Technical Contents

Engineering Guide: 3D Printed Service

Engineering Insight Precision in Metal Additive Manufacturing

Precision defines the viability of metal additive manufacturing for mission-critical applications. While 3D printing enables unprecedented geometric complexity, deviations in dimensional accuracy or material integrity can cascade into catastrophic field failures. In aerospace brackets, medical implants, or hydraulic manifolds, tolerances tighter than ±0.05mm are non-negotiable. Surface roughness directly impacts fatigue life, and internal porosity compromises pressure containment. Without rigorous process control, the theoretical advantages of AM become liabilities. At Wuxi Lead Precision Machinery, we treat precision not as a target but as a system—spanning laser calibration, inert gas management, thermal modeling, and post-processing protocols.

Our engineering discipline stems from delivering components where failure is unacceptable. We engineered titanium structural nodes for Olympic timing systems requiring micron-level repeatability under dynamic loads. For military clients, we produced Inconel 718 actuators surviving 1,200°C thermal cycles with zero distortion. These projects demanded more than printing; they required predictive simulation of residual stresses, real-time melt pool monitoring, and NDT validation exceeding AS9100 standards. Each build undergoes iterative thermal compensation to counteract layer-wise distortion—a capability honed through 12,000+ production hours.

Material science is equally critical. Generic AM parameters for 316L stainless steel yield inconsistent grain structures, risking intergranular corrosion in marine environments. Our proprietary parameter sets, validated through ASTM E8 tensile testing and ASTM E562 grain analysis, ensure mechanical properties match forged equivalents. This is why global defense primes and Formula 1 teams specify our post-processed AM components for flight-critical assemblies.

Below outlines our certified production capabilities for metal additive services:

| Parameter | Specification | Validation Method |

|---|---|---|

| Dimensional Tolerance | ±0.02mm (critical features) | CMM with 0.0005mm probe accuracy |

| Surface Roughness | Ra 1.6μm (as-built), Ra 0.4μm (polished) | ISO 4287 profilometry |

| Material Density | >99.95% (no porosity >25μm) | ASTM E1915 X-ray tomography |

| Build Volume | 500 x 500 x 500mm | Laser interferometer mapping |

| Supported Alloys | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg | Full material traceability |

True precision in AM merges machine capability with metallurgical expertise. It requires rejecting the “print-and-ship” mentality for closed-loop quality systems that anticipate failure modes before the first layer deposits. At Wuxi Lead, every build log, thermal image, and tensile report feeds a knowledge base refined across Olympic, military, and energy sector programs. When your design pushes AM to its limits, reliability isn’t optional—it’s engineered.

