Introduction: Navigating the Global Market for resin molds large

Large resin molds have become indispensable components across various industries worldwide, enabling efficient mass production of customized and complex resin-based products. From construction and automotive parts to home décor and industrial equipment, the ability to source robust, precisely engineered large resin molds directly impacts product quality, production timelines, and ultimately, bottom-line profitability. For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe—where demand for both local manufacturing and import of finished goods is on the rise—making informed sourcing decisions for large resin molds offers a tangible competitive advantage.

However, navigating the global market for these essential tools presents numerous challenges. Differences in manufacturing technologies—ranging from advanced injection molding and extrusion methods to specialized blow molding techniques—affect everything from design capabilities to lead times and scalability. Additionally, variations in resin material types, supplier quality standards, and cost structures complicate purchasing decisions for buyers aiming to balance quality, reliability, and cost-effectiveness.

This comprehensive guide tackles these issues head-on by providing actionable insights across every aspect of large resin mold procurement. Buyers will discover in-depth analyses of available mold types and manufacturing processes, critical considerations for selecting suitable resin materials, best practices for evaluating supplier capabilities and quality assurance procedures, and an overview of current global market dynamics and cost trends. The guide also addresses frequently asked questions and regional market nuances relevant to stakeholders from Brazil to Egypt and beyond.

Armed with the knowledge contained in this guide, international B2B buyers will be empowered to identify optimal sourcing strategies—reducing risk, accelerating production, and ensuring their procurement decisions align seamlessly with strategic growth objectives.

Understanding resin molds large Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Large Injection Molds | High-precision steel/aluminum cavities; complex detailing | Automotive parts, appliances, bulk packaging | Exceptional repeatability and finish; high initial tooling cost; long lifespan |

| Large Blow Molds | Hollow cavity for air expansion; suited for large items | Tanks, drums, containers | Enables lightweight, strong forms; suited for high-volume; limited to hollow parts |

| Large Compression Molds | Molded under pressure/heat; minimal runners/gates | Industrial panels, composite parts | Efficient with bulky/flat shapes; may limit intricate details; moderate cost |

| Large Silicone Molds | Flexible, reusable; enables intricate/set geometries | Prototyping, decor, art, specialty items | Excellent detail capture; lower durability than metal; faster turnaround |

| Large Extrusion Molds | Long/directional shaping; continuous profile creation | Construction profiles, pipes, frames | Minimal waste; highly scalable; shapes limited to linear forms |

Large Injection Molds

Large injection molds are precision-engineered cavities, often made from hardened steel or aluminum, designed to produce intricate, high-quality components on a mass scale. Suitable for industries such as automotive, appliance manufacturing, and high-volume packaging, these molds deliver consistent part quality and tight tolerances. B2B buyers should consider the high upfront tooling investment against the long mold lifespan and cycle speed, especially for repetitive orders. Local support and the ability to rapidly adjust for product variations are key factors when sourcing internationally.

Large Blow Molds

These molds utilize a hollow cavity that, when combined with air pressure, creates large, hollow parts such as tanks, industrial drums, and sizeable containers. Blow molds excel in applications where lightweight yet strong plastic forms are required. Their efficiency in producing large volumes is particularly appealing for sectors with bulk liquid or granular material handling needs. Buyers must balance high productivity with the process’s limitation to hollow items and consider OEM support for ongoing maintenance.

Large Compression Molds

With compression molding, large resin charges are placed into open molds and compressed under heat until set. This process is highly effective for flat or modestly contoured shapes—such as composite panels or large industrial equipment covers—where sheer size and strength are priorities over fine detail. For buyers, compression molds often strike a balance between tooling affordability and suitability for thick, robust parts, although intricate features may be harder to achieve.

Large Silicone Molds

Constructed from flexible silicone, these large molds enable the shaping of complex, decorative, or unique geometries. They are vital for rapid prototyping, limited-run specialty decor products, and artisan manufacturing. Silicone molds are valued for their ability to reproduce fine details and are ideal for buyers seeking custom or frequently changing designs. Durability is generally lower than metal, but their lower cost and faster production cycles make them attractive for custom or trend-driven product lines.

Large Extrusion Molds

Extrusion molds shape molten resin into continuous, linear profiles—enabling efficient manufacture of items like pipes, construction profiles, and window frames. Their design supports scalability and high throughput with minimal material waste, making them a staple for construction and infrastructure sectors. However, buyers should note that extrusion is limited to producing linear shapes and evaluate mold design flexibility and die-change efficiency to ensure adaptability for regional market requirements.

