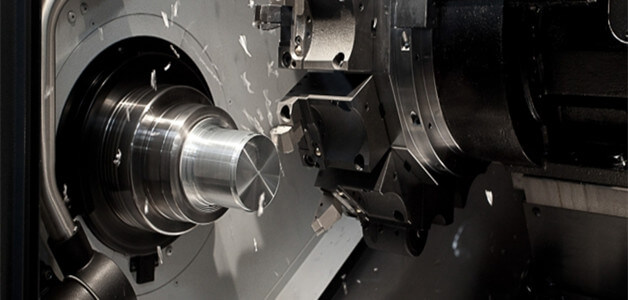

Automotive CNC Machining Service for you

Wuxi Lead Precision Machinery, with its state-of-the-art CNC facility and expert workforce, is the perfect partner for your CNC auto parts needs!

What We Offer in Automotive CNC Machining?

Automotive components are complex in nature and require various manufacturing techniques including CNC machining as well as casting, forging, and precision grinding. Here at Wuxi Lead Precision Machinery, we are well-equipped to handle the geometric intricacies of CNC car parts.

Our capabilities include:

4-axis machining up to 0.005 mm dimensional accuracy

An exceptionally smooth surface finish of up to Ra 0.2

A variety of materials including hard-to-cut automotive materials.

Basically, everything you need for automotive CNC machining!

With a talented design and product development team in the house, we welcome all projects from rapid prototyping to large-scale production.

Automotive Components Machining at Wuxi Lead Precision Machinery

We offer Automotive CNC Machining of the following high-precision automotive components with a range of surface treatment options to resist wear and corrosion.

Engine Components: Cylinder heads, piston, crankshafts, camshafts, engine blocks.

Transmission Parts: Gears, shafts, and housings.

Braking System: Brake rotors, clippers, and brake drums.

Suspension System Components: Suspension arms and mounting brackets.

Interior and Exterior Components

Fuel Injectors

Why Choose Wuxi Lead Precision Machinery for Automotive CNC Machining?

The automotive industry is the hub of innovation in manufacturing, and automotive CNC machining technologies are its lifeblood! The high complexity and precision requirements of automotive parts is the reason why CNC machining is the method of choice for many high-end car part manufacturers.

The rapid advancements in the capabilities of CNC machines, cutting tool technologies, and material handling capabilities are one of the main driving forces behind developments in auto machining.

At Wuxi Lead Precision Machinery, we strive for quality. Our successful collaborations with many well-known names in the automotive industry are testament to our dedication to achieve complete customer satisfaction.

On-Demand Customization

Whether you need a low-volume production run for a customized product or high-volume batches, standard or exotic materials, we have got you covered!

Cost Effective Production

With our efficient processes and use of automation technologies, we optimize our machine shop automotive processes for minimal costs and maximum productivity.

Customer Service

From product design to production to quality testing, we are your most reliable CNC car parts partner. Share your ideas and let us handle the rest!

FAQs for CNC Automotive Machining

What are the advantages of CNC automotive machining? CNC technology offers high precision, surface quality, and productivity.

Is CNC machining suitable for automotive parts? CNC machining is the prime choice for most automotive components due to its compatibility with complex geometric designs.

Is CNC compatible with other automotive manufacturing techniques? CNC machining is commonly used in conjunction with processes like casting, forging, 3D printing, and laser cutting to produce high quality parts.

Is CNC machining worth the higher cost? Generally, CNC machining is more expensive than traditional operations. However, the higher productivity, quality, and customer appeal have been proven to make CNC machining a more viable option for automotive parts.