Technical Contents

Engineering Guide: Cnc Machining Service Online

Engineering Insight Precision as the Non-Negotiable Core of Online CNC Machining Services

In high-stakes manufacturing sectors, precision transcends mere specification; it defines product reliability, safety, and ultimate market success. When sourcing CNC machining services online, the perceived convenience of digital platforms must never compromise the uncompromising accuracy demanded by aerospace, medical, defense, and advanced industrial applications. True precision engineering ensures components function flawlessly within complex assemblies under extreme conditions, where microns determine operational integrity. Selecting an online provider requires rigorous validation of their metrology capabilities, process controls, and material science expertise—not just quoting speed. The digital interface is merely the access point; the critical value lies in the physical mastery of the machine shop behind it.

Wuxi Lead Precision Machinery operates at this critical intersection of digital accessibility and physical excellence. Our online service portal streamlines RFQ submission and project tracking, but the foundation of every component we produce remains our decades-honed commitment to micron-level accuracy. This is not theoretical capability. We routinely achieve tolerances down to ±0.001mm and surface finishes reaching Ra 0.2µm, validated through continuous in-process inspection and final CMM reporting. Our infrastructure integrates multi-axis CNC machining centers with advanced metrology labs operating under ISO 9001 and AS9100 standards, ensuring every online order undergoes the same scrutiny as direct enterprise contracts.

The following table outlines key precision metrics achievable across our standard production processes for critical materials:

| Specification Category | Capability Range | Measurement Standard | Typical Application Context |

|---|---|---|---|

| Dimensional Tolerance | ±0.001mm to ±0.005mm | ISO 2768-mK / Custom GD&T | Aerospace actuators, medical implants |

| Surface Roughness (Ra) | 0.2µm to 1.6µm | ISO 1302 | Hydraulic seals, optical mounts |

| Geometric Accuracy (Flatness) | ≤ 0.002mm per 100mm | ASME Y14.5 | Semiconductor stages, metrology bases |

| Material Compatibility | Titanium, Inconel, 17-4PH, PEEK | ASTM/AMS Standards | Defense systems, downhole tools |

| Process Validation | 100% First Article Inspection + SPC | PPAP Level 3 | Automotive safety systems |

This precision pedigree is proven through mission-critical projects. We engineered timing system components for the Beijing Winter Olympics, where microsecond synchronization demanded absolute dimensional stability across temperature fluctuations. Similarly, our production of critical defense components for aerospace platforms required adherence to stringent military specifications (MIL-STD-883), involving complex geometries in hardened alloys with zero defect tolerance. These engagements were not one-off achievements but validations of systemic capability—processes now embedded in every online order.

Choosing an online CNC service means selecting a partner whose digital efficiency is matched by physical rigor. At Wuxi Lead Precision Machinery, our online platform delivers transparency and speed, but the enduring value is our demonstrable precision heritage. Request a quote through our portal, and you engage the same engineering discipline trusted by Olympic committees and defense primes. Precision isn’t just what we measure; it’s how we operate.