Related Video: How To Make Silicone Molds For Resin Casting

Key Industrial Applications of resin molds large

| Industry/Sector | Specific Application of resin molds large | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of large, complex automotive components | Precision, repeatability, scalability for high volume | Mold durability, cycle time, resin compatibility, CAD/CAM support |

| Construction & Infrastructure | Fabrication of precast concrete forms and panels | Rapid prototyping, reduced costs, custom designs | Load tolerance, surface finish, weather resistance, ease of demolding |

| Consumer Goods | Manufacture of bulk storage tanks & furniture | Lightweight parts, design flexibility, cost efficiency | Food-safe resin, UV resistance, mold lifespan, customization options |

| Industrial Packaging | Creation of shipping containers and drums | Uniform wall thickness, robustness, mass production | Impact resistance, regulatory compliance, logistical dimensions |

| Renewable Energy | Casting of large turbine blades & wind power components | Supports complex geometries, lightweight solutions | Resin strength, dimensional stability, meeting certification standards |

Automotive Manufacturing

Large resin molds play a pivotal role in producing oversized or intricate automotive components, such as bumpers, dashboards, door panels, and under-the-hood assemblies. For manufacturers seeking mass production with tight tolerances and consistent quality—common requirements in regions assembling vehicles for both domestic and export markets (including Brazil and Egypt)—these molds allow rapid replication, integration of complex features, and reduction of post-processing steps. International buyers should ensure that suppliers can offer molds that are robust, maintain dimensional accuracy, and are compatible with modern high-performance resins, as well as support digital production workflows (e.g., CAD/CAM).

Construction & Infrastructure

In the construction sector, large resin molds are extensively used for producing precast concrete forms, exterior panels, decorative architectural elements, and infrastructure components. The main advantage is the ability to manufacture high-strength, custom-shaped parts with superior surface finishes at scale—ideal for large housing projects or civil engineering works prevalent in rapidly urbanizing African and Middle Eastern markets. B2B buyers must assess mold resilience under repeated use, the smoothness of demolding, tolerance to environmental conditions, and supplier capability for customization to comply with local construction standards.

Consumer Goods

Bulk storage tanks, planters, and even large-format furniture are frequently manufactured using large resin molds through processes like blow or rotational molding. This approach enables cost-effective mass production of lightweight, durable items suitable for both domestic and commercial use, which is crucial for distributors and retailers across South America and Europe. Buyers should demand resins that are not only structurally sound but also food-grade or UV-resistant where necessary, and verify that manufacturers offer options for design customization to cater to regional consumer preferences.

Industrial Packaging

For international logistics and trade, the use of large resin molds in manufacturing drums, intermediate bulk containers (IBCs), pallets, and shipping crates is widespread. Such products must reliably protect cargo across challenging transit environments, including ports in North Africa or long-haul routes across Europe. The business value here is derived from producing packaging with uniform dimensions, high impact resistance, and compliance with shipping and safety regulations. When sourcing, prioritize moldmakers who understand target market standards and can provide traceability for quality assurance.

Renewable Energy

Resin molds are increasingly critical in the renewable sector for casting large wind turbine blades, solar panel frames, and composite support structures. The ability to mold complex aerodynamic shapes helps energy companies improve performance while reducing weight—essential for installations in wind farms or solar parks in wide-open locations from Egypt to Spain. For buyers, key considerations include sourcing suppliers who can guarantee molds with high dimensional fidelity, appropriate resin compatibility for superior mechanical strength, and the ability to comply with rigorous industry certifications such as IEC or TUV.

Related Video: 3D Printed Molds For Resin Casting – Does That Even Work?

Strategic Material Selection Guide for resin molds large

Polycarbonate (PC)

Polycarbonate is a high-performance thermoplastic frequently chosen for large resin molds that require clarity, mechanical strength, and thermal stability. Its key properties include excellent impact resistance, transparency, high dimensional stability, and the ability to withstand temperatures up to about 120°C. In B2B resin molding projects, especially where optical clarity or precision is paramount, PC is frequently considered.

Pros: Exceptionally durable; maintains properties in harsh environments; suitable for intricate designs; good chemical resistance to many substances.

Cons: Higher cost compared to general-purpose materials; susceptible to scratching; can be affected by prolonged UV exposure unless stabilized.

Application Impact: Suitable where high clarity and toughness are needed — for example, large display or lighting fixtures, or medical device molds.

Regional Considerations: Compliant with international regulations (ASTM, DIN, ISO). Readily available in Europe and the Middle East; in Africa and South America, import logistics may increase costs, so ensure suppliers can guarantee consistent grade and documentation. PC can be specified to RoHS or FDA/food contact standards if required.

High-Density Polyethylene (HDPE)

HDPE is widely regarded for its chemical resistance and affordability. It offers moderate mechanical strength, excellent flexibility, and can withstand repeated exposure to most acids, bases, and solvents, with a temperature range up to about 80°C.

Pros: Economical; lightweight; resistant to a broad range of chemicals; relatively easy to process for large-size molds.

Cons: Limited mechanical strength; unsuitable for high-pressure or high-temperature applications; lower dimensional stability than engineering plastics.

Application Impact: Best suited for utility products, large containers, and settings where chemical compatibility matters more than precision or strength.

