CNC Custom Machining China

The Right Partner for CNC Machining Needs in China

Choose Lead Precision Machinery for your prototype needs, large-scale production runs, and custom CNC parts.

Tolerances: Up to 0.005 mm

Surface Roughness: Up to Ra 0.4

Instant Quotes: Available online

Advanced Equipment: 4-Axis CNC Machines

CNC Machining Services We Offer

We offer CNC milling services that help you achieve any intricate 2D or 3D designs.

Our milling facility has

8 Okuma HMCs for precision work on larger-scale projects,

4 Fada VMCs for detailed vertical operations,

and 1 Okuma Genos VMC that excels in high-speed milling

with enhanced features of chip removal and automatic tool changes.

Size Range: 2-1000mm diameter |

Tolerance: +/-0.005mm

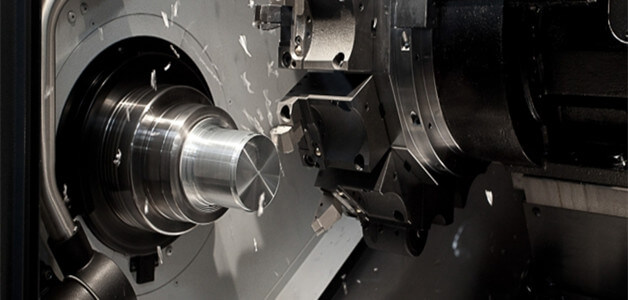

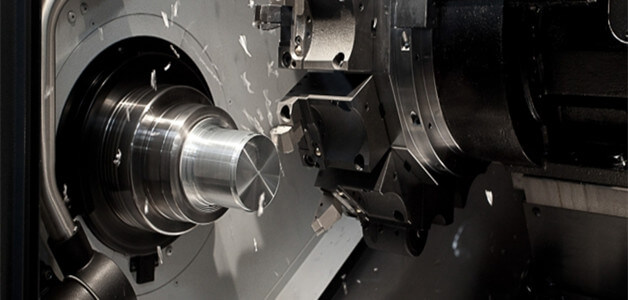

Our CNC Turning services allow you to shape symmetrical and cylindrical geometries with precision.

Our turning setup includes

Okuma Twin Spindle Lathes for efficient multi-tasking

and Mazak Single Spindle Quick Turn CNC Lathes for custom projects

that require concentricity and roundness.

Tolerance: +/-0.005mm |

Surface Finish: Up to Ra0.4 |

Size Range: Dia (1 – 300mm)

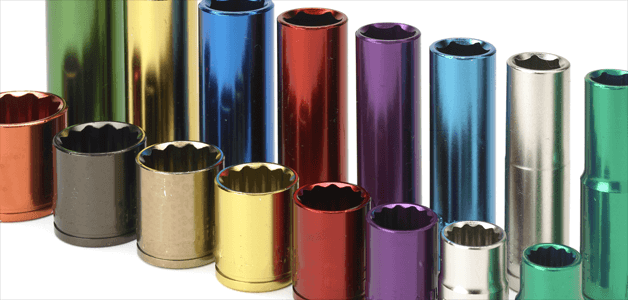

With our advanced surface finishing techniques, you can turn your rough machined surfaces into refined final products. Our surface treatments modify the substrate material to improve its corrosion resistance, wear resistance, and aesthetic appeal.

Primary Finishes We Offer:

Anodized: Provides a durable and corrosion-resistant finish.

Sand Blasted: Creates a uniform, matte texture that improves surface adhesion.

Polished: Results in a high-gloss finish that enhances the appearance and smoothness.

Electroplated: An electrochemical process adds a protective and decorative metal coating.

Materials for CNC Parts

Choose from our diverse material range

Aluminum Machining

Celebrated for its low density and high strength-to-weight ratio. Ideal choice for applications requiring lightweight yet durable components. Aviation, automotive, and construction are key application areas.

