Technical Contents

Engineering Guide: Aluminium Molding Machine

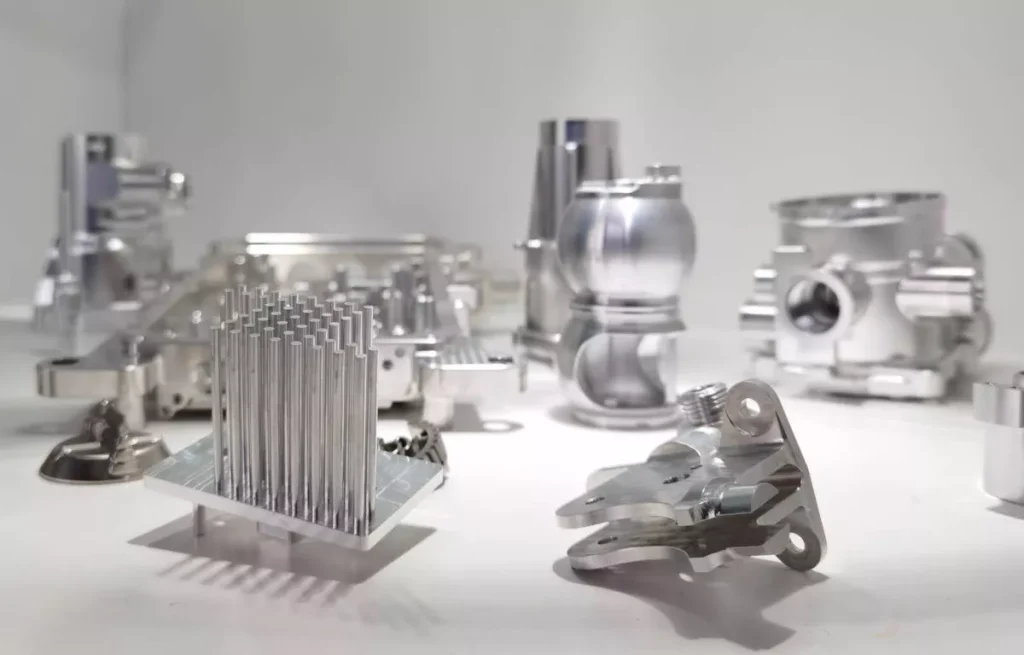

Engineering Insight: Precision as the Core Imperative in Aluminum Molding

Achieving true precision in aluminum molding is not merely a desirable specification; it is the fundamental requirement separating functional components from critical failures in demanding applications. Aluminum’s unique thermal conductivity and solidification characteristics demand exceptional control throughout the molding cycle. Minute deviations in temperature distribution, pressure application, or mold alignment translate directly into porosity, dimensional instability, or compromised mechanical properties in the final part. In sectors like aerospace, defense, and high-performance automotive, where components face extreme stress, temperature fluctuations, and stringent safety protocols, such imperfections are unacceptable. The physics of molten aluminum flow – its viscosity, surface tension, and rapid heat transfer – necessitates molding machinery capable of micron-level repeatability in clamp force, injection speed, and shot consistency. Without this level of precision engineering, achieving the required material integrity, geometric accuracy, and surface finish for mission-critical parts becomes impossible. Thermal equilibrium within the mold cavity must be meticulously managed; inconsistent cooling rates induce internal stresses and warpage, undermining the very purpose of precision casting.

Wuxi Lead Precision Machinery understands this imperative intrinsically. Our engineering philosophy centers on building aluminum molding machines where precision is engineered into every component and controlled system, not merely measured as an outcome. This commitment is rigorously validated through our work supplying machinery and components for projects where failure is not an option. Our precision manufacturing capabilities have directly supported critical infrastructure for the Olympic Games, ensuring flawless performance under global scrutiny. Furthermore, we meet the exacting standards demanded by military and defense contractors, where components must perform reliably in the most extreme environments. This experience is not incidental; it is the direct result of our relentless focus on thermal stability, structural rigidity, and closed-loop process control within our molding systems. We engineer for zero-defect production from the first shot.

