Introduction: Navigating the Global Market for acrylonitrile butadiene styrene clear

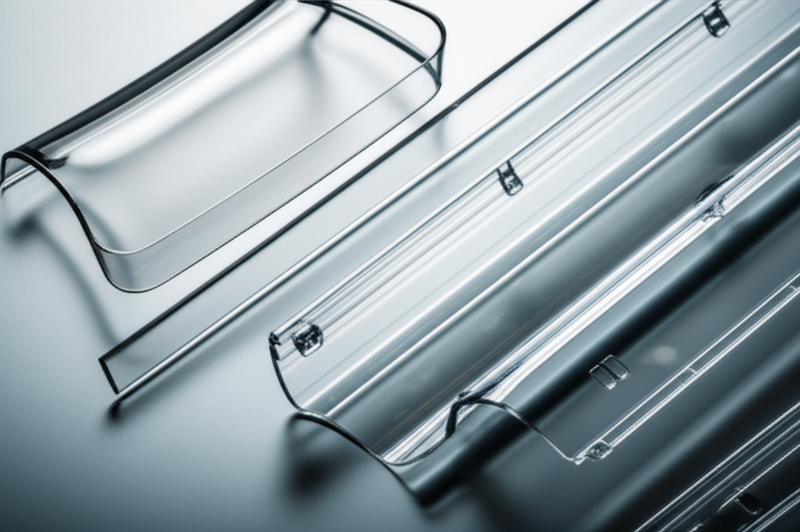

Acrylonitrile butadiene styrene clear (commonly known as clear ABS) is redefining product development, manufacturing, and supply chains across global industries. For B2B buyers in dynamic markets like Africa, South America, the Middle East, and Europe, the strategic selection and procurement of clear ABS is critical—not only for product quality and durability, but also for operational efficiency and competitive differentiation. As demand for specialized plastics continues to rise in sectors such as automotive, electronics, consumer goods, and construction, understanding the full landscape of clear ABS solutions has never been more essential.

Clear ABS stands apart for its unique balance of transparency, toughness, chemical resistance, and versatility, making it an indispensable material for applications where aesthetics and performance must go hand-in-hand. However, navigating the complexities of the international ABS market poses significant challenges: material grade selection, supplier verification, compliance with varied quality standards, price volatility, logistics, and adapting to local market expectations.

This comprehensive guide addresses these challenges head-on. It covers a wide array of topics vital to confident B2B sourcing, including:

- Types and grades of clear ABS—from general-purpose to high-impact formulations

- Material properties and application insight—detailed performance data tailored to industry needs

- Manufacturing and quality control best practices—benchmark standards and supplier vetting

- Supplier ecosystem mapping—including leading international and regional players

- Cost structures and price negotiation strategies

- Market trend analysis and procurement forecasts

- Frequently asked questions and troubleshooting tips

By weaving together technical expertise with actionable sourcing guidance, this guide empowers B2B buyers—whether in Egypt’s industrial zones, Brazil’s manufacturing hubs, France’s innovation corridors, or the Gulf’s growing consumer markets—to make informed, confident purchasing decisions. Get ready to unlock reliable, high-performance supply options and achieve greater value from your international ABS sourcing strategies.

Understanding acrylonitrile butadiene styrene clear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| General Purpose Clear ABS | Balanced clarity, good toughness, cost-effective | Displays, packaging, lighting covers, point-of-sale items | Affordable, easy to process; moderate clarity, limited UV/weather resistance |

| High Impact Clear ABS | Enhanced impact strength, maintains high transparency | Protective shields, safety panels, transportation parts | Superior durability, tough in cold climates; slightly reduced transparency, higher price |

| High Flow Clear ABS | Superior melt flow, excellent for complex/thin-walled parts | Medical device housings, intricate electronics, tubing | Fills complex molds, reduces cycle time; lower mechanical strength, costlier |

| UV-Resistant Clear ABS | Formulated for outdoor use, improved stability against sunlight | Outdoor signage, architectural panels, lighting fixtures | Withstands UV exposure, less yellowing; premium pricing, sometimes limited mechanical range |

| Flame Retardant Clear ABS | Meets fire safety standards, clear composition | Electronics enclosures, public transportation interiors | Improves fire safety compliance; potential minor loss of transparency, higher material cost |

General Purpose Clear ABS

General Purpose Clear ABS offers a strong balance between clarity, cost, and mechanical properties. Its versatility makes it a staple for applications needing moderate transparency but not specialized performance. B2B buyers benefit from its broad availability and straightforward processing, which supports efficient production for consumer products, displays, and protective covers. However, it may not be ideal for harsh outdoor or high-heat environments, as its weather and UV resistance is limited.

High Impact Clear ABS

High Impact Clear ABS is engineered for applications where both transparency and exceptional toughness are required. Its impact resistance stands out, even in low-temperature conditions, making it suited for safety panels, protective barriers, and high-stress environments such as transportation. Buyers in regions with extreme climates (e.g., parts of Africa or Eastern Europe) will value its durability. The trade-off is slightly reduced optical clarity and increased cost, but the material’s reliability often offsets these drawbacks for safety-critical projects.

High Flow Clear ABS

High Flow Clear ABS is optimized for precision molding, enabling efficient formation of complex, thin-walled, or detailed components. This variant is particularly appealing to buyers manufacturing intricate housings or medical and electronics parts, where dimensional stability and fine detail are crucial. While its enhanced flow reduces cycle times and can lower rejection rates, the mechanical properties may be somewhat compromised, and the per-unit cost is higher. Buyers should assess whether performance or design complexity takes precedence.

