Technical Contents

Engineering Guide: Molding Polycarbonate

Engineering Insight Precision Imperatives in Polycarbonate Molding

Polycarbonate molding demands exceptional precision engineering far beyond standard thermoplastics. Its high melt viscosity, sensitivity to thermal gradients, and propensity for internal stress formation necessitate absolute control over every process parameter. Inconsistent thermal management induces birefringence in optical components or catastrophic warpage in structural parts. Even micron-level deviations in mold geometry or temperature distribution compromise part integrity, transparency, and dimensional stability. For high-value applications like aerospace glazing, medical device housings, or safety-critical components, such failures are unacceptable. Precision is not merely desirable; it is the fundamental requirement for functional polycarbonate parts.

Achieving this level requires integrated mastery of material science, mold design, and process control. Wuxi Lead Precision Machinery leverages decades of specialized experience in high-tolerance metal fabrication to address these challenges. Our custom molds utilize advanced thermal management systems with zone-controlled cooling channels machined to ±0.005mm tolerances. This ensures uniform heat extraction critical for minimizing residual stress and preventing optical distortion. We employ hardened, mirror-polished tool steels processed through stringent CNC grinding and EDM finishing protocols to achieve surface finishes essential for optical clarity and part ejection. Material flow analysis is rigorously validated against real-world cavity pressure data, optimizing gate design and injection profiles to eliminate weld lines and sink marks.

The following specifications highlight critical parameters where precision directly dictates polycarbonate part success:

| Parameter | Critical Range | Precision Requirement | Impact of Deviation |

|---|---|---|---|

| Melt Temperature | 280°C – 320°C | ±3°C | Degradation (yellowing) or poor flow |

| Mold Temperature | 80°C – 110°C | ±2°C | Internal stress, warpage, poor optics |

| Injection Pressure | 80 – 150 MPa | ±5 MPa | Flash, short shots, high residual stress |

| Cooling Rate | Controlled Linear | ±0.5°C/sec | Crystallinity issues, dimensional drift |

| Cavity Surface Finish | Optical Grade | Ra ≤ 0.05 μm | Haze, light scattering, adhesion failure |

Our commitment to precision is proven in mission-critical deployments. We engineered molds for transparent structural elements in Beijing Olympic venues, where optical clarity and structural resilience under extreme weather were non-negotiable. Similarly, our molds consistently produce military-grade sighting system components meeting stringent MIL-STD dimensional and environmental specifications. These projects demanded zero defect tolerance and validated our ability to control the complex interplay of heat, pressure, and time inherent in polycarbonate processing.

Demanding applications require uncompromising control. Wuxi Lead Precision Machinery applies aerospace-grade metrology and military-spec process validation to every polycarbonate molding project. Our engineering team collaborates from initial design through production validation, ensuring your parts meet the highest functional and aesthetic standards. Contact our engineering team to discuss how precision metal manufacturing solves your polycarbonate challenges.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions tailored for high-performance applications involving molding polycarbonate components. As a leader in custom metal manufacturing, we specialize in producing precision tooling, molds, and support fixtures critical to the injection molding process. Our technical capabilities are engineered to meet the stringent demands of industries such as medical devices, automotive electronics, and consumer technology, where polycarbonate’s optical clarity, impact resistance, and thermal stability are essential.

