Technical Contents

Engineering Guide: Cnc Site

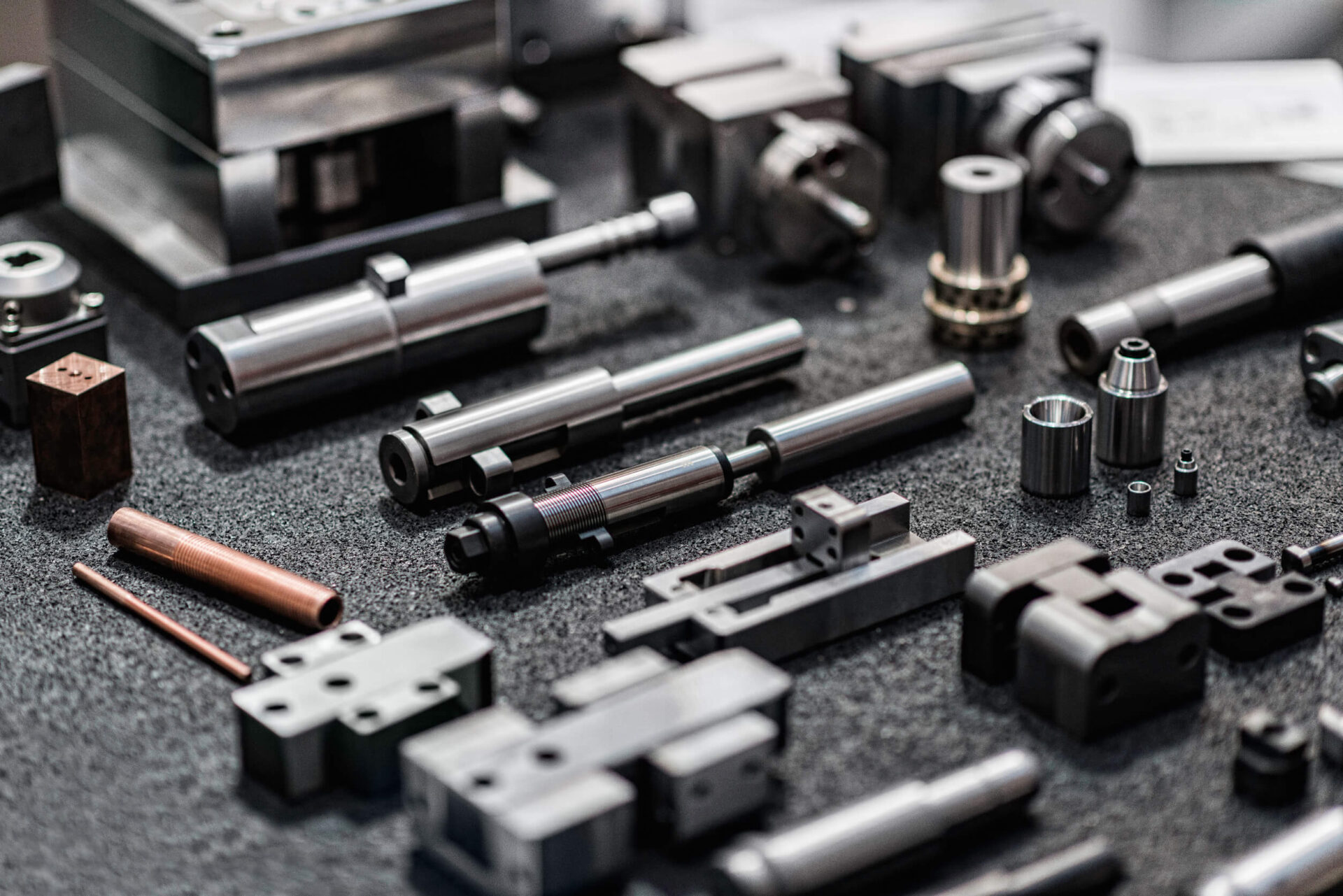

Engineering Insight: The Critical Role of Precision in Modern CNC Machining

In the world of high-performance manufacturing, precision is not merely a target—it is a non-negotiable standard. At Wuxi Lead Precision Machinery, we understand that even the smallest deviation in a component can cascade into significant failures in final applications, especially in sectors such as aerospace, defense, and high-end sports engineering. Our decades of experience in precision CNC machining have been forged in the crucible of real-world demands, where tolerance isn’t measured in millimeters—but in microns.

