Technical Contents

Engineering Guide: Rubber Overmolding

Engineering Insight: The Critical Role of Precision in Rubber Overmolding

In high-performance industrial applications, rubber overmolding is far more than a simple joining process—it is a precision engineering discipline that directly impacts product reliability, durability, and functionality. At Wuxi Lead Precision Machinery, we approach rubber overmolding as a convergence of advanced material science, tight tolerance control, and repeatable manufacturing excellence. This level of precision is non-negotiable, especially when serving sectors such as aerospace, defense, and high-end automotive, where failure is not an option.

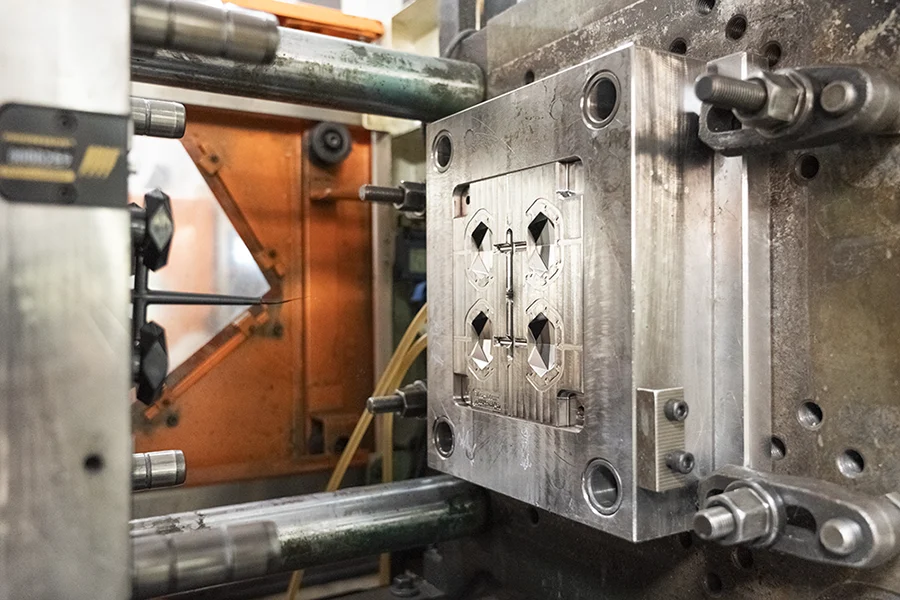

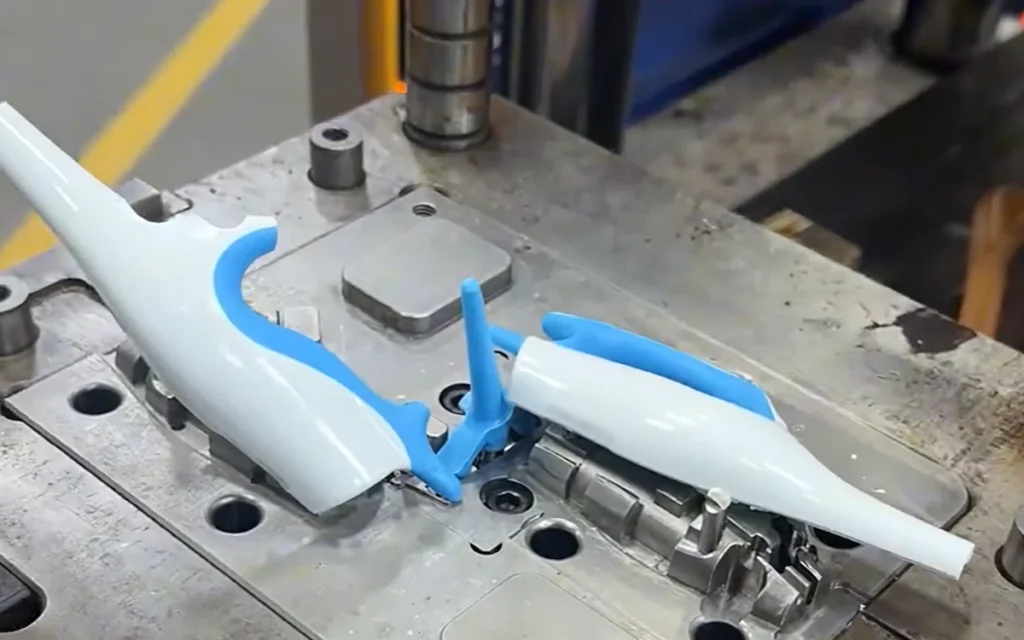

Rubber overmolding involves bonding elastomeric materials to metal substrates under tightly controlled thermal and pressure conditions. The success of this process hinges on the dimensional accuracy of the metal component, surface preparation quality, mold design fidelity, and process repeatability. Even micron-level deviations in the base metal part can lead to inconsistent bond strength, flash formation, or compromised sealing performance. This is where Wuxi Lead’s expertise in custom metal manufacturing becomes a decisive advantage.