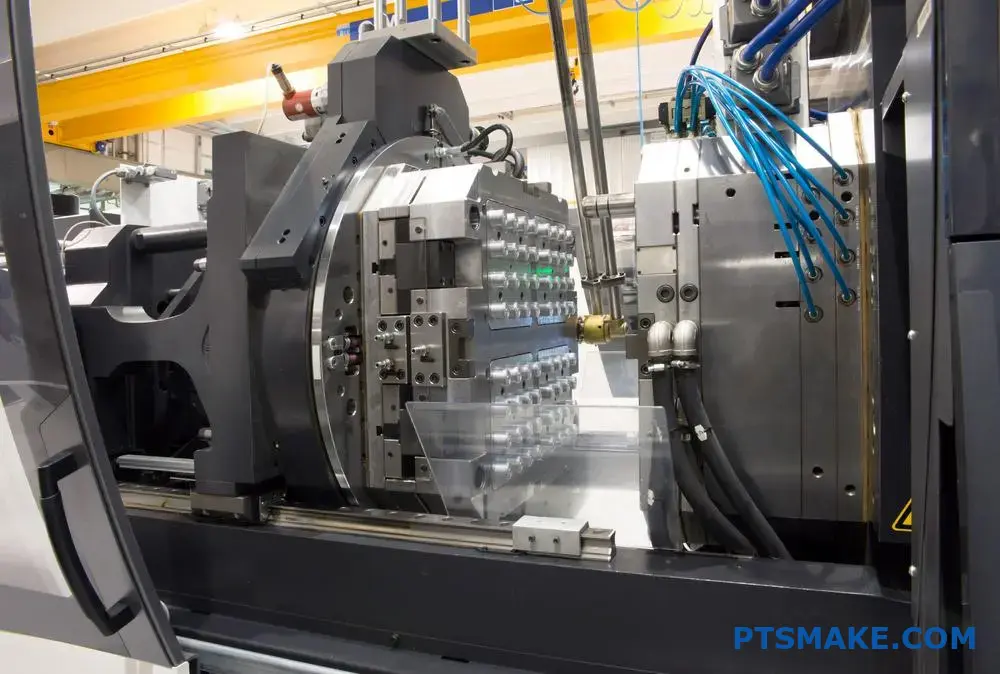

At the core of our production workflow is state-of-the-art 5-axis CNC machining technology. This advanced system enables us to create complex mold geometries with exceptional accuracy and surface finish, directly influencing the quality of molded polycarbonate parts. Unlike conventional 3-axis systems, our 5-axis CNC centers allow simultaneous multi-directional cutting, reducing setup times and minimizing cumulative tolerances. This results in tighter conformity to design specifications and improved mold longevity. Our machining centers operate with high-speed spindles and dynamic tool path optimization, ensuring efficient material removal and fine detail reproduction—critical when manufacturing mold cavities and cores for optical-grade polycarbonate applications.

To ensure every component meets exacting standards, we implement a rigorous quality control protocol centered on Coordinate Measuring Machine (CMM) inspection. Each mold and critical component undergoes comprehensive dimensional verification using Zeiss and Mitutoyo CMM systems. These high-precision measurement platforms provide traceable, repeatable data across all critical features, including cavity wall thickness, gate geometry, and alignment surfaces. Our inspection process adheres to ISO 10360 standards, and all reports are documented for full production traceability. This level of scrutiny ensures that molds perform consistently in high-cycle production environments, minimizing flash, warpage, and dimensional drift in the final polycarbonate parts.

Our technical expertise extends beyond machining and inspection—we integrate material science knowledge with manufacturing precision to optimize mold performance for polycarbonate processing. This includes thermal management design, surface texturing, and wear-resistant coatings applied with precision to enhance release characteristics and reduce cycle times. All processes are supported by in-house engineering review, ensuring manufacturability, durability, and compliance with international quality benchmarks.

The following table outlines key technical specifications and achievable tolerances for our mold manufacturing services:

| Parameter | Capability | Standard Tolerance | Notes |

|---|---|---|---|

| Positional Accuracy | 5-axis CNC Machining | ±0.005 mm | Full simultaneous 5-axis motion |

| Linear Dimensions | Milling & Turning | ±0.010 mm | Measured via CMM |

| Surface Finish | Mold Cavities | Ra 0.05 – 0.4 µm | Polishing and texturing available |

| Geometric Tolerances | Form & Profile | ±0.012 mm | GD&T-compliant inspection |

| Feature Repeatability | Batch Production | ±0.008 mm | Verified over 10 consecutive runs |

| Measurement Uncertainty | CMM Inspection | < 0.003 mm | ISO 10360-2 compliant |

Wuxi Lead Precision Machinery combines advanced equipment, disciplined quality control, and deep materials understanding to deliver mold solutions that consistently produce high-integrity polycarbonate components.

