Technical Contents

Engineering Guide: Prototype Site

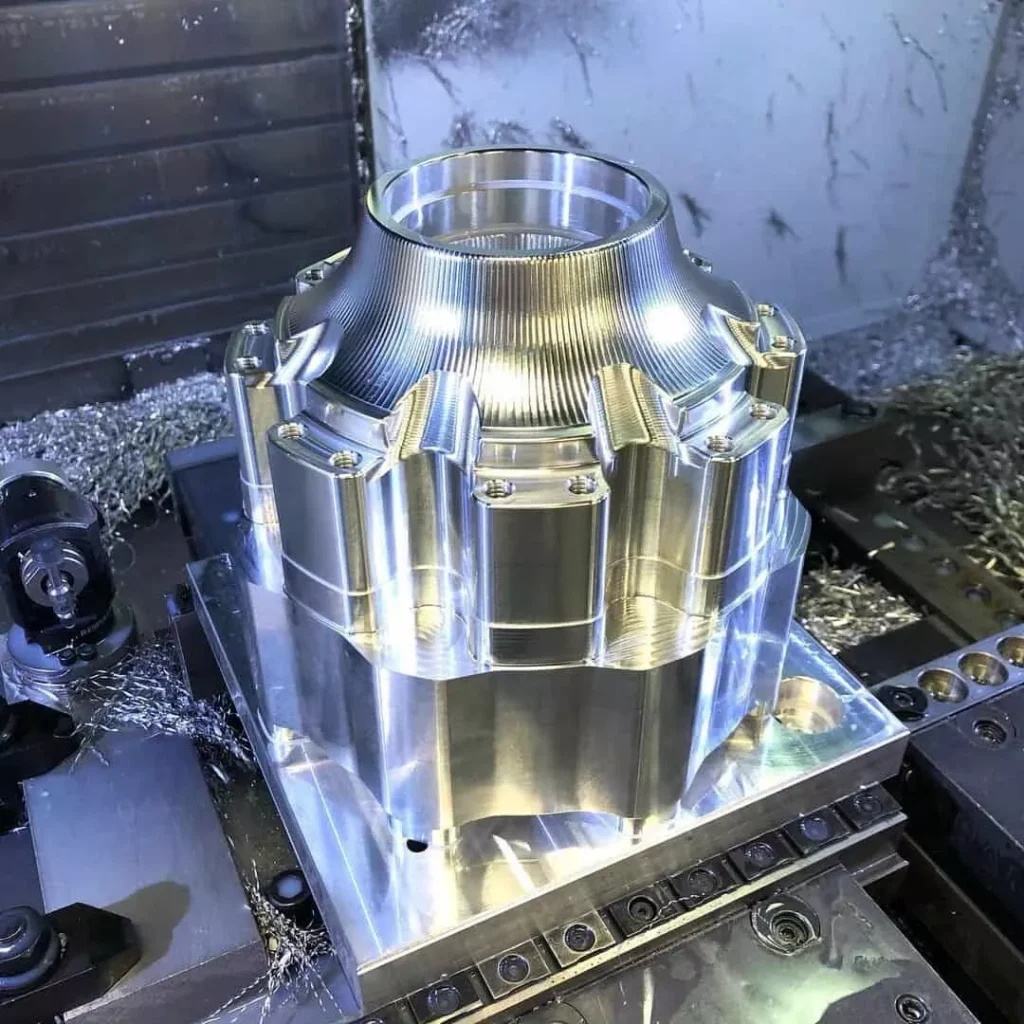

Engineering Insight: The Critical Role of Precision in Prototype Development

In the realm of custom metal manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, functionality, and innovation are built. At Wuxi Lead Precision Machinery, we understand that the prototype phase is where theoretical design meets real-world performance. It is during this stage that dimensional accuracy, material integrity, and process repeatability converge to determine the success of a final product. For industries where failure is not an option—such as aerospace, defense, and high-performance industrial systems—precision in prototyping is non-negotiable.

Our engineering team approaches every prototype with the rigor demanded by mission-critical applications. With decades of experience in high-tolerance CNC machining and custom fabrication, we have supported projects for Olympic-standard equipment and military-grade systems, where even micron-level deviations can compromise operational integrity. These projects demand more than advanced machinery; they require a culture of precision embedded into every phase of development—from material selection and CAD modeling to in-process inspection and final validation.