Our engineering team ensures that every metal substrate is machined to exact specifications, with surface finishes and geometries optimized for maximum adhesion. We utilize CNC machining centers with sub-micron positioning accuracy and in-process metrology to maintain consistency across production runs. This precision extends into mold design, where thermal expansion coefficients, flow dynamics, and gate placement are simulated and validated before tooling fabrication.

Wuxi Lead Precision Machinery has delivered mission-critical overmolded components for applications in Olympic-grade sporting equipment and military-grade deployment systems. In these environments, components are subjected to extreme temperatures, mechanical stress, and corrosive conditions. Our overmolded assemblies have demonstrated long-term performance under such demands, a testament to our rigorous process control and material qualification protocols.

We work with a range of elastomers—including silicone, EPDM, NBR, and FKM—each selected based on chemical resistance, temperature range, and mechanical requirements. Our in-house material testing lab validates bond strength, compression set, and aging characteristics to ensure compliance with international standards such as ISO 9001 and MIL-STD-810.

The integration of precision metalwork and elastomer technology defines the future of high-reliability overmolding. At Wuxi Lead, we do not merely manufacture parts—we engineer performance-critical solutions where every micron contributes to operational success.

Typical Rubber Overmolding Specifications at Wuxi Lead Precision Machinery

| Parameter | Range / Capability |

|---|---|

| Tolerance (metal substrate) | ±0.005 mm |

| Surface Finish (Ra) | 0.4 – 3.2 µm |

| Material Compatibility | Silicone, NBR, EPDM, FKM, TPE |

| Bond Strength | Up to 18 N/mm (peel test, ASTM D429) |

| Operating Temperature Range | -55°C to +250°C (depending on elastomer) |

| Production Volume Capacity | Prototypes to 500,000+ units/year |

| Quality Standards | ISO 9001, MIL-STD-810, RoHS |

Precision Specs & Tolerances

Precision Metal Components for Rubber Overmolding Applications

Wuxi Lead Precision Machinery delivers mission-critical metal substrates engineered specifically for high-reliability rubber overmolding processes. Our expertise lies in transforming complex designs into dimensionally stable, surface-perfect metal cores that ensure flawless polymer adhesion and long-term part integrity. As a vertically integrated manufacturer, we control every variable from raw material sourcing to final inspection, eliminating supply chain vulnerabilities common in precision overmolding projects.

Our 5-axis CNC machining centers form the backbone of this capability, enabling single-setup fabrication of intricate geometries with undercuts, compound angles, and micro-features essential for secure rubber bonding. Utilizing Makino and DMG MORI platforms with sub-micron positioning accuracy, we achieve repeatability critical for overmold tool clearance and venting requirements. Advanced toolpath strategies minimize micro-vibrations, producing surface finishes as fine as Ra 0.4 µm on critical bonding surfaces without secondary polishing—directly preventing rubber bleed and delamination risks. Material compatibility spans aerospace aluminum alloys, medical-grade stainless steels, and beryllium-copper inserts, all processed under strict environmental controls to eliminate contaminants compromising adhesion.

Quality validation is non-negotiable in overmolding applications. Every component undergoes 100% CMM inspection using Zeiss CONTURA systems with automated probe calibration, verifying conformity to geometric dimensioning and tolerancing (GD&T) callouts per ASME Y14.5 standards. Our inspection protocols specifically target features impacting overmold performance: edge radii controlling rubber flow, draft angles preventing tear-out, and critical datum alignments ensuring uniform wall thickness. Statistical process control (SPC) data is integrated into real-time machining adjustments, maintaining capability indices (Cp/Cpk > 1.67) across production runs. This rigor guarantees dimensional stability during thermal cycling in the molding press, eliminating costly rework due to shrinkage mismatches.

