as Brazil, Nigeria, and Turkey. This approach reduces lead times and mitigates risk.

-

Advancements in Manufacturing Technologies: The integration of rapid prototyping (3D printing), smarter injection molding, and CNC machining offers buyers greater flexibility and quicker iterations. For buyers in emerging markets, access to these services—especially via contract manufacturers—levels the playing field and allows for easier product customization.

-

Direct-to-Manufacturer Relationships: Digital B2B platforms and online sourcing hubs are empowering buyers to connect directly with ABS part producers, bypassing traditional intermediaries. This often results in better pricing transparency and increased agility in order fulfillment.

-

Focus on End-to-End Solutions: Suppliers are increasingly offering comprehensive packages that include design, prototyping, tooling, production, and even after-sales support. For buyers in regions with limited local technical expertise, these turnkey solutions minimize complexity and help ensure product reliability.

-

Region-Specific Trends: Buyers from resource-constrained African and Latin American markets often prioritize cost efficiency and access to smaller batch production. Meanwhile, European and Middle Eastern buyers may demand higher compliance with regulatory standards and documentation, influencing supplier selection criteria.

As the sector continues to mature, successful B2B procurement strategies now hinge on geographic diversification, increased use of digital sourcing tools, and leveraging suppliers’ value-added services. Staying attuned to these trends enables buyers to secure higher quality ABS parts at competitive costs while adapting to shifting market realities.

Sustainability and Ethical Sourcing Considerations

Growing environmental awareness and regulatory pressures are reshaping sourcing strategies for ABS parts. Stakeholders across the value chain increasingly expect not only reliable quality and performance, but also demonstrable commitments to sustainability and ethical practices.

Key sustainability and ethical sourcing considerations include:

-

Environmental Impact of ABS: Although durable and recyclable, virgin ABS is derived from petroleum-based resins, raising concerns about lifecycle emissions. International buyers are now examining suppliers’ efforts to reduce waste, enhance recycling initiatives, and minimize energy consumption during production.

-

Availability of Green ABS Materials: The ABS sector is seeing steady growth in the adoption of recycled or bio-based ABS resins. Some suppliers offer post-consumer recycled (PCR) ABS, while others invest in closed-loop recycling programs. Procuring eco-friendly ABS not only lessens environmental impact but can also help buyers meet evolving regulations and market expectations, especially in Europe and increasingly in Middle Eastern and African markets.

-

Ethical Supply Chains: Transparent and responsible supply chains are essential. Buyers should look for vendors adhering to international standards such as ISO 14001 (environmental management) or those certified by recognized sustainability labels. A growing number of procurement teams require declarations on ethical labor, traceability, and environmental stewardship from their partners.

-

Certifications and Compliance: Due diligence increasingly involves verifying material traceability, compliance with RoHS (Restriction of Hazardous Substances), REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), and other region-specific directives. Beyond regulation, voluntary certifications (such as UL Environment or cradle-to-cradle certifications) are indicators of a supplier’s commitment to continuous improvement in sustainability.

Action Points for Buyers:

– Request disclosure of suppliers’ sustainability initiatives.

– Prioritize suppliers with established recycling programs and green certifications.

– Negotiate supply agreements that emphasize ongoing improvement in eco-efficiency and transparency.

Evolution and Historical Context of ABS Parts in B2B

Acrylonitrile butadiene styrene (ABS) emerged in the mid-20th century as a breakthrough engineering plastic, quickly gaining traction due to its blend of mechanical strength, processability, and cosmetic appeal. Originally developed for automotive and consumer products, ABS’s unique advantages positioned it as the material of choice for applications requiring impact resistance and design versatility.

In B2B sectors, the evolution of ABS has been closely linked to advances in injection molding, enabling mass production of complex parts at scale. Over decades, ABS parts production has expanded from simple housings and toys to include precision medical devices, electrical enclosures, and industrial components. Today’s ABS industry is characterized by globalized supply networks, digital procurement, and a growing commitment to environmental stewardship, all of which present new opportunities—and challenges—for international buyers.

By closely monitoring these dynamic factors and adapting sourcing strategies, B2B buyers are better positioned to secure reliable, innovative, and sustainable ABS parts that meet evolving market and regulatory demands.

Related Video: Tariffs will cause ‘massive shock’ to U.S. cost of living and will reshape global trade: Expert

Frequently Asked Questions (FAQs) for B2B Buyers of abs parts

-

How can I effectively vet ABS parts suppliers for international B2B trade?

Thorough supplier vetting is crucial. Start by requesting business licenses, references, and documentation of previous export experience. Evaluate the supplier’s track record with global clients, particularly in your target regions. Ask for photos or videos of their production facilities, and consider third-party on-site inspections. Confirm that they comply with relevant international standards and certifications (e.g., ISO 9001, RoHS). Finally, review online ratings, trade show participation, and check for responsiveness during communications to gauge professionalism and reliability. -

Can ABS parts be customized to meet unique industry or regional requirements?

