Technical Contents

Engineering Guide: Mindful Advantage Customer Service Number

Engineering Insight: The Role of Precision in Custom Metal Manufacturing

In the realm of custom metal manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, safety, and innovation are built. At Wuxi Lead Precision Machinery, we understand that the difference between functional success and operational failure often lies within tolerances measured in microns. This commitment to exacting standards defines our engineering philosophy and drives every component we produce for aerospace, defense, and high-performance industrial applications.

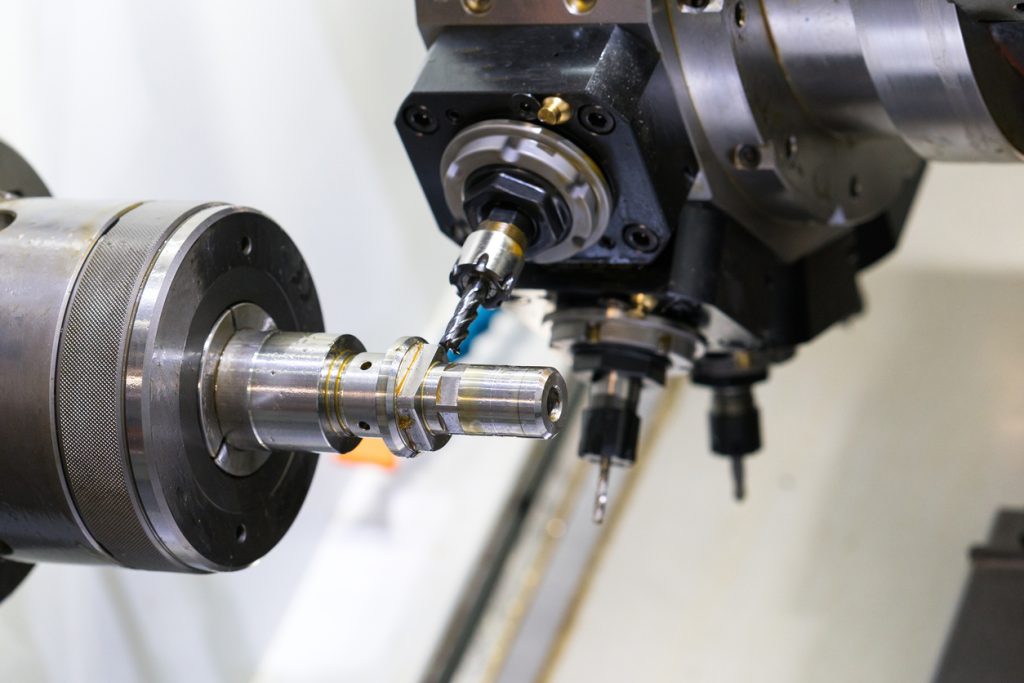

Precision manufacturing transcends the ability to meet tight tolerances; it encompasses consistency, material integrity, and long-term durability under extreme conditions. Our engineering team leverages advanced CNC machining, multi-axis milling, and real-time quality verification systems to ensure every part conforms to design intent. Whether producing complex titanium housings for military-grade avionics or high-strength aluminum components for Olympic-standard competition equipment, our processes are calibrated to deliver repeatability across batches and years.

Our experience in supporting Olympic and military-grade projects has reinforced the critical importance of precision under pressure. In Olympic applications, even minor deviations in component geometry can affect athlete performance and equipment safety. Similarly, military specifications demand absolute compliance with MIL-STD and AS9100 standards, where failure is not an option. These high-stakes environments have shaped our quality control protocols, pushing us to exceed standard industry benchmarks.

At the core of our capability is a vertically integrated production ecosystem. From initial design consultation to final inspection, every stage is managed in-house, allowing for full traceability and adaptive refinement. Our metrology lab employs coordinate measuring machines (CMM), optical comparators, and laser scanning to validate dimensional accuracy down to ±0.002 mm. This level of scrutiny ensures that every component not only meets but anticipates the demands of its operational environment.