Material & Finish Options

Material Selection Fundamentals for Polycarbonate Molding

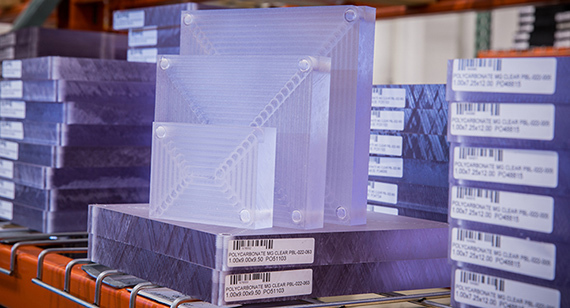

Selecting the optimal mold material is critical for polycarbonate (PC) injection molding due to PC’s high processing temperatures (280–320°C) and inherent abrasiveness. Poor material choice accelerates wear, causes part adhesion, and compromises dimensional stability. At Wuxi Lead Precision Machinery, we prioritize thermal management, hardness, and chemical resistance to ensure mold longevity and part quality. Below is a technical comparison of industry-standard materials for PC applications.

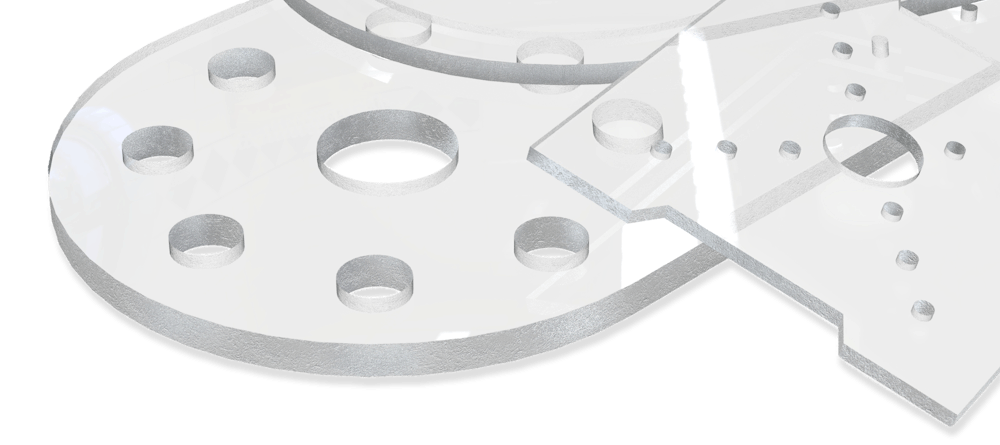

Aluminum Alloys (e.g., 7075-T6)

Aluminum offers exceptional thermal conductivity (130–180 W/mK), enabling rapid cooling cycles essential for reducing PC warpage. Its machinability allows complex geometries at lower costs, making it ideal for prototyping and low-volume production. However, aluminum’s lower hardness (150 HB) limits lifespan in high-cycle PC runs, where abrasive filler additives accelerate surface erosion. Use aluminum only when cycle counts remain under 50,000 and thermal efficiency outweighs wear concerns.

Tool Steels (e.g., H13, S136)

H13 and S136 steels dominate high-volume PC molding. H13 (50–54 HRC) provides superior toughness for large molds subjected to thermal cycling, while S136 (stainless variant) delivers exceptional corrosion resistance against PC degradation byproducts. Both maintain hardness at elevated temperatures, resisting abrasive wear from glass-filled PC grades. Though slower to machine and 30–50% costlier than aluminum, steel molds achieve 500,000+ cycles with proper maintenance—justifying investment for production volumes exceeding 100,000 parts.

