Technical Contents

Engineering Guide: 3D Turkey Mold

Engineering Insight: The Critical Role of Precision in 3D Turkey Mold Manufacturing

In the specialized domain of custom metal manufacturing, the production of 3D turkey molds represents a unique intersection of artistic detail and engineering rigor. These molds, often used in decorative metal casting for seasonal consumer goods, architectural elements, or promotional collectibles, demand an exceptionally high degree of dimensional accuracy and surface fidelity. At Wuxi Lead Precision Machinery, we recognize that the success of such components hinges not only on aesthetic replication but on the precision engineering that ensures consistency, repeatability, and structural integrity across production runs.

A 3D turkey mold is inherently complex, featuring intricate feather textures, lifelike contours, and fine anatomical details that must be faithfully reproduced in metal. Even minor deviations in cavity geometry or surface finish can result in casting defects such as incomplete fills, porosity, or surface roughness. These imperfections not only compromise the visual quality but can also affect downstream processes like polishing, plating, or assembly. Therefore, achieving micron-level precision in mold fabrication is not a luxury—it is a necessity.

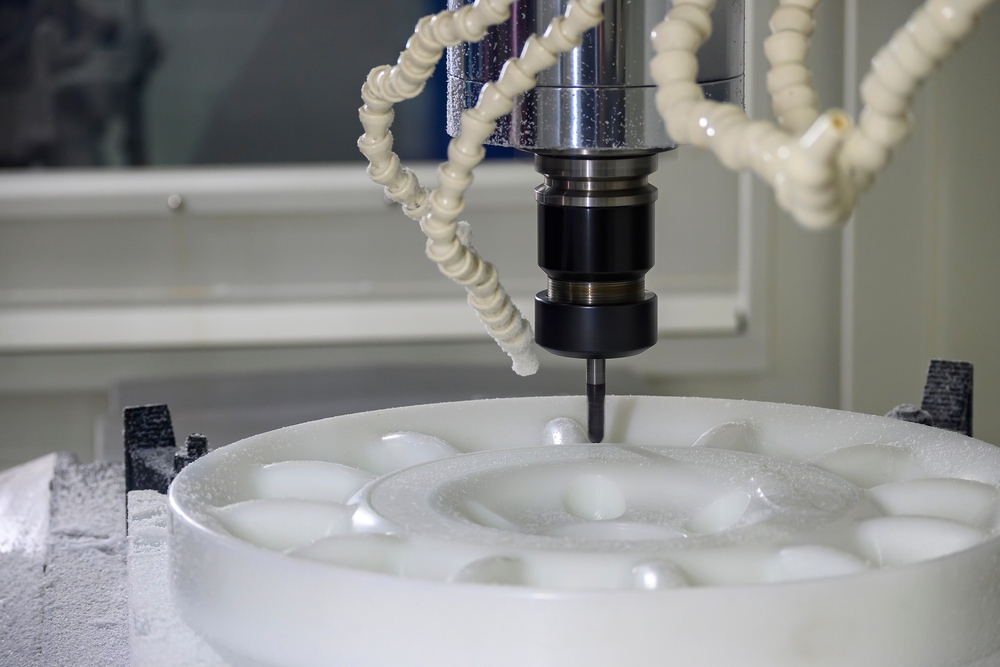

Our approach at Wuxi Lead Precision Machinery integrates advanced CNC machining, high-resolution 3D scanning, and proprietary finishing techniques to ensure every mold meets exacting standards. Utilizing multi-axis milling centers with sub-micron positioning accuracy, we are able to translate digital 3D models into physical tooling with exceptional fidelity. This capability is rooted in our extensive experience serving high-stakes industries, including aerospace, defense, and Olympic-grade equipment manufacturing, where tolerances are non-negotiable and failure is not an option.