The table below outlines key precision specifications inherent in Lead Precision’s high-end aluminum molding platforms, reflecting our engineering response to these demanding requirements:

| Specification | Performance Range | Engineering Significance |

|---|---|---|

| Clamping Force | 800 – 6500 Tons | Ensures cavity integrity under high injection pressure, preventing flash and maintaining dimensional stability |

| Shot Weight (Al) | 1.5 – 120 kg | Precise metering for consistent fill and solidification, minimizing porosity |

| Platen Parallelism | ≤ 0.03 mm/m | Critical for uniform pressure distribution and part flatness |

| Positioning Repeatability | ± 0.01 mm | Guarantees consistent core placement and part geometry |

| Hydraulic Pressure Control | ± 0.5 bar | Enables exact replication of injection profiles for material integrity |

| Mold Temperature Control | ± 1.0 °C | Essential for managing solidification rate and minimizing residual stress |

This level of machine performance translates directly into client success. Precision molding minimizes costly scrap, reduces secondary operations, and delivers parts meeting the most stringent aerospace (AMS, AS), automotive (IATF 16949), and military (MIL-SPEC) standards. At Wuxi Lead Precision Machinery, we do not manufacture molding machines; we engineer the foundation for your most demanding aluminum components, proven where precision is paramount. Our Olympic and military project heritage is the ultimate testament to this capability.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom aluminum molding machine production, leveraging state-of-the-art infrastructure and engineering expertise. Our manufacturing platform is built around high-precision 5-axis CNC machining centers, enabling the creation of complex, net-shape components with superior surface integrity and dimensional accuracy. These multi-axis systems allow simultaneous movement across five planes, eliminating the need for multiple setups and significantly reducing cumulative tolerances. This capability is essential for producing intricate molds, dies, and structural components used in high-performance aluminum molding applications across automotive, aerospace, and industrial equipment sectors.

Each machining operation is supported by integrated CAD/CAM programming and real-time tool path optimization, ensuring efficient material removal and consistent part geometry. Our 5-axis CNC fleet is maintained under strict environmental controls to minimize thermal drift, further enhancing repeatability and precision. All machines are operated by certified technicians with over a decade of experience in precision aluminum systems, ensuring that each component meets the exacting demands of modern molding technology.

Quality assurance is embedded throughout the manufacturing process. Every critical dimension is verified using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), providing non-contact and tactile measurement with micron-level resolution. Our CMM inspection protocol follows ISO 10360 standards and includes full first-article inspection reports (FAIR), in-process checks, and final certification. Data from CMM inspections are directly correlated with original CAD models using PolyWorks software, enabling deviation analysis and continuous process improvement.

We maintain full traceability for all materials and processes, with documented inspection records archived for every production batch. Our quality management system is ISO 9001:2015 certified, ensuring compliance with international standards for design, production, and service delivery. In addition to dimensional verification, we perform surface roughness testing, hardness validation, and visual inspection under controlled lighting to ensure defect-free outputs.

The following table outlines the standard technical specifications and achievable tolerances for our aluminum molding machine components:

| Parameter | Standard Capability | Precision Range (Optimized) |

|---|---|---|

| Dimensional Tolerance | ±0.025 mm | ±0.010 mm |

| Positional Accuracy | ±0.020 mm | ±0.008 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm (polished finishes) |

| Feature Repeatability | ±0.015 mm | ±0.005 mm |

| Maximum Work Envelope (XYZ) | 2000 x 1000 x 800 mm | Custom configurations available |

| Angular Tolerance (5-axis) | ±0.05° | ±0.02° |

Our technical capabilities are designed to support both prototype development and high-volume production, with rapid turnaround and full design-for-manufacturability (DFM) support. Wuxi Lead Precision Machinery ensures that every aluminum molding machine component meets the highest standards of performance, durability, and precision.