Regional Considerations: Commonly available in nearly all regions; favored for water/contact applications in Africa and South America due to cost and robust supply chains. Ensure compliance with national standards (such as SON in Nigeria, ABNT in Brazil, or EN in Europe). Inquire about UV stabilization if outdoor deployment is likely.

Aluminum-Filled Epoxy Resin

Aluminum-filled epoxy resins are a specialty composite, combining the ease of resin molding with enhanced strength, thermal conductivity, and durability thanks to aluminum powder or granules as filler. This formulation is prized for prototyping and low- to medium-run production of large resin mold tooling.

Pros: Superior dimensional stability versus pure polymer; dissipates heat well; can be machined after curing for fine finishes.

Cons: Higher material and processing cost; longer cure cycle; weight is increased compared to unfilled resins; more complex initial setup.

Application Impact: Ideal for large, precise molds requiring moderate strength and fast cooling (e.g., automotive, industrial prototypes).

Regional Considerations: Availability may vary outside mature industrial markets—verify local suppliers in Africa or South America. Often conforms to ASTM D638 or ISO 527. Check for the ability to meet specific food-contact or medical-grade certifications if relevant. Consider local training for safe handling and storage due to chemical sensitivity.

Stainless Steel (for Mold Bases)

Though not a “resin,” stainless steel is a common mold base material for large resin molds, sometimes used in hybrid assemblies. Grades like 304 or 316 offer impressive mechanical properties, corrosion resistance, and longevity. Often employed where mold longevity or harsh processing conditions are concerns.

Pros: Very high durability; resists corrosion from processing resin chemicals; excellent dimensional precision.

Cons: Significantly higher upfront cost; difficult to modify after fabrication; heavy, raising transport and handling costs.

Application Impact: Used in settings demanding high-strength, repeated mold cycles, or stringent hygiene (food, medical, or export parts for EU/US).

Regional Considerations: Cost can be prohibitive in price-sensitive markets. Stainless steel mold bases are standard in Europe and increasingly in the Middle East; African and South American buyers may need to partner with international tool shops for best results. Ensure fabricators adhere to recognized standards (ASTM A240, EN 10088).

Summary Table

| Material | Typical Use Case for resin molds large | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate (PC) | Precision, high-clarity, impact-resistant molds | Toughness and clarity | Costly; scratch/UV sensitivity | High |

| High-Density Polyethylene (HDPE) | Large containers, chemical storage, utility molds | Inexpensive, chemical resistance | Limited strength/stability | Low |

| Aluminum-Filled Epoxy Resin | Mold prototyping, medium-run production molds | Dimensional stability; heat conductivity | Costly, longer cure, availability varies | Medium to High |

| Stainless Steel (Mold Base) | Durable, high-cycle mold bases for resin applications | Longevity, corrosion resistance | High cost, heavy, less flexible for changes | High |

In-depth Look: Manufacturing Processes and Quality Assurance for resin molds large

Understanding Manufacturing Workflows for Large Resin Molds

For buyers sourcing large resin molds internationally, in-depth knowledge of the manufacturing and quality assurance processes is essential. This transparency not only helps mitigate risks but also ensures product consistency—critical for sectors such as construction, automotive, industrial goods, and large-scale art installations. The following breakdown offers guidance on the standard manufacturing workflow, applicable quality control (QC) benchmarks, and actionable insights to help international B2B buyers evaluate and ensure mold quality across borders.

Key Manufacturing Stages

1. Material Selection and Preparation

The choice of material forms the cornerstone of both performance and durability in large resin molds. Manufacturers may select between different resin types—including epoxy, polyurethane, or thermosetting plastics—based on the intended end use, chemical resistance requirements, and dimensional stability.

- Material Inspection: Suppliers conduct raw material analysis, focusing on chemical composition, moisture content, and batch uniformity to prevent inconsistencies that may affect the molding process or final product.

- Pre-processing: Resins and hardeners are weighed precisely and mixed under controlled conditions. For thermoplastics, pellet drying is essential to minimize moisture, reducing the risk of voids or bubbles in the final mold.

2. Forming and Molding Processes

Several key manufacturing techniques are leveraged based on mold size, complexity, and end-user requirements:

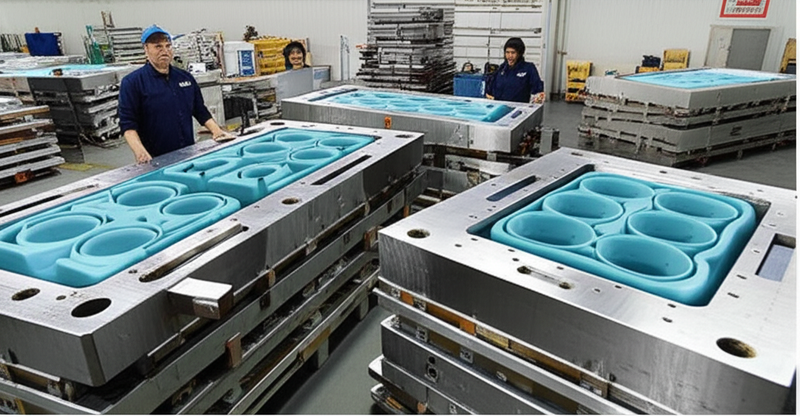

- Injection Molding: Used for precision and high-volume production. Molten resin is injected into a closed steel or aluminum mold under high pressure, allowing for detailed features and tight tolerances.