We recognize that our clients rely on more than just machinery—they depend on engineering insight, responsive communication, and a partner who understands the consequences of compromise. This is where the concept of mindful advantage comes into focus. It is not enough to be precise; we must be attentive, proactive, and technically fluent in the challenges our customers face. Our customer service team, accessible through dedicated support channels, operates as an extension of your engineering department—providing real-time updates, technical documentation, and rapid problem resolution.

Precision, when combined with mindful partnership, becomes a strategic advantage. It enables innovation without risk, scalability without sacrifice, and performance without compromise.

Key Manufacturing Specifications

| Parameter | Capability |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.01 mm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Carbon Steel |

| Maximum Part Size | 1200 mm × 800 mm × 600 mm |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (customizable) |

| Quality Standards | ISO 9001, AS9100, MIL-STD-810 |

| Inspection Tools | CMM, Optical Comparator, Laser Scanner |

| Lead Time (Standard) | 15–25 days (varies by complexity) |

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers uncompromising precision for the most demanding custom metal components. Our core strength lies in advanced multi-axis machining integrated with rigorous metrology, ensuring every part meets exacting aerospace, medical, and industrial specifications. We specialize in transforming complex 3D CAD models into high-integrity metal components using state-of-the-art equipment and processes validated by stringent quality control.

Our primary production platform centers on high-performance 5-axis CNC machining centers, including DMG MORI CTX beta 1250 and Hermle C 800 U models. These machines enable simultaneous five-axis contouring, eliminating the need for multiple setups and significantly reducing cumulative error. This capability is essential for manufacturing intricate geometries such as impellers, turbine blades, medical implants, and complex structural housings from a single billet. We routinely machine challenging materials including titanium alloys (Ti-6Al-4V), high-temperature nickel superalloys (Inconel 718, Hastelloy), hardened tool steels (HRC 58+), and aerospace-grade aluminum alloys (7075-T6, 2024). Our machining processes achieve superior surface finishes down to Ra 0.4 µm and maintain exceptional geometric integrity critical for functional performance.

Verification of dimensional accuracy is non-negotiable. Every critical feature undergoes comprehensive inspection using Zeiss CONTURA and GLOBAL S coordinate measuring machines (CMMs). Our certified metrology lab operates under ISO 17025 guidelines, utilizing calibrated probes and advanced software (ZEISS CALYPSO) for full GD&T analysis. This systematic approach ensures traceability from raw material certification through final inspection reports, providing documented evidence of conformance to your print requirements. Process capability studies (Cp/Cpk) are standard practice for high-volume production runs, guaranteeing consistent output within defined tolerance bands.

The achievable precision across common materials and feature types is reflected in our standard tolerance capabilities, adhering to ISO 2768-mK as a baseline but routinely exceeding these for critical applications:

| Feature Type | Aluminum Alloys | Stainless Steel | Titanium Alloys | Hardened Steel (HRC 58+) |

|---|---|---|---|---|

| Linear Dimensions (mm) | ±0.005 | ±0.008 | ±0.010 | ±0.012 |

| Hole Diameter (mm) | ±0.003 | ±0.005 | ±0.006 | ±0.008 |

| Positional Tolerance | ±0.005 | ±0.008 | ±0.010 | ±0.012 |

| Profile of Surface | 0.010 | 0.015 | 0.020 | 0.025 |

| Surface Roughness (Ra) | 0.4 µm | 0.8 µm | 1.0 µm | 1.6 µm |

This combination of 5-axis machining agility and CMM-validated accuracy directly translates to reduced assembly time, minimized scrap, and enhanced product reliability for our clients. We partner with engineering teams early in the design phase to optimize manufacturability, ensuring your complex metal components are produced with the highest levels of precision, repeatability, and material integrity required for mission-critical applications. Trust Wuxi Lead to execute your most challenging precision metal manufacturing requirements.