Material & Finish Options

Material Selection for High-Performance Aluminum Molding Machines

Selecting the optimal material for aluminum molding machine components is critical for achieving precision, longevity, and cost efficiency in demanding production environments. At Wuxi Lead Precision Machinery, our engineering team prioritizes material properties that directly impact machine rigidity, thermal stability, and resistance to wear. Aluminum alloys, steel variants, and titanium each serve distinct roles based on application requirements, load conditions, and environmental exposure. Understanding these differences ensures your investment delivers consistent output and minimizes downtime.

Aluminum alloys, particularly aerospace-grade 6061-T6 and 7075-T6, are preferred for non-critical structural elements like housings and covers due to their exceptional strength-to-weight ratio and thermal conductivity. These alloys reduce machine inertia, enabling faster cycle times, while their natural corrosion resistance lowers maintenance needs. However, aluminum lacks the surface hardness required for high-wear zones such as clamp plates or ejector pins, where deflection under pressure could compromise part tolerances. For such components, hardened tool steels like H13 or P20 are indispensable. These steels offer superior compressive strength and wear resistance, maintaining dimensional stability under extreme clamping forces exceeding 5,000 tons. Steel’s higher density also dampens vibration during high-speed operations, critical for micron-level molding accuracy.

Titanium alloys, such as Ti-6Al-4V, are reserved for specialized applications involving aggressive chemical exposure or extreme temperature fluctuations, like aerospace component molding. While titanium provides unparalleled corrosion resistance and a strength-to-weight ratio surpassing steel, its high cost and challenging machinability limit widespread use. We recommend titanium only when aluminum and steel fail to meet specific environmental or performance thresholds.

Surface finishing, particularly anodizing, significantly enhances aluminum components. Type II (sulfuric acid) anodizing provides moderate wear resistance and aesthetic appeal for non-load-bearing parts. For critical molding surfaces, Type III (hardcoat) anodizing is essential, creating a ceramic-like layer up to 50µm thick with Rockwell hardness exceeding 70 HRC. This finish drastically improves abrasion resistance against abrasive-filled polymers and extends tool life by 30–50% compared to untreated aluminum. Crucially, anodizing must be applied post-machining to avoid dimensional shifts, a process Wuxi Lead integrates into our quality-controlled finishing protocols.

The following table summarizes key material properties for molding machine applications

| Material | Density (g/cm³) | Yield Strength (MPa) | Corrosion Resistance | Relative Cost |

|---|---|---|---|---|

| 6061-T6 Aluminum | 2.7 | 276 | Good | Low |

| H13 Tool Steel | 7.8 | 1,300 | Moderate | Medium |

| Ti-6Al-4V | 4.4 | 880 | Excellent | High |

Material selection directly influences machine ROI through performance consistency and lifecycle costs. Wuxi Lead engineers collaborate with clients to analyze production demands, ensuring each component utilizes the optimal material-finish combination. Consult our technical team to refine your specifications for maximum operational efficiency.

Manufacturing Process & QC

The production process for high-performance aluminium molding machines at Wuxi Lead Precision Machinery follows a rigorously controlled sequence: Design, Prototyping, and Mass Production. This structured approach ensures maximum precision, repeatability, and zero-defect output, meeting the exacting standards of advanced manufacturing industries such as automotive, aerospace, and industrial automation.

Design is the foundational phase, where engineering excellence meets application-specific requirements. Our team of senior CNC engineers and mechanical designers utilize advanced CAD/CAM software to develop 3D models and finite element analysis (FEA)-validated structures. Every component is optimized for thermal stability, load distribution, and dynamic response under high-pressure molding conditions. Material selection focuses on high-grade aluminium alloys with enhanced tensile strength and thermal conductivity. Design reviews are conducted in collaboration with the client to confirm dimensional accuracy, interface compatibility, and manufacturability before any physical work begins.

Prototyping follows design finalization and serves as a critical validation step. A fully functional prototype is produced using five-axis CNC machining centers with micron-level precision. This prototype undergoes comprehensive testing, including stress cycling, thermal expansion analysis, and mold flow simulation. All performance data is recorded and analyzed to identify potential deviations. Any adjustments are implemented in the digital model and re-validated before progression. This iterative process ensures that the final design is not only functional but also robust under continuous industrial operation.

