Introduction: Navigating the Global Market for metal hardness tester

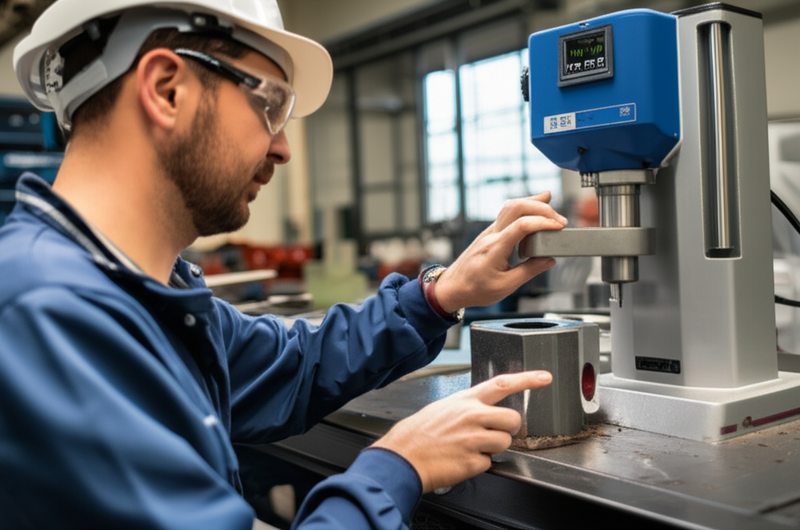

In today’s interconnected industrial landscape, the ability to reliably measure the hardness of metals is pivotal for sectors ranging from automotive manufacturing in Europe to infrastructure development in Africa, energy projects in the Middle East, and mining operations in South America. A metal hardness tester is not just a laboratory tool—it is a frontline instrument safeguarding product quality, process consistency, and regulatory compliance across global supply chains. For B2B buyers navigating this market, the stakes are high: selecting the right tester directly impacts operational efficiency, project success, and ultimately, organizational reputation.

Why does hardness testing matter so much? Hardness measurements provide critical data on a material’s resistance to deformation and wear—core indicators for selecting suitable metals in high-performance applications. From verifying incoming raw materials to optimizing heat treatment processes and ensuring finished parts meet stringent international standards, hardness testers are integral to both manufacturing and quality assurance (QA/QC). The proper instrument helps identify defects early, minimizes costly downtimes, and assures that products will withstand demanding service environments.

This guide is designed to be a definitive resource for international B2B buyers. You’ll gain actionable insights into the leading hardness testing methods—Rockwell, Brinell, Vickers, and more—along with their suitability for various materials and industry applications. The comprehensive coverage spans practical buying criteria, advances in testing technology, quality control integration, emerging suppliers, procurement pitfalls, cost structures, and evolving market trends. Featuring region-specific sourcing considerations for buyers from Africa, South America, the Middle East, and Europe, this guide is structured to support informed and strategic procurement decisions in a globally competitive market.

With the right knowledge, buyers can turn the challenge of selecting a metal hardness tester into a competitive advantage—ensuring each procurement decision strengthens their position in local and international markets.

Understanding metal hardness tester Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rockwell Hardness Tester | Direct readout, multiple scales (A, B, C), wide indenter/load choices | Metal fabrication, automotive, tool manufacturing | Fast and easy to use; slightly less precise for thin/hard pieces |

| Brinell Hardness Tester | Hard steel/carbide ball indenter, large and deep indentation | Foundries, construction, heavy machinery | Ideal for coarse/heterogeneous metals; slower, leaves large marks |

| Vickers Hardness Tester | Diamond pyramid indenter, measures diagonal impression (micro & macro), suitable for thin materials | Aerospace, electronics, laboratories | Highly versatile/accurate; more complex operation, higher cost |

| Portable Hardness Tester | Hand-held, often ultrasonic or impact-based, suitable for field use | On-site QA, maintenance, large processes | Highly mobile, quick setup; may be less precise than benchtop |

| Knoop Hardness Tester | Asymmetric diamond indenter, microhardness for brittle, thin or layered materials | Electronics, coatings, research | Perfect for micro-areas/brittle samples; limited to lab use |

Rockwell Hardness Tester

Rockwell testers are widely adopted in industrial settings for their speed, simplicity, and versatility. Using multiple scales and indenter types, they accommodate a broad spectrum of metals from soft copper alloys to hardened tool steels. These instruments provide rapid, direct digital readouts, making them ideal for high-throughput environments such as automotive manufacturing or metal workshops. For B2B buyers, key factors include selecting a model with suitable scale ranges and the ability to switch indenters, ensuring alignment with diverse material testing needs and compliance with international standards (e.g., ASTM, ISO).

Brinell Hardness Tester

Brinell testers utilize a hard ball indenter under heavy loads to assess materials with non-uniform or coarse microstructures, such as cast iron, aluminum alloys, or forged steel. The method’s larger, visible indentation allows assessment of heterogeneous metals, crucial for foundries and heavy machinery manufacturers. Buyers should note that Brinell machines typically operate at lower speeds and may require more workspace, but are indispensable for testing large or rough components. When procuring, consider indenter sizes, load capabilities, and reliable automatic measurement software for consistent, large-volume testing.