Material & Finish Options

When selecting materials for precision metal components, performance, durability, and cost-efficiency must be balanced according to the application’s operational demands. At Wuxi Lead Precision Machinery, we specialize in custom manufacturing using three primary metals: aluminum, steel, and titanium. Each material offers distinct mechanical and chemical properties, making them suitable for specific industrial environments. Understanding these characteristics ensures optimal part performance and longevity.

Aluminum is widely chosen for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for aerospace, automotive, and consumer electronics applications where weight reduction is critical without compromising structural integrity. The most common grades we work with include 6061 and 7075, offering good weldability and high tensile strength, respectively. Aluminum naturally forms a protective oxide layer, but when enhanced with anodizing, its surface hardness and wear resistance improve significantly.

Steel remains the backbone of heavy-duty industrial applications due to its high strength, toughness, and affordability. We utilize both carbon steel and stainless steel variants depending on the need for hardness versus corrosion resistance. Stainless steel grades such as 304 and 316 are particularly effective in medical, food processing, and marine environments due to their superior resistance to oxidation and chemical exposure. While heavier than aluminum, steel provides unmatched durability under high stress and impact loads.

Titanium stands at the premium end of material selection, offering an exceptional strength-to-density ratio and outstanding resistance to extreme environments. It performs reliably in high-temperature conditions and is highly resistant to saltwater and chemical corrosion, making it the material of choice for aerospace, defense, and biomedical implants. Though more expensive and challenging to machine, titanium’s long-term reliability in critical applications justifies its use where failure is not an option.

Surface finishing plays a crucial role in enhancing both functionality and aesthetics. Anodizing is a widely used electrochemical process, primarily applied to aluminum. It thickens the natural oxide layer, improving wear resistance, corrosion protection, and allowing for color dye integration for identification or branding. Type II and Type III (hardcoat) anodizing are available depending on required thickness and performance. Other finishes such as powder coating, passivation, and polishing are also offered based on material and application.

Below is a comparative overview of key material properties for common grades used in custom manufacturing.

| Material | Grade | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | High | Aerospace, Automotive |

| Aluminum | 7075-T6 | 572 | 2.8 | Moderate | Defense, High-Performance |

| Stainless Steel | 304 | 505 | 8.0 | Very High | Medical, Food Processing |

| Stainless Steel | 316 | 580 | 8.0 | Excellent | Marine, Chemical Processing |

| Titanium | Grade 5 (Ti-6Al-4V) | 950 | 4.4 | Exceptional | Aerospace, Biomedical |

Material and finish selection directly impacts the performance, cost, and lifecycle of precision components. Wuxi Lead Precision Machinery supports clients in making informed decisions tailored to their engineering and operational requirements.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Engineered Perfection from Concept to Volume

Our production process integrates rigorous engineering discipline with advanced manufacturing technology to deliver zero-defect metal components for demanding industrial applications. This begins with collaborative design engineering where our team partners with clients to optimize part geometry, material selection, and manufacturability. We employ advanced CAD/CAM simulation tools to identify potential stress points, thermal deformation risks, and assembly conflicts before physical work commences. This Design for Manufacturing (DFM) phase ensures the design aligns with material properties and process capabilities, establishing the foundation for defect prevention. Material certifications and traceability protocols are locked in at this stage, eliminating downstream variability.

Prototyping transitions validated designs into tangible validation. We utilize high-precision 5-axis CNC milling and turning centers to produce functional prototypes matching final production intent. Every prototype undergoes comprehensive metrology using calibrated CMMs, optical comparators, and surface roughness testers against the original CAD model and client specifications. This is not merely sample creation; it is a critical verification loop where dimensional accuracy, material integrity, and functional performance are quantified. Client feedback is incorporated iteratively, with engineering change orders (ECOs) rigorously documented and re-validated to ensure no compromise to the zero-defect target.