The following table details our standard tolerance capabilities for overmolding-critical features:

| Feature Category | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.003 mm | CMM / High-Precision Micrometer |

| Angular Features | ±0.05° | ±0.02° | Optical Comparator / CMM |

| Surface Finish (Bonding Areas) | Ra 1.6 µm | Ra 0.4 µm | Portable Profilometer |

| Positional Tolerance (GD&T) | ±0.015 mm | ±0.005 mm | CMM with Iterative Alignment |

| Hole Concentricity | Ø0.020 mm | Ø0.008 mm | CMM / Air Gaging |

This precision foundation directly translates to overmolding success: consistent metal substrate dimensions prevent flash, ensure uniform rubber coverage, and maximize interfacial integrity. Wuxi Lead’s integrated approach—combining advanced CNC execution with metrology-driven quality assurance—eliminates the guesswork in metal-rubber interface engineering. We partner with clients during design feasibility stages to optimize part geometry for manufacturability, ensuring your overmolded assemblies meet the most stringent performance demands in automotive, medical, and industrial sectors. Trust our technical rigor to deliver metal components where tolerances aren’t just met—they enable your product’s reliability.

Material & Finish Options

Material selection is a critical phase in the rubber overmolding process, particularly when integrating metal substrates with elastomeric compounds. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that ensure optimal adhesion, durability, and performance in demanding industrial environments. The choice of base metal—aluminum, steel, or titanium—directly influences the mechanical integrity, weight, corrosion resistance, and overall functionality of the overmolded component.

Aluminum is frequently selected for rubber overmolding due to its favorable strength-to-weight ratio, excellent thermal conductivity, and ease of machining. It is particularly suitable for applications requiring lightweight assemblies, such as in automotive and aerospace systems. When paired with rubber, aluminum provides a rigid backbone while allowing for vibration damping and sealing functionality. However, aluminum’s natural oxide layer must be properly managed to ensure strong bonding with the elastomer. This is typically achieved through surface treatments such as anodizing.

Steel, particularly stainless and tool grades, offers superior strength, wear resistance, and dimensional stability. It is ideal for high-stress environments, including industrial machinery and hydraulic systems. While heavier than aluminum, steel provides exceptional durability and long-term reliability. For rubber overmolding, steel substrates often undergo chemical or abrasive surface preparation to enhance adhesion. In corrosive environments, passivation or coating may be applied in addition to bonding primers.

Titanium, though more costly, delivers unmatched strength-to-density performance and extraordinary corrosion resistance, especially in marine and biomedical applications. Its biocompatibility and resistance to extreme environments make it a preferred choice for high-end medical devices and offshore equipment. Titanium requires specialized surface activation techniques—such as plasma spraying or chemical etching—to achieve robust rubber-to-metal bonding.

Finishing processes further enhance performance and longevity. Anodizing, primarily used for aluminum, creates a porous, hard oxide layer that improves both corrosion resistance and mechanical interlock with rubber. Type II (sulfuric acid) and Type III (hard coat) anodizing are commonly employed, with the latter offering greater thickness and wear resistance. The anodized layer must be sealed properly to prevent moisture ingress, which could compromise adhesion over time.

Below is a comparative overview of key material properties relevant to rubber overmolding applications.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Anodizing Option | Machinability |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | Moderate to Good | Type II / Type III | Excellent |

| Stainless Steel 304 | 8.0 | 505 | Excellent | Not Applicable | Good |

| Titanium Grade 5 (Ti-6Al-4V) | 4.4 | 900 | Exceptional | Not Applicable | Fair |

At Wuxi Lead Precision Machinery, we collaborate closely with clients to match material and finish selections with application-specific demands, ensuring optimal performance and cost-efficiency in every overmolded assembly.

Manufacturing Process & QC

Rubber Overmolding Production Process: Precision Engineering for Zero Defects

Achieving flawless rubber overmolding demands an integrated, rigorously controlled process from initial concept to final delivery. At Wuxi Lead Precision Machinery, our CNC-engineered metal substrates form the critical foundation, enabling seamless rubber adhesion and dimensional integrity. We implement a three-phase methodology strictly enforced to eliminate defects and ensure product reliability under demanding operational conditions.

Design Phase: Precision Engineering Foundation

The process begins with collaborative Design for Manufacturability (DFM) analysis. Our engineering team scrutinizes 3D models and material specifications, focusing on critical interfaces between the metal component and elastomer. We verify draft angles, gate locations, venting requirements, and bond geometry using advanced simulation software. This phase identifies potential stress points, shrinkage risks, and adhesion challenges before tooling commences. Material compatibility between the specified rubber compound (e.g., silicone, TPE, EPDM) and the precisely machined metal substrate (stainless steel, aluminum, brass) is rigorously validated. Tolerances for the metal part are held to ±0