CNC Grinding Services for Prototype Production

Quality CNC grinding services for prototype production in custom and large-scale uses. The right partner for advanced tools and instant quotes.

CNC Grinding Services for Prototype Production

Since its inception, Wuxi has met its customers’ demands by supplying thousands of customized machining aerospace components worldwide.

We have mostly done business with independent aerospace contractors and have extensive, complex firm assignments from the military. Whether you need a one-time service or batch manufacturing, we meet your demands with full attention.

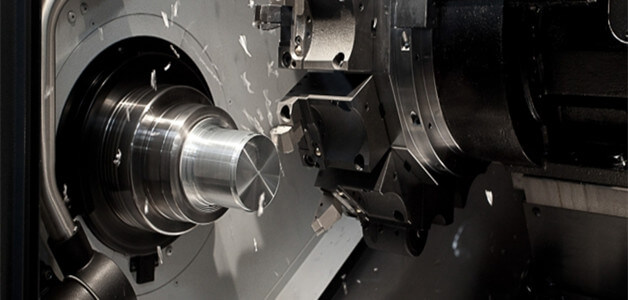

Lead Machinery offers three sets of custom CNC grinding services. They include surface finishing, symmetrical components turning, and milling. Our CNC surface grinder can help you attain intricate 3D and 2D designs with enhanced auto parts.

Milling

Our milling services accommodate tolerances of +/-0.005 mm and diameters between 2 and 1000 mm. We also use enhanced features like automatic tools and chip removal. The milling facility covers 1 VMC for high speed, 4 Fada VMCs suitable for detailed vertical operations, and 8 HMCs for large-scale projects.

Turning

Lead Machinery shapes cylindrical and symmetrical geometries with excellent precision. We provide a Dia (1 – 300mm) size range up to Rao. There are four surface finishes and a tolerance of +/-0.005 mm |. Our turning setup covers CNC grinding services with Mazak Single Spindle Quick Turn Lathes and efficient multitasking with Twin Spindle Lathes.

Finishing

Lead Machinery leverages advanced finishing tools to turn your rough CNC surface grinder into outstanding auto parts. Overall, the surface treatment process modifies the substrate material with wear resistance, aesthetic appeal, and corrosion resistance.

Our finishing procedures include electroplated surfaces, which use electrochemicals to add a decorative and protective metal coating. We also offer sand-blasted finishes, which boost surface adhesion and create a matte and uniform structure.

In addition, anodized finishes offer corrosion resistance and durability. Lead Machinery CNC grinding services also provide polished products with a high-gloss finish for enhanced smoothness and appearance.

CNC Machining Material

Lead Machinery offers diverse CNC grinding materials, including aluminum, stainless steel, brass, titanium, and plastic.

Our machining serves diverse uses since it suits insulated and lightweight settings.

Meanwhile, titanium is lighter and stronger than steel and can withstand up to 500 degrees Celsius in medical, chemical, and auto uses.

Brass uses Zinc-copper alloy with corrosion resistance and excellent machinability.

It offers a golden and decorative appearance to suit uses such as snake tubes, shells, condensers, water tanks, and drainage pipes.

Our stainless steel CNC surface grinder offers exceptional corrosion resistance since it has high chromium content.

Why Choose Us?

Our advanced tools and expert team will deliver amazing results on your custom CNC machining projects. We provide products surpassing standard options with unique sizes, materials, and performance. Thus, our services cover precision and designs.

Material Range

Lead Machinery advances the material range to serve diverse industries. In other words, we offer metal CNC machining for diverse metals such as brass, titanium, steel, and aluminum. Other options include acrylic, ABS, nylon, polycarbonate, and Teflon.

Diverse Settings

We cater to diverse uses, including military, electronics, medical, optics, and auto. Our products are common in communication devices, armament parts, diagnostic equipment, and dental implants. Lead Machinery also caters to PCB components.

Experience

Our company boasts over ten years of experience in CNC machining, producing quality products for machinery factories, auto parts, and mining conveyors. Thus, we have honed skills in the latest CNC grinding techs for efficiency.

Art Machinery

Lead Machinery uses advanced systems to deliver superior CNC grinding products. Simply put, we meet diverse applications since our procedure uses high-end lathes and multi-axis machining to meet diverse demands in the CNC landscape.

High Precision

Most settings require custom parts with exact specifications to ensure a perfect fit. Our services deliver as low as +/-0.0005mm tolerances.

Get Quality CNC Grinding With Lead Machinery Today!

Are you looking to work with a reliable CNC grinding manufacturer?

Lead Machinery offers reliable CNC grinding services for custom projects across China.

We use advanced tools and diverse tolerance options. Contact us today for instant quotes!