Precision Specs & Tolerances

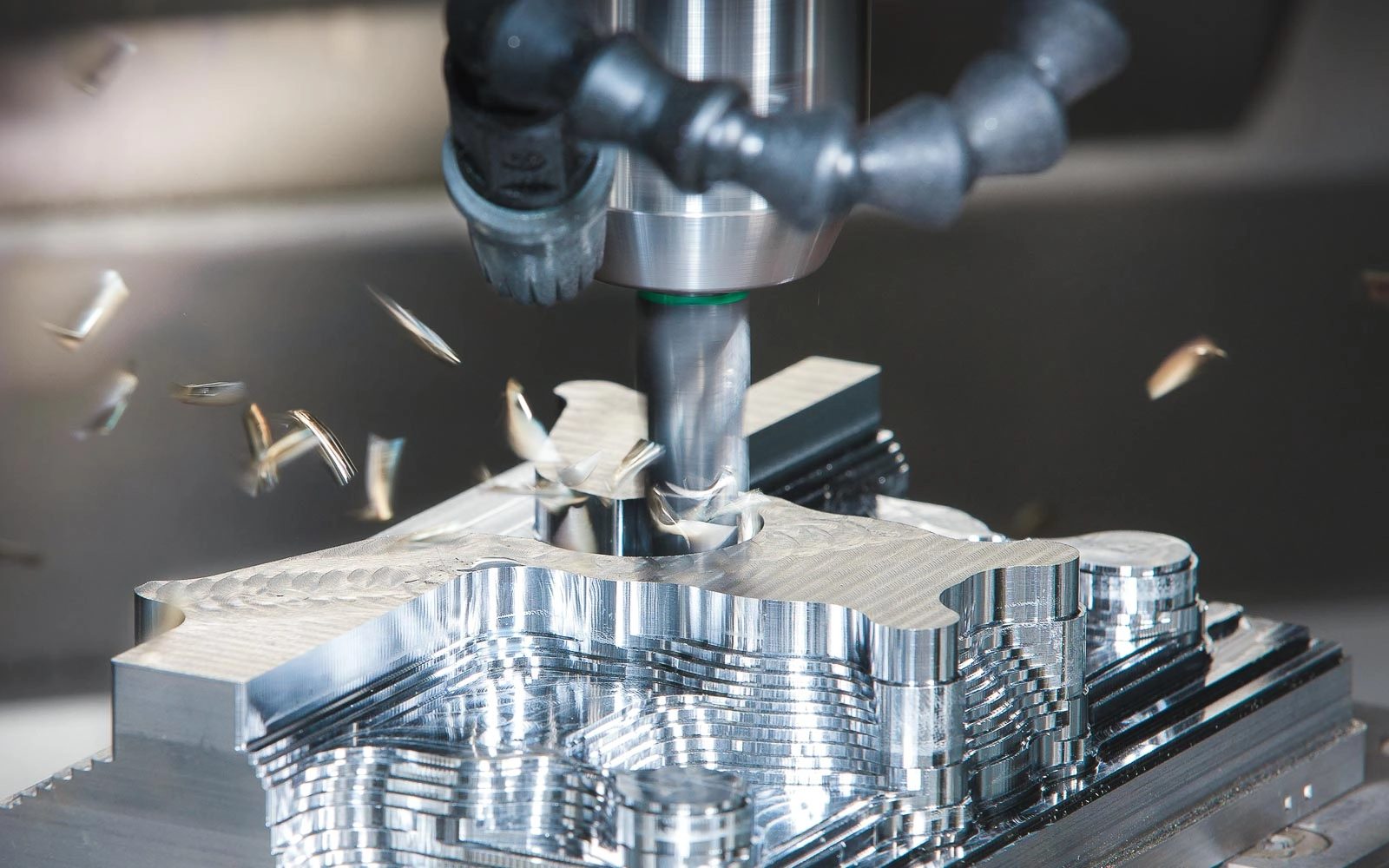

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions through state-of-the-art 5-axis CNC machining and rigorous quality control protocols. Our technical capabilities are engineered to meet the demanding requirements of aerospace, medical, automotive, and industrial technology sectors, where precision, repeatability, and material integrity are non-negotiable. At the core of our production floor lies a fleet of high-performance 5-axis CNC machining centers, enabling complex geometries and tight tolerances on a wide range of metallic materials including titanium, stainless steel, aluminum alloys, Inconel, and hardened tool steels.

The integration of 5-axis technology allows simultaneous movement across all five axes, minimizing setup times and maximizing accuracy. This capability supports the production of intricate components with undercuts, deep cavities, and organic contours that are unachievable with traditional 3-axis systems. Our machining centers are equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation, ensuring consistent part quality and reduced cycle times. All programs are developed using advanced CAM software with simulation and collision detection, guaranteeing process reliability before any material is cut.

Quality assurance is embedded throughout every stage of production. Each component undergoes comprehensive inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), providing micron-level verification of critical dimensions, geometric tolerances, and surface relationships. Our CMM system is calibrated to international standards and operated by certified metrology technicians, ensuring traceability and compliance with ISO 9001 and AS9100 requirements. In addition to final inspection, in-process checks are conducted to detect and correct deviations early, minimizing rework and ensuring on-time delivery of conforming parts.

Our commitment to precision is reflected in the tolerances we consistently achieve across diverse part configurations and materials. Below is a summary of our standard and precision tolerance capabilities.

| Feature Type | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 300 mm |

| Hole Diameter | ±0.015 mm | ±0.008 mm | Reamed/precision bored |

| Positional Tolerance | ±0.020 mm | ±0.005 mm | Relative to datum |

| Flatness | 0.02 mm | 0.005 mm | Over 100 mm surface |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm | Machined surface |

| Angular Tolerance | ±0.05° | ±0.01° | Critical interfaces |

Wuxi Lead Precision Machinery combines advanced equipment, skilled engineering, and a disciplined quality system to deliver components that meet the highest standards of performance and reliability. Our technical capabilities are not just about machinery—they reflect a culture of precision, accountability, and continuous improvement.