Our engineering philosophy centers on the principle that precision begins long before the spindle engages the workpiece. It starts with material selection, continues through meticulous process planning, and is sustained by continuous monitoring and adaptive control throughout production. This end-to-end approach ensures that every machined component meets or exceeds the tightest tolerances required by our clients.

Wuxi Lead has had the distinct honor of contributing to projects of national and international significance, including components used in Olympic-level sporting equipment and mission-critical military systems. These applications demand not only extreme dimensional accuracy but also exceptional repeatability and material integrity. In such environments, failure is not an option. Our work on Olympic-grade components, for example, required tolerances under ±0.002 mm to ensure optimal aerodynamic performance and structural reliability under dynamic loads. Similarly, military applications demanded hardened alloys machined to exacting surface finish standards, with zero tolerance for defects.

To meet these challenges, we employ state-of-the-art CNC machining centers equipped with high-resolution probing systems, thermal compensation technology, and real-time tool wear monitoring. Our engineering team applies advanced simulation software to predict and correct potential deviations before cutting begins, reducing waste and ensuring first-time-right production.

The table below outlines the precision capabilities that define our machining performance across critical parameters:

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.01 mm | ±0.002 mm |

| Surface Roughness (Ra) | 1.6 μm | 0.2 μm |

| Positional Accuracy | ±0.005 mm | ±0.001 mm |

| Repeatability | ±0.003 mm | ±0.0005 mm |

| Material Compatibility | Aluminum, Steel, Titanium, Inconel, Composites | Same, with certified traceability |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Custom setups beyond 2m |

Precision, at this level, is not achieved by equipment alone. It is the result of skilled engineers, rigorous quality control protocols, and a culture of continuous improvement. At Wuxi Lead Precision Machinery, we treat every project as a mission—where accuracy, reliability, and performance are engineered into every micron of every part. For industries where excellence is mandatory, we deliver precision without compromise.

Precision Specs & Tolerances

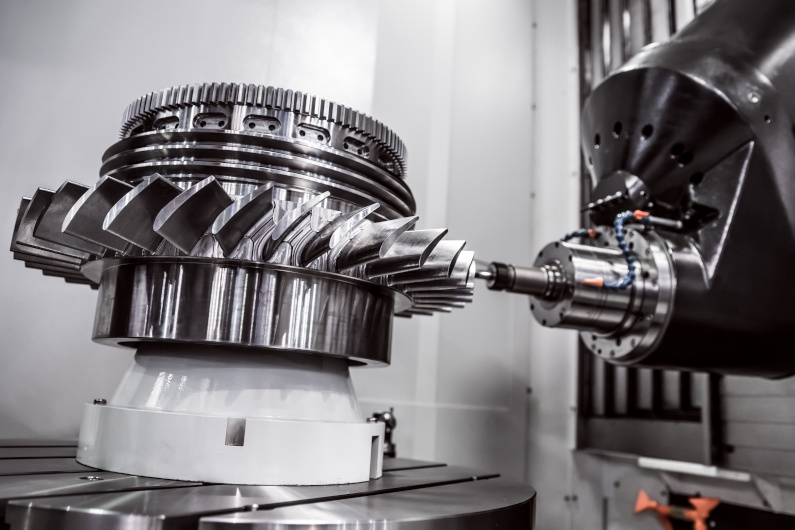

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery operates at the forefront of advanced manufacturing, delivering exceptional precision and complexity for the most demanding aerospace, medical, energy, and industrial components. Our core strength lies in sophisticated multi-axis machining, specifically centered around our fleet of state-of-the-art 5-axis CNC machining centers. These machines, primarily comprising DMG MORI and MAZAK platforms, provide unparalleled flexibility and accuracy for intricate geometries impossible with conventional 3-axis systems. Our 5-axis capabilities enable single-setup machining of complex contours, deep cavities, and organic shapes, significantly reducing lead times, minimizing handling errors, and ensuring superior part integrity. Typical work envelopes accommodate components up to Ø800mm x 1000mm, with spindle speeds reaching 24,000 RPM and equipped with high-precision Renishaw probing systems for in-process verification and automatic tool compensation. We machine a wide spectrum of materials including titanium alloys (Ti-6Al-4V), Inconel 718, high-grade stainless steels (17-4PH, 316L), aluminum alloys (7075, 6061), and advanced engineering plastics, maintaining strict environmental controls and thermal compensation protocols to ensure dimensional stability throughout production.