Titanium Alloys (e.g., Ti-6Al-4V)

Titanium’s niche application arises in extreme scenarios requiring non-magnetic properties or exceptional corrosion resistance. Its thermal conductivity (7 W/mK) is critically low for PC, risking uneven cooling and part defects. While hardness (36 HRC) surpasses aluminum, abrasive PC wear still degrades surfaces faster than steel. Titanium’s exorbitant cost and machining complexity restrict use to specialized medical or aerospace tooling where alternatives fail.

Anodizing: Essential for Aluminum & Critical for PC Release

Anodizing is non-negotiable for aluminum molds processing PC. Standard Type II anodizing (5–25 µm) improves wear resistance but remains insufficient. Opt for hardcoat Type III anodizing (25–50 µm, 500–900 HV), which creates a ceramic-like surface that minimizes PC adhesion and extends mold life by 2–3x. Crucially, anodized surfaces must be sealed with nickel acetate to prevent micro-porosity—unsealed pores trap PC, causing surface defects and accelerated wear.

Material Performance Comparison

| Property | Aluminum 7075-T6 | H13 Tool Steel | S136 Stainless Steel | Ti-6Al-4V |

|---|---|---|---|---|

| Thermal Conductivity (W/mK) | 130–180 | 28–36 | 20–25 | 6–7 |

| Hardness (HRC/HB) | 150 HB | 50–54 HRC | 48–52 HRC | 36 HRC |

| Corrosion Resistance | Low | Moderate | High | Exceptional |

| Typical PC Cycle Life | < 50,000 | 300,000–1M+ | 500,000–2M+ | < 100,000 |

| Primary Use Case | Prototyping | High-volume | Corrosive PC grades | Specialized |

Material selection directly dictates PC molding efficiency and part quality. For most production scenarios, H13 or S136 steel delivers the optimal balance of durability and thermal performance. Partner with Wuxi Lead to analyze your specific PC grade, volume, and geometry—we engineer mold substrates and surface treatments to maximize your operational ROI.

Manufacturing Process & QC

Design Phase: Precision Engineering for Polycarbonate Molding

The foundation of successful polycarbonate molding begins with meticulous design engineering. At Wuxi Lead Precision Machinery, we initiate every project with a comprehensive analysis of the client’s functional requirements, environmental conditions, and dimensional tolerances. Polycarbonate, known for its high impact resistance, optical clarity, and thermal stability, demands precise mold geometry to avoid warpage, sink marks, and internal stresses. Our design team utilizes advanced CAD/CAM software—such as Siemens NX and SolidWorks—to develop 3D models that simulate flow dynamics, cooling efficiency, and ejection mechanics. Finite Element Analysis (FEA) ensures structural integrity under injection pressures up to 150 MPa. All designs are validated through Design for Manufacturing and Assembly (DFMA) principles to minimize complexity and maximize repeatability. Collaboration with the client at this stage ensures alignment on part functionality, surface finish (ranging from matte to optical-grade polish), and gating strategy—critical for zero-defect production.

Prototyping: Validating Performance Before Scale

Once the mold design is approved, we proceed to prototyping using high-precision CNC-machined aluminum or pre-hardened steel molds. This phase allows for rapid iteration and real-world testing of the polycarbonate component under actual processing conditions. Injection parameters—including melt temperature (typically 280–320°C), mold temperature (80–110°C), and holding pressure—are optimized to eliminate voids, short shots, and residual stress. Each prototype undergoes rigorous metrological inspection using coordinate measuring machines (CMM) and optical profilometers to verify dimensional accuracy within ±0.02 mm. Material batch consistency is verified through spectrographic analysis and moisture testing, as polycarbonate must be dried to below 0.02% moisture content pre-processing. Any deviations are corrected in mold geometry or process settings before transitioning to full-scale production. This iterative validation ensures that the final tooling performs flawlessly during mass manufacturing.