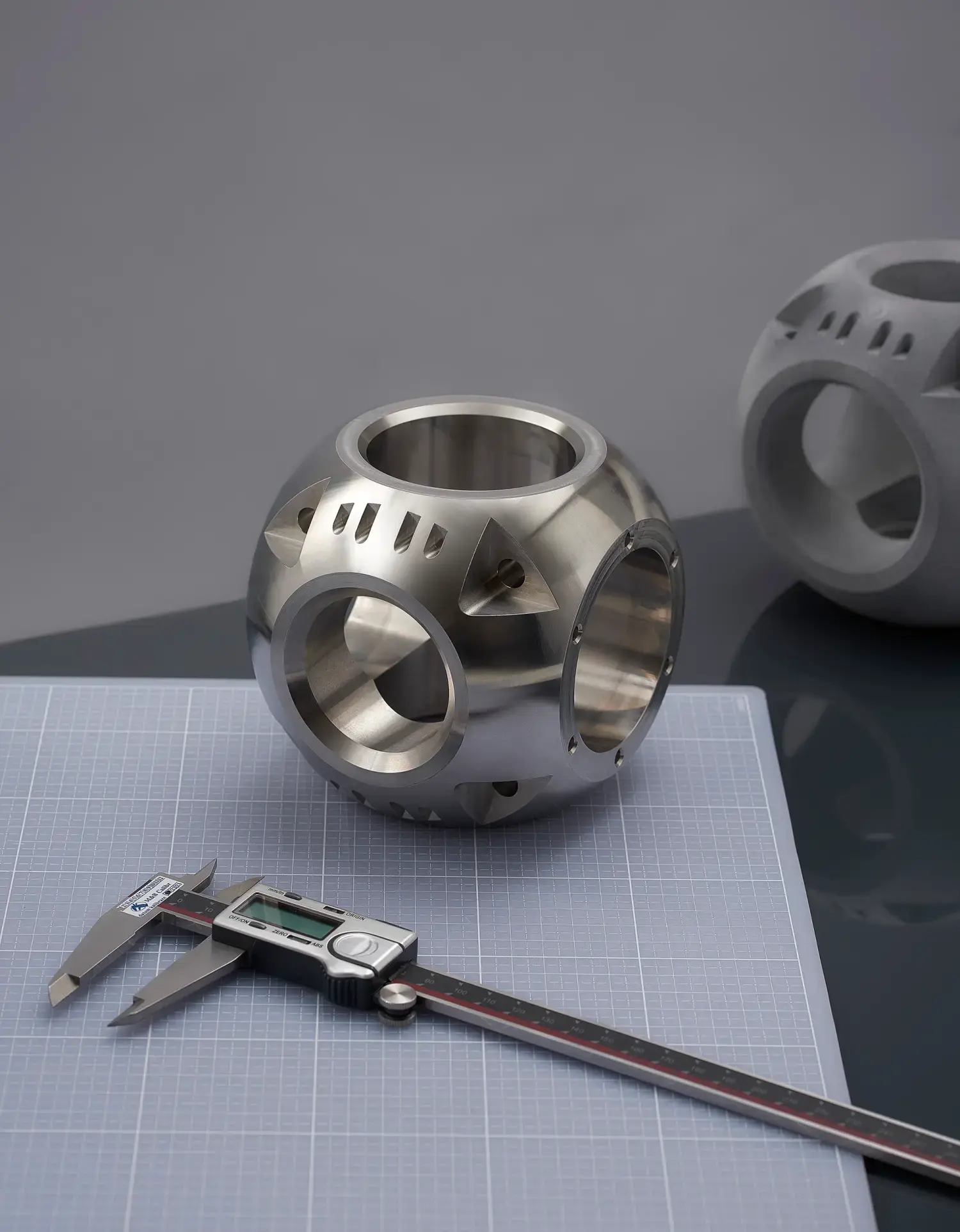

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced CNC machining services tailored to meet the rigorous demands of high-precision industries such as aerospace, medical, automotive, and industrial automation. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly reducing setup times and enhancing part consistency. This capability is critical for manufacturing components with intricate contours, deep cavities, or non-orthogonal features that are common in mission-critical applications.

Our machining fleet includes vertical and horizontal 5-axis CNC machines equipped with high-speed spindles, automatic tool changers, and real-time tool monitoring systems. These features ensure minimal downtime, superior dimensional stability, and the ability to machine a wide range of materials—from aerospace-grade aluminum and titanium to medical stainless steel and high-performance polymers. Each machine operates under strict environmental controls to maintain thermal stability, further ensuring repeatability and precision across production runs.

Quality assurance is integrated into every phase of our manufacturing process. All critical dimensions are verified using a蔡司 CONTURA G2 Coordinate Measuring Machine (CMM), certified to ISO 10360 standards. The CMM enables full 3D inspection with sub-micron resolution, providing comprehensive GD&T analysis, surface profile evaluation, and first-article inspection reports. In addition to CMM validation, our quality technicians perform in-process inspections using digital micrometers, bore gauges, and optical comparators to maintain conformance throughout production.

We adhere to ISO 9001:2015 quality management standards and support full traceability with material certifications, process documentation, and inspection reports available upon request. Our engineering team collaborates closely with clients during design for manufacturability (DFM) reviews to optimize part geometry, reduce costs, and accelerate time to market without compromising performance.

The following table outlines our standard machining tolerances and capabilities:

| Feature | Specification |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm (standard), ±0.005 mm (tight) |

| Surface Roughness (Ra) | As low as 0.4 µm (16 µin) |

| Maximum Work Envelope (5-axis) | 1,200 × 800 × 750 mm |

| Minimum Wall Thickness | 0.5 mm (aluminum), 0.8 mm (steel) |

| Hole Diameter (minimum) | 0.3 mm with peck drilling |

| Angular Tolerance | ±0.05° |

| Repeatability (Cp/Cpk) | ≥1.67 across production batches |

Our combination of advanced 5-axis technology, rigorous quality control, and engineering expertise positions Wuxi Lead Precision Machinery as a trusted partner for high-end CNC machining services delivered through a seamless online ordering and tracking platform.