Precision in prototyping ensures that design assumptions are accurately tested under real conditions. It allows engineers to validate fit, function, and thermal or mechanical behavior with confidence. At Lead Precision, we utilize state-of-the-art 5-axis CNC centers, coordinate measuring machines (CMM), and real-time tool monitoring systems to maintain tolerances as tight as ±0.002 mm. This level of control enables seamless transition from prototype to production, minimizing rework and accelerating time-to-market.

Beyond equipment, our process excellence is rooted in a deep understanding of material behavior and geometric complexity. Whether machining titanium alloys for defense applications or aluminum alloys for lightweight sporting equipment used at the Olympic level, we apply material-specific strategies to manage stress relief, tool wear, and surface finish. Each prototype is treated as a benchmark for series production, ensuring scalability without compromise.

The following table outlines key specifications that define our precision prototyping capabilities:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.2 – 1.6 μm (adjustable) |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Tool Steels |

| CNC Equipment | 3-axis, 4-axis, 5-axis machining centers |

| Inspection Tools | CMM, Optical Comparator, Laser Scanning |

| Lead Time (Prototype) | 7–15 days (varies by complexity) |

Our track record in delivering precision-critical components for Olympic and military applications underscores our commitment to engineering excellence. When performance, durability, and accuracy define success, Wuxi Lead Precision Machinery ensures that every prototype meets the highest standards of quality and consistency.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Metal Prototyping

Wuxi Lead Precision Machinery delivers uncompromising precision for demanding custom metal prototypes and low-volume production runs. Our core strength lies in integrating cutting-edge multi-axis machining with rigorous, traceable quality control systems. This ensures every component meets the exacting geometric and functional requirements of aerospace, medical, semiconductor, and advanced industrial applications from the very first prototype iteration.

Our foundation is a modern fleet of high-torque, high-accuracy 5-axis CNC machining centers. These systems eliminate the need for multiple setups by simultaneously controlling tool movement across X, Y, Z linear axes and two rotational axes (A/B or A/C). This capability is critical for machining complex organic shapes, deep cavities, intricate undercuts, and fully contoured surfaces found in turbine blades, surgical implants, and fluidic manifolds. The result is superior part integrity, reduced lead times by up to 40% compared to 3-axis methods, and elimination of cumulative setup errors. All machines maintain sub-micron repeatability through thermal compensation systems and regular laser calibration per ISO 230-2 standards, ensuring consistent dimensional stability across extended production runs.

Quality verification is not an afterthought but an integrated, documented process at Wuxi Lead. Every critical dimension and geometric feature undergoes non-destructive inspection using state-of-the-art Coordinate Measuring Machines (CMMs). Our Zeiss and Hexagon CMMs, operating within a climate-controlled metrology lab (20°C ±0.5°C), provide full 3D point cloud analysis against the original CAD model. This generates comprehensive AS9100-compliant inspection reports detailing actual measurements versus nominal values, including GD&T callouts. Surface finish is verified using calibrated profilometers, while material certification and heat treatment documentation are rigorously tracked. This closed-loop system guarantees that every prototype shipped meets the specified tolerance stack-up and functional intent, providing clients with absolute confidence for design validation and regulatory submissions.

The following table details our standard achievable tolerance capabilities across common engineering materials. Specific project requirements may allow for tighter control through process optimization.

| Material Category | Dimensional Tolerance (mm) | Geometric Tolerance (mm) | Typical Surface Finish (Ra µm) |

|---|---|---|---|

| Aluminum Alloys (e.g., 6061, 7075) | ±0.005 | ±0.010 (Flatness) | 0.8 – 1.6 |

| Stainless Steels (e.g., 304, 316, 17-4PH) | ±0.008 | ±0.015 (True Position) | 0.4 – 0.8 |

| Titanium Alloys (e.g., Ti-6Al-4V) | ±0.010 | ±0.020 (Concentricity) | 0.8 – 1.6 |