Material & Finish Options

Material Selection for Precision Metal 3D Printing

Selecting the optimal material for metal additive manufacturing is critical for achieving functional performance, dimensional accuracy, and cost efficiency in demanding industrial applications. At Wuxi Lead Precision Machinery, we guide clients through this decision based on rigorous analysis of mechanical requirements, environmental exposure, and post-processing needs. Aluminum, steel, and titanium alloys dominate high-performance sectors like aerospace, medical, and energy, each offering distinct advantages and considerations for 3D printing.

Aluminum alloys, particularly AlSi10Mg and 7075, provide an exceptional strength-to-weight ratio essential for aerospace and automotive components. AlSi10Mg offers good castability, moderate strength, and excellent thermal conductivity, making it suitable for complex heat exchangers and lightweight structural parts. High-strength 7075 aluminum delivers aerospace-grade mechanical properties but requires precise parameter control during printing and mandatory heat treatment to achieve target specifications. Both alloys benefit significantly from post-build machining to meet tight tolerances.

Stainless steel variants, especially 316L and 17-4 PH, are workhorses for corrosion resistance and structural integrity. 316L excels in marine, chemical, and medical implant applications due to its superior resistance to pitting and crevice corrosion. 17-4 PH stainless steel provides high strength through precipitation hardening, ideal for demanding tooling, valves, and aerospace fittings requiring both durability and moderate corrosion resistance. Achieving full density and consistent mechanical properties in stainless steel demands meticulous process control and often stress-relief annealing.

Titanium Ti6Al4V (Grade 5) remains the premier choice for extreme environments. Its unparalleled strength-to-weight ratio, biocompatibility, and exceptional resistance to high temperatures and corrosive media make it indispensable for critical aerospace components, medical implants, and downhole oil & gas tools. Printing titanium requires an inert atmosphere to prevent contamination and careful thermal management to minimize residual stress. Near-net-shape parts typically undergo Hot Isostatic Pressing (HIP) to eliminate internal porosity and ensure structural reliability.

Surface finishing, particularly anodizing for aluminum components, enhances wear resistance, corrosion protection, and aesthetic control. Type II (sulfuric acid) anodizing provides a standard decorative and protective layer, while Type III (hardcoat) anodizing delivers significantly thicker, harder surfaces for severe wear applications. Crucially, anodizing adds dimensional thickness; our engineering team precisely accounts for this during build preparation to maintain critical tolerances post-finishing. Not all 3D printed aluminum surfaces anodize uniformly due to micro-porosity, necessitating specific surface preparation protocols we implement.

Material properties directly influence print strategy and final part performance. The following table summarizes key characteristics for common 3D printed alloys:

| Material | Yield Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Primary Applications |

|---|---|---|---|---|

| AlSi10Mg | 200-250 | 2.67 | Moderate | Lightweight structures, heat exchangers |

| 7075 Aluminum | 450-500+ (T6) | 2.81 | Low-Moderate | Aerospace brackets, high-strength parts |

| 316L Stainless | 350-500 | 8.00 | Excellent | Medical implants, marine components |

| 17-4 PH Steel | 1000-1300 (H900) | 7.75 | Good | Tooling, valves, high-strength fittings |

| Ti6Al4V | 830-900 | 4.43 | Excellent | Aerospace, medical implants, oil & gas |

Wuxi Lead Precision Machinery leverages extensive material science expertise and in-house metallurgical analysis to validate each build parameter set for your specific alloy and application. Our process ensures not only geometric accuracy but also the certified mechanical and chemical properties your mission-critical components demand. Consult our engineering team early in the design phase for optimal material and finishing selection.

Manufacturing Process & QC

From Design to Mass Production: A Zero-Defect Manufacturing Process

At Wuxi Lead Precision Machinery, our production process is engineered for precision, repeatability, and uncompromising quality. Specializing in custom metal manufacturing with advanced 3D printing integration, we deliver end-to-end solutions that transition seamlessly from concept to full-scale production. Our methodology ensures zero defects across every stage—design, prototyping, and mass production—by combining cutting-edge technology with rigorous quality control protocols.

