Technical Contents

Engineering Guide: Mold Supply

Engineering Insight: The Non-Negotiable Foundation of Precision in Mold Supply

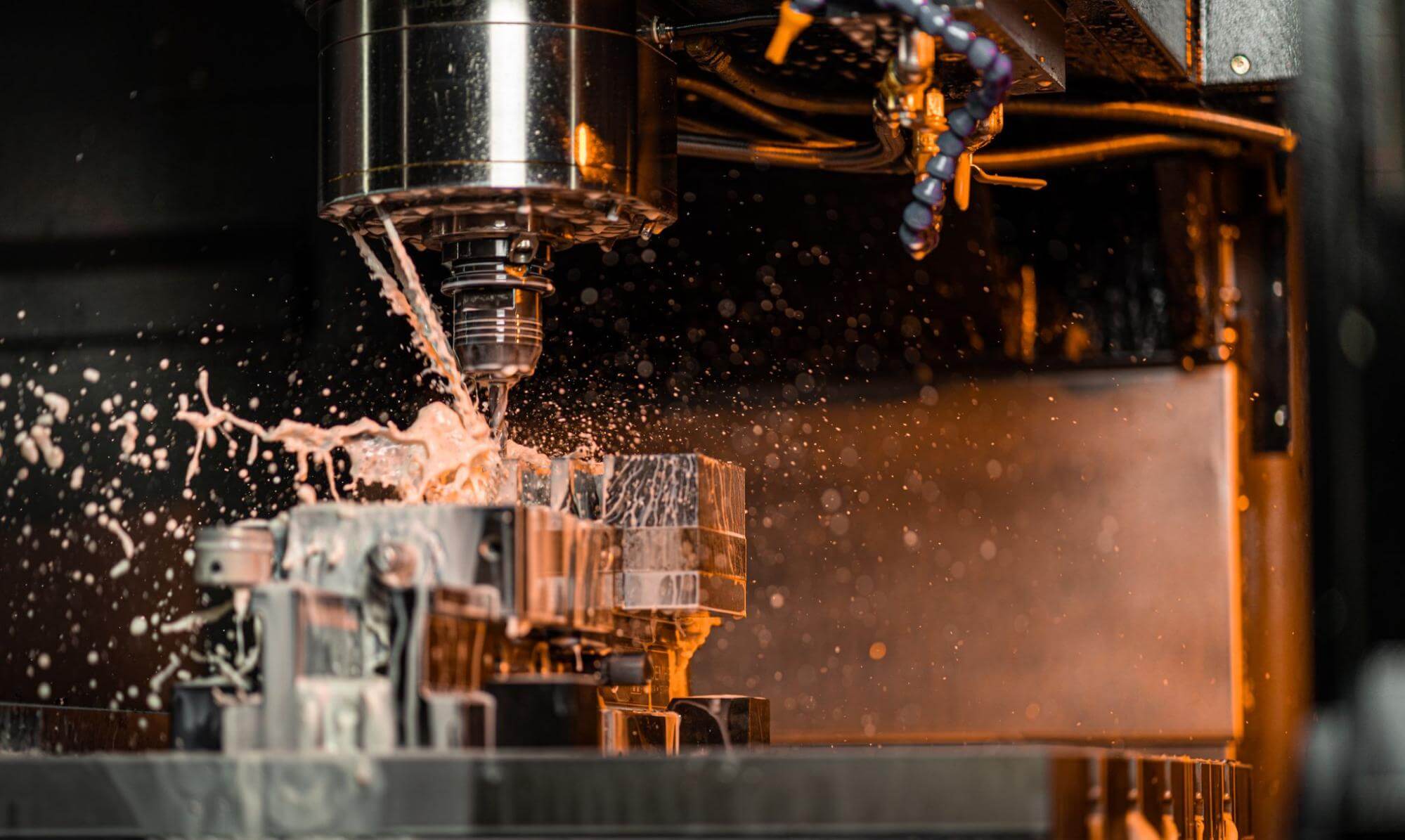

In custom metal manufacturing, the mold is not merely a tool; it is the absolute determinant of final part quality, production efficiency, and ultimately, your product’s market success. Compromising on mold precision guarantees downstream consequences: dimensional instability, excessive scrap rates, accelerated wear, and costly production halts. At Wuxi Lead Precision Machinery, we treat mold supply as the critical engineering discipline it is, where tolerances measured in microns directly translate to profitability and reputation for our clients. Precision machining isn’t an optional premium; it is the fundamental requirement for molds capable of sustaining high-volume, repeatable production under demanding industrial conditions.