- Blow Molding: Suitable for hollow or large, thin-walled shapes. The parison (a molten tube of resin) is inflated within the mold, following set profiles.

- Hand Lay-up and Casting: Common for unique, extra-large, or complex shapes. Multiple layers of resin and reinforcing fibers (e.g., fiberglass) are built up by hand or poured into an open mold.

Throughout this stage, temperature, pressure, and cycle time are tightly monitored to ensure optimal cure and structural integrity.

3. Demolding, Assembly, and Secondary Operations

After curing, the mold is demolded. For multipart molds, sections are assembled using specialized adhesives or mechanical fasteners. Secondary processes may include:

- Trimming/Deflashing: Removing excess material, known as flash, for precise edges and surfaces.

- Machining: CNC milling or drilling to refine details or add holes/fittings.

- Surface Finishing: Processes such as sanding, polishing, or Teflon coating to achieve desired surface properties (e.g., gloss, release capability).

4. Cleaning and Packaging

Before shipment, products undergo cleaning to remove processing residues, followed by protective packaging (e.g., shrink-wrap, custom crating) to prevent transportation damage.

Quality Control: Standards, Checkpoints, and Testing

Relevant International Standards

- ISO 9001: Sets requirements for quality management systems, ensuring traceability, process documentation, and continuous improvement.

- CE Marking (Europe): Essential for molds that will be used in regulated markets or applications, confirming conformity with health, safety, and environmental protection standards.

- Country/Industry-Specific Regulations: Depending on application, buyers may require compliance with standards such as ASTM (USA), API (oil & gas), or local equivalents (e.g., INMETRO for Brazil, Egyptian Organization for Standardization).

Quality Control Stages

Large resin mold manufacturers employ comprehensive QC systems, typically divided into:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival for consistency, purity, and supplier compliance certificates.

- In-Process Quality Control (IPQC): Monitoring during forming and curing. This includes real-time measurement of temperature, pressure, cycle time, and in-situ visual inspections for defects like warping, incomplete cure, or surface blemishes.

- Final Quality Control (FQC): A thorough inspection of completed molds. Methodologies include dimensional checks (using gauges, CMMs), mechanical testing (hardness, tensile tests), and functional testing (trial mold releases, leak tests for hollow forms).

Common Testing Methods

- Dimensional Verification: CAD comparison and measurement to ensure tolerances—critical for molds intended for automated systems or high-precision applications.

- Non-Destructive Testing (NDT): Ultrasound, X-ray, or dye penetrant inspection to detect internal flaws (voids, delamination) without damaging the product.

- Mechanical Property Testing: Evaluating hardness, flexural strength, and surface finish according to ASTM or ISO standards.

- Functional Simulation: For critical molds, trial runs using actual molding materials to verify proper demolding, filling, and product quality.

Ensuring Supplier QC: Actionable Steps for International Buyers

1. Pre-award Due Diligence

- Supplier Audits: Perform on-site or virtual audits assessing quality management systems, process capabilities, and production infrastructure.

- Certifications Validation: Verify copies of ISO 9001 or other relevant certificates—check expiry dates and issuing bodies for authenticity.

- Reference Checks: Request references or case studies from clients in your region or similar industries.

2. Real-time QC Assurance During Production

- Production Monitoring: Establish checkpoints during key stages and request regular photographic or video updates.

- Interim QC Reports: Require detailed IPQC and FQC documentation as part of the contract, specifying acceptance criteria and measurement results.

3. Third-party Inspections

- Independent Laboratory Testing: Engage internationally recognized labs to perform material verification (especially for high-specification or regulated markets).

- Pre-shipment Inspection: Employ third-party quality inspection companies to evaluate, sample, and test finished molds before shipment and payment release.

4. Ongoing Supplier Partnerships

- Continuous Improvement Feedback: Incorporate data from service performance, field failures, or user feedback into ongoing quality improvement cycles.

- Cultural and Regulatory Alignment: Discuss and document expectations around labeling, documentation (e.g., CE declarations, test reports), and after-sales support, tailored to your region (e.g., additional paperwork for African or Brazilian customs).

Nuances for Buyers in Diverse Global Markets

International buyers from Africa, South America, the Middle East, and Europe should be aware of key differences in sourcing:

- Documentation Requirements: Import regulations may necessitate specific declarations (e.g., certificates of origin, test reports in local languages, conformity marks like INMETRO for Brazil or EC declaration for Europe).

- Environmental/Climate Adaptation: Communicate application context—molds used in desert or tropical conditions may require additional UV or chemical resistance verification.