UV-Resistant Clear ABS

UV-Resistant Clear ABS incorporates additives to withstand prolonged exposure to sunlight, making it the material of choice for outdoor or architectural applications. Buyers serving the Middle East, North Africa, or Southern Europe—regions with high UV intensity—should prioritize this type to avoid yellowing or degradation in end products. While this variant reduces maintenance and replacement costs over time, it comes at a higher upfront price and may offer limited options regarding mechanical and processing properties.

Flame Retardant Clear ABS

Flame Retardant Clear ABS is designed for sectors requiring compliance with stringent flammability regulations, such as electronics, transport infrastructure, and public spaces. It provides peace of mind and regulatory alignment for B2B buyers supplying sensitive environments in Europe or globally. While delivering vital safety benefits, buyers should weigh the slightly reduced clarity and increased procurement cost against the critical need for fire-safe materials in their applications.

Related Video: What are Transformer Models and how do they work?

Key Industrial Applications of acrylonitrile butadiene styrene clear

| Industry/Sector | Specific Application of acrylonitrile butadiene styrene clear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive & Transport | Instrument cluster covers, lighting diffusers, interior panels | High impact resistance, transparency, design flexibility | Optical clarity, UV stability, compliance with automotive standards |

| Electrical & Electronics | Display panels, device casings, LED housings | Electrical insulation, aesthetic appeal, chemical resistance | Dimensional stability, flame retardancy, REACH/RoHS compliance |

| Consumer Goods | Transparent housings for appliances, protective gear, display items | Durable, visually attractive, cost-effective | Food-grade safety (if required), surface finish quality, colorability |

| Medical & Laboratory Equipment | Diagnostic device covers, test tube racks, sample holders | Chemical resistance, easy sterilization, clarity for monitoring | Biocompatibility, ISO certification, resistance to sterilization processes |

| Building & Construction | Transparent piping, guards, glazing alternatives | Lightweight, weather-resistant, high impact strength | UV/weather resistance, compliance with local building codes |

Automotive & Transport

Acrylonitrile butadiene styrene (ABS) clear is increasingly specified for automotive components where transparency and impact resistance are critical, such as instrument cluster covers, interior ambient light guides, and headlight diffusers. These applications demand materials that resist shattering while providing excellent optical clarity, enabling both functional displays and innovative lighting designs. For buyers in regions like Africa and South America, sourcing transparent ABS ensures longevity in diverse climates and enhances product aesthetics at a competitive cost. It is vital to evaluate UV stability and ensure conformity to sector standards such as ISO 9001 and specific OEM requirements.

Electrical & Electronics

Clear ABS is well-suited to manufacturing display panels, protective casings, and LED housings for a wide range of devices. The material’s exceptional electrical insulation and chemical resistance ensure performance in demanding environments. Transparent casing facilitates device monitoring and branding, while its moldability allows for complex designs at scale. International buyers, especially in the Middle East and Europe, should prioritize grades with robust flame retardancy, dimensional stability under thermal cycling, and compliance with REACH and RoHS regulations for export markets.

Consumer Goods

In the consumer products sector, clear ABS is used for transparent housings in appliances (e.g., blenders, mixers), protective visors, storage containers, and visually appealing display items. Its strength and ease of fabrication translate into long-lasting, attractive products at scale. For businesses supplying large retail chains in France or emerging e-commerce platforms in Egypt, food-contact suitability and consistent high-gloss finishes are critical. Buyers are encouraged to specify surface finish requirements and verify certifications for applications involving direct user contact.

Medical & Laboratory Equipment

In medical and laboratory settings, clear ABS is utilized for diagnostic device covers, test tube racks, and sample holders, where visibility and chemical resistance are paramount. The material is suitable for autoclaving and cleaning with standard laboratory reagents, facilitating sterility and safe observation of samples. Buyers from regional medical suppliers in Africa or South America should insist on grades with proven biocompatibility and documented ISO 13485 certification, ensuring the material will not compromise sensitive laboratory or clinical workflows.

Building & Construction

Construction and infrastructure sectors deploy clear ABS for components such as transparent piping, machine guards, and glazing alternatives in areas where glass may be too heavy or fragile. Its lightweight yet robust nature provides a practical advantage, especially in regions with high shipping costs or seismic activity. When sourcing for projects in the Middle East or Africa, it is crucial to request enhanced UV and weather-resistant formulations and to ensure the material satisfies relevant local construction standards and environmental requirements.

Related Video: Acrylonitrile Butadiene Styrene (ABS) Characteristics, Properties & Applications || ABS Polymer ||

Strategic Material Selection Guide for acrylonitrile butadiene styrene clear

When evaluating materials used for manufacturing or integrating acrylonitrile butadiene styrene (ABS) clear—with special relevance to buyers in Africa, South America, the Middle East, and Europe—it is crucial to balance optical clarity, mechanical performance, processing requirements, and cost-effectiveness. Various grades and alternative transparent polymers compete with or complement ABS clear in global supply chains. Below is an expert analysis of key materials commonly considered for clear ABS product manufacturing and substitution, highlighting critical technical and B2B sourcing factors.

1. Standard (General Purpose) Clear ABS

Key Properties:

Clear ABS is engineered by optimizing the composition and structure of the polymer to achieve transparency, maintaining the inherent toughness, dimensional stability, and moderate impact strength typical of ABS. It offers a moderate heat deflection temperature (HDT ~93–100°C), decent chemical resistance (suitable for dilute acids and bases), and reliable electrical insulation. Its light transmittance is generally lower than that of acrylic (PMMA) but adequate for many non-optical applications.