The process begins with design optimization, where our engineering team collaborates closely with clients to refine CAD models for additive manufacturability. We analyze geometric complexity, material selection, thermal behavior, and structural integrity using simulation software to predict performance under real-world conditions. This stage ensures that every component is not only functional but optimized for the metal 3D printing process, minimizing stress accumulation and post-processing requirements.

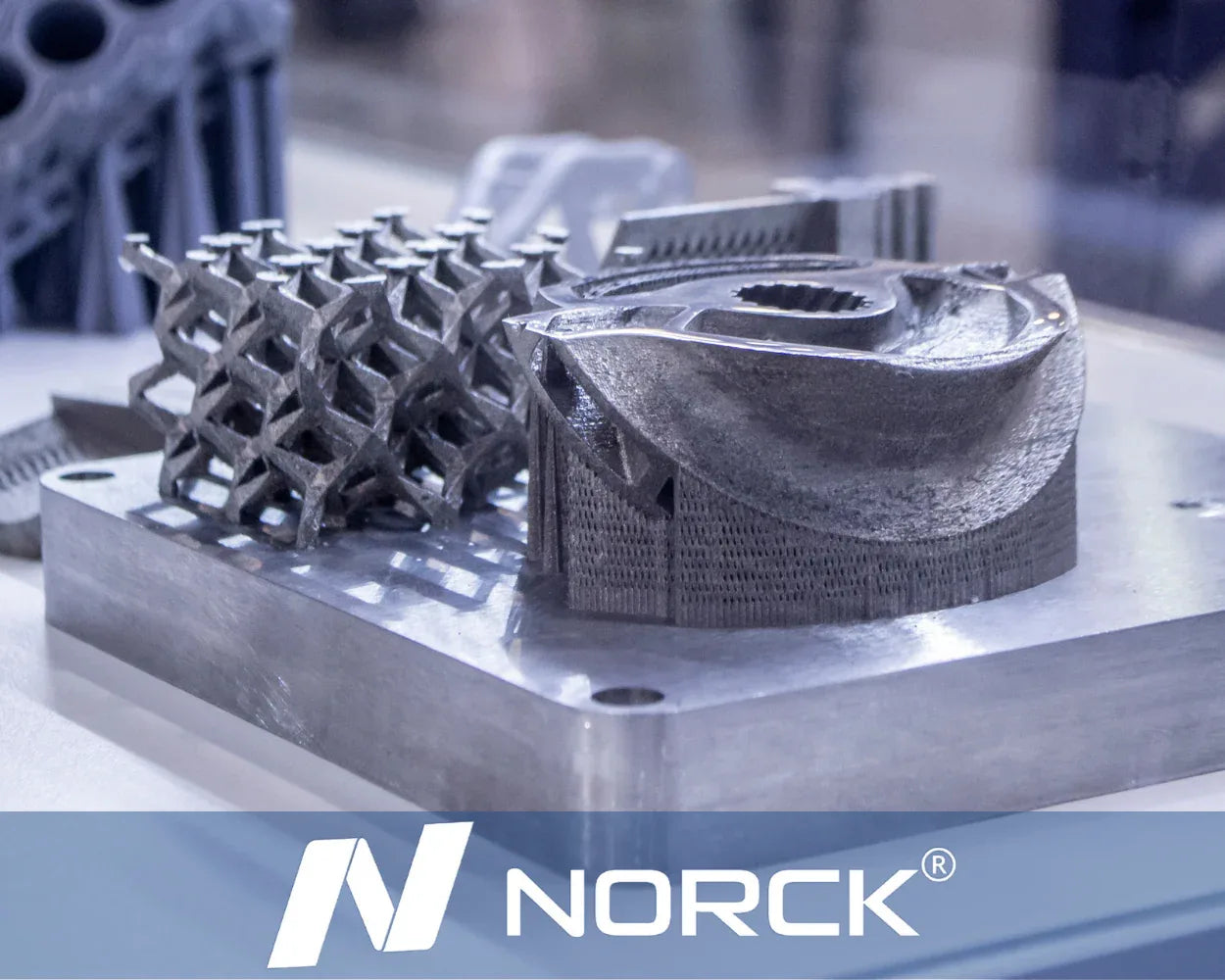

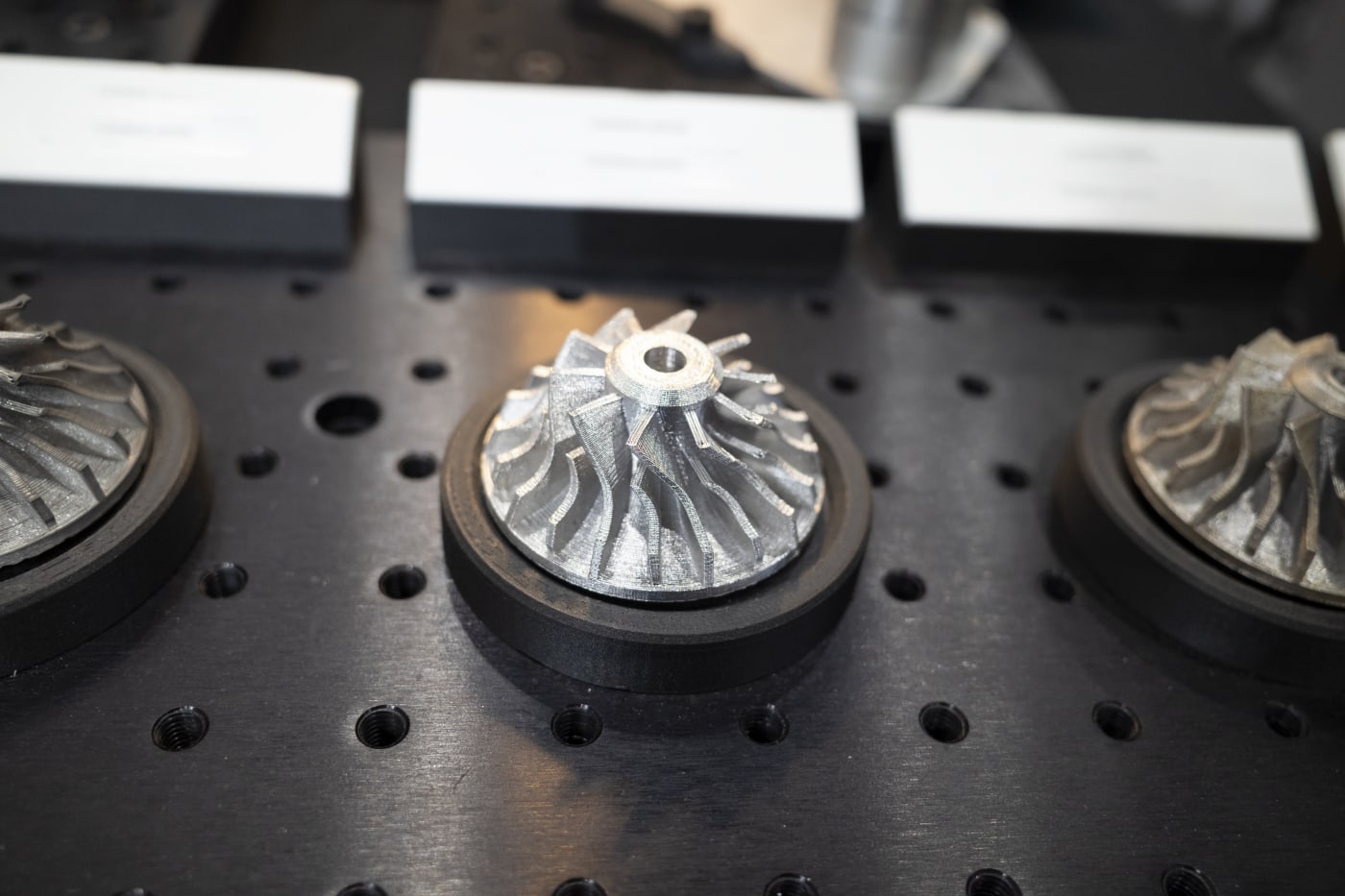

Next, we move into precision prototyping. Utilizing state-of-the-art metal additive manufacturing systems such as selective laser melting (SLM) and direct metal laser sintering (DMLS), we produce high-fidelity prototypes in the final production material—typically titanium, stainless steel, Inconel, or aluminum alloys. Each prototype undergoes full metrological inspection via coordinate measuring machines (CMM) and 3D scanning to validate dimensional accuracy within ±0.02 mm. Functional testing, including pressure, fatigue, and thermal cycling, confirms performance compliance before approval for mass production.