| Engineering Plastics (e.g., PEEK, Delrin) | ±0.025 | ±0.050 | 1.6 – 3.2 |

| Exotic Alloys (e.g., Inconel 718, Hastelloy) | ±0.012 | ±0.025 | 0.8 – 1.6 |

These capabilities, combined with our engineering expertise in material science and process planning, enable Wuxi Lead to transform complex digital designs into physically perfect metal prototypes. We prioritize dimensional accuracy and functional performance at the prototype stage, directly accelerating your path to reliable, high-integrity production.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, directly influencing the performance, durability, and cost-efficiency of the final prototype or production component. At Wuxi Lead Precision Machinery, we specialize in precision CNC machining of high-performance metals, with aluminum, steel, and titanium being the most widely used materials for industrial and engineering applications. Each material offers distinct mechanical properties and compatibility with finishing processes such as anodizing, enabling tailored solutions for aerospace, automotive, medical, and electronics industries.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for lightweight structural components and heat-sensitive applications. The most commonly used grades are 6061 and 7075. 6061 offers good weldability and moderate strength, making it ideal for general-purpose prototypes. 7075, with higher tensile strength, is preferred in aerospace and high-stress environments. Aluminum is highly compatible with anodizing, a process that enhances surface hardness and corrosion resistance while allowing for color coding and improved aesthetics.

Steel, particularly stainless steel grades such as 304 and 316, provides superior strength, wear resistance, and thermal stability. 304 stainless steel is widely used for its balanced mechanical properties and resistance to oxidation. 316 offers enhanced corrosion resistance due to molybdenum content, making it suitable for marine and chemical environments. While steel is not anodized, it can be finished with passivation, polishing, or powder coating to improve surface integrity and appearance. Carbon steels like 1045 are also available for applications requiring high mechanical strength and machinability.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for extreme environments. It offers exceptional strength-to-density ratio, outstanding corrosion resistance, and biocompatibility, making it ideal for aerospace, defense, and medical implant applications. Though more challenging to machine due to its low thermal conductivity and high reactivity, titanium’s long-term performance justifies its use in mission-critical components. Titanium can be anodized to achieve decorative finishes and improved surface wear characteristics.

When selecting a material, consider the operational environment, mechanical loads, weight constraints, and required surface treatment. Below is a comparison of key mechanical properties for commonly used materials.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Anodizing Compatible | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | High | Yes | Prototypes, Enclosures |

| Aluminum 7075 | 572 | 2.8 | Moderate | Yes | Aerospace, Defense |

| Stainless 304 | 505 | 8.0 | High | No | Medical, Food Processing |

| Stainless 316 | 570 | 8.0 | Very High | No | Marine, Chemical |

| Titanium Ti-6Al-4V | 950 | 4.4 | Excellent | Yes | Aerospace, Implants |

At Wuxi Lead Precision Machinery, we support material certification, in-house testing, and expert consultation to ensure optimal material and finish selection for your custom manufacturing needs.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Zero-Defect Production Process for Mission-Critical Components

At Wuxi Lead Precision Machinery, we engineer reliability into every stage of custom metal manufacturing. Our rigorously controlled process transforms conceptual designs into flawless high-volume production, specifically engineered for aerospace, medical, and semiconductor applications where failure is not an option. We eliminate defects at the source through integrated engineering validation and closed-loop manufacturing control.

The process begins with collaborative Design for Manufacturability (DFM) analysis. Our engineering team partners with your designers using Siemens NX software to scrutinize geometry, material selection, and tolerancing against our advanced CNC capabilities. This phase identifies potential stress points, assembly conflicts, and manufacturability risks before metal is cut, ensuring the design inherently supports zero-defect production. We provide actionable feedback to optimize part geometry for both performance and process stability, significantly reducing downstream rework.

Prototyping is not merely a validation step but a critical process refinement phase. Using identical 5-axis milling and turning centers designated for final production, we manufacture functional prototypes from your specified material—be it Inconel 718, Ti-6Al-4V, or medical-grade stainless steel. Each prototype undergoes comprehensive metrology, including full CMM reporting and non-destructive testing where required. This allows us to validate not only the part’s dimensional integrity but also the robustness of the manufacturing sequence itself. Client feedback is integrated within 3-5 days, enabling rapid iteration until the process consistently yields perfect components.