Pros & Cons:

Pros include reasonable durability, balanced toughness, cost-effectiveness compared to engineering-grade clear polymers, and good processability (injection molding, extrusion). Compared to opaque ABS, clear grades have slightly reduced impact resistance and increased susceptibility to UV-induced yellowing unless stabilized. They can also have slightly higher per-kg cost because of additional purification and blending steps.

Application Impact:

Clear ABS is widely used in displays, housings, light covers, and protective helmets requiring visibility. It is best suited for indoor or semi-sheltered environments due to limited weather resistance.

B2B Considerations:

For international buyers, clear ABS is commonly available to ASTM, ISO, and DIN standards. Compliance documentation and RoHS statements are typically needed for EU and Middle Eastern (e.g., Egypt, Saudi Arabia, France) buyers. Sourcing regional grades with UV stabilization is advisable for Africa and the Middle East, where sunlight exposure is intense. Supply chains are mature in Europe and emerging in South America, impacting procurement lead times and minimum order quantities.

2. Polycarbonate (PC)

Key Properties:

Polycarbonate is a premium transparent engineering plastic with superior impact strength, high HDT (~120–135°C), and outstanding optical clarity. It offers better resistance to repeated stresses and higher continuous use temperatures. Chemical resistance is moderate: PC is resistant to water and many acids, but not to solvents or alkalis.

Pros & Cons:

Its main advantages are exceptional impact toughness and clarity, making PC the standard for safety glazing, machine guards, and optical components. However, it is significantly more expensive than ABS clear, more susceptible to scratching, and often cannot be painted directly. Molding and extrusion require precise temperature control, increasing manufacturing complexity.

Application Impact:

PC is chosen for applications demanding durability and visibility, such as protective visors, transparent housings, and LED optics. It also performs better outdoors, especially when UV-stabilized.

B2B Considerations:

PC is readily available as an import or from multinationals with local compounding in Turkey, Egypt, France, and Brazil. Compliance with UL, EN, and relevant local fire and safety standards is crucial. For regions with volatile currency or logistics, PC’s higher price and longer lead times must be anticipated.

3. Polymethyl Methacrylate (PMMA, Acrylic)

Key Properties:

PMMA is renowned for optical transparency (transmits up to 92% of visible light), excellent surface gloss, and UV resistance. Its HDT (~85–100°C) is typically lower than PC but comparable to clear ABS. Mechanical strength is moderate; PMMA is stiffer but also more brittle and susceptible to cracking on impact.

Pros & Cons:

Key advantages include superior clarity, color versatility, and weatherability, making PMMA ideal for signage, glazing, and architectural applications. Its drawbacks center on fragility: poor impact strength, limited chemical resistance (swells in ketones, esters), and lower suitability for load-bearing or high-stress items.

Application Impact:

PMMA is favored for products where aesthetics and light transmission are critical but impact or load resistance can be compromised. It is not recommended for components subject to regular mechanical abuse or requiring dimensional accuracy under stress.

B2B Considerations:

Commonly sourced to ISO and DIN grades for Europe, and well-suited to Middle Eastern and African applications where UV stability is vital. Buyers must verify that PMMA resins or sheets meet local safety and emissions standards, especially for products used indoors or in food-contact scenarios.

4. Transparent ABS Blends (e.g., ABS/PC, ABS/SAN)

Key Properties:

Blended transparent ABS grades, such as ABS/PC and ABS/SAN, are engineered for optimized clarity, impact strength, and/or chemical resistance. ABS/PC offers improved heat and impact resistance compared to standard ABS, while ABS/SAN blends enhance optical clarity and chemical resistance.

Pros & Cons:

Blends deliver property profiles tailored for specific end uses. ABS/PC excels in demanding environments but at higher costs; ABS/SAN is often more chemically and optically stable but less tough. Both can complicate processing and require supplier technical assistance.

Application Impact:

They are preferred for cases where standard clear ABS inadequately balances clarity and performance, such as demanding medical housings, instrument covers, or cosmetic packaging.

B2B Considerations:

Buyers should specify targeted blend ratios and verify conformance to standards like UL or JIS. In regions like Africa and South America, actual local availability may vary, so advance inquiry and vendor qualification are required.

Summary Table

| Material | Typical Use Case for acrylonitrile butadiene styrene clear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Clear ABS (General Purpose) | Device covers, point-of-sale displays, light diffusers | Good balance of clarity, toughness, and cost | Limited UV/weather resistance and less optical brilliance than PMMA | Low to Medium |

| Polycarbonate (PC) | Safety lenses, protective visors, durable transparent panels | Superior impact strength and heat resistance | Higher price, scratches easily, picks up stress cracks from solvents | High |

| PMMA (Acrylic) | Glazing panels, signage, decorative displays | Highest clarity and surface gloss, UV resistant | Brittle, low impact strength, can craze/crack | Medium |

| Transparent ABS Blends (ABS/PC, ABS/SAN) | Cosmetic packaging, precision housing, instrument covers | Tailored property profiles, improved |

In-depth Look: Manufacturing Processes and Quality Assurance for acrylonitrile butadiene styrene clear

Clear acrylonitrile butadiene styrene (ABS) presents unique challenges and opportunities for buyers sourcing high-performance, transparent engineering plastic. Understanding the nuances of its manufacturing and quality assurance processes is essential for procurement professionals, especially when sourcing from diverse global regions. Below is a comprehensive, practical guide summarizing key stages, verification strategies, and standards relevant for B2B buyers.

Key Manufacturing Stages and Techniques

1. Material Preparation

- Resin Selection: Clear ABS typically utilizes specialized formulations with minimized butadiene content and fine-tuned copolymer ratios to enhance optical clarity. Impurities or subgrade raw materials can result in yellowing or haze, so sourcing certified, high-purity feedstocks is crucial.