Our engineering philosophy centers on mitigating the inherent stresses of the molding process – thermal cycling, material flow pressure, and mechanical ejection forces – through meticulous design validation and ultra-precise fabrication. This requires more than advanced CNC equipment; it demands deep material science understanding, rigorous thermal analysis, and iterative process validation. We have consistently proven this capability on projects where failure was not an option. Our molds have performed flawlessly in components for Olympic-standard sporting equipment, where microscopic inconsistencies would compromise athlete performance, and within critical military subsystems, where absolute reliability under extreme environmental stress is mandated. These engagements underscore our commitment to engineering excellence where precision is non-negotiable.

The tangible output of this disciplined approach is evident in the measurable performance characteristics of our molds. We achieve levels of accuracy and surface integrity that directly extend mold life and part consistency, significantly reducing total cost of ownership. Consider the core specifications we routinely deliver and validate:

| Critical Specification | Lead Precision Standard | Industry Typical | Impact on Production |

|---|---|---|---|

| Dimensional Tolerance (Core/Cavity) | ±0.001 mm | ±0.005 mm | Eliminates post-mold machining; ensures perfect part fit |

| Surface Finish (Cavity) | Ra 0.05 µm (Mirror Polish) | Ra 0.2 – 0.8 µm | Reduces ejection force; prevents part sticking; enhances aesthetics |

| Thermal Uniformity (Simulated) | ΔT ≤ 2°C across cavity | ΔT ≥ 5°C | Prevents warpage; ensures consistent material flow; minimizes cycle time |

| Hardness Consistency (After Treatment) | ±2 HRC across component | ±5 HRC | Maximizes wear resistance; prevents premature failure points |

This level of control is achieved through our integrated engineering workflow: starting with finite element analysis (FEA) for structural and thermal optimization, progressing through multi-axis simultaneous machining with real-time in-process probing, and concluding with comprehensive metrology using 5-axis CMMs and optical comparators against the original CAD model. Every mold we supply is a testament to the principle that precision in the mold cavity is the single most cost-effective investment in your manufacturing process. It minimizes waste, maximizes uptime, and guarantees that the part leaving your press meets the exacting standards your customers demand. Partner with Wuxi Lead Precision Machinery for mold supply engineered not just to function, but to excel under the most rigorous production demands.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision mold supply for global industrial clients. Our production infrastructure is built around 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional accuracy and surface finish. This level of machining flexibility supports intricate mold designs commonly required in automotive, aerospace, medical, and consumer electronics industries. With simultaneous multi-axis motion, our 5-axis CNC systems reduce setup times, minimize human error, and maintain tight tolerances across highly contoured components.

All machining operations are supported by a rigorous quality control framework centered on CMM (Coordinate Measuring Machine) inspection. Each component undergoes comprehensive dimensional verification using calibrated Zeiss and Hexagon CMM systems, ensuring compliance with international standards such as ISO 9001 and AS9100. Our inspection protocols cover first-article inspection, in-process checks, and full final audits, providing full traceability and data-backed quality assurance. This systematic approach ensures that every mold meets the exact functional and dimensional requirements of the client’s application.

Our technical team combines decades of mold engineering experience with advanced simulation software to optimize toolpaths, material selection, and cooling channel design prior to production. This proactive engineering reduces trial-and-error during mold trials, accelerates time-to-market, and enhances mold longevity. We work with a wide range of tool steels and high-performance alloys, including P20, H13, S136, and hardened stainless steels up to 60 HRC, supporting both prototype and high-volume production tooling.

The table below outlines our standard machining capabilities and achievable tolerances under controlled production conditions.

| Parameter | Specification |

|---|---|

| Maximum Work Envelope (XYZ) | 1200 mm × 800 mm × 700 mm |

| Spindle Speed | Up to 24,000 rpm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Standard Tolerance (Machined Parts) | ±0.01 mm |

| Fine Feature Tolerance (5-Axis Machined) | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.4 μm |

| Minimum Internal Corner Radius | 0.2 mm (with micro tooling) |

| Material Hardness Capability | Up to 60 HRC (pre-hardened and hardened steels) |

| Inspection Equipment | Zeiss Contura & Hexagon GLOBAL S CMMs |

These technical benchmarks reflect our commitment to precision, consistency, and performance in every mold we manufacture. At Wuxi Lead Precision Machinery, we do not just meet specifications—we engineer solutions that enhance mold functionality, durability, and production efficiency for our clients’ most demanding applications.