Vickers Hardness Tester

The Vickers method stands out for its universal applicability, ranging from extremely thin sheets to thick structural plates. Its diamond pyramid indenter enables minute impressions read under microscopes, making it a top choice for detailed microstructure analysis in precision industries, such as aerospace and electronics. For B2B purchasers, these testers offer unmatched accuracy and data richness, important for research, failure analysis, and high-quality manufacturing. Buyers should scrutinize optical/microscopic capabilities, automation options, and software integration for quality documentation.

Portable Hardness Tester

Portable hardness testers bring mobility and flexibility to quality assurance, enabling rapid on-site evaluations—particularly valuable in field maintenance for oil and gas, construction, or transportation sectors prevalent across Africa and the Middle East. These units often use ultrasonic, Leeb rebound, or portable Rockwell methods to give immediate results without sample removal. Buyers must balance convenience against slightly reduced measurement precision. Essential considerations include device robustness, battery life, ease of calibration, and compatibility with the range of alloys typically processed in the buyer’s industry.

Knoop Hardness Tester

Knoop testers excel at measuring microhardness in ultra-thin, brittle materials or surface coatings, thanks to a uniquely shaped diamond indenter producing elongated, shallow marks. Favored in electronics, plating, and advanced materials research—especially in Europe’s high-tech manufacturing—they are suited for labs requiring highly localized hardness readings. For B2B procurement, prioritize microscopes with high-resolution imaging, compliance with relevant test standards, and automated measurement/reporting features to streamline accuracy and throughput in R&D or quality control environments.

Related Video: Portable Metal Hardness Tester

Key Industrial Applications of metal hardness tester

| Industry/Sector | Specific Application of metal hardness tester | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive & Transportation | Quality control of engine and drivetrain components | Prevents premature part failure, ensures safety | Compliance with OEM standards; suitability for varied alloys |

| Metal Fabrication & Manufacturing | Incoming materials verification and process optimization | Reduces rejection rates, enhances product reliability | Versatile tester types, scalability for mass production |

| Oil & Gas | Inspection of pipelines, valves, and structural equipment | Mitigates risk of leaks and downtime | Portability for field use, resistance to harsh environments |

| Construction & Infrastructure | Testing of steel reinforcements and structural beams | Ensures structural integrity, regulatory compliance | Ability to handle large/irregular shapes, traceability of results |

| Aerospace | Certification of critical load-bearing parts | Guarantees component performance and safety | High accuracy, support for lightweight/specialty alloys |

Automotive & Transportation

Metal hardness testers play a crucial role in the automotive sector for verifying the strength and durability of engine parts, gears, axles, and drivetrain components. In markets such as Europe and emerging automotive hubs across Africa and the Middle East, these devices ensure that components meet international safety and performance standards. Effective hardness testing helps manufacturers avoid costly recalls and maintain brand reputation. For buyers, it’s vital to select testers compatible with a range of metals and alloys, while also ensuring adherence to local or global OEM specifications.

Metal Fabrication & Manufacturing

In metalworking and manufacturing, hardness testing is essential for both raw material verification and ongoing quality checks during production. This is especially critical in regions with diverse supply chains such as South America and parts of Africa, where material consistency can vary. By integrating hardness testers, fabricators minimize material rejection rates and ensure that finished products perform reliably in demanding applications. Scalability, test speed, and compatibility with different hardness scales (Brinell, Rockwell, Vickers) are important sourcing criteria, especially for operations scaling up to higher production volumes.

Oil & Gas

For oil and gas operations—prevalent in the Middle East, Africa, and South America—the integrity of pipelines, valves, and drilling components directly affects safety and operational uptime. Portable metal hardness testers allow engineers to assess material degradation, wear, or improper heat treatments in the field, minimizing the risk of leaks or catastrophic failures. International buyers in this sector should look for testers designed for rugged use, able to withstand harsh weather and chemicals, with certifications that meet industry standards for equipment.

Construction & Infrastructure

In construction, particularly for infrastructure projects across Europe, Africa, and the Middle East, hardness testers validate the quality of steel reinforcements, beams, and structural connectors before and after installation. Ensuring correct hardness levels is critical for compliance with building codes and preventing structural failures. Buyers benefit from testers capable of handling large, coated, or irregularly shaped samples, and which offer reliable documentation for quality audits and regulatory reviews.

Aerospace

Aerospace manufacturers in regions such as France and Italy rely on precision hardness testing for high-value components where safety is non-negotiable. Testing is used to certify the hardness of alloys used in turbine blades, landing gear, and fuselage structures, ensuring that only materials meeting stringent standards enter service. Businesses must prioritize testers offering micro-scale accuracy, traceable measurement records, and support for specialty or lightweight metal alloys to meet strict certification and audit requirements.

Related Video: Portable Metal Hardness Tester dmq QH5

Strategic Material Selection Guide for metal hardness tester

Comparative Analysis of Common Materials for Metal Hardness Testers

Selecting the right material for metal hardness testers is fundamental to ensuring accuracy, repeatability, and optimal performance across a variety of industrial environments. Material choice impacts not only the durability and operational life of the tester, but also its compliance with international standards and its adaptability to local conditions. Below, we examine four of the most widely used materials in the construction of metal hardness testers, highlighting their properties, advantages, disadvantages, and region-specific considerations relevant for B2B purchasing decisions.