- Additive Masterbatching: Optical-grade clarifiers and UV stabilizers may be blended to improve light transmission and weathering resistance. This process demands precise dosing and homogeneous mixing to avoid visual defects or uneven performance.

2. Melt Processing and Forming

- Extrusion/Compounding: The dry-blended material is compounded and pelletized under tightly controlled temperature regimes (usually 200–250°C). Due to sensitivity to thermal degradation—which would compromise clarity—tight controls and inert gas atmospheres are sometimes used for optical grades.

- Injection Molding or Extrusion: Final shaping is typically performed in high-precision injection molding machines or extrusion lines for sheets, rods, or custom profiles. For clear ABS, mold temperature, injection speed, and cooling rate are critical variables—improper control leads to flow marks, optical distortion, or internal stress.

3. Assembly & Fabrication (If Required)

- Secondary Operations: Processes such as CNC machining, ultrasonic welding, or adhesive bonding may be applied for assemblies. These must be conducted with care—excessive heat or stress during post-processing can cause crazing (microcracking), especially problematic for clear variants.

- Surface Coating/Finishing: In some applications, additional coatings (anti-scratch, anti-reflective) are applied. Coating uniformity, adhesion, and chemical compatibility with clear ABS require rigorous attention.

4. Finishing & Packaging

- Deflashing, Polishing, Cleaning: Post-molding, parts are carefully de-flashed and cleaned in dust-free zones. For transparent ABS, any contamination, particulate matter, or surface imperfection is particularly apparent and reduces product value.

- Protective Packaging: To prevent scuffing during transit, products are typically packed in soft, non-abrasive, anti-static materials—especially for optics, displays, or high-value medical components.

Quality Control Protocols in ABS Clear Manufacturing

International and Industry Quality Standards

- ISO 9001: Nearly all reputable manufacturers operate under ISO 9001-certified quality management systems. This ensures consistency, traceability, and continuous process improvement.

- Industry-Specific Standards: For applications in medical devices, electronics, or automotive, compliance with ISO 13485 (medical), IATF 16949 (automotive), CE marking (European Union), or other international certifications may be required. Ensure suppliers declare these standards in their documentation.

- Regional Requirements: Importers in Egypt, France, and other regulated markets should request conformity to local standards (e.g., EU RoHS, REACH) and understand any specific labeling or certification obligations.

Key Quality Control Checkpoints

- Incoming Quality Control (IQC): Inspections and material tests on every lot of incoming resin focus on melt flow index, color, and contamination. For clear ABS, haze, yellowness index, and absence of particulate contamination are prioritized.

- In-Process Quality Control (IPQC): During molding or extrusion, real-time monitoring of temperature profiles, pressure, and screw speeds is standard. Sample parts are checked visually and dimensionally at set intervals. Optical properties are periodically verified using haze meters and spectrophotometers.

- Final Quality Control (FQC): Before shipment, every batch undergoes comprehensive inspection including:

- Visual inspection for flow marks, air bubbles, surface inclusions, and transparency.

- Optical tests such as light transmittance and haze measurement (ASTM D1003 or ISO 13468).

- Mechanical tests for impact strength, tensile properties, and dimensional conformity.

- Thermal and chemical resistance testing to verify specification compliance.

Common Laboratory and On-site Testing Methods

- Spectrophotometry and Haze Testing: Evaluates optical clarity and color consistency.

- Melt Flow Index (MFI): Confirms processability and consistency between lots.

- Izod/Charpy Impact Testing: Confirms toughness critical for many end uses.

- Dimensional Analysis: Ensures tight tolerances for assemblies or precision components.

- Surface Quality Inspection: Microscopic or automated vision checks identify minute defects undetectable to the naked eye.

Ensuring Supplier Quality as an International B2B Buyer

Supplier Assessment and Audit

- Factory Audits: Conduct, commission, or participate in on-site supplier audits to verify cleanliness, segregation of clear vs. opaque lines (avoiding cross-contamination), and review calibration records for equipment used in optical testing.

- Documentation Review: Demand batch-level Certificates of Analysis (COA) stating optical and mechanical test results. Verify supporting evidence of compliance with declared international and industry standards.

Third-party and Pre-shipment Inspections

- Engage Reputable Agencies: Organizations like SGS, Bureau Veritas, TÜV SÜD, or regionally recognized bodies can perform pre-shipment random sampling and compliance checking.

- Witness Testing: For critical projects, consider video-linked or live-streamed factory acceptance tests to observe transparency and performance measurements in realtime.

On-going Performance Monitoring

- In-Market Testing: Arrange for sample validation in accredited local labs post-delivery, particularly when importing into regulated markets. This helps safeguard against quality drift or substitution.

- Reject/Claim Protocols: Establish clear agreements for addressing substandard batches, including rapid replacement, financial penalties, or quality improvement action plans.

Nuances and Best Practices for International Buyers

- Contract Clarity: Clearly specify requirements for transparency (light transmittance, haze limits), physical specifications, regulatory compliance, and documentation in purchase agreements.

- Cultural and Logistical Considerations: Factor in potential communication gaps or differences in QC mentality. For Africa, South America, and Middle Eastern markets, language localization and contextualizing regulatory requirements can reduce risk.

- Regional Testing Gaps: Some regions may lack local labs capable of high-precision optical tests—consider collaborative testing arrangements or sending critical samples to European labs for verification.

Actionable Takeaways

- Shortlist manufacturers holding ISO 9001 and, when necessary, relevant sector certifications.

- Insist on clear QC processes at IQC, IPQC, and FQC stages, with particular emphasis on transparency and material purity.