- Logistics Considerations: For large molds, packaging and handling requirements become critical—ensure suppliers use ISPM-15 compliant packaging for wood crating, commonly required by African and South American regulators.

Key Takeaways for B2B Resin Mold Buyers

- Insist on documented, stage-specific QC backed by international standards to minimize risk and ensure traceable, reliable products.

- Leverage third-party audits and inspections—especially when entering new supplier relationships or sourcing across unfamiliar regulatory environments.

- Proactively communicate local market and end-use requirements to ensure molds are fit-for-purpose and compliant with all import and industry regulations.

- Maintain ongoing dialogue with manufacturing partners to stay ahead of evolving standards or customer expectations in your region.

By following these strategies, buyers can confidently source large resin molds that meet both performance and compliance criteria, reducing supply chain risks and optimizing long-term value.

Related Video: Inside the Molded Foam Manufacturing Process

Comprehensive Cost and Pricing Analysis for resin molds large Sourcing

Understanding the Cost Structure of Large Resin Mold Sourcing

When procuring large resin molds, international B2B buyers operate in a pricing landscape shaped by multiple, often interrelated, cost components. A thorough grasp of these elements is paramount to managing budgets, negotiating effectively, and optimizing sourcing strategies—particularly when importing across borders.

Key Cost Components

1. Raw Materials

Material selection significantly impacts unit price. High-grade plastics or specialized resins (e.g., silicone, polyurethane) typically command higher costs but may be necessary to meet regulatory, durability, or end-use requirements. Material prices are also subject to global market fluctuations.

2. Labor

Manufacturing large molds is labor-intensive, especially for custom designs. Labor cost disparities can be significant depending on geographic origin; for example, Asian suppliers may offer more cost-effective rates than European counterparts, but this may also entail trade-offs regarding communication, lead times, or quality control.

3. Manufacturing Overhead

This includes energy consumption, machine maintenance, factory operating costs, and depreciation of equipment. For advanced molding techniques like injection or blow molding, overhead is higher, but per-unit cost drops with scale.

4. Tooling & Setup

Large resin molds often require bespoke tool fabrication. Tooling is usually a substantial up-front investment, frequently amortized over production volume. The more complex the mold geometry, the higher the tooling cost.

5. Quality Control (QC)

QC expenses cover in-process checks, post-production inspection, and testing for compliance with international standards (e.g., ISO, CE). Stringent QC, though vital for export markets, adds to the overall cost basis.

6. Logistics

Shipping large, bulky molds entails considerable freight costs, customs duties, insurance, and potential warehousing charges. Incoterms (FOB, CIF, DDP, etc.) determine which party assumes these expenses.

7. Supplier Margin

The final quote includes the supplier’s markup, which varies by region, business model, and negotiation.

Core Price Influencers

Production Volume (MOQ & Scale)

Bulk orders yield significant cost savings per unit due to economies of scale—especially relevant for buyers able to aggregate purchases over multiple projects or product lines.

Product Specifications & Customization

Custom dimensions, intricate features, or special surface treatments (e.g., high-gloss finishes) can substantially elevate pricing, primarily due to increased tooling complexity and added labor.

Material Choice

Selecting premium, certified, or specialty resins increases material and potential regulatory costs but may be mandated for certain industries or export markets.

Quality Standards & Certifications

Compliance with regional or global standards—in addition to add-on certifications for export (especially to the EU or Middle East)—directly affect pricing due to higher QC and documentation demands.

Supplier Profile & Location

Experienced, reputable suppliers often charge a premium, though they frequently offer lower risk and higher QC standards. Geopolitical stability, language, and proximity to ports also influence cost and lead time.

Incoterms & Payment Terms

Responsibility for shipping, insurance, and customs varies by Incoterm. DDP or CIF often result in a higher upfront price but shift logistical burdens onto the supplier, which can add value for buyers unfamiliar with import procedures.

Actionable Tips for International B2B Buyers

- Request Transparent Breakdowns: Always ask for detailed quotes disaggregating material, tooling, labor, and logistics. This aids meaningful negotiation and helps identify hidden costs.

- Optimize Volume: Where feasible, consolidate orders to leverage MOQ pricing tiers and negotiate volume-based discounts.

- Balance Customization with Cost: Standardize specifications across projects where possible and evaluate the ROI of each customization request.

- Clarify Incoterms & Insurance: Ensure full understanding of which party bears which costs, especially for ocean freight shipments to Africa, the Middle East, or South America where port and inland fees can vary.

- Evaluate Supplier Reliability: Prioritize suppliers with export experience, verifiable references, and a track record in your destination region. This reduces risk of hidden delays or compliance issues.

- Compare End-to-End Costs (TCO): Consider the full landed cost—including tariffs, duties, and after-sales service—not simply the ex-works price.

- Anticipate and Plan for Fluctuations: Factor in resin price volatility and possible transportation surcharges due to global supply chain disruptions.

