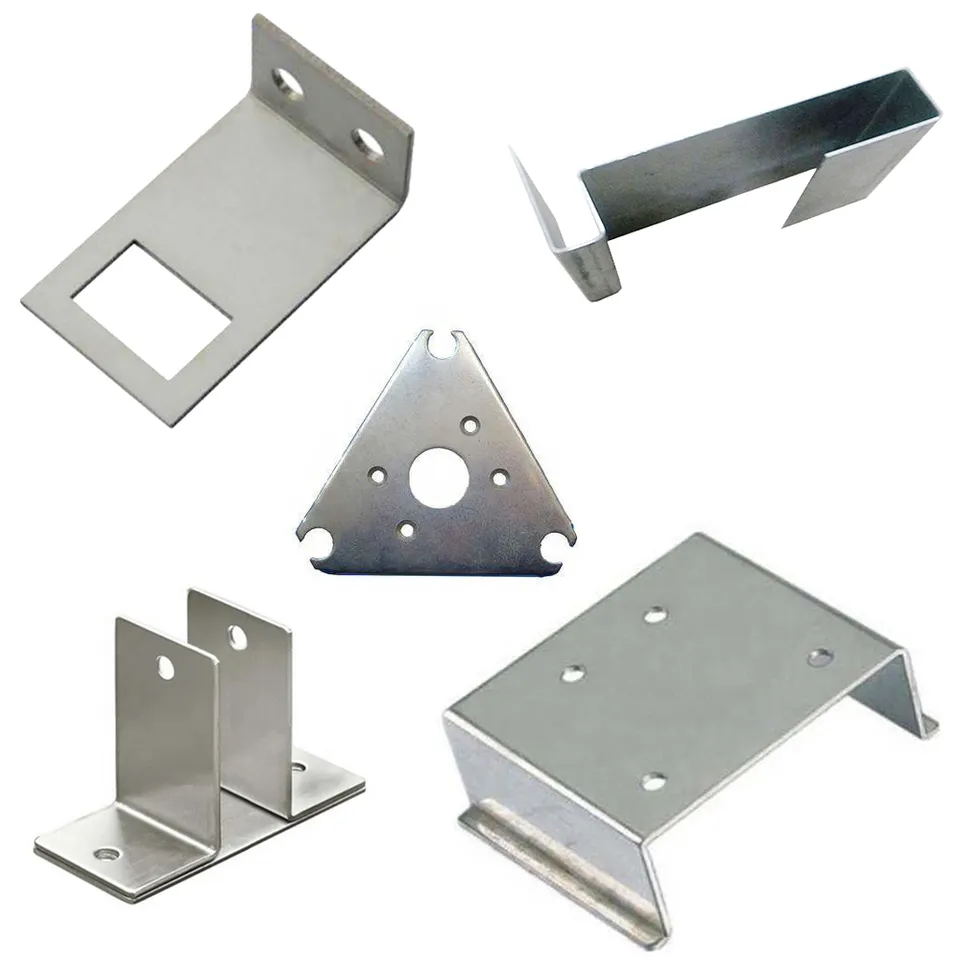

Custom Metal Stamping Services

Our CAM-integrated CNC stamping facilities can produce custom metal stamping parts according to your unique requirements and design specifications. We make the custom metal stamping dies at our own machining factory to craft them with fine details. A team of expert engineers at our factory is ready to handle your complex design with utmost accuracy and precision.

ISO 21223:2019 Quality Control

Tolerance Down to ± 0.01mm ( 0.004” )

50 + Metal and Alloy Options

Stamping, Punching, Blanking, Bending, and Many More operations

Our Production Capabilities

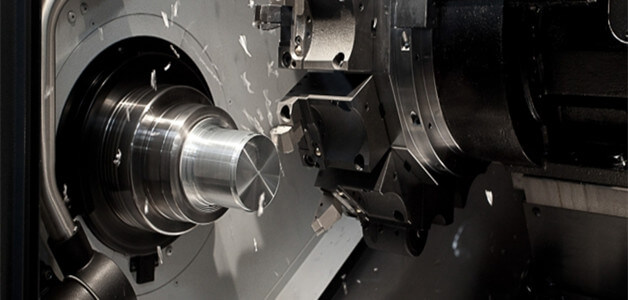

We have advanced CNC metal stamping machines with automated punch presses, from 20 to 200 tons. These are capable of fulfilling diverse custom metal stamping needs across the industries.

Maximum Part Size | 1500 x 1000 mm ( 5 x 3 ft ) |

|---|---|

Thickness Range | 0.25 to 6 mm |

Tonnage Capacity | 20 to 200 tons |

Linear Tolerance | ± 0.01mm ( 0.004” ) |

Angular Tolerance | ± 1° |

Minimum Spcing Between Holes | 1- 0.5 x thickness |

Edge to Feature | 0. 4 mm |

Additional Processes |

Material Options for Custom Metal Stamping

Custom Metal Stamping Services at our factory can handle 50+ metals and alloys, from soft aluminum to hard steel alloys.