- Implement or commission independent, third-party inspections—especially for large or mission-critical orders.

- Strengthen contracts with robust product specifications, documentation requirements, and agreed remediation steps.

- Stay informed about regional regulatory updates affecting ABS transparency, chemical safety, and certification obligations in target markets.

By mastering these manufacturing and QC fundamentals, B2B buyers from diverse regions can confidently source clear ABS, ensuring both optimal product quality and regulatory conformance in their respective markets.

Related Video: Water Quality Testing

Comprehensive Cost and Pricing Analysis for acrylonitrile butadiene styrene clear Sourcing

Key Cost Components in ABS Clear Procurement

When sourcing acrylonitrile butadiene styrene (ABS) clear for manufacturing or resale, a thorough breakdown of the supply chain cost drivers is critical for informed purchasing. The core cost structure typically includes:

- Raw Materials: ABS clear resin’s price is driven by market rates for acrylonitrile, butadiene, and styrene, which are derived from petrochemical feedstocks. Transparent grades require higher-purity and specialized compounding, elevating base material costs compared to standard opaque ABS.

- Labor: Labor inputs vary between suppliers and regions. Facilities in Asia may offer labor cost advantages, but buyers should balance these benefits with factors such as lead times and quality management.

- Manufacturing Overhead: This encompasses energy consumption, facility depreciation, regulatory compliance, environmental controls, and waste management. ABS’s processing—especially for clear variants—demands high-precision equipment and tighter controls, marginally increasing overhead.

- Tooling and Molding: For customized parts, initial tooling investment can be significant. Transparent ABS may require dedicated molds to maintain optical clarity and prevent contamination.

- Quality Control (QC): Premium ABS clear requires rigorous inspection to avoid haze, yellowing, or inclusions. High QC standards add incremental cost but are essential for applications like medical or consumer electronics housings.

- Logistics and Packaging: Shipping bulk resin or finished parts incurs costs influenced by weight, packaging standards (e.g., moisture barriers), and route complexity. International shipments may also face tariffs or additional handling fees depending on import regulations in regions such as Africa, South America, or the EU.

- Supplier Margin: Manufacturers and traders include a profit margin reflective of service levels, customer base, and regional competition.

Principal Price Influencers

Several variables impact the final ABS clear price in B2B transactions:

- Order Volume & Minimum Order Quantity (MOQ): Larger orders generally secure volume discounts. However, MOQs can be high for custom or specialty grades.

- Technical Specifications & Customization: Clear ABS is available in multiple grades distinguished by impact strength, flow rate, flame retardancy, or UV resistance. Tailored formulations, masterbatch coloring, or anti-UV additives can drive up pricing.

- Material Quality & Certification: Third-party certifications (e.g., RoHS, REACH, FDA, UL94) are important for buyers in regulated industries or segments like electronics and automotive, often adding a premium of 5–15%.

- Supplier Location & Experience: Proven, reputable suppliers may command higher prices but offset risk of defects or shipment delays. Region-specific considerations—such as the need for halal certification in the Middle East or customized packaging for African climates—also affect cost.

- Incoterms (EXW, FOB, CIF, DDP, etc.): The chosen Incoterm shifts responsibility for costs and risks. CIF or DDP price quotes may appear higher but include all freight, insurance, and import formalities—a potential benefit for buyers unfamiliar with cross-border logistics.

- Market Volatility: Prices for ABS raw materials fluctuate based on global petrochemical supply, currency shifts, and geopolitical factors. Forward contracts or indexed pricing may be available with large-volume commitments.

Actionable Insights for International Buyers

To enhance cost-efficiency and achieve favorable terms, international B2B buyers—particularly those in Africa, South America, the Middle East, and Europe—should:

- Benchmark Delivered Cost: Assess total landed cost including duties, VAT, inland freight, and customs brokerage—not just supplier unit price. For example, buyers in Egypt or Brazil may face different tariff structures compared to EU counterparts.

- Engage in Strategic Negotiation: Leverage market knowledge, compare multiple offers, and highlight potential for long-term partnership or repeat orders to negotiate better pricing, payment terms, or MOQs.

- Consider Total Cost of Ownership (TCO): Factor in quality consistency, delivery reliability, after-sales support, and technical assistance. Cheaper suppliers may incur higher downstream costs from defects, product returns, or unplanned downtime.

- Optimize Supply Chain Logistics: Consolidate shipments, select optimal Incoterms, and explore regional warehousing to reduce freight and customs delays. Partnering with freight forwarders experienced in African or Latin American corridors can prevent surprises.

- Specify Needs Clearly: Provide detailed technical requirements—such as optical clarity, UV resistance, or specific certifications—to avoid scope creep or post-award adjustments that inflate costs.

- Monitor Market Trends: Stay informed on petrochemical price movements and regional demand cycles, timing purchases when possible to avoid peak pricing or supply constraints.

Disclaimer: All cost estimates in this analysis are indicative and for reference only. Actual prices will vary according to project specifics, supplier negotiations, and prevailing global market conditions.

By understanding the detailed cost structure and the nuances of global ABS clear sourcing, buyers can achieve more predictable pricing outcomes and sustainable supply relationships.