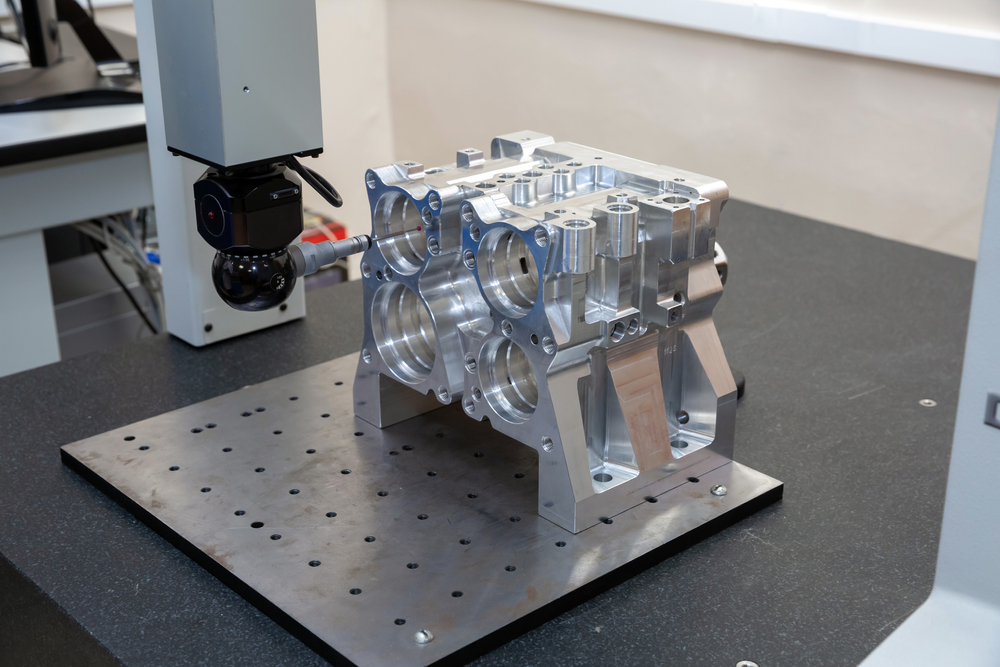

The experience gained from producing mission-critical components for military applications and precision parts for Olympic athletes has instilled in our team a culture of zero-defect manufacturing. This discipline directly benefits clients in the decorative and consumer goods sectors, where we apply the same rigorous quality control protocols—such as full-dimensional inspection via coordinate measuring machines (CMM) and real-time process monitoring—to ensure every 3D turkey mold performs flawlessly in casting operations.

Below are the typical technical specifications we achieve for custom 3D turkey mold production:

| Parameter | Specification |

|---|---|

| Material Options | H13 Tool Steel, P20 Steel, Stainless 316 |

| Machining Tolerance | ±0.005 mm |

| Surface Roughness (Ra) | 0.2 – 0.8 µm (polished finish) |

| Maximum Mold Size | 600 mm × 400 mm × 300 mm |

| 3D Scanning Resolution | 0.01 mm point accuracy |

| Lead Time (Prototype) | 12–18 days |

| Quality Certification | ISO 9001:2015, Full CMM Report |

Precision is not merely a technical benchmark—it is a commitment to excellence. At Wuxi Lead Precision Machinery, we bring the same level of engineering discipline to 3D turkey molds as we do to defense systems and Olympic technology, ensuring our clients receive tooling that delivers performance, longevity, and unmatched detail.