Mass Production: Zero-Defect Manufacturing Execution

With prototype approval, we deploy hardened P20 or H13 steel molds built for longevity and thermal stability under high-cycle operations. Our automated production lines integrate robotic part handling, real-time pressure and temperature monitoring, and in-line vision systems to detect surface defects instantly. All molding machines are maintained to ISO 2768-1 standards, with preventive maintenance logs ensuring consistent clamp force, shot size, and cooling performance. The process is governed by Statistical Process Control (SPC), with Cp/Cpk values maintained above 1.67 to guarantee process capability. Every batch is traceable through our MES system, recording machine settings, operator IDs, and environmental conditions. Final inspection includes dimensional checks, tensile testing, and optical clarity evaluation per ASTM D638 and ISO 11473. With this closed-loop quality system, Wuxi Lead achieves zero-defect output in polycarbonate molding—delivering high-performance components for automotive, medical, and electronics industries.

| Parameter | Specification |

|---|---|

| Material | Polycarbonate (PC), UV-stabilized or flame-retardant grades |

| Melt Temperature | 280–320°C |

| Mold Temperature | 80–110°C |

| Injection Pressure | Up to 150 MPa |

| Dimensional Tolerance | ±0.02 mm |

| Surface Finish | SPI-SPE (matte) to SPI-A1 (optical polish) |

| Tooling Material | P20, H13, or S136 steel |

| Production Capacity | 10,000–500,000 units/month |

| Quality Standard | ISO 9001, IATF 16949, ASTM D638, ISO 11473 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Polycarbonate Molding Excellence

Achieving flawless polycarbonate components demands more than standard molding capabilities. Material sensitivity, stringent optical clarity requirements, and microscopic tolerance stack-ups necessitate engineering precision that transcends conventional manufacturing. At Wuxi Lead Precision Machinery, we engineer solutions for the most demanding polycarbonate applications—medical optics, aerospace glazing, and high-impact safety components—where failure is not an option. Our CNC-machined molds deliver zero-defect production through material science expertise and process control honed over 15 years of specialized polymer manufacturing.

Our proprietary molding systems integrate multi-axis cavity compensation and real-time pressure monitoring to eliminate warpage and internal stress. This is critical for polycarbonate’s high viscosity and thermal sensitivity, ensuring consistent wall thickness and optical homogeneity. Below are core specifications defining our polycarbonate molding capability:

| Parameter | Specification | Industry Standard |

|---|---|---|

| Cavity Precision | ±0.002 mm (Ra 0.025 µm) | ±0.01 mm |

| Clamp Force Range | 800–6,500 Tons | Up to 4,000 Tons |

| Melt Temp Control | ±0.5°C stability | ±2.0°C |

| Cycle Time Reduction | 18–22% vs. conventional systems | Baseline |

| Optical Clarity Yield | 99.8% defect-free (ASTM D1003) | 95–97% |

These metrics reflect our commitment to eliminating common polycarbonate failures: sink marks from uneven cooling, hazing from moisture contamination, and dimensional drift during ejection. Our engineers collaborate from initial design through production validation, leveraging mold flow analysis to optimize gate placement and injection profiles specific to your resin grade. We address material hygroscopicity with integrated drying systems operating below 50 ppm moisture—critical for maintaining impact strength and transparency.

Partnering with Lead Precision means accessing tier-1 aerospace and medical device manufacturing protocols. We implement full traceability via IoT-enabled machines, documenting every micron of mold deflection and thermal fluctuation. Our DFM process identifies cost drivers early—such as unnecessary undercuts or non-optimized draft angles—reducing tooling revisions by 40%. For polycarbonate, where cycle time directly impacts residual stress, our adaptive control algorithms dynamically adjust hold pressure based on cavity sensor feedback, ensuring part integrity without sacrificing throughput.

Do not compromise on polymers where precision defines performance. Contact our engineering team today to discuss your polycarbonate molding challenge. We will provide a detailed capability assessment, including mold flow simulation and a production timeline, within 72 hours.

Initiate your zero-defect polycarbonate project: [email protected]

Wuxi Lead Precision Machinery—Where Material Science Meets Manufacturing Certainty.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.