Rigorous quality assurance is not an endpoint but an integrated process within our manufacturing workflow. Every critical dimension and feature undergoes meticulous verification using our advanced Coordinate Measuring Machine (CMM) systems. We utilize Nikon Altera 7.7.7 and similar high-accuracy CMMs, certified to ISO 10360-2 standards, providing traceable measurement uncertainty down to ±1.7 + L/350 µm. Our certified metrology technicians perform comprehensive first-article inspections, in-process checks, and final batch verification against stringent customer drawings and international standards (ASME Y14.5, ISO 2768). This systematic approach, combined with Statistical Process Control (SPC) methodologies applied to key characteristics, guarantees consistent conformance and provides actionable data for continuous process refinement. Our quality management system is ISO 9001:2015 certified, underpinning our commitment to reliability and repeatability.

The achievable precision of our processes is fundamental to customer success. The following table details our standard and tight capability ranges for critical geometric characteristics, reflecting real-world production conditions under controlled quality management:

| Feature | Standard Tolerance Capability | Tight Capability (Requires Specific Process Control) |

|---|---|---|

| Linear Dimensions (mm) | ±0.010 | ±0.005 |

| Geometric Tolerances (Position, Profile) | ±0.020 | ±0.010 |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Hole Diameter (Drilled) | +0.025 / -0.000 | +0.010 / -0.000 |

| Hole Diameter (Reamed) | +0.010 / -0.000 | +0.005 / -0.000 |

| Angularity | ±0.05° | ±0.02° |

This documented capability, validated through our CMM processes and process control, ensures our clients receive components that meet exacting functional requirements, enabling seamless assembly and optimal performance in their end applications. Wuxi Lead’s integrated technical capabilities provide the foundation for solving complex manufacturing challenges with confidence.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the appropriate material is critical in precision CNC machining, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in machining high-tolerance components from aluminum, steel, and titanium—three of the most widely used engineering metals. Each material offers distinct mechanical properties, making them suitable for specific industrial applications ranging from aerospace and automotive to medical and energy sectors.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is a common choice for structural and non-critical load-bearing components due to its weldability and moderate strength. For higher performance demands, 7075-T6 offers superior strength, often used in aerospace applications. Aluminum’s low density reduces part weight significantly, a key advantage in transportation and portable equipment.

Steel provides high tensile strength, wear resistance, and dimensional stability under load. We commonly machine alloy steels such as 4140 and 1018. 4140, with its chromium and molybdenum content, delivers excellent toughness and is ideal for shafts, gears, and tooling. 1018, a low-carbon steel, offers good machinability and is often selected for prototypes and non-critical mechanical parts. Stainless steels like 304 and 316 provide enhanced corrosion resistance, essential in food processing, chemical, and marine environments.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the premium choice for extreme conditions. It offers exceptional strength-to-density ratio, outstanding corrosion resistance, and performance at elevated temperatures. Though more challenging to machine due to its low thermal conductivity and tendency to gall, titanium is indispensable in aerospace, medical implants, and high-performance automotive applications.

Surface finishes further enhance material performance. Anodizing is a widely used electrochemical process for aluminum, improving surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing provides a decorative and protective layer, while Type III (hardcoat anodizing) delivers a thick, durable finish suitable for industrial use. Anodized layers can also be dyed for identification or aesthetic purposes.

Below is a comparative overview of key mechanical properties for commonly machined materials.

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Common Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 276 | 2.70 | Enclosures, brackets, frames |

| Aluminum 7075-T6 | 572 | 503 | 2.81 | Aerospace components, fittings |

| Steel 4140 | 655 | 415 | 7.85 | Shafts, tooling, high-stress parts |

| Steel 304 | 515 | 205 | 8.00 | Medical, food processing, hardware |

| Titanium Ti-6Al-4V | 900 | 830 | 4.43 | Aircraft, medical implants, racing |

Understanding the interplay between material properties and application requirements ensures optimal part design and longevity. At Wuxi Lead Precision Machinery, our engineering team supports clients in selecting the right material and finish to meet exacting performance standards.

Manufacturing Process & QC

Precision CNC Production Process: From Concept to Zero-Defect Fulfillment

At Wuxi Lead Precision Machinery, we engineer manufacturing certainty. Our rigorously controlled production process transforms client specifications into flawless components through an integrated tri-phase methodology: Design Validation, Precision Prototyping, and Scalable Mass Production. This systematic approach is foundational to achieving our Zero Defects commitment for mission-critical aerospace, medical, and industrial applications.

Design validation begins with comprehensive DFM analysis. Our engineering team collaborates directly with your CAD data, identifying potential manufacturability constraints, material stress points, and tolerance stack-ups before metal is cut. We utilize advanced simulation software to model toolpaths, thermal dynamics, and fixture requirements, ensuring the design is optimized for both performance and producibility. This phase prevents costly downstream revisions and establishes the precise dimensional and geometric benchmarks for all subsequent stages.