1. Tool Steel (e.g., AISI O1, D2, H13)

Key Properties:

Tool steels are characterized by high hardness, excellent wear resistance, and moderate to good toughness. They maintain their hardness over a broad temperature range and are resistant to deformation under repeated loads.

Pros & Cons:

Pros: Tool steel’s durability makes it ideal for indenters and load-bearing components. It’s relatively easy to machine and can be hardened to exacting specifications. Tool steels often comply with global standards (ASTM, DIN, JIS).

Cons: Susceptible to corrosion if not properly coated or alloyed, driving the need for protective finishes or regular maintenance—especially in humid or corrosive environments. Cost is moderate but can escalate for high-alloy or specialty grades.

Impact on Application:

Its ability to maintain dimensional stability under high loads means tool steel ensures consistent indentation, critical for repeatable hardness results.

International B2B Considerations:

European buyers (Italy, France) often specify conformity with EN or DIN standards, while Africa and the Middle East may focus on ASTM or ISO compliance. Reliable local or regional sourcing is essential to minimize lead times. In humid climates (e.g., West Africa, coastal South America), rust prevention must be prioritized.

2. Stainless Steel (e.g., 420, 440C)

Key Properties:

Stainless steels add crucial corrosion resistance, making them suitable for applications exposed to moisture, chemicals, or changing environments. Grades like 440C offer high hardness after heat treatment.

Pros & Cons:

Pros: Excellent resistance to oxidation and corrosion. Good hardness and relatively straightforward maintenance. Stainless steel can be used both for tester frames and internal components.

Cons: Typically more expensive than tool steel. Some grades are prone to galling or seizing during assembly. Hardness, while high, may still be inferior to some tool steels, especially in continuous heavy-use scenarios.

Impact on Application:

Stainless steel construction is key for reliable operation in laboratories, plants, or field applications with high humidity or the potential for chemical exposure.

International B2B Considerations:

Preferred in regions where humidity and corrosion are major issues—coastal Africa, parts of the Middle East, and northern Europe. DIN and ASTM standards are most commonly referenced; local regulations in some South American countries may require proof of anti-corrosion performance.

3. Carbide (e.g., Tungsten Carbide)

Key Properties:

Carbides, particularly tungsten carbide, are renowned for exceptional hardness, surpassing that of most steels, and outstanding wear resistance. They withstand repetitive impact and heat without significant deformation.

Pros & Cons:

Pros: Superior wear resistance dramatically extends indenter life and preserves measurement accuracy. Required for testing ultra-hard materials or high-throughput industrial settings.

Cons: Very high cost compared to steel and stainless steel. Brittle—vulnerable to cracking if mishandled or exposed to accidental impacts. Difficult and expensive to machine or repair.

Impact on Application:

Best used for precision indenters in Vickers or Rockwell hardness testers, especially where the test volume is high or the sample materials are very hard.

International B2B Considerations:

Essential for automotive, aerospace, and heavy manufacturing sectors. Availability sometimes limited in emerging markets (certain African or Latin American countries); buyers should verify supply chain and after-sales support.

4. Cast Iron

Key Properties:

Offers excellent vibration damping, decent compressive strength, and inherent stability. Does not match the hardness or corrosion resistance of alloy steels but is easy to cast and machine.

Pros & Cons:

Pros: Highly cost-effective for heavy frames and machine bases, supporting stable test setups and reducing mechanical noise. Simple to manufacture shapes with intricate geometries.

Cons: Prone to corrosion and surface pitting if unprotected. Brittle—may crack under impact or stress, especially in extreme conditions. Not suitable for precision moving parts.

Impact on Application:

Used mainly for tester bodies or support structures rather than precision components. Provides bulk and stability, ideal for fixed laboratory environments.

International B2B Considerations:

Favored in cost-sensitive markets where environmental conditions allow. European and Middle Eastern buyers sometimes demand additional surface treatments to meet rust-resistance standards, while in many African regions indoor-only use complies with typical workflow.

Material Selection Summary Table

| Material | Typical Use Case for metal hardness tester | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Tool Steel (e.g., AISI O1, D2) | Indenter tips, loading mechanisms | High hardness and durability; global standards compliance | Corrosion risk in humid environments; needs coatings | Medium |

| Stainless Steel (e.g., 440C) | Tester frames, internal components exposed to moisture | Corrosion resistant; versatile applications | Higher cost than tool steel; potential for galling | High |

| Tungsten Carbide | Precision indenters, high-wear components | Exceptional hardness and wear resistance | Very brittle; high initial and replacement cost | High |

| Cast Iron | Tester frames, support structures | Vibration damping; economical | Low hardness; can corrode and is brittle | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for metal hardness tester

Metal hardness testers are precision instruments central to ensuring product quality across industries such as automotive, aerospace, energy, and manufacturing. For B2B buyers globally—especially those sourcing from or importing to Africa, South America, the Middle East, and Europe—it’s crucial to understand the typical manufacturing workflows, quality control touchpoints, and certification nuances that signal a reliable supplier and a fit-for-purpose product.