Material & Finish Options

Material Selection for Precision CNC Machining: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal material is fundamental to achieving performance, cost-efficiency, and longevity in precision CNC machined components. At Wuxi Lead Precision Machinery, our engineering team collaborates closely with clients to match material properties to specific application demands, ensuring manufactured parts meet stringent functional and environmental requirements. Understanding the core characteristics of common aerospace, medical, and industrial alloys is critical for informed decision-making.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate applications requiring an exceptional strength-to-weight ratio, excellent thermal conductivity, and inherent corrosion resistance. 6061-T6 offers superior weldability and machinability, making it ideal for structural frames, enclosures, and marine hardware. 7075-T6 provides near-steel strength while maintaining light weight, essential for high-stress aerospace fittings and military components. Aluminum’s natural oxide layer offers moderate protection, but anodizing significantly enhances surface durability and aesthetics.

Carbon and alloy steels, including 4140, 4340, and 1018, deliver superior hardness, wear resistance, and structural integrity under extreme loads and temperatures. 4140 and 4340 are heat-treatable for demanding applications like shafts, gears, and tooling where fatigue resistance is paramount. 1018 provides excellent machinability for lower-stress components such as brackets and bushings. Steel requires protective finishes like plating or painting to prevent corrosion, especially in harsh environments.

Titanium Grade 5 (Ti-6Al-4V) is the premier choice for critical applications demanding the highest strength-to-weight ratio, exceptional corrosion resistance across extreme environments (seawater, chemicals), and biocompatibility. Its use is prevalent in aerospace landing gear, medical implants, and high-performance automotive. Machining titanium requires specialized tooling, rigid setups, and controlled parameters due to its low thermal conductivity and tendency to gall – expertise Wuxi Lead applies through ISO 9001-certified processes.

Anodizing is the preferred surface treatment for aluminum components, creating a durable, non-conductive, corrosion-resistant oxide layer. Type II (Sulfuric Acid) anodizing provides standard protection and dye acceptance for color coding. Type III (Hardcoat) anodizing delivers significantly thicker, harder, and more wear-resistant surfaces essential for hydraulic pistons, firearm components, and high-abrasion interfaces. Proper masking and process control are vital for dimensional accuracy on critical features.

Material selection directly impacts manufacturability, cost, and final part performance. The following table summarizes key properties for common CNC machining alloys:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Key Advantages | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | 276 | Good strength, weldability, corrosion | Frames, marine hardware, enclosures |

| Aluminum 7075-T6 | 2.8 | 572 | 503 | High strength, lightweight | Aerospace fittings, high-stress parts |

| Steel 4140 | 7.85 | 655 | 414 | High strength, toughness, wear res. | Shafts, gears, tooling |

| Steel 1018 | 7.87 | 440 | 370 | Excellent machinability, cost-effective | Brackets, pins, low-stress parts |

| Titanium Ti-6Al-4V | 4.43 | 900 | 830 | Highest strength/weight, corrosion res. | Aerospace, medical implants |

Wuxi Lead Precision Machinery leverages decades of material science expertise and advanced CNC capabilities to guide clients through this critical selection process. We provide comprehensive material certification and stringent in-process quality control, ensuring the chosen alloy and finish deliver optimal performance for your specific operational environment. Contact our engineering team for a detailed material suitability assessment.

Manufacturing Process & QC

From Design to Mass Production: A Zero-Defect CNC Machining Workflow

At Wuxi Lead Precision Machinery, our production process is engineered for precision, consistency, and reliability. We specialize in high-end CNC machining services that support clients from initial concept to full-scale manufacturing. Our end-to-end workflow integrates design validation, rapid prototyping, and scalable mass production—all governed by a zero-defect philosophy.

The process begins with design analysis. Our engineering team reviews CAD models and technical drawings to assess manufacturability, material selection, and geometric complexity. We perform Design for Manufacturing (DFM) evaluations to identify potential issues early, recommend optimizations, and ensure compliance with tight tolerance requirements. This collaborative stage minimizes rework and accelerates time-to-market.