Aluminum

Aluminum is a ductile metal with a silver-like appearance. The aluminum alloys provide high strength at low weight and parts are highly durable due to their corrosion resistance. Additionally aluminum also offers good electrical and thermal conductivity. Some popular stamping grades include 1100, 2024, 7075, 5052, 6061, and 6063.

Steel

Steel is a high-strength and durable metal with excellent formability and affordability. It can be custom metal stamped for diverse uses.

It offers enhanced strength and excellent corrosion resistance but comes with an extra cost. Stainless steel alloys are suitable for high-stress applications. The common grades include 301, 304, 316, 410, 420, and 440 A, etc.

Copper

Copper provides excellent electrical and thermal conductivity, formability, corrosion resistance, biocompatibility, and decorative appearance. So, copper stamping parts made with grades ASTM 152 C11000-O60 and B152 are popular in performance-sensitive applications.

Brass

It is a copper alloy made with a combination of zinc, which improves the strength and helps to customize the original copper properties. Meanwhile, popular grades for custom metal stamping are; C26000, C220, C280, etc.

Custom Metal Stamping Applications

Automotive

The precise and low-cost manufacturing of custom metal stamping in high volumes makes it suitable for producing automotive components like engine brackets, chassis frames, door latch plates, brake assembly parts, etc.

Copper, brass, aluminum, and other metals are used in custom metal stamping for battery connectors, heat sinks, housing for electrical devices, switch components, antenna brackets, etc.

Biocompatible and other high-performance alloys are stamped to create various medical instruments, diagnostic equipment housing components, a few implants, catheter clamps, medical furniture, etc.

Agriculture

Metal stamping service has an essential role in the production of advanced and low-cost agricultural machinery parts. Stamping is used to make harvester blades, sprayer nozzles, seeded components, hinges, plates, and several other components.

Aerospace

Typically, sheet metal stamping creates structural, fixing, and interior components of aircraft. The accuracy and consistency of stamping directly contribute to their safe and reliable performance.

Hardware and Machinery

Various industry machinery and hardware items are made with stainless steel, aluminum, or other metal stamping processes. For example, conveyor belt system parts, grating, ladder steps, drive shaft mounts, etc.

Why Choose Our Custom Metal Stamping Services?

Custom Die and Tooling

Our expert tool makers operate the CNC, EDM, Laser, and other machinery for custom tools and die based on the unique features of the final part. We use hardened steel, carbides, and other tough materials for die and tooling.

Precise and Accurate Parts

Our CNC-controlled equipment and automated punching mechanisms ensure minimal human intervention during the process and achieve the tightest tolerances consistently. So, our custom metal stamping parts can be the best option for your tolerance-sensitive applications.

Design Flexibility

We fabricate parts with bends, holes, reliefs, notches, tabs, irregular curvatures, and other various complex features.

Competitive Pricing

A strong network of material suppliers and streamlined manufacturing allows us to offer competitive pricing without compromising quality, for all production volumes. We follow rapid die or tooling for prototyping and standard and durable die for mass production to optimize the cost.

Quality Control Inspection

Quality is our core value. We conduct First Article Inspections (FAI), In-process Inspections, and Final Inspections to ensure the desired quality. The gauges, calipers, CMM machines, laser scanners other measuring equipment are for this.

Surface Finishing Facility

We can further integrate the surface finishing services with the custom metal stamping. You can customize the surface properties and appearance with post-processing and surface finish techniques like anodizing, coating, painting, and electroplating.

What is Metal Stamping Technology?

Stamping is one of the popular sheet metal forming technologies, which is used to transform raw metal sheets into functional parts and products of designed shape. It is also known as the Press stamp die process because the working of metal stamping is based on the principle of die and punch setup. The stamping die holds the worksheet above its cavities and the punch vertically applies tonnages enforcing into die cavities and permanently deforming into that shape.

Custom metal stamping can involve forming operations like piercing, bending, deep-drawing, blanking, etc, depending on the complexity of the desired parts.

Progressive Die Stamping

It is a streamlined sheet metal forming technique that handles multiple types of forming operations at different stations subsequently. The work steadily moves from one station to another station and the corresponding mechanism performs individual operations. For example, the first sheet metal is punched, then it is pierced, and the next station bends it to produce the final part.

This technique is ideal for precision metal stamping parts with multiple geometrical features. It reduces production time and offers excellent repeatability.

Four Slide Stamping

The decoiler and guiding system fed the sheet and up to four tools can work on this sheet by sliding it into different sides at a right angle. This method is suitable for highly intricate custom metal stamping like an automotive key fob terminal.