Popular Aluminum Alloys we machine:

Grade | Ultimate Tensile Strength (MPa) | Hardness (HB) | Elongation at Break (%) | Corrosion Resistance |

2024 | 470 – 500 | 120 | 18 – 22 | High |

6061-T6 | 310 – 330 | 95 | 10 – 20 | High |

6063 | 280 – 320 | 70 – 75 | 20 – 25 | High |

7050 | 540 – 560 | 140 – 160 | 10 – 12 | Good |

7075-T6 | 560 – 600 | 140 – 160 | 9 – 13 | Moderate |

Stainless Steel Machining

Exceptional corrosion resistance, thanks to high chromium content (at least 10.5%). Alloying elements nickel, carbon, molybdenum, and manganese to improve its overall durability, strength, and aesthetic appearance. Applications include kitchenware, medical instruments, automotive components, and construction materials.

Stainless steel alloys lead machinery deals with:

Alloy Series | Ultimate Tensile Strength (MPa) | Elongation at Break (%) | Hardness (HB) | Corrosion Resistance |

304 | 480 – 620 | 45 – 60 | 195– 205 | High |

316 | 480 – 620 | 30 – 50 | 210 – 220 | Very High |

410 | 440-460 | 18 – 22 | 205 – 215 | Moderate |

430 | 440-460 | 20 –24 | 180 – 186 | Low |

Brass CNC Machining

Zinc-copper alloy with excellent machinability and corrosion resistance. Also, has a decorative appeal due to its golden appearance.

Common uses include drainage pipes, water tanks, condensers, shells, and snake tubes.

Titanium Machining

Very high strength-to-weight ratio. Strong but much lighter compared to steel.

It can withstand high temperatures up to 500°C.

Best for aerospace, automotive, chemical, and medical applications.

Plastics Machining

Lightweight and insulative properties make them usable across a range of applications.

Plastics we deal with:

Material | Density (g/cm³) | Tensile Strength (MPa) | Wear Resistance |

PTFE (Teflon) | 2.16 | 26 | Medium |

PC (Polycarbonate) | 1.2 | 75 | High |

Nylon | 1.15-1.36 | 185 | High |

ABS | 1.04 | 37 | Medium |

Acrylic (PMMA) | 1.19 | 72 | Low |

Industries we Cater

Automation

Precision parts of automation systems, robotic system components

Optics

Machined parts for optical systems, imaging systems

Medical

Surgical instruments, dental and orthopedic implants, diagnostic equipment

Electronics

Enclosures and housings, PCB components, socket parts

Military

Naval ship components, armament parts, communication devices

Why Choose Lead Precision Machinery?

Trust Your Custom Projects to Our Expert Team and Advanced Setup

Standard parts often don’t meet unique performance, size, or material requirements for certain applications. When you’re testing or developing new products, custom prototypes are essential. Even some complex assemblies in industries like aerospace, automotive, and electronics demand non-standard, specialized components.

Custom CNC Machining is pivotal for achieving this precision. With a customized machining approach, you can design parts that meet specific dimensional criteria and select materials that withstand unique environmental conditions.

Lead Precision Machinery delivers top-tier CNC machining in China. We specialize in CNC milling, turning, and surface finishing for metals and plastics. Our facility has high-tech multi-axis CNC machines that handle complex geometries with ease. With more than 15 years of experience in custom CNC machining, our skilled team upholds the highest quality standards and ensures precise compliance with client specifications.

High Precision Standards

Modern applications require parts that are manufactured to exact specifications to ensure perfect fit and function. We deliver products with tolerances as low as ±0.0005mm.

State of the Art Machinery

In the evolving CNC landscape, advanced systems lead to superior machining jobs. Considering that, our machining fleet has high-end multi-axis CNC milling machines and lathes from Okuma, to meet diverse product demands.

Decades of Experience

Experience counts! With over 15 years in the machining industry, we have honed our skills, adapting to the latest technologies and industry practices to deliver unmatched quality.

Versatile Material Range

As products evolve, so does our material catalog. We offer metal machining services for popular metals such as aluminum, steel, titanium, and brass, as well as various plastics.

FAQ

What tolerance can lead precision machinery to help me achieve?

Lead Precision Machinery can achieve precision tolerances as low as ±0.005 mm.

What’s the cost of CNC machining in China?

That depends on the machining operation and the type of machine you’re utilizing. For operation on 3-axis machining, the milling cost is between $15 to $20/hour. CNC Turning costs about $15/hour, on average. Whereas, the same operation on a 4-axis or higher machine costs $30/hour.

Do you have any minimum order quantity?

No minimum order quantity is required at Lead Precision Machinery; we accommodate everything from a single prototype to large production runs.