Once the design is finalized, we proceed to prototyping. Using 3-, 4-, and 5-axis CNC machining centers, we produce functional prototypes that mirror final production quality. These prototypes are subjected to rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface finish testers. Feedback from prototype testing is used to refine toolpaths, fixturing, and process parameters before transitioning to mass production.

Our mass production phase leverages automated machining cells, in-process gauging, and real-time monitoring systems to maintain dimensional accuracy across thousands of parts. Each production run is supported by statistical process control (SPC) and first-article inspection reports (FAIR) to ensure consistency. Our facility operates under ISO 9001-certified quality management systems, with full traceability from raw material to finished component.

Zero defects are achieved through proactive quality integration. Every operator is trained in precision machining standards, and every machine undergoes regular calibration. We employ automated inspection systems for high-volume runs and conduct final audits on all shipped batches. This disciplined approach ensures that every part meets or exceeds customer specifications.

CNC Machining Capabilities at Wuxi Lead Precision Machinery

| Parameter | Specification |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis milling, turning |

| Tolerance Capability | ±0.005 mm (±0.0002″) |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (16–125 µin) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31 x 24 in) |

| Materials Supported | Aluminum, Stainless Steel, Titanium, Brass, PEEK, Delrin, and more |

| Production Volume Range | Prototypes to 100,000+ units annually |

| Quality Standards | ISO 9001, FAIR, PPAP, SPC, CMM Inspection |

This structured workflow ensures that from the first sketch to the final shipment, Wuxi Lead delivers precision-engineered components with uncompromising quality.

Why Choose Wuxi Lead Precision

Elevate Your Precision Manufacturing Partnership

In the demanding landscape of high-precision component production, selecting a CNC machining partner transcends simple vendor selection. It requires aligning with an engineering extension of your own team, capable of transforming complex designs into flawless physical realities while mitigating supply chain risk. Wuxi Lead Precision Machinery delivers this critical capability, operating at the intersection of advanced technology, rigorous quality systems, and responsive engineering collaboration. We understand the non-negotiable requirements of aerospace, medical device, and semiconductor manufacturing: absolute dimensional integrity, material consistency, and on-time delivery under stringent regulatory frameworks. Our facility in Wuxi, China, is not merely a production site; it is a strategic asset engineered to integrate seamlessly into your global operations, offering significant cost efficiency without compromise to precision or reliability. We proactively address common offshore concerns through transparent communication protocols, dedicated project management, and adherence to international quality standards, ensuring your project progresses with visibility and control from CAD file to certified shipment.

Our technical foundation is built upon a modern fleet of CNC equipment operated by master machinists and supported by comprehensive in-house metrology. This enables us to consistently achieve the tight tolerances and complex geometries demanded by cutting-edge applications. The following specifications represent our core production capabilities, reflecting our commitment to handling your most challenging projects:

| Capability Category | Specification Detail |

|---|---|

| Positional Accuracy | ±0.001 mm (0.00004 inches) |

| Repeatability | ±0.0005 mm (0.00002 inches) |

| Material Expertise | Aluminum Alloys, Titanium, Stainless Steels (including 17-4PH, 316L), Inconel, Brass, PEEK, Delrin, Engineering Plastics |

| Machine Types | 3-Axis, 4-Axis, 5-Axis Milling; Precision Turning (Swiss & Chucker); Multi-Task Machining Centers |

| Maximum Work Envelope | Milling: 1200 x 800 x 600 mm; Turning: Ø300 mm x 600 mm |

| Surface Finishes | As Machined, Deburred, Bead Blasted, Anodizing (Type II/III), Passivation, Precision Polishing |

Partnering with Lead Precision means gaining a responsive engineering ally, not just a machine shop. We engage early in the Design for Manufacturability (DFM) phase, providing actionable feedback to optimize your components for cost-effective, high-yield production without sacrificing performance. Our integrated quality management system, certified to ISO 9001:2015 standards, ensures every process step is documented, monitored, and validated. Real-time production data and proactive communication eliminate guesswork, keeping you informed at every milestone. We specialize in low-to-medium volume production runs where precision and flexibility are paramount, offering scalable solutions that adapt to your evolving program needs.

Eliminate the uncertainty in your precision supply chain. Contact our engineering team today to discuss how Lead Precision Machinery can deliver the repeatable precision, technical expertise, and partnership reliability your next critical project demands. Initiate a confidential consultation and receive a detailed capability assessment tailored to your specific component requirements. Reach out directly to secure your competitive advantage.

Contact [email protected] to schedule your engineering review.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.