Yes, ABS parts are highly customizable in terms of color, finish, dimensions, and functional modifications. Share detailed drawings, CAD files, or prototypes with potential suppliers. Specify any required local or industry certifications for your market (such as CE for Europe or Inmetro for Brazil). Discuss options for additives (e.g., flame retardants, UV stabilizers, glass filling) to enhance material properties. Early involvement of your technical team and close collaboration with your supplier’s engineers is key to ensuring quality, compliance, and optimal performance. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for ABS parts?

MOQs vary widely—expect a minimum from hundreds for prototype runs to several thousand units for mass production. Lead times typically range from 4 to 8 weeks, depending on part complexity, tooling requirements, and order size. Negotiate clear payment terms; 30% down payments with balance upon delivery are common. For larger or repeat orders, suppliers may offer more flexible options like letters of credit or phased payments. Always clarify timelines (including for tooling and shipping) up front to align with your project schedules. -

What quality assurance processes and certifications should I require from ABS parts suppliers?

Ask suppliers about their quality control systems, such as ISO 9001 certification, in-house testing capabilities, and batch traceability. Require pre-shipment inspection reports and, if possible, third-party quality audits. For regulated sectors—medical, automotive, electronics—insist on documentation for material conformity (e.g., REACH, RoHS, FDA, CE). Specify acceptance standards (dimensional tolerances, surface finish, functional testing) in your purchase agreement to ensure delivered goods consistently meet your expectations. -

What are practical shipping and logistics considerations when importing ABS parts internationally?

Determine if your supplier offers Incoterms options suitable for your needs (e.g., FOB, CIF, DDP). Ask about their experience handling export documents—commercial invoices, packing lists, certificates of origin, and any required compliance certificates. Choose shipping methods (air, sea, or multimodal) based on your budget and timeline. Factor in import duties, VAT/GST, and local regulatory requirements for plastics. For Africa, South America, and remote regions, confirm the availability of reliable freight forwarding partners. -

How do I handle disputes or claims related to product quality or delivery delays?

Include clear terms in your purchase contracts regarding dispute resolution and remedies. Specify inspection and acceptance procedures upon receipt, as well as detailed non-conformance protocols (e.g., processes for reporting, evidence submission, root cause analysis). Engage in open dialogue to resolve issues early. When disputes can’t be settled mutually, utilize international arbitration (such as ICC or SIAC), which is recognized in global B2B commerce. Retain documentation and correspondences to support your position in any formal proceedings. -

What steps should I take to ensure regulatory and environmental compliance for ABS parts in different regions?

Laws around plastics and chemical substances differ greatly by region. In the EU, ensure REACH and RoHS compliance; for South America and Africa, check country-specific material safety data and local packaging requirements. For medical and electrical applications, verify relevant sectoral certifications. Ask suppliers for comprehensive compliance documentation and test reports. Stay updated on evolving regulations related to sustainability, extended producer responsibility, and recycling, as these can affect import eligibility and market acceptance. -

How can I optimize long-term supplier relationships to improve costs and security of ABS parts supply?

Develop multi-year contracts or preferred supplier agreements to secure better pricing and priority production slots. Invest in ongoing supplier development—such as sharing forecasts, participating in joint quality reviews, and collaborating on cost-reduction initiatives (e.g., design for manufacturability). Diversify your supplier base to minimize risk, but reward reliable partners with repeat business. Establish clear KPIs on quality, delivery, and communication, and review performance regularly for continuous improvement.

Strategic Sourcing Conclusion and Outlook for abs parts

As global industries continue to evolve, ABS parts remain indispensable for manufacturers seeking a balance between strength, cost efficiency, and design flexibility. For B2B buyers — particularly those in emerging markets across Africa, South America, the Middle East, and Europe — leveraging the advantages of ABS enables access to reliable solutions for sectors ranging from automotive to healthcare and consumer electronics.

Key considerations for successful ABS part sourcing include:

- Prioritizing Quality and Compliance: Partner with suppliers who demonstrate rigorous quality control, adhere to international standards, and offer traceability. This ensures your components consistently meet performance and regulatory requirements.

- Embracing Customization and Technology: Utilize suppliers offering advanced tooling, prototyping, and molding technologies. Custom solutions enable tailored products that address specific market and application needs.

- Evaluating Total Cost and Logistics: Beyond material price, assess the supplier’s ability to deliver at scale, offer stable lead times, and support efficient logistics—crucial for navigating import/export challenges in diverse regions.

- Sustainability and Innovation: Explore partnerships that invest in material innovations and sustainable practices to future-proof your supply chain.

Strategic ABS sourcing is not merely a procurement function—it is a driver of competitive differentiation and operational resilience. Now is the time to build partnerships with globally capable, quality-oriented suppliers. Proactively assess your sourcing strategy to capitalize on emerging technologies and dynamic markets, positioning your business for sustainable growth in a rapidly changing manufacturing landscape.