Precision Specs & Tolerances

Technical Capabilities for Precision 3D Turkey Mold Manufacturing

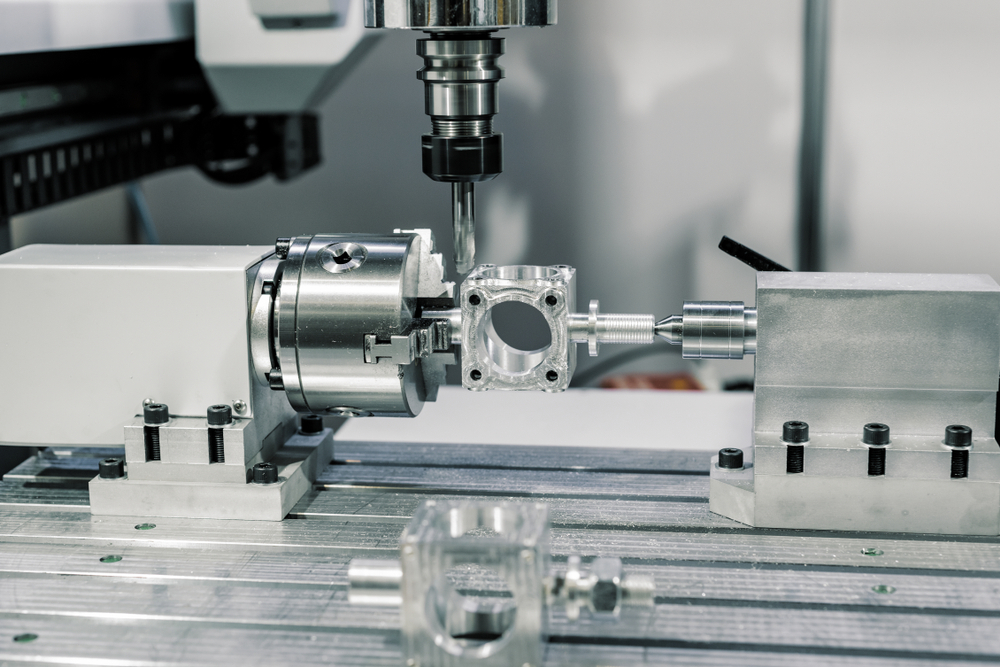

Wuxi Lead Precision Machinery delivers uncompromising accuracy for complex 3D turkey mold production through integrated advanced manufacturing and rigorous quality control systems. Our core competency lies in multi-axis metal machining, specifically leveraging state-of-the-art 5-axis CNC technology. This capability is essential for the intricate undercuts, compound curves, and seamless surface transitions inherent in high-fidelity turkey molds. Utilizing HAAS UMC-750 and DMG MORI CTX beta 1250 5-axis machining centers, we achieve complete part geometry in a single setup. This eliminates cumulative error from multiple fixtures, ensures superior surface integrity critical for food-safe release properties, and significantly reduces lead times compared to traditional 3-axis methods combined with EDM. Advanced FANUC and Siemens controls, coupled with Renishaw probing systems for in-process verification, guarantee dimensional stability throughout the machining cycle, even for large, complex mold cores and cavities in tool steels like H13 and P20.

Quality assurance is not a final step but an embedded process. Every critical feature of our 3D turkey molds undergoes comprehensive validation using Zeiss CONTURA G2 Coordinate Measuring Machines (CMM). Our AS9100-certified inspection protocol includes full 3D scanning against the original CAD model, verifying not only linear dimensions but also complex profile tolerances, surface continuity, and critical draft angles essential for efficient脱模. This metrology-driven approach provides clients with certified inspection reports detailing actual measured values versus specifications, ensuring the mold meets stringent food industry safety and performance requirements before shipment. Material certifications and heat treatment documentation are standard, providing full traceability.

The precision achievable directly impacts mold longevity, part consistency, and production efficiency. Our standard and precision tolerance capabilities across common mold materials are detailed below. Surface finish requirements down to Ra 0.4 µm (16 µin) are routinely achieved through optimized CNC finishing strategies and optional hand polishing stages.

| Material Type | Feature Category | Standard Tolerance | Precision Tolerance |

|---|---|---|---|

| Tool Steel (H13, P20) | Linear Dimensions | ±0.010 mm (±0.0004″) | ±0.005 mm (±0.0002″) |

| Tool Steel (H13, P20) | Profile / Contour | ±0.015 mm (±0.0006″) | ±0.008 mm (±0.0003″) |

| Stainless Steel | Linear Dimensions | ±0.012 mm (±0.0005″) | ±0.006 mm (±0.00025″) |

| Stainless Steel | Profile / Contour | ±0.018 mm (±0.0007″) | ±0.010 mm (±0.0004″) |

| Aluminum Alloys | Linear Dimensions | ±0.008 mm (±0.0003″) | ±0.004 mm (±0.00015″) |

| Aluminum Alloys | Profile / Contour | ±0.012 mm (±0.0005″) | ±0.006 mm (±0.00025″) |

Note: Achievable tolerances depend on specific geometry complexity, part size, and material. Precision tolerances require dedicated process planning and extended machining time.

This level of dimensional fidelity minimizes trial-and-error during mold commissioning at the client’s facility, reduces scrap rates in production, and extends the operational life of the mold by ensuring even pressure distribution and optimal cooling channel alignment. Wuxi Lead’s integrated technical capability—from complex 5-axis programming to certified metrology—provides the foundation for reliable, high-performance 3D turkey molds that meet the exacting demands of modern food processing equipment manufacturers.