Prototyping is not merely a sample step; it is a critical process qualification gate. Using the exact materials, tooling, and CNC platforms designated for volume production, we manufacture functional prototypes under full production parameters. Every dimension undergoes rigorous CMM inspection against the validated design, with surface finishes, material properties, and critical features measured to micron-level accuracy. Client feedback on these prototypes directly informs final process lock-down, confirming that the manufacturing sequence consistently yields parts meeting all specifications before committing to scale.

Mass production executes with uncompromising discipline. Our facility leverages a controlled network of multi-axis CNC machining centers, grinding systems, and coordinate measuring machines operating under SPC protocols. Real-time in-process monitoring tracks key parameters like tool wear, spindle load, and thermal drift, automatically triggering corrective actions before deviations occur. Every component undergoes 100% critical feature inspection via automated CMMs or vision systems, with full traceability from raw material lot to finished part. This closed-loop system, combined with our ISO 9001-certified quality management, ensures batch-to-batch consistency and absolute adherence to your zero-defect requirement.

Core Production Capabilities

| Parameter | Specification | Equipment Utilized |

|---|---|---|

| Positional Tolerance | ±0.001 mm | DMG MORI, MAZAK, HAAS |

| Surface Finish (Ra) | As low as 0.8 µm | Precision Grinding Centers |

| Materials | Aluminum Alloys, Titanium, Inconel, Stainless Steels, Engineering Plastics | Multi-Axis CNC Mills & Lathes |

| Max Work Envelope | 1200 x 800 x 600 mm | 5-Axis Vertical Machining Centers |

| In-Process Inspection | Real-time SPC, Automated CMM | Zeiss, Mitutoyo Systems |

This integrated process eliminates guesswork. By rigorously validating design intent, proving capability through production-equivalent prototyping, and enforcing statistical control during volume runs, Wuxi Lead delivers not just parts, but guaranteed operational certainty for your most demanding applications. Zero Defects is our standard, engineered into every phase.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, reliability, and long-term value. As a global leader in high-end CNC machining, we specialize in turning complex engineering designs into flawless, production-ready components. Our clients span aerospace, medical device manufacturing, automotive R&D, and industrial automation—industries where tolerances matter, repeatability is non-negotiable, and quality cannot be compromised.

When you partner with Lead Precision, you gain access to more than advanced machinery. You gain a committed engineering ally. Our team of seasoned CNC specialists works closely with your engineers from concept through completion, ensuring every part meets exact specifications and exceeds industry standards. With over 15 years of precision manufacturing experience and a state-of-the-art facility in Wuxi, China, we combine deep technical expertise with scalable production capacity to support both prototyping and high-volume runs.

Our commitment to quality is embedded in every process. We operate under ISO 9001:2015 certification, with full traceability, in-process inspections, and final QA validation on every batch. Whether you require tight tolerances down to ±0.002 mm, complex 5-axis geometries, or materials ranging from aerospace-grade aluminum to medical stainless steel and exotic alloys, we have the capability to deliver with consistency and precision.

We understand that in high-performance industries, time-to-market is critical. That’s why we’ve optimized our workflows to reduce lead times without sacrificing quality. Our agile manufacturing system enables rapid setup, efficient changeovers, and real-time progress tracking—giving you full visibility and faster turnaround.

To ensure you get the right solution for your needs, we offer comprehensive technical consultation before production begins. Our engineering team reviews your CAD models, suggests design for manufacturability (DFM) improvements, and advises on material selection and surface treatments—helping you reduce costs and improve performance.

Below are key capabilities that define our precision CNC machining services

| Specification | Detail |

|---|---|

| Machining Processes | 3-Axis, 4-Axis, 5-Axis CNC Milling, CNC Turning, Mill-Turn, Wire EDM |

| Tolerances | Up to ±0.002 mm |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium, Brass, Copper, PEEK, Delrin, and Exotics |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis), 1500 x 1000 x 800 mm (3-axis) |

| Surface Finishes | As-machined, Anodizing (Type II & III), Plating, Powder Coating, Passivation, Polishing |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP, CMM Reporting |

| Production Capacity | Low-volume prototyping to high-volume series production |

Your next breakthrough component starts with the right manufacturing partner. Contact us today at [email protected] to discuss your project, request a quote, or schedule a technical review. Let Wuxi Lead Precision Machinery be the precision behind your innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.