Spotlight on Potential acrylonitrile butadiene styrene clear Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘acrylonitrile butadiene styrene clear’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

7 acrylonitrile butadiene styrene companies leading global industries (www.verifiedmarketresearch.com)

A prominent force in the global petrochemicals and plastics industry, this company delivers high-performance Acrylonitrile Butadiene Styrene (ABS) resins—including clear grades—tailored for critical applications in electronics, automotive, and consumer goods manufacturing. Its large-scale operations are characterized by advanced polymer processing, strict quality controls, and a commitment to consistent resin clarity and mechanical strength. For international B2B buyers in Africa, South America, the Middle East, and Europe, the organization stands out for comprehensive supply chain capabilities, broad market coverage, and experience in meeting diverse global technical and compliance standards. The group’s robust R&D investments lead to product innovation, while its proven export track record ensures reliable long-term partnerships for buyers seeking transparency, durability, and processability in ABS clear materials.

Chemicalresearchinsight (chemicalresearchinsight.com)

Chemicalresearchinsight positions itself as a prominent player in the global acrylonitrile butadiene styrene (ABS) market, with a strong focus on clear ABS grades coveted for their transparency and impact resistance. The company emphasizes advanced polymer engineering and sustainable manufacturing processes, catering to diverse sectors such as automotive, electronics, and consumer goods. Buyers benefit from their commitment to consistent product quality and responsive technical support, which are crucial for transparent ABS applications requiring stringent optical and mechanical standards.

With robust supply chains and documented international sourcing—serving markets in Africa, South America, the Middle East, and Europe—Chemicalresearchinsight offers tailored logistics solutions for global B2B customers. While public specifics on certifications are limited, their sustained industry presence and market leadership suggest compliance with international quality and safety norms.

Key Suppliers of Acrylonitrile Butadiene Styrene Grades (omnexus.specialchem.com)

Key Suppliers of Acrylonitrile Butadiene Styrene Grades provide an extensive portfolio of ABS grades, including specialized transparent (clear) variants, catering to diverse industry needs ranging from automotive parts to consumer electronics and medical applications. The platform consolidates offerings from multiple established global manufacturers, allowing buyers to access technical data, certification information, and request product samples efficiently. Noteworthy strengths include transparent ABS grades engineered for outstanding impact resistance and optical clarity, supporting sophisticated end-use requirements. Many listed suppliers demonstrate a history of supplying international markets, with a focus on flexible logistics, regulatory compliance, and quality certifications such as ISO 9001. The platform’s global coverage and emphasis on custom technical support make it valuable for buyers in Africa, South America, the Middle East, and Europe seeking consistent material performance and fast sourcing options.

Quick Comparison of Profiled Manufacturers

| Manufacturer | Brief Focus Summary | Website Domain |

|---|---|---|

| 7 acrylonitrile butadiene styrene companies leading global industries | Global ABS clear supplier; strong export experience | www.verifiedmarketresearch.com |

| Chemicalresearchinsight | Transparent ABS specialist, global B2B supplier | chemicalresearchinsight.com |

| Key Suppliers of Acrylonitrile Butadiene Styrene Grades | Global ABS grades portfolio, transparent grades, certified suppliers | omnexus.specialchem.com |

Essential Technical Properties and Trade Terminology for acrylonitrile butadiene styrene clear

Key Technical Properties for Sourcing ABS Clear

When evaluating acrylonitrile butadiene styrene (ABS) clear for industrial procurement, it is crucial to understand the technical specifications that influence product suitability, performance, and compliance. These properties determine how ABS clear will perform in your applications—whether in automotive, consumer electronics, medical devices, or packaging—and how they align with quality expectations in African, South American, Middle Eastern, and European markets.

1. Transparency & Optical Clarity

Clear ABS grades are engineered for high transparency, providing a glass-like appearance with moderate haze. This property is critical for applications requiring visible contents, illuminated displays, or aesthetic parts. Consistent clarity indicates quality and precise production methods—vital for sectors like cosmetics packaging and electronics, where end-user perception is paramount.

2. Impact Strength

ABS clear boasts excellent impact resistance, measured using notched Izod or Charpy tests (typically 100–400 J/m). High impact strength ensures durability during manufacturing, shipping, and end use, especially in demanding environments or temperature fluctuations. For African and Middle Eastern buyers, this translates into fewer product failures in logistics or consumer handling, reducing warranty risks.

3. Heat Deflection Temperature (HDT)

This metric specifies the temperature at which ABS clear deforms under a set load—generally ranging from 90°C to 100°C for standard grades, with some heat-resistant variations reaching up to 115°C. HDT directly impacts suitability for hot climates (notably in the Middle East and Africa) or applications exposed to moderate heat, such as appliance housings and automotive interior components.

4. Chemical Resistance

Clear ABS resists water, dilute acids, and alkalis, but is vulnerable to esters, ketones, and some hydrocarbons. Understanding the chemical compatibility is vital when ABS clear will contact cleaners, adhesives, or other chemicals during production or in the final application, helping avoid premature degradation or failure.

5. Dimensional Stability & Tolerance

ABS clear exhibits low shrinkage and superior dimensional stability compared to many commodity plastics, making it suitable for precision-molded parts. Tolerance specifications (e.g., ±0.05 mm) ensure interchangeability and reduce assembly issues in international supply chains—crucial for OEMs and module integrators in Europe and South America.

6. Material Grade & Certification

ABS clear is available in multiple grades, such as general-purpose, high-impact, or plating-grade, each tailored for distinct B2B requirements. Buyers should confirm compliance with global standards (RoHS, REACH, ISO) and, where relevant, request material data sheets (MDS) or certificates of analysis for regulatory assurance.

Critical Trade Terminology for ABS Clear Procurement

For efficient and risk-minimized international trade, mastering the following terms will streamline negotiations, procurement, and delivery:

1. MOQ (Minimum Order Quantity)

MOQ defines the smallest batch a supplier is willing to produce or ship. This is especially significant for buyers consolidating shipments across borders or testing new suppliers. Negotiate MOQ to match your market demand and storage capacity; lower MOQs generally command a price premium.