Key Manufacturing Stages for Metal Hardness Testers

1. Material Selection and Preparation

The foundation of a reliable metal hardness tester lies in the judicious selection of raw materials. High-grade steels, reinforced plastics, and, in many cases, industrial ceramics are chosen for their stability, resistance to deformation, and longevity. Leading manufacturers rigorously vet suppliers and often require supporting material certifications including chemical composition, mechanical properties, and traceability records. For electronic subcomponents (sensors, displays, PCBs), international buyers should verify adherence to RoHS (Restriction of Hazardous Substances) and, where applicable, local import regulations.

2. Precision Machining and Component Fabrication

The forming and fabrication stage focuses on achieving tight dimensional tolerances and surface finishes essential for high-accuracy measurement devices. Computer numerical control (CNC) machining is employed to manufacture the indenter, anvil, and load application systems—the heart of devices like Rockwell or Vickers testers. Robust calibration blocks and electronic housings are concurrently produced, often involving multi-stage processes such as:

- Turning and milling: For core metal components and mechanical assemblies

- Laser cutting or EDM (Electrical Discharge Machining): For intricate geometries or micro-mechanical parts

- Surface hardening or coating: To prolong indenter life and maintain calibration stability

3. Sub-Assembly and Main Assembly

A controlled assembly process, typically in a clean environment, ensures that modular components (indenter assembly, load cells, levers/balances, electronics) are integrated without introducing contamination or mechanical stress. For digital testers, PCBs are populated and tested separately before final enclosure. Leading manufacturers use error-proofing (poka-yoke) and barcode tracking to minimize assembly errors and improve traceability.

4. Calibration and Final Testing

Calibration is a defining benchmark—testers are precisely adjusted using certified hardness reference blocks to meet or exceed ISO/ASTM standards for measurement uncertainty and repeatability. Both mechanical and electronic verification steps are conducted, simulating standard test cycles to ensure consistency across multiple units and over repeated tests. Automated software validation is introduced for digital models, verifying data logging, user interface, and output accuracy.

5. Finishing, Branding, and Packaging

Post-assembly, units are subject to final surface treatment (e.g., anti-corrosion coatings, anodizing, or powder coating for metal housings). Branding, laser-etching of serial numbers, and labelling for market-specific compliance (e.g., CE mark for Europe, Conformité Africaine for some African markets) are typically performed prior to carefully engineered packaging that protects sensitive calibration and sensor systems during international transit.

Quality Control Protocols, International Standards, and B2B Best Practices

Ensuring consistent quality and regulatory compliance is paramount, especially for B2B buyers operating in strictly regulated or high-liability industries. Reputable hardness tester manufacturers implement multi-level QC procedures designed for traceability and proven reliability.

Critical QC Stages

-

Incoming Quality Control (IQC):

– All raw materials, precision components, and electronic sub-assemblies are inspected on arrival.

– Material certificates and supplier audit reports are cross-checked for each batch.

– Non-conforming components are segregated and escalated for root-cause analysis. -

In-Process Quality Control (IPQC):

– Continuous inspection during machining and assembly.

– Use of coordinate measuring machines (CMM), laser micrometers, and force sensors to detect deviations from design tolerances.

– Regular calibration of assembly tools and jigs to maintain process integrity. -

Final Quality Control (FQC):

– Every finished tester undergoes a full functional test, measurement verification (using certified reference blocks), and safety compliance checks.

– Units are often subjected to accelerated life testing and environmental stress screening—particularly relevant for buyers in regions with extreme climates.

– All test results are documented and tied to the product serial number for post-sale traceability.

International and Industry-Specific Standards

- ISO 9001: Foundation for quality management systems across most reputable hardness tester manufacturers—expect routine audits and continuous improvement initiatives.

- CE Marking (Europe): Necessary for legal entry into the EU, including markets like France and Italy. Ensures compliance with key directives for safety, EMC (Electromagnetic compatibility), and RoHS.

- ASTM E18 (Rockwell), ASTM E384 (Vickers/Knoop), ISO 6506-1 (Brinell), ISO 6507: Referenced for method-specific calibration, testing accuracy, and uncertainty targets.

- API, EN, or regional norms: May be specifically requested in industrial (e.g., oil/gas, automotive, aerospace) or geographically regulated projects.

- Local certifications: African and South American buyers may require SONCAP (Nigeria), INMETRO (Brazil), or other verifications for customs clearance.

Actionable Insights for B2B Buyers: Evaluating Supplier Quality

1. Verifying Quality Credentials

- Request comprehensive documentation: Insist on recent ISO 9001 certificates, detailed test/calibration reports, and proof of compliance with application-specific standards.

- Product-specific traceability: Ask for a calibration certificate for each tester, ideally linking test results to both the device serial and the reference block.

- Third-party inspection reports: Leverage independent QC companies (SGS, TÜV, Bureau Veritas) to witness final testing or conduct random sampling before shipment.

2. Onsite Audits and Remote Assessment

- Factory audits: If volumes and strategic importance justify it, arrange an initial or recurring audit. Focus on process control, calibration routines, and supply chain transparency.

- Remote virtual factory tours: Especially valuable for buyers in Africa or South America where due diligence travel may be cost-prohibitive; many quality manufacturers now offer real-time video tours or secure data rooms for document review.