Material & Finish Options

Material Selection for Precision Mold Manufacturing

Selecting the optimal material for mold construction directly impacts production efficiency, part quality, and total cost of ownership. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your specific application demands, production volume, and surface finish requirements. This guide clarifies critical considerations for aluminum, steel, and titanium alloys, alongside anodizing processes essential for mold longevity.

Aluminum alloys, particularly 7075-T6, offer exceptional machinability and thermal conductivity. These properties accelerate cooling cycles in prototyping and low-to-medium volume production, reducing lead times significantly. While aluminum lacks the wear resistance of hardened steels, its lightweight nature simplifies mold handling and is ideal for resin-based composites or rapid tooling where cycle counts remain under 10,000. Surface treatments like hard anodizing are mandatory to enhance durability against abrasion.

Tool steels such as H13 and S136 dominate high-volume injection molding. H13 provides superior toughness and thermal fatigue resistance for aluminum or zinc die casting, maintaining integrity under repeated thermal cycling. S136 stainless steel excels in corrosive environments, like PVC or medical-grade plastic molding, where resistance to chemical degradation is non-negotiable. Both require precise heat treatment to achieve 48-52 HRC hardness, ensuring dimensional stability over millions of cycles.

Titanium alloys (e.g., Ti-6Al-4V) serve niche applications demanding extreme strength-to-weight ratios and corrosion immunity, such as aerospace composite molding. However, their high cost, challenging machinability, and lower thermal conductivity often outweigh benefits for standard molds. Titanium is typically reserved for specialized scenarios where its unique properties justify the investment.

Critical material properties are summarized below for direct comparison:

| Material | Hardness (HRC) | Thermal Conductivity (W/mK) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Aluminum 7075 | 15-20 | 130 | Low (uncoated) | Prototyping, low-volume tooling |

| H13 Steel | 48-52 | 28-36 | Moderate | Die casting, high-temp injection |

| S136 Steel | 50-54 | 20-25 | High | Medical, optical, corrosive resins |

| Ti-6Al-4V | 36-41 | 6-7 | Very High | Aerospace composites |

| Anodizing Type II | N/A | N/A | Medium | General wear/corrosion protection |

| Anodizing Type III | N/A | N/A | High | Critical wear surfaces, sealing |

Anodizing transforms aluminum mold surfaces into durable, non-conductive oxide layers. Type II (sulfuric acid) anodizing provides economical corrosion and mild wear resistance for general use. For molds facing severe abrasion or requiring precise sealing—such as in co-injection processes—Type III (hardcoat) anodizing delivers 50-75 µm thickness with superior hardness (60-70 Rockwell C equivalent). Both processes improve release properties but require strict dimensional control during machining to accommodate coating growth.

Material selection is never one-size-fits-all. We rigorously evaluate your part geometry, resin type, expected cycles, and surface specifications to recommend the optimal solution. Partner with Wuxi Lead to convert material science into manufacturing advantage—ensuring your molds achieve maximum ROI through precision engineering and metallurgical expertise.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our custom metal manufacturing process for mold supply is engineered to deliver precision, consistency, and zero-defect performance across every production phase. We integrate advanced engineering practices with rigorous quality assurance to ensure that each mold meets exacting client specifications and industry standards. Our process is structured into three core stages: Design, Prototyping, and Mass Production, each optimized for performance, durability, and repeatability.

The Design phase begins with a comprehensive review of client requirements, including part geometry, material specifications, production volume, and functional environment. Our engineering team utilizes state-of-the-art CAD/CAM software to develop 3D models and simulate mold behavior under operational conditions. Finite element analysis (FEA) and mold flow simulations are conducted to predict potential stress points, cooling efficiency, and filling patterns. This data-driven approach ensures optimal gate placement, cooling channel layout, and ejection systems, minimizing defects before physical production begins. Design for manufacturability (DFM) reviews are conducted collaboratively with clients to refine tolerances, surface finishes, and assembly compatibility.