Regional Considerations

Buyers in Africa and South America may face higher logistics costs, longer lead times, and potentially greater hurdles at customs. Middle Eastern importers should pay close attention to compliance with regional standards and required documentation. European buyers may prioritize suppliers with robust certifications and familiarity with EU regulatory frameworks.

Disclaimer: All cost and pricing discussions are indicative and subject to change based on market trends, material prices, and international trade variables. Final terms should always be confirmed directly with the supplier prior to purchase.

By systematically analyzing these cost factors and leveraging actionable negotiation strategies, international buyers can secure favorable terms, ensure supply continuity, and achieve competitive total costs in large resin mold sourcing.

Spotlight on Potential resin molds large Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘resin molds large’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Google (www.google.com)

Google, as reflected in global industry searches, is frequently referenced when sourcing large resin molds, though specific details about the company’s direct manufacturing operations in this niche are limited. Buyers should note that Google functions primarily as an aggregator of search results rather than a direct manufacturer or certified supplier of large resin molds. No extensive public documentation verifies Google’s adherence to quality standards, production certifications, or specialized manufacturing capabilities for resin molds. For international B2B buyers—especially those sourcing for markets in Africa, South America, the Middle East, and Europe—this underscores the importance of thoroughly vetting end suppliers found via Google search, rather than assuming Google itself as a source. Leveraging Google enables efficient comparison of global manufacturers, facilitates access to a wide supplier network, and supports due diligence processes, but does not substitute for engaging with accredited production partners.

Quick Comparison of Profiled Manufacturers

| Manufacturer | Brief Focus Summary | Website Domain |

|---|---|---|

| Search platform, not direct manufacturer or supplier. | www.google.com |

Essential Technical Properties and Trade Terminology for resin molds large

Understanding Technical Specifications for Large Resin Molds

When sourcing large resin molds for industrial or commercial manufacturing, understanding the core technical properties and trade language is essential for effective procurement. This knowledge not only improves supplier communication but also ensures that molds delivered meet your production, quality, and budgetary requirements. Here, we outline the most critical technical specifications and trade terms that international B2B buyers—whether in Brazil, Egypt, Germany, or beyond—should prioritize.

Key Technical Properties

-

Material Grade

– The chemical composition and quality of the resin or polymer used to manufacture the mold itself, or the intended casting. Common grades include industrial, food-safe, or medical-grade resins, each offering different durability and performance characteristics. Specifying the correct grade assures the mold’s suitability for your operational environment, product lifecycle, and relevant local or international standards. -

Dimensional Tolerance

– Tolerances refer to the permissible limits of variation in a mold’s dimensions. For large resin molds, even minor deviations can have significant impacts on fit, function, or downstream assembly. B2B buyers must clarify acceptable tolerance ranges (e.g., ±0.2 mm) up front to minimize costly rework and ensure consistent output. -

Surface Finish

– The final texture, gloss, or matte character of the mold’s cavity, which directly affects the appearance and release of molded products. Common finishes include SPI grades (A1 high polish to D3 coarse), as well as specialized coatings to enhance demolding or durability. For applications where aesthetics matter—such as consumer goods packaging—surface finish is a critical property to define and inspect. -

Cavity Size and Volume

– The internal dimensions of the mold, which determine the maximum size and volume of resin products that can be cast. Specifying this property ensures compatibility with end-use requirements and helps suppliers calculate material yields and cycle times accurately. -

Cycle Life (Mold Longevity)

– Indicates the expected number of production cycles a mold can endure before requiring repair or replacement. This directly impacts cost-per-part calculations and ROI, especially in high-volume manufacturing typical for B2B buyers. -

Compatibility with Molding Processes

– Large resin molds may need to be compatible with specific molding technologies such as injection molding, blow molding, or extrusion processes. Confirming process compatibility in advance avoids mismatched production setups that could result in delays or additional expenses.

Essential Trade Terminology

-

MOQ (Minimum Order Quantity)

– The lowest quantity of molds or molded parts a supplier is willing to produce per purchase order. MOQs can range from dozens to thousands depending on mold complexity and production method. Understanding a supplier’s MOQ is critical for aligning with your projected demand and optimizing inventory. -

RFQ (Request for Quotation)

– A formal inquiry asking potential suppliers to provide pricing, lead times, and terms based on detailed mold specifications. Submitting a comprehensive RFQ streamlines the procurement process and helps compare offers on an apples-to-apples basis. -

OEM (Original Equipment Manufacturer)

– Refers to suppliers who manufacture products (here, molds or molded components) to the buyer’s specifications, often incorporating proprietary designs. Engaging with an OEM is common in custom projects where intellectual property and confidential designs are vital. -

Incoterms

– International commercial terms published by the International Chamber of Commerce, defining the responsibilities of buyers and sellers for global shipments (e.g., EXW, FOB, CIF). Selecting and understanding the appropriate Incoterm minimizes shipping risks and clarifies responsibility for duties, insurance, and freight. -

Lead Time

– The total time required from ordering to receiving molds or molded products. This encompasses production, quality checks, packaging, and transportation. Accurate knowledge of lead times is essential for production planning and customer commitments. -

Tooling Cost

– The upfront investment required for design and manufacture of the production mold (the “tool”). Tooling costs for large resin molds can be substantial; B2B buyers should factor these into total project budgets, possibly negotiating payment milestones or amortization.