3. Ongoing Quality Assurance

- Monitor change control: Ensure your supplier notifies you of any significant process/material change impacting the tester’s compliance or calibration status.

- After-sales calibration and support: Assess the availability of local calibration services or the ease of shipping testers back for periodic re-certification. For regions with limited calibration infrastructure, verify that the product includes easy-to-use, user-level verification tools.

- Feedback loops: Partner with suppliers that actively solicit post-shipment feedback, allowing them to remediate emerging issues quickly—particularly important for buyers serving regulated sectors or end-customers with specific certification needs.

4. Regional Considerations and Certification Nuances

Different markets have varying expectations and enforcement rigor:

- Europe (Italy, France): Strict adherence to CE, EMC, and related EU directives; importers are liable for compliance, so comprehensive documentation is essential.

- Middle East: Growing trend towards ISO/ASTM alignment, but customs/market-specific documentation (e.g., SASO in Saudi Arabia) can be critical.

- Africa: Expect to provide full documentation to customs and clients; some markets require third-party pre-shipment inspection (PSI).

- South America: Brazil and Argentina, among others, impose local standards and require locally recognized certifications for electronics and industrial instruments.

Conclusion and Strategic Recommendations

By understanding each step of the manufacturing process and the full spectrum of quality assurance protocols, international B2B buyers can better qualify suppliers, mitigate risk, and ensure consistent, compliant metal hardness testers for their intended applications. Prioritizing transparent supplier documentation, leveraging third-party QC, and staying abreast of regional certification requirements are cornerstones of successful cross-border sourcing in this precision-driven sector.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for metal hardness tester Sourcing

Key Cost Components in Metal Hardness Tester Manufacturing

Sourcing metal hardness testers internationally requires a firm grasp of the underlying cost structure. The overall unit price is shaped by several fundamental components:

- Materials: Core material costs include high-grade metals for the frame, diamond or hardened indenter tips, precision electronics, and durable plastics for housing and controls.

- Labor: Skilled assembly, calibration, and quality assurance—especially for testers requiring meticulous accuracy—contribute significantly, and wage differences across sourcing regions (e.g., Asia vs. Europe) notably affect unit cost.

- Manufacturing Overhead: Facility costs, machinery maintenance, and energy consumption factor into the manufacturer’s overhead allocation.

- Tooling and Setup: For custom models or large orders, specialized tooling, jigs, or mold creation may be a one-time addition—often amortized for higher volumes.

- Quality Control: Rigorous multi-stage testing and calibration lead to additional costs, particularly if certifications (e.g., ISO, CE) are mandated by the importing country or region.

- Logistics and Packaging: Transportation (air, sea, or rail), insurance, export packaging (crates, climate protection), and customs clearance fees are often underestimated but significant, especially for intercontinental shipments.

- Supplier Margin: Final pricing includes supplier overhead and profit, which varies based on manufacturer reputation, order scale, and market demand.

Major Price Influencers for B2B Sourcing

A buyer’s final landed cost for a metal hardness tester can fluctuate considerably depending on these dynamic factors:

- Order Volume & Minimum Order Quantity (MOQ): Larger, consolidated orders can unlock economies of scale, leading to lower per-unit prices, while low-volume purchases may carry premiums or setup surcharges.

- Product Specifications & Customization: Advanced capabilities (e.g., digital displays, multi-method testing, advanced data interfaces) and bespoke branding or mechanical specs increase overall cost.

- Material Grade & Indenter Type: Higher-precision testers using certified diamond indenters or advanced sensors fetch a premium over models with standard components.

- Quality Standards & Certifications: Compliance with industry, regional, or application-specific certifications (ISO, ASTM, CE marking) impacts both price and supplier eligibility for regulated markets.

- Supplier Location, Reputation & Manufacturing Volume: Suppliers with established quality records and mass production capability, especially in major manufacturing hubs, generally offer more competitive pricing. Proximity to main shipping ports also impacts final shipping cost.

- Incoterms & Shipping Arrangements: EXW, FOB, CIF, and DAP terms substantially alter the scope of included costs—buyers in Africa, South America, and the Middle East should be especially vigilant about who bears responsibility and risk at each shipping stage.

Practical Buyer Tips for International Sourcing

International buyers—particularly those from Africa, South America, the Middle East, Italy, and France—can optimize procurement strategy with these actionable approaches:

- Negotiate Beyond Unit Price: Seek itemized quotes that clarify tooling, calibration, and documentation charges. Use multi-unit or long-term agreements to drive cost savings, and request bundled aftersales support or calibration accessories where possible.

- Evaluate Total Cost of Ownership (TCO): Factor in maintenance needs, calibration frequency, local technician availability, and spare parts costs—not just the initial purchase price—especially for markets with limited local support infrastructure.

- Balance Customization and Cost-Efficiency: While tailored features enhance value, standardizing on widely supported models can yield better spare part availability and lower lifecycle costs.

- Verify Certifications and Compliance: In regions with strict market-entry requirements (e.g., Europe’s CE), confirm documentation in advance to avoid costly delays or rejections at customs.

- Leverage Regional Hubs and Consolidators: For emerging and remote markets, using a regional logistics partner or consolidator can mitigate shipping risks and reduce single-shipment costs.