2. RFQ (Request for Quotation)

RFQ is a formal document requesting pricing and commercial terms from suppliers. Include precise material specs, required certifications, delivery timelines, and target Incoterms for clarity. A detailed RFQ minimizes misunderstandings, accelerates supplier responses, and sets the stage for transparent negotiations.

3. Incoterms (International Commercial Terms)

Incoterms (like FOB, CIF, DAP) are standardized terms governing the allocation of delivery responsibilities, shipping costs, and risk transfer. Knowledge of Incoterms is critical for African and South American buyers to prevent hidden charges and disputes over insurance or customs clearance.

4. OEM (Original Equipment Manufacturer)

An OEM buys ABS clear either to produce branded products or as a component for integration into a final assembly. Clarify whether your purchase is for OEM production, as this may affect pricing, traceability requirements, and after-sales support.

5. Lead Time

Lead time refers to the period between order confirmation and delivery readiness. It affects your project timelines and inventory planning. Discuss lead times upfront with suppliers, accounting for production scale, shipping routes, and seasonal logistics disruptions common in cross-continental trade.

6. COA, MDS, or SDS (Certificates and Data Sheets)

These documents—Certificate of Analysis (COA), Material Data Sheet (MDS), and Safety Data Sheet (SDS)—provide technical, safety, and compliance data. Ensure suppliers agree to provide these, as they are necessary for customs clearance, regulatory compliance, and product liability management, especially in regulated markets like the EU.

International B2B buyers who grasp these property metrics and trade terms are better positioned to reduce risk, ensure consistent quality, and negotiate competitive terms for ABS clear procurement. This knowledge lays the groundwork for reliable supply chains and successful product launches across diverse global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the acrylonitrile butadiene styrene clear Sector

Global Market Overview and Key Sourcing Trends

The demand for acrylonitrile butadiene styrene (ABS) clear materials has surged globally, driven by growth in automotive, electronics, medical devices, and consumer goods industries. International B2B buyers, particularly from emerging markets in Africa, South America, and the Middle East, as well as established markets in Europe, are increasingly drawn to the unique properties of clear ABS—its high impact resistance, transparency, thermal stability, and versatility. Market dynamics reflect an ongoing shift towards lightweight, durable, and aesthetically appealing plastics for components such as automotive interiors, transparent housings for electronics, and protective medical device covers.

Technological advancements have enhanced the production of ABS clear variants, enabling improved clarity and impact strength that rival traditional polycarbonate and acrylic options. Digital sourcing platforms and B2B marketplaces have facilitated real-time access to global inventories, supplier credentials, and pricing benchmarks. For buyers in regions like Egypt, Brazil, Saudi Arabia, and France, this digital integration has streamlined the vetting of raw material sources, contract manufacturers, and logistics partners.

Key sourcing trends include a preference for customized ABS grades—such as those tailored for flame retardancy, plating, or high-flow/moldability—as well as rapid sampling for validation in end-applications. Buyers are increasingly prioritizing suppliers that offer robust documentation, technical support, and stable supply chains. Price volatility in feedstocks (acrylonitrile, butadiene, styrene) and evolving environmental regulations, particularly in Europe and the Middle East, have made flexible sourcing strategies and dual-vendor models essential for risk mitigation.

Sustainability and Ethical Sourcing Considerations

As the spotlight on environmental stewardship intensifies, sustainability in ABS clear sourcing is no longer optional but a core procurement criterion. The environmental footprint of ABS production—largely tied to petrochemical origins—requires buyers to assess suppliers’ efforts in emissions reduction, waste management, and energy efficiency. European regulations (REACH, RoHS) and growing environmental movements in South America and Africa are compelling suppliers to innovate through renewable energy use, solvent-free processing, and closed-loop recycling.

Ethical sourcing extends beyond environmental parameters to include worker safety, fair labor practices, and community impact. B2B buyers are advised to favor suppliers certified under recognized environmental and social responsibility standards, such as ISO 14001 (Environmental Management), ISO 45001 (Occupational Health and Safety), and emerging certifications for recycled or bio-based ABS. The rise of ‘green’ ABS—manufactured using post-consumer recycled feedstocks or bio-attributed monomers—is offering new avenues for sustainable procurement.

Transparency is key: buyers should demand comprehensive lifecycle analyses, supply chain traceability, and material origin declarations. Suppliers that can deliver on both product performance and verifiable sustainability metrics will increasingly have a competitive edge, especially as ESG criteria become integral to B2B procurement policies in Europe and across multinational corporations.

Evolution of ABS Clear in Global Trade

The development of ABS as a clear plastic resin marks a significant evolution in engineering thermoplastics. Originating in the mid-20th century, ABS clear was developed to meet demand for transparent yet robust and processable materials—filling the gap between brittle acrylics and less transparent polycarbonates. Over the decades, manufacturers have fine-tuned the polymerization process, introducing new catalysts and blending techniques to improve optical clarity and impact resistance.

Today, ABS clear stands out for its combination of toughness, chemical resistance, and formability, enabling manufacturers and OEMs worldwide to design complex, light-transmitting parts without sacrificing strength or process efficiency. Its evolution has been closely linked with advances in compounding, eco-design, and digital manufacturing, making it a staple in forward-looking supply chains and global B2B trade.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of acrylonitrile butadiene styrene clear

-

How can I effectively vet and select reliable suppliers of acrylonitrile butadiene styrene clear (ABS clear) for international trade?