Mass Production is executed in our ISO 9001-certified facility with full traceability and real-time quality monitoring. Each machine is assembled on dedicated production lines using calibrated tools and documented work instructions. In-process inspections occur at every major stage, supported by coordinate measuring machines (CMM) and laser alignment systems. Final testing includes 72-hour continuous dry runs and performance benchmarking against predefined KPIs. Only units that pass all criteria are approved for shipment.

Throughout the entire process, Wuxi Lead enforces a zero-defect philosophy through statistical process control (SPC), root cause analysis, and continuous improvement protocols. Our commitment to precision engineering ensures that every aluminium molding machine delivered performs reliably in the most demanding production environments.

| Specification | Detail |

|---|---|

| Machine Type | Custom Aluminium Molding Machine |

| Construction Material | High-strength aluminium alloy (A6061-T6, A7075-T6) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Control System | Siemens 840D / Fanuc 31i |

| Cooling System | Integrated closed-loop chiller with PID control |

| Production Lead Time (Prototype) | 4–6 weeks |

| Production Lead Time (Mass Batch) | 8–12 weeks (scalable) |

| Quality Standard | ISO 9001:2015, ISO 14001, CE Certified |

Why Choose Wuxi Lead Precision

Elevate Your Aluminium Production Through Engineering Partnership

Wuxi Lead Precision Machinery operates at the convergence of advanced engineering and industrial pragmatism. For global manufacturers demanding uncompromising quality in aluminium die casting, our machines represent not merely equipment but a strategic production asset. We engineer solutions where micron-level precision meets the rugged demands of 24/7 operation, directly impacting your yield rates and total cost of ownership. Our technical team possesses deep expertise in complex aluminium flow dynamics, thermal management, and cavity pressure optimization—critical factors often overlooked by generic machinery suppliers. When you partner with Lead Precision, you gain access to engineered stability, not just hardware.

Consider the tangible differentiators embedded in our LPM Series Aluminium Die Casting Systems. These platforms are validated across aerospace structural components, automotive powertrain housings, and high-integrity electronics enclosures. The table below outlines core performance specifications achievable under real-world production conditions:

| Parameter | Specification Range | Industry Standard Benchmark |

|---|---|---|

| Clamping Force | 800–5,500 Tons | 600–4,000 Tons |

| Shot Speed Consistency | ±0.5 m/s (Repeatability) | ±1.5 m/s |

| Platen Parallelism | ≤ 0.03 mm/m² | ≤ 0.08 mm/m² |

| Thermal Control Accuracy | ±1.0°C (Die Surface) | ±3.0°C |

| Cycle Time Reduction | 12–18% vs. Legacy Systems | Baseline |

This performance stems from our integrated approach: German-sourced servo-hydraulic systems, proprietary real-time monitoring algorithms, and finite element analysis-driven structural frames. We eliminate guesswork through data—every machine delivers full traceability of injection profiles, cooling curves, and ejection forces. For high-mix production environments, our modular tooling interfaces reduce changeover times by 30%, directly enhancing your operational flexibility.

Your production challenges require more than off-the-shelf machinery. They demand a partner who understands the physics of molten aluminium under pressure and the financial impact of unplanned downtime. Lead Precision collaborates from initial feasibility studies through sustained production support, ensuring your investment delivers measurable ROI. Our global service network provides immediate technical response, while our engineering team remains engaged to optimize your process parameters long after installation.

Initiate a technical dialogue that moves beyond specifications. Contact our engineering sales division to discuss your specific component requirements, material grade challenges, or throughput targets. We will provide a detailed capability assessment and machine configuration proposal within 48 business hours.

Contact [email protected] to schedule a confidential production audit. Include your part drawings or process pain points for immediate technical evaluation. Partner with precision—where Chinese manufacturing scale meets German engineering rigor.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.