- Consider Exchange Rates and Payment Terms: Secure quotations in stable or home currency and seek favorable payment schedules to minimize exposure to currency fluctuations and cash flow risks.

- Assess Warranty and Local Support: Prioritize suppliers offering reliable warranty, remote assistance, and access to spare parts or calibration support in your region.

Disclaimer: All referenced costs and pricing insights are indicative only. Actual prices vary by supplier, order volume, customization, and logistic arrangements. Always solicit multiple quotations and run TCO analyses tailored to your operational context before finalizing procurement.

By understanding these cost elements and negotiation levers, B2B buyers can achieve competitive pricing, regulatory compliance, and sustained value when sourcing metal hardness testers internationally.

Spotlight on Potential metal hardness tester Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘metal hardness tester’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Google (www.google.com)

Google is a globally recognized technology company with a robust ecosystem that facilitates B2B industrial sourcing through its advanced search and marketplace platforms, rather than direct manufacturing. While there is limited verified public information confirming Google as a direct manufacturer or supplier of metal hardness testers, the company is frequently referenced as a discovery gateway for reputable global and regional suppliers in this sector. Google’s technology connects B2B buyers—especially from Africa, South America, the Middle East, and Europe—to leading manufacturers offering metal hardness testers compliant with international standards. This broad accessibility enhances sourcing efficiency, comparison of options, and access to supplier certifications. For buyers seeking verified manufacturers or direct factory links, Google’s tools are invaluable for conducting due diligence, benchmarking, and finding competitive pricing across international markets.

Quick Comparison of Profiled Manufacturers

| Manufacturer | Brief Focus Summary | Website Domain |

|---|---|---|

| B2B sourcing gateway, not a direct manufacturer. | www.google.com |

Essential Technical Properties and Trade Terminology for metal hardness tester

Key Technical Specifications for Metal Hardness Testers

When sourcing metal hardness testers for industrial or laboratory applications, international B2B buyers must assess several technical properties to ensure suitability, reliability, and compliance with industry standards. The following critical specifications should be thoroughly evaluated during procurement and contract negotiations:

-

Hardness Scale Compatibility

Hardness testers are designed to operate with specific scales such as Rockwell (HR), Brinell (BHN), and Vickers (HV). Each scale caters to distinct material types and application needs. For example, Rockwell scales are common for metals like steel, while Vickers is essential for precise measurements on thin coatings or microstructures. Confirming scale compatibility is crucial, as it impacts the tester’s accuracy and relevance for your product range. -

Load Range and Accuracy

The applied force (load) and its precision directly influence testing results. Leading testers offer a broad and adjustable load range (commonly from a few grams up to several kilograms), catering to various material hardness levels. Accuracy—usually specified as a percentage of the applied load—ensures that results are consistent and compliant. High accuracy minimizes discrepancies, supporting global quality standards and customer requirements. -

Indenter Type and Durability

The indenter, often made from diamond or hardened steel, determines the tester’s compatibility with certain materials and longevity under intensive use. Different tests require specific indenter shapes and materials (e.g., diamond cones for Rockwell, steel balls for Brinell). Assessing indenter replacement intervals and material grade is vital to optimize lifecycle costs and minimize downtime, particularly in regions where servicing logistics may be challenging. -

Measurement Resolution and Data Output

Resolution refers to the smallest increment the tester can detect—critical for precise quality control, especially with high-specification exports. Many modern testers offer digital interfaces and data exporting features (USB, RS232, or wireless), enabling efficient reporting and integration with broader quality management systems. For buyers in Africa, South America, and diverse European markets, these data capabilities streamline compliance and audit trails. -

Sample Size/Shape Accommodation

The physical design specifies minimum and maximum sample sizes (thickness, diameter) and shapes (flat, cylindrical) the tester tolerates. This property is particularly important when testing a wide array of parts or products, ensuring versatility and reducing the need for multiple devices. -

Operating Environment

Consider the tester’s tolerance to ambient conditions—such as humidity, dust, and temperature range. Equipment destined for the Middle East, Africa, or facilities with variable climates must demonstrate robust environmental resilience.

Common Industry and Trade Terms in Global Hardness Tester Procurement

Familiarity with standard trade and technical jargon streamlines international negotiations and reduces risk. Below are frequently encountered terms and their practical significance for B2B buyers:

-

OEM (Original Equipment Manufacturer)

Refers to manufacturers that produce equipment—like a hardness tester—either under their brand or for third-party branding. Sourcing from a reputable OEM ensures product authenticity, compliance with certifications (CE, ISO, etc.), and often access to technical support and spare parts. -

MOQ (Minimum Order Quantity)

The smallest batch a supplier will accept per order. Knowing the supplier’s MOQ is essential for planning inventory investment, especially for buyers entering new markets or seeking pilot quantities before full-scale procurement. -

RFQ (Request for Quotation)

A formal inquiry issued by buyers to gather pricing, specifications, and delivery terms from multiple suppliers. A well-structured RFQ process helps compare offers on a like-for-like basis and facilitates transparent international bidding. -

Incoterms (International Commercial Terms)

Standardized rules, such as FOB (Free on Board), CIF (Cost, Insurance, and Freight), or DAP (Delivered at Place), indicate who is responsible for shipping, insurance, customs duties, and risk transfer points in global trade. Selecting appropriate Incoterms clarifies costs and liabilities, particularly for complex cross-continental shipments. -

Calibration Certificate

A document verifying that the hardness tester has been calibrated according to recognized standards (typically ISO or ASTM). International buyers should always request calibration certificates to ensure reliable results and compliance with auditing bodies. -

After-Sales Service & Spare Parts Availability

This term encompasses ongoing technical support, local agent presence, and spare parts supply. Robust after-sales service reduces equipment downtime—crucial when importing to locations with longer logistics chains (e.g., remote mining operations or manufacturing sites in Africa or South America).