Prototyping follows design finalization, serving as a critical validation step. We produce functional prototype molds using high-precision CNC machining, wire EDM, and surface grinding technologies. These prototypes are used to manufacture sample parts under near-production conditions. Each sample undergoes dimensional inspection via coordinate measuring machines (CMM), surface roughness testing, and material verification. Any deviations are traced back to the mold design or process parameters and corrected in real time. This iterative validation ensures that the mold performs flawlessly before entering full-scale production.

Mass Production is executed on automated, monitored lines with strict adherence to documented process controls. Each mold is manufactured from premium-grade tool steels such as P20, 718H, or H13, selected based on wear resistance, thermal stability, and expected cycle life. Machining is performed on 5-axis CNC centers with sub-micron accuracy, followed by precision polishing and surface treatments such as nitriding or PVD coating where required. Throughout production, statistical process control (SPC) systems monitor key parameters, and first-article inspections are conducted on every batch. Our zero-defect philosophy is enforced through 100% in-process inspections and final audits conducted by independent quality engineers.

All molds are delivered with full documentation, including material certificates, heat treatment reports, inspection data, and maintenance guidelines. This end-to-end control ensures that every mold from Wuxi Lead Precision Machinery performs reliably in high-volume production environments.

| Specification | Detail |

|---|---|

| Material Options | P20, 718H, H13, S136, NAK80 |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.05 – 0.8 µm (polished or textured) |

| Machining Accuracy | 5-axis CNC, ±0.002 mm repeatability |

| Quality Standards | ISO 9001:2015, PPAP, FAI, SPC |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Production Mold) | 30–60 days |

Why Choose Wuxi Lead Precision

Elevate Your Mold Supply Chain Through Precision Engineering Partnership

Wuxi Lead Precision Machinery stands as your definitive engineering partner for mission-critical mold manufacturing. We transcend conventional supplier relationships by embedding our expertise directly into your product development lifecycle. Our integrated approach combines advanced CNC multi-axis machining, proprietary heat treatment protocols, and closed-loop quality control systems to deliver molds that achieve zero-defect production at scale. For global OEMs and tier-1 mold makers, this translates to accelerated time-to-market, reduced total cost of ownership, and uncompromised part consistency across millions of cycles. We engineer solutions where standard tolerances are insufficient—addressing complex geometries, exotic materials, and extreme wear environments inherent in aerospace, medical, and automotive applications.

Our technical capabilities are quantifiably superior, as demonstrated in the core specifications below. Every mold plate, cavity, and core undergoes rigorous metrology validation against your exacting standards before shipment.

| Process Type | Tolerance Range | Material Range | Max Work Envelope |

|---|---|---|---|

| 5-Axis Hard Milling | ±0.001mm | H13, S7, 420SS, Inconel 718 | 1200 x 800 x 600mm |

| Wire EDM | ±0.0005mm | Tool Steels, Tungsten Carbide | 500 x 400 x 350mm |

| Surface Grinding | Ra 0.05µm | P20, NAK80, Aluminum 7075-T6 | 1500 x 1000 x 500mm |

| Laser Texturing | 0.5-20µm Depth | All Hardened Tool Steels | 1000 x 600mm Area |

This precision is sustained through our ISO 9001:2015 and IATF 16949 certified facility in Wuxi, where 32 FANUC and DMG MORI machining centers operate under real-time thermal compensation systems. Our engineers collaborate from initial DFM analysis through first-article inspection, utilizing Zeiss CONTURA CMMs and 3D scanning to validate conformity to your CAD models. Unlike transactional suppliers, we implement corrective action protocols within 24 hours of any deviation—ensuring your production schedules remain protected. The result is molds achieving 500,000+ cycles without rework, even in high-corrosion polymer environments.

Initiate your precision project today by contacting our engineering team directly. Send your technical specifications, CAD files, and production requirements to [email protected]. Our senior applications engineers will respond within 4 business hours with a comprehensive capability assessment and timeline proposal. For urgent RFQs, include “PRIORITY MOLD REVIEW” in the subject line to trigger our expedited evaluation process. Partner with a manufacturer that treats your success as our own engineering mandate—where tolerances are non-negotiable and delivery integrity is absolute. Your next-generation mold supply chain begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.