Familiarity with these properties and terms allows B2B buyers to make well-informed, risk-mitigated purchasing decisions, optimize supplier negotiations, and drive reliable outcomes in global resin mold procurement. Consider incorporating these criteria into your vendor assessment and contract documentation for best results.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the resin molds large Sector

Global Market Overview & Key Trends

The market for large resin molds is experiencing accelerated growth, driven by robust demand from manufacturing, automotive, construction, and consumer goods sectors. For international B2B buyers—in rapidly industrializing regions such as Africa (e.g., Egypt, Nigeria), South America (e.g., Brazil), the Middle East, and various European countries—the sector promises both new opportunities and competitive challenges.

Key global drivers include the rising adoption of automation in mold production and the diversification of resin applications, particularly in packaging, industrial components, and infrastructure projects. The ability to mass-produce high-quality parts through processes like injection and blow molding enables large manufacturers to achieve scalability and cost-effectiveness. As a result, sourcing preferences are shifting toward suppliers who can offer both high-volume capabilities and advanced mold technologies, such as multi-cavity molds and precision engineering.

Technological innovation is further propelling industry standards upward. The integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) tools significantly enhances mold accuracy and repeatability. For B2B buyers, especially those sourcing internationally, establishing relationships with suppliers who utilize Industry 4.0 practices—such as real-time production tracking, predictive maintenance, and digital quality assurance—can deliver strategic advantages in quality control and order fulfillment speed.

Sourcing trends indicate strong momentum toward digital procurement platforms, enabling buyers to compare multiple suppliers based on credentials, certifications, and lead times. Particularly in markets with infrastructure constraints or importation complexities, such as parts of Africa and South America, localizing supply chains or partnering with regional mold makers is gaining traction. Additionally, with ongoing supply chain disruptions and logistical uncertainties, some European and Middle Eastern buyers are now prioritizing nearshore and diversified supplier networks to bolster resilience.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central concern for international buyers of large resin molds. The environmental impact of resin production—particularly from fossil fuel-derived plastics—places the sector under scrutiny for its carbon footprint, resource consumption, and end-of-life waste management. Consequently, buyers face increasing pressure from regulators, stakeholders, and end customers to ensure that their procurement choices align with environmental best practices.

Ethical supply chains and transparent sourcing are now key differentiators in vendor evaluation. Many large buyers are embedding sustainability criteria into their supplier qualification processes, favoring partners who demonstrate responsible resin sourcing, efficient material usage, and responsible waste management—such as closed-loop recycling or take-back programs for old molds. Third-party certifications, such as ISO 14001 (environmental management systems), are valuable indicators of supplier commitment to sustainability. In addition, demand is rising for molds produced from recycled or bio-based resins, which can help buyers meet their own sustainability goals or comply with nationally mandated standards on circular economy practices.

Adopting green procurement is not just about compliance; it also impacts total cost of ownership (TCO) and brand reputation. Transparent documentation around the use of low-emission materials, energy-efficient manufacturing facilities, and fair labor practices is increasingly sought after—especially in markets like Europe, where regulatory requirements and consumer expectations are especially stringent. For buyers in emerging markets, aligning with ethical sourcing standards opens up access to global markets, international financing, and partnership opportunities.

Evolution and Historical Perspective

The evolution of large resin mold technologies echoes broader developments in industrial manufacturing. Historically, early mold-making relied on manual casting and limited material options. With the advent of synthetic polymers in the 20th century, rapid advances in injection and blow molding revolutionized the sector—unlocking unprecedented production speed, flexibility, and scalability.

Initially, high upfront tooling costs and technical expertise limited advanced mold adoption to developed markets. However, progressive globalization and technological dissemination have democratized access, enabling emerging economies in Africa, South America, and the Middle East to become both significant consumers and, increasingly, producers of large resin molds. The ongoing integration of automation, digitalization, and sustainability into mold manufacturing is now shaping a globally interconnected, agile, and eco-conscious supply landscape—an environment where informed B2B buyers can secure both cost and strategic advantages.

Related Video: Incoterms® 2020 Explained for Import Export Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of resin molds large

-

How do I assess and vet reliable suppliers of large resin molds for international trade?

Begin by conducting thorough background research on potential suppliers, focusing on their industry experience, reputation, and past international dealings. Request business registration documents, references from previous global clients, and proof of export capabilities. Visiting manufacturing facilities virtually or in person—where feasible—allows you to inspect quality controls and production scale. Always prioritize suppliers with established export documentation processes and clear communication channels. Utilize third-party verification platforms and engage in sample orders prior to large-scale procurement to further validate reliability. -

What options do I have for customization of large resin molds to fit my product specifications?