By understanding these technical attributes and trade terms, B2B buyers enhance procurement confidence, support informed decision-making, and ensure smoother cross-border transactions in the metallurgical equipment sector.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the metal hardness tester Sector

Global Market Drivers and Sourcing Trends

The demand for metal hardness testers is growing in tandem with the expansion of advanced manufacturing, automotive, aerospace, and infrastructure projects worldwide. As competitive pressures intensify and quality assurance becomes an international imperative, B2B buyers across Africa, South America, the Middle East, as well as European countries like Italy and France, are increasingly seeking to enhance their materials testing capabilities. Among the most influential market drivers are the accelerating adoption of Industry 4.0 practices, the globalization of supply chains, and evolving regulatory standards for safety and performance.

Digital transformation is redefining the sourcing landscape. Modern hardness testers are moving beyond analog systems towards digital, automated, and portable platforms—significantly simplifying on-site and in-line testing. Buyers favor systems with integrated data acquisition, wireless connectivity, and compatibility with quality management software, as these features drive both traceability and productivity. Customization is emerging as a sourcing trend, with enterprises requesting testers tailored to unique industry needs—such as portable units for field service in mining operations or micro-hardness testers for advanced electronics manufacturing.

Geopolitical considerations and fluctuating logistics costs further influence sourcing strategies. African and South American buyers prioritize local representation and after-sales support to mitigate risks associated with long-distance supply chains. In the Middle East, rising domestic manufacturing ambitions fuel investment in next-generation testers that can meet diverse standards—such as ASTM, ISO, and DIN. European companies tend to value technology partnerships, seeking suppliers who not only deliver instrumentation but also support systems integration, calibration services, and ongoing training.

Recent years have also seen a steady move toward supplier diversification. B2B buyers are widening their vendor bases to ensure resilience against disruptions, engaging with both established global brands and specialized regional manufacturers from Asia and Eastern Europe. Strategic buyers are leveraging digital procurement platforms to compare certifications, warranty options, and service agreements, making the sourcing process more transparent and efficient.

Sustainability and Ethical Sourcing

Environmental stewardship and social responsibility are increasingly central to procurement decisions. B2B buyers are under mounting pressure to minimize not just their own carbon footprints but also those of their supply chains. This is especially true for sectors such as automotive, aerospace, and mining—major consumers of hardness testing equipment—where environmental, social, and governance (ESG) compliance is now a competitive differentiator.

Hardness tester manufacturers are responding with more sustainable practices throughout the device lifecycle. Energy efficiency is a core design priority, as digital systems tend to consume less power than legacy analog instruments. Materials with lower embodied energy or recycled content, such as casings made from sustainable polymers, are being adopted to meet green procurement requirements. Packaging is shifting toward biodegradable or reduced-plastic alternatives to decrease environmental impact during transportation and delivery.

Buyers should require documentation of green certifications or environmental compliance, such as ISO 14001, RoHS, or CE markings, as part of their due diligence. Transparent ethical sourcing—ensuring that suppliers uphold fair labor standards and source conflict-free materials—mitigates reputational risks and aligns with international procurement guidelines. Third-party audits and traceability protocols are growing in importance, particularly for government and publicly listed buyers.

Selecting partners committed to responsible manufacturing also supports longer equipment lifespans and lower lifecycle costs. Many top suppliers offer modular testers or upgradable firmware, minimizing waste and facilitating repair or refurbishment. B2B buyers in Africa and South America can benefit by prioritizing vendors who offer localized service centers, reducing environmental impact related to international shipping for repairs and parts.

The Evolution of Metal Hardness Testing: A Brief Perspective

Metal hardness testing has evolved from simple, qualitative methods such as the Mohs scale to a comprehensive suite of quantitative tests—like Rockwell, Brinell, and Vickers—designed for distinct material classes and industrial needs. In the early industrial era, accuracy and repeatability were limited by human observation. Over time, test standards became more rigorous and instrumentation more precise, enabling consistent cross-border quality assurance.

Today, the field is shaped by rapid advancements in sensor technology, automation, and data integration. Modern testers offer not only reliable measurement but also the ability to embed results directly into digital quality assurance systems. This historical progression underpins the sector’s ongoing transformation—meeting the expectations of global buyers who demand both technical excellence and alignment with sustainability and ethical goals.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of metal hardness tester

-

How can I evaluate and select reputable international suppliers of metal hardness testers?

Start by reviewing suppliers’ track records via trade platforms, customer references, and industry certifications (such as ISO 9001 or CE conformity if selling into Europe). Prioritize partners with localized support in your region or within target logistics routes for Africa, South America, the Middle East, or Europe. Request recent case studies or testimonials, verify business licenses, and assess responsiveness during pre-sale communication. Independent audits or virtual facility tours can also add assurance. Transparent documentation and clear communication around warranty, service, and calibration are key indicators of a trustworthy supplier. -

Are metal hardness testers customizable to suit different regional standards and applications?