Material & Finish Options

Material selection is a critical decision in custom metal manufacturing, especially when producing precision components such as 3D turkey molds used in high-cycle industrial applications. At Wuxi Lead Precision Machinery, we specialize in delivering durable, high-tolerance metal solutions tailored to performance demands, production volume, and environmental conditions. The choice between aluminum, steel, and titanium directly impacts mold longevity, thermal performance, and surface finish quality. Each material offers distinct mechanical and thermal properties that must align with the operational requirements of the molding process.

Aluminum alloys, particularly 6061 and 7075, are widely used for prototyping and medium-volume production molds due to their excellent thermal conductivity, lightweight nature, and machinability. These properties allow for faster cycle times and reduced energy consumption during molding operations. While aluminum lacks the wear resistance of steel, it performs exceptionally well in low to moderate pressure applications and is ideal when rapid heat dissipation is required. For enhanced surface durability and corrosion resistance, aluminum molds are often finished with hard anodizing, a process that transforms the outer layer into a dense, wear-resistant aluminum oxide coating.

Steel, especially tool steels such as H13, P20, and S136, is the preferred choice for high-volume production molds. Its superior hardness, wear resistance, and dimensional stability under thermal cycling make it ideal for long-run applications where consistency and part quality are paramount. Stainless variants like S136 offer excellent corrosion resistance, crucial in environments exposed to moisture or aggressive release agents. While steel molds have longer lead times and higher machining costs, their extended service life often results in lower total cost of ownership for large-scale manufacturing.

Titanium alloys, such as Ti-6Al-4V, are reserved for specialized applications requiring extreme strength-to-density ratios and exceptional corrosion resistance. Though rarely used for full mold bodies due to cost and machinability challenges, titanium is occasionally employed in critical mold inserts or cores exposed to high stress and corrosive media. Its biocompatibility and non-reactive nature also make it suitable for food-grade or medical molding applications where contamination must be avoided.

Surface finishing plays a vital role in mold performance. Anodizing, particularly Type III (hard anodizing), is highly recommended for aluminum molds. This electrolytic passivation process increases surface hardness up to 600 HV, enhances wear resistance, and provides excellent dielectric properties. The porous structure of the anodized layer also allows for dye impregnation, enabling color-coded molds for easy identification in multi-cavity setups.

Below is a comparative overview of key material properties for mold applications:

| Material | Hardness (HB) | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Common Applications | Suitable for Anodizing |

|---|---|---|---|---|---|

| Aluminum 6061 | 95 | 167 | 310 | Prototypes, low-volume molds | Yes |

| Steel H13 | 230 | 36 | 1,500 | High-volume production | No |

| Steel S136 | 250 | 28 | 1,600 | Corrosion-resistant molds | No |

| Titanium Ti-6Al-4V | 360 | 7.2 | 950 | High-stress inserts | Limited |

Selecting the optimal material and finish requires a thorough understanding of your production goals. Wuxi Lead Precision Machinery supports clients in making data-driven decisions to ensure maximum efficiency, durability, and return on investment.

Manufacturing Process & QC

Precision Manufacturing Process for 3D Turkey Forming Molds

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production sequence for custom 3D turkey forming molds, ensuring absolute compliance with the demanding standards of the food processing industry. Our integrated Design, Prototyping, and Mass Production workflow is engineered for zero defects, guaranteeing molds that deliver consistent product geometry, surface finish, and operational longevity under high-volume production conditions. This process is fundamental to minimizing client downtime and maximizing return on investment.

The journey begins with collaborative Design Engineering. Our team works directly with client specifications and 3D CAD models, performing comprehensive Design for Manufacturability (DFM) and Finite Element Analysis (FEA). This critical phase optimizes mold geometry for structural integrity under thermal cycling and pressure, ensures seamless material flow during forming, and validates critical ejection mechanisms. We meticulously define material selection, cooling channel layouts, and surface treatments to meet FDA requirements and prevent product adhesion or contamination. Every design iteration undergoes rigorous virtual validation before physical work commences, eliminating costly downstream errors.