Most reputable manufacturers offer customization services, enabling buyers to specify dimensions, materials, design complexity, and finishing. Engage in detailed technical discussions with the supplier’s engineering team to communicate requirements, sharing CAD drawings or prototypes if available. Confirm molds can be tailored for your resin type and end-use. Ask about design assistance and rapid prototyping to streamline approvals. Always obtain and approve final technical drawings before production begins to avoid costly misunderstandings. -

What are the typical minimum order quantities (MOQs), lead times, and payment terms when ordering large resin molds internationally?

MOQs for large resin molds can vary significantly—some manufacturers accommodate single-unit orders, while others require bulk commitments. Lead times often range from 4 to 12 weeks, considering both mold complexity and shipping schedules. Payment terms are typically staged: an initial deposit (30–50%), balance upon completion or before shipment. It is prudent to negotiate for secure payment methods, such as letters of credit or escrow services, to protect both parties, especially in cross-border transactions. -

What quality assurance processes and certifications should I request from suppliers?

Request documentation of robust quality management systems, such as ISO 9001 certification or equivalent. Insist on pre-shipment inspection reports, material certificates (especially for food-grade or medical molds), and adherence to applicable international standards. Suppliers should offer process transparency, including detailed testing procedures for dimensional accuracy, toughness, and mold longevity. Consider arranging third-party audits or inspections to ensure that product quality meets your requirements before shipping. -

How can I ensure efficient and cost-effective international logistics for shipping large resin molds?

Work with suppliers who have proven export experience, as large molds often require special handling and compliant packaging. Discuss shipping options, such as FCL (Full Container Load) versus LCL (Less-than-Container Load), based on order volume and mold size. Request detailed packing lists, HS codes, and country-of-origin certificates for customs clearance. Where possible, partner with reputable freight forwarders who can assist with route optimization, insurance, and real-time tracking to mitigate risks and delays. -

What steps should I take to address and resolve disputes, such as product defects or shipping issues, with overseas suppliers?

Incorporate clear terms on dispute resolution within your purchase contract, stipulating inspection criteria, warranty conditions, and mechanisms for remediation or replacement. Establish timelines for raising claims on defects or delays, and request that suppliers maintain after-sales support. Utilize international arbitration services, such as the ICC (International Chamber of Commerce), for significant disputes. Keeping thorough written records of communication and agreements is essential for supporting your case if issues escalate. -

Which certifications and documentation are essential for import compliance in markets such as Africa, South America, the Middle East, and Europe?

Import regulations and documentation requirements differ by region. Common essentials include commercial invoices, packing lists, bills of lading/air waybills, and certificates of origin. Specific countries or product end-uses may require compliance with regulatory certificates, such as CE marking for the EU, or SASO for Saudi Arabia. Confirm with both your country’s authorities and your supplier’s export team to gather all necessary documents in advance, reducing the risk of customs delays. -

How can I maximize value and avoid hidden costs when sourcing large resin molds internationally?

Perform total landed cost analysis, factoring in mold price, shipping, import duties, and taxes. Clarify if the quoted price includes tooling modifications, initial sampling, or additional design iterations. Discuss warranty and maintenance terms to prevent unexpected after-sales expenses. Where feasible, negotiate for cost-sharing arrangements on development for large-volume or repeat projects. Finally, ensure transparent invoicing and request detailed breakdowns to spot and mitigate potential hidden charges early in the procurement process.

Strategic Sourcing Conclusion and Outlook for resin molds large

Large resin molds represent a pivotal investment for B2B buyers seeking to scale production efficiency and product quality. Key takeaways for international buyers include the importance of aligning mold selection with your preferred manufacturing technology—whether injection, extrusion, or blow molding—and the careful matching of materials to final application needs. Proactively evaluating supplier capabilities, understanding toolmaking precision, and factoring in both initial and long-term operational costs remain fundamental to achieving cost-effective scale and reliable part performance.

Strategic sourcing delivers manifold benefits. By leveraging a global supplier base and rigorous due diligence, buyers in regions such as Africa, South America, the Middle East, and Europe can mitigate risks related to supply chain disruptions, fluctuating resin prices, and shifting regulatory landscapes. A robust sourcing strategy not only drives price competitiveness but also secures access to value-added services such as design optimization, rapid prototyping, and consistent post-sales support. Collaboration with technologically advanced and ethically compliant manufacturers accelerates time-to-market while safeguarding long-term business interests.

Looking ahead, the landscape for large resin molds continues to evolve alongside innovations in plastics processing and digital manufacturing. Buyers who emphasize strategic partnerships, sustainability, and ongoing process optimization will be best positioned to capitalize on emerging opportunities. Now is the time to review supplier relationships, invest in high-quality tooling, and adopt sourcing practices that empower your business to thrive amid global competition. Take decisive steps today to secure your competitive edge in tomorrow’s marketplace.