Yes, many manufacturers offer varying configurations, such as different hardness scales (Rockwell, Brinell, Vickers), languages for software interfaces, and power supply specifications to suit local standards (e.g., 220V/50Hz in Europe). Buyers should clearly specify any industry- or region-specific compliance requirements, such as ASTM, ISO, or local calibration needs. Customization options may also include data connectivity (USB, Bluetooth, wireless) and export report formats for integration with existing quality systems. Always confirm the supplier’s capability to provide documentation and calibration certificates recognized in your target market. -

What are typical minimum order quantities (MOQs), lead times, and payment terms for international B2B orders?

MOQs for metal hardness testers are often low, sometimes as little as one unit, especially for high-value or precision instruments. Standard lead times range from 2 to 8 weeks depending on customization, factory schedules, and shipping method. Payment terms vary: popular options include 30% advance and 70% balance before shipment, or letters of credit for large orders. Always negotiate payment schedules that reflect your risk management needs, and clarify all banking and remittance procedures to prevent transaction delays. -

What quality assurance and certification standards should I demand for international purchases?

Demand suppliers adhere to recognized standards such as ISO 6508 (for Rockwell), ISO 6506 (Brinell), or ASTM equivalents. For European imports, CE marking is critical. Ask for calibration certificates traceable to internationally recognized labs, comprehensive user manuals in your preferred language, and evidence of quality management systems (e.g., ISO 9001). Third-party inspection before shipping, or test reports from an accredited lab, provide added assurance. Consider requesting a sample report or trial data set to verify measurement accuracy. -

How are metal hardness testers typically shipped internationally, and what special logistics considerations apply?

These testers are precision instruments and require secure, shock- and moisture-resistant packaging. They are shipped via air or sea freight, depending on urgency and order size. Ask about Incoterms—such as FOB, CIF, or DAP—which determine who is responsible for shipping, insurance, and customs clearance. Clarify if the supplier provides export documentation (commercial invoice, packing list, certificate of origin) and whether after-sales support is available in your country. Factor in customs duties, VAT/GST, and local regulations that may impact importation. -

What after-sales support is essential for international B2B buyers of metal hardness testers?

Prioritize suppliers offering remote technical support, comprehensive user training (in-person, online, or via video materials), and prompt warranty service. Inquire about availability and lead times for spare parts or consumables. Some suppliers maintain partnerships with local calibration labs—leverage this for routine maintenance and certification renewals. Consider service-level agreements (SLAs) that specify response times and escalation procedures for critical support requests, especially if you serve demanding industries such as manufacturing, mining, or automotive. -

How do I handle disputes or issues with international suppliers, especially regarding equipment quality or non-conformance?

Always establish clear contractual terms regarding product specifications, tolerances, delivery dates, and recourse for non-conforming goods. Use purchase agreements that include arbitration clauses and agreed dispute resolution forums (e.g., ICC arbitration in a neutral country). Retain all correspondence and transaction records. Where possible, use secure payment methods that offer buyer protection (letters of credit, escrow services). In case of disputes, document all findings with photos, inspection reports, and third-party assessments to support your case. -

What are best practices for verifying compliance with import regulations and technical standards in my country or region?

Research and stay up-to-date on your country’s import requirements for metrological equipment—this may involve certifications or pre-approval from government agencies (such as customs bureaus or standards institutes). Consult with local agents or customs brokers who have experience with laboratory or industrial testing devices. Before finalizing a purchase, request copies of all relevant compliance documents and check compatibility with regional voltage, environmental, and safety requirements. Non-compliance can result in costly delays or even confiscation at the port of entry, so upfront diligence is vital.

Strategic Sourcing Conclusion and Outlook for metal hardness tester

As global industries continue to demand precision and reliability, metal hardness testers have become indispensable in ensuring product quality and engineering integrity. For international B2B buyers across Africa, South America, the Middle East, and Europe, investing in the right hardness testing solutions directly contributes to improved manufacturing processes and enhanced competitiveness.

Key strategic sourcing considerations include:

- Aligning test methods with application needs: Evaluate Rockwell, Brinell, or Vickers testers based on the material types, thickness, and industry standards relevant to your sector.

- Verifying supplier credibility and support: Prioritize suppliers who offer robust after-sales service, calibration support, and localized technical guidance, especially for buyers navigating diverse regulatory or climatic conditions.

- Balancing cost and performance: Consider both upfront investment and long-term value, aiming for equipment that ensures durability, measurement accuracy, and compliance with international quality certifications.

- Leveraging innovation: Explore advanced models with digital interfaces, automated data capture, and integration capabilities to future-proof your testing operations.

Looking ahead, the dynamic landscape of global trade and manufacturing will increasingly reward organizations that couple technical rigor with smart sourcing strategies. Embrace ongoing market trends and emerging technologies to ensure your hardness testing equipment continues to meet evolving industry demands. Now is the time for forward-thinking procurement decisions that reinforce quality, bolster operational resilience, and drive sustained business growth in global markets.