Mass production leverages the insights from prototyping within a fully controlled environment. Our smart factory floor integrates IoT-enabled CNC machines with real-time SPC (Statistical Process Control) monitoring. Each operation—milling, turning, grinding, or EDM—is governed by validated toolpaths, in-process gauging, and automated data logging. First-article inspections (FAI) per AS9102 standards precede every production run, while ongoing lot sampling verifies sustained conformance. Environmental controls maintain stable temperature and humidity, while tool wear sensors trigger automatic compensation or replacement. This closed-loop system ensures every component meets exacting tolerances without relying on end-of-line inspection alone.

The following table summarizes key capabilities enabling this zero-defect execution:

| Capability | Specification | Application Impact |

|---|---|---|

| Geometric Tolerance | ±0.002 mm | Ensures fit/function in aerospace hydraulic systems |

| Surface Finish | Ra 0.2 µm (mirror grade) | Critical for medical implant biocompatibility |

| Material Range | Titanium Gr5, Inconel 718, 17-4PH SS, Aluminum 7075 | Supports extreme temperature/corrosion environments |

| In-Process Metrology | Real-time SPC on critical dimensions | Prevents batch deviations before completion |

| Traceability | Full lot-level material & process data | Enables rapid root-cause analysis if required |

Zero defects are achieved by designing quality into every phase—not inspecting it in. Our process eliminates rework cycles and supply chain disruptions by ensuring perfection at source. This disciplined approach delivers on-time, right-first-time components that meet the most stringent aerospace, medical, and energy sector requirements. Partner with Wuxi Lead to transform your precision metal manufacturing challenges into guaranteed outcomes.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we engineer precision partnerships. As a globally trusted name in custom metal manufacturing, we specialize in delivering high-tolerance CNC machining, sheet metal fabrication, and complex assembly solutions tailored to the exacting demands of industries such as aerospace, medical devices, industrial automation, and advanced robotics. When you choose to partner with us, you gain more than a supplier; you gain a committed engineering ally focused on your project’s success from prototype to full-scale production.

Our facility in Wuxi, China, operates under strict ISO 9001:2015 standards, ensuring every process—from material sourcing to final inspection—is traceable, repeatable, and optimized for quality. We combine state-of-the-art 5-axis CNC centers, automated sheet metal lines, and robotic welding cells with a team of seasoned engineers who bring decades of applied manufacturing experience. This fusion of advanced technology and human expertise enables us to solve complex production challenges, reduce lead times, and improve cost efficiency for our clients.

What sets us apart is our commitment to mindful, responsive customer service. We understand that every project carries unique technical, logistical, and strategic considerations. That’s why our engineering and project management teams engage early and remain involved throughout the product lifecycle. Whether you need Design for Manufacturability (DFM) feedback, rapid prototyping, or scalable production runs with JIT delivery, we align our capabilities with your operational goals.

Below are key technical capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| CNC Machining | 3-axis to 5-axis milling, turning, mill-turn; max work envelope 1200 x 800 x 600 mm |

| Tolerance | ±0.005 mm typical; tight-tolerance capabilities to ±0.001 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, Carbon Steel, Plastics |

| Sheet Metal | Laser cutting, CNC punching, bending, welding; thickness range 0.5–6.0 mm |

| Surface Finishes | Anodizing, powder coating, passivation, polishing, plating, brushing |

| Quality Assurance | CMM, optical comparators, roughness testers, first-article inspection reports |

| Production Scale | Low-volume prototyping to high-volume serial production |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

We invite global OEMs, engineering firms, and innovation-driven enterprises to contact us directly and experience the Lead Precision difference. For immediate assistance with quotations, technical reviews, or project planning, email us at [email protected]. Our team responds within 12 business hours and is equipped to support English, German, and Mandarin communications.

Partnering with Wuxi Lead Precision Machinery means choosing precision, reliability, and a customer-centric approach that elevates your manufacturing advantage. Let’s build the future—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.