Evaluating reliable suppliers requires thorough due diligence. Begin by reviewing the supplier’s business licenses, export track record, and certifications such as ISO 9001. Request references from current overseas clients, and consider using third-party inspection agents for on-site audits. Engage in detailed technical discussions to assess product expertise, and prioritize suppliers who provide transparent documentation, including product data sheets and quality reports. For buyers in regions like Africa, South America, and the Middle East, working with established trading platforms or industry associations can further minimize risk. -

What customization options are typically available for ABS clear, and how should I communicate my requirements to suppliers?

ABS clear can often be tailored in terms of grade (e.g., high-impact, high-flow), transparency, formulation additives (UV stabilizers, flame retardants), and physical form (granules, sheets). Clearly specify required properties, intended application, and compliance standards (such as RoHS or REACH for Europe). Provide technical drawings and performance expectations where possible. Use written specifications in both English and the supplier’s native language to avoid misinterpretation, and request pre-shipment samples for evaluation to ensure your customization needs are met. -

What are the standard minimum order quantities (MOQ), typical lead times, and accepted payment terms when sourcing ABS clear globally?

MOQs for ABS clear often range from 1–5 metric tons, but may be higher depending on the grade and customization level. Lead times typically vary between 2–6 weeks post-order confirmation, though complex customizations may require more. Common payment terms include T/T (Telegraphic Transfer), L/C (Letter of Credit), and in some trade hubs, D/P (Documents against Payment). Buyers should negotiate phased payments—such as a deposit with balance after inspection—and always clarify terms in the purchase contract to manage financial exposure. -

Which quality assurance measures and certifications should I require when importing ABS clear?

Ensure suppliers comply with recognized quality standards such as ISO 9001 and, where relevant, ISO 14001 for environmental management. Request third-party test reports verifying key parameters: transparency, impact strength, melt flow index, and absence of restricted substances. For European markets, demand REACH and RoHS compliance; Middle Eastern buyers may require SASO or GCC certification; African and South American buyers should check for standards recognized by local authorities. Specify independent quality inspection at both pre-dispatch and arrival stages. -

How is ABS clear typically packaged and transported for international shipments to ensure material integrity?

ABS clear is most often packed in moisture-resistant, sealed polyethylene bags, placed inside heavy-duty cartons or woven sacks. Palletization is standard for ease of handling and to prevent deformation. For maritime shipping to Africa, South America, or the Middle East, request containerization to avoid temperature/humidity fluctuations. Confirm with your supplier the use of desiccants, proper labeling, and batch traceability. Insist on a detailed shipping list and insurance coverage for loss or damages in transit. -

What are the key considerations for importing ABS clear regarding duties, tariffs, and regulatory compliance in different regions?

Understand that tariff codes (often HS code 3903.30) can impact duty rates, which vary by country. Comply with national import standards—such as CE Marking (Europe), SASO (Saudi Arabia), or SONCAP (Nigeria). Obtain all necessary documentation, including certificates of origin, safety data sheets (SDS), and conformity attestations. Collaborate with experienced customs brokers to navigate regulatory complexities and avoid clearance delays or penalties. -

How can I mitigate risks related to non-conformity, damages, or disputes with overseas suppliers of ABS clear?

Mitigate risks by specifying rigorous inspection procedures, both pre-shipment (in the supplier’s location) and pre-acceptance (upon arrival). Use international trade contracts (e.g., Incoterms) detailing recourse options for damages or non-conformance. Agree on a clear dispute resolution mechanism, such as arbitration under ICC rules. Maintain all documentation—emails, contracts, inspection reports—to support claims. Consider purchase via reputable escrow services or trade platforms offering buyer protection programs. -

What support should I expect from suppliers for technical queries and post-sale service for ABS clear?

A qualified supplier should offer technical datasheets, processing guidelines, and prompt responses to application queries. For buyers in regions facing climatic or regulatory challenges, request support on material compatibility, local approval processes, and troubleshooting for molding or extrusion issues. Ensure after-sales service is contractually specified, including timelines for response, provision of replacement material if defects are found, and long-term documentation for traceability. This proactive support streamlines onboarding of ABS clear into your supply chain and manufacturing process.

Strategic Sourcing Conclusion and Outlook for acrylonitrile butadiene styrene clear

As global industries continue to evolve, acrylonitrile butadiene styrene clear (ABS clear) stands out as a versatile material offering an optimal balance of strength, impact resistance, and transparency. For B2B buyers across Africa, South America, the Middle East, and Europe, the key to unlocking its value lies in a strategic sourcing approach—one that not only evaluates technical specifications but also considers local processing capabilities, supply reliability, and regulatory compliance.

Key Takeaways for International Buyers

- Performance Differentiation: ABS clear variants deliver outstanding mechanical properties, ideal for sectors ranging from automotive and electronics to healthcare and consumer goods. Understanding grade distinctions—such as impact strength, flow characteristics, and chemical resistance—enables buyers to align material selection with end-use requirements.

- Supply Chain Optimization: Geopolitical dynamics and logistical challenges, particularly relevant in emerging markets, underscore the need for diversified supplier networks. Establishing trusted partnerships with proven producers reduces risk and ensures consistent quality.

- Regulatory & Environmental Considerations: Buyers should remain vigilant about both local and international standards regarding chemical safety, flammability, and recyclability—factors increasingly influencing procurement decisions globally.

Looking Ahead

The global demand for advanced plastics like ABS clear is anticipated to accelerate, propelled by innovation in manufacturing, rising quality expectations, and the drive for sustainable solutions. Forward-thinking B2B buyers will benefit from investing in supplier relationships, staying abreast of material advancements, and fostering transparent dialogue with partners. Now is the time to recalibrate sourcing strategies—securing long-term competitive advantage and resilience in this dynamic market.