Precision Prototyping follows, utilizing our advanced 5-axis CNC milling and wire EDM capabilities. We manufacture fully functional prototype molds from the intended production-grade material, typically high-polish austenitic stainless steel (e.g., 17-4 PH or 316L). These prototypes undergo exhaustive physical validation: dimensional inspection via coordinate measuring machines (CMM) against the master CAD file, material flow trials using actual turkey product, thermal performance testing, and cycle life simulation. Client approval of the prototype’s performance and output quality is mandatory before release to full production, ensuring the design translates flawlessly to reality.

Zero-Defect Mass Production leverages our certified ISO 9001:2015 manufacturing cell. Production occurs under strict Statistical Process Control (SPC), with real-time monitoring of critical parameters like spindle load, tool wear, and coolant conditions. Every machining operation employs calibrated tooling and in-process gauging. Final molds undergo 100% inspection: comprehensive CMM reporting on all critical dimensions, surface roughness verification (Ra), vacuum leak testing for cooling channels, and final visual inspection under controlled lighting. Only molds meeting every specification are packaged using anti-corrosion methods and shipped with full traceability documentation.

Critical Mold Specifications Achieved

| Parameter | Specification | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | CMM (Calibrated to ISO 17025) |

| Surface Roughness (Ra) | ≤ 0.4 μm (Mirror Polish) | Surface Roughness Tester |

| Material | ASTM A564 17-4 PH H1150 | Mill Certificates + PMI |

| Cooling Channel Integrity | Zero Leaks @ 1.5x Op. Pressure | Hydrostatic Pressure Test |

| Cycle Time Consistency | ±0.5 seconds | Production Monitoring SPC |

| Zero Defects Verification | 100% Conformance | Final Inspection Dossier |

This disciplined, closed-loop process eliminates variability. Wuxi Lead transforms conceptual requirements into flawless, high-performance 3D turkey molds ready for immediate integration into your production line. Contact our engineering team to initiate a zero-defect manufacturing program for your next project.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom 3D Turkey Mold Manufacturing

When precision, repeatability, and material integrity define your production success, partnering with Wuxi Lead Precision Machinery ensures your 3D turkey mold requirements are met with engineering excellence. As a leading custom metal manufacturing specialist based in China, we deliver high-performance molds tailored for food processing, packaging, and industrial automation applications—where dimensional accuracy and surface finish are non-negotiable.

Our advanced CNC machining centers, combined with decades of metallurgical expertise, enable us to produce complex 3D turkey molds from food-grade stainless steel, aluminum alloys, and hardened tool steels. Every mold is engineered to withstand high-cycle operations while maintaining tight tolerances down to ±0.005 mm. We integrate CAD/CAM simulation, multi-axis contouring, and in-process metrology to guarantee that your mold performs seamlessly in high-speed forming, injection, or compression environments.

At Lead Precision, we understand that your mold is not just a component—it’s the foundation of consistent product quality, throughput efficiency, and brand reputation. That’s why we apply a collaborative engineering approach from concept to delivery. Our team works directly with your design specifications, offering DFM analysis, material optimization, and rapid prototyping to reduce time-to-market and eliminate costly revisions.

We serve global OEMs, food equipment integrators, and industrial manufacturers who demand reliability, compliance, and scalability. Our facility is ISO 9001-certified, with full traceability on materials and processes, ensuring every 3D turkey mold meets international standards for hygiene, durability, and performance.

Below are standard technical specifications for our custom 3D turkey molds. All parameters are adjustable based on client requirements.

| Specification | Detail |

|---|---|

| Material Options | 304/316 Stainless Steel, 6061/7075 Aluminum, H13 Tool Steel |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.2–0.8 µm (polished, bead-blasted, or as-machined) |

| Maximum Mold Size | 800 mm × 600 mm × 400 mm |

| Machining Axes | 3-axis, 4-axis, and 5-axis CNC |

| Lead Time | 15–25 days (varies by complexity) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection Report (FAIR) provided |

| Applications | Food molding, packaging automation, industrial forming |

Your next-generation 3D turkey mold deserves the precision engineering and responsive service that only a true manufacturing partner can provide. At Wuxi Lead Precision Machinery, we don’t just fulfill orders—we solve production challenges.

Contact us today to begin your custom project. Email our engineering team at [email protected] for a detailed consultation, DFM review, or quote. Let Lead Precision become your trusted partner in high-precision metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.