Mass production leverages the validated process parameters and tooling. Our facility operates under strict IATF 16949 and ISO 13485 protocols, with real-time SPC monitoring on all critical dimensions. Every machine cell employs automated in-process gauging and tool wear compensation, while our dedicated quality lab conducts hourly CMM checks against the approved prototype baseline. This closed-loop system ensures immediate correction of any process drift, maintaining dimensional stability across 10,000+ part runs. Final inspection combines automated optical scanning, fluorescent penetrant testing for critical surfaces, and full first-article inspection reports traceable to material certs.

Key Process Specifications

| Phase | Material Capability | Typical Tolerances | Inspection Depth | Lead Time (Standard) |

|---|---|---|---|---|

| Prototyping | Titanium, Inconel, Stainless Steels, Aluminum Alloys | ±0.005 mm | Full CMM + NDT as specified | 3-5 days |

| Mass Production | All prototyping materials + specialty alloys | ±0.002 mm (critical features) | Hourly SPC + 100% critical feature check | 2-4 weeks (volume dependent) |

This seamless transition from design through prototyping to high-volume production, governed by predictive quality controls and identical equipment, is how Wuxi Lead guarantees zero-defect delivery. We don’t just manufacture parts—we engineer supply chain certainty for your most demanding applications. Partner with us to convert precision requirements into production reality.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Custom Metal Manufacturing Excellence

When your project demands precision, reliability, and engineering integrity, partnering with Wuxi Lead Precision Machinery ensures your custom metal components are manufactured to the highest global standards. As a leading provider of CNC machining, sheet metal fabrication, and precision assembly services in China, we specialize in transforming complex designs into high-performance parts for industries including aerospace, medical devices, automation, and advanced industrial equipment.

Our mission is to serve as an extension of your engineering team, offering not just manufacturing capability but technical collaboration from prototype to full-scale production. At Wuxi Lead, we understand that precision is not measured in millimeters alone—it’s defined by consistency, material integrity, and adherence to your exact specifications. With over a decade of experience serving multinational clients, we combine advanced CNC technology with rigorous quality control to deliver components that meet ISO 9001:2015 and AS9100D standards.

Our facility in Wuxi is equipped with state-of-the-art 3-, 4-, and 5-axis machining centers, laser cutting systems, CNC bending machines, and robotic welding stations. This allows us to handle low-volume prototypes with rapid turnaround and scale seamlessly into high-volume production without compromising quality. Whether you require tight tolerances of ±0.005 mm, complex geometries, or exotic materials such as titanium, Inconel, or high-strength aluminum alloys, our team has the expertise to meet your demands.

We pride ourselves on transparency, responsiveness, and technical depth. From the moment you submit your inquiry, our engineering team conducts a comprehensive design for manufacturability (DFM) review, offering actionable feedback to optimize cost, lead time, and performance. This collaborative approach reduces iterations, accelerates time-to-market, and ensures first-time-right production.

Our capabilities are backed by a full suite of inspection and metrology tools, including CMM machines, optical comparators, and surface roughness testers, ensuring every component is verified before shipment. We support global logistics with reliable packaging, customs documentation, and on-time delivery to North America, Europe, and Asia.

To ensure your project succeeds, we invite you to engage with our team early in the development process. By aligning your design goals with our manufacturing expertise, we minimize risk and maximize efficiency.

For engineering inquiries, quotes, or technical collaboration, contact us today at [email protected]. Let Wuxi Lead Precision Machinery be your trusted partner in precision manufacturing.

| Specification | Capability |

|---|---|

| Machining Tolerances | ±0.005 mm |

| Max Work Envelope (Machining) | 1200 x 800 x 600 mm |

| CNC Turning Diameter | Up to 300 mm |

| Sheet Metal Thickness | 0.5 – 12 mm |

| Supported Materials | Aluminum, Steel, Stainless Steel, Titanium, Copper, Inconel, Brass |

| Surface Finishes | Anodizing, Powder Coating, Passivation, Plating, Bead Blasting |

| Quality Standards | ISO 9001:2015, ISO 14001, AS9100D |

| Lead Times (Prototype) | 7–15 days, depending on complexity |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.