Once the prototype is validated, we initiate zero-defect mass production. Our automated production cells operate under strict environmental controls, with real-time monitoring of laser power, scan speed, layer adhesion, and inert gas purity. Every build is supported by in-situ monitoring systems that detect anomalies during printing, enabling immediate corrective action. Post-processing—including heat treatment, stress relieving, CNC machining, surface finishing, and penetrant testing—is performed in-house under ISO 9001-certified workflows.

Final inspection is non-negotiable. Each component passes through a multi-stage quality gate: visual inspection, dimensional verification, material composition analysis (via OES spectroscopy), and non-destructive testing (NDT). Only parts meeting 100% conformance are shipped, ensuring zero-defect delivery.

Our integrated approach minimizes lead times while maximizing reliability, making Wuxi Lead the trusted partner for aerospace, medical, and high-performance industrial clients demanding precision at scale.

| Parameter | Specification |

|---|---|

| Dimensional Accuracy | ±0.02 mm |

| Layer Resolution | 20–50 μm |

| Build Envelope (Max) | 500 × 500 × 400 mm |

| Materials | Ti6Al4V, 316L, Inconel 718, AlSi10Mg, Tool Steel |

| Surface Roughness (as-printed) | Ra 8–12 μm |

| Post-Processing Options | CNC Machining, HIP, Polishing, Passivation |

| Quality Standards | ISO 9001, AS9100 (aerospace compliance) |

Why Choose Wuxi Lead Precision

Elevate Your Complex Metal Components with Lead Precision Engineering

In the demanding landscape of advanced manufacturing, achieving geometric complexity without sacrificing structural integrity remains a critical challenge. Wuxi Lead Precision Machinery delivers certified metal additive solutions engineered for mission-critical applications in aerospace, medical, and energy sectors. Our integrated approach combines proprietary laser powder bed fusion technology with aerospace-grade post-processing protocols to transform your most intricate designs into flight-ready or implant-certified components. We eliminate the traditional trade-offs between design freedom and mechanical performance, ensuring every part meets ASTM F75 or AMS 7000 standards upon delivery.

Our production capabilities are defined by measurable precision and material science expertise. The following specifications reflect our standard production envelope for titanium, Inconel, and cobalt-chrome alloys:

| Specification | Capability |

|---|---|

| Material Options | Ti6Al4V ELI, Inconel 718, CoCr, 316L |

| Layer Thickness | 20–50 μm |

| Build Volume | 250 x 250 x 325 mm |

| Surface Roughness (as-built) | Ra 8–12 μm |

| Dimensional Accuracy | ±0.05 mm per 100 mm |

| Post-Processing | HIP, Stress Relief, CNC Machining, Micro-Polishing |

| Certification | ISO 13485, AS9100, Material Traceability |

Beyond raw printing capacity, our value lies in closed-loop quality control. Every build undergoes in-situ melt pool monitoring and full volumetric CT scanning to detect subsurface discontinuities invisible to conventional inspection. Our metrology lab validates final dimensions against CAD nominal within 15μm using Zeiss CONTURA CMM systems—critical for hydraulic manifolds or turbine blade assemblies where micro-leakage risks compromise entire systems. This rigor reduces your validation cycles by up to 40% compared to standard additive service bureaus.

Partnering with Lead Precision means accessing China’s most tightly controlled metal AM ecosystem without supply chain opacity. Our Wuxi facility operates under U.S. ITAR-compliant data protocols, with dedicated project engineers managing your workflow from DfAM consultation through first-article inspection. We specialize in low-volume, high-complexity runs where traditional casting or five-axis milling become cost-prohibitive—such as conformal-cooled injection molds or patient-specific orthopedic implants.

Initiate your project with engineering-grade validation data, not generic quotes. Email Contact [email protected] with your STEP file and application requirements. Our technical team will respond within 4 business hours with a feasibility assessment, material recommendation, and traceable cost breakdown. For urgent medical or aerospace tooling needs, reference project code LEAD-URGENT to trigger expedited review. Your next breakthrough component requires partners who speak the language of tolerances, not just technology. Let us prove why global Tier 1 suppliers trust Lead Precision for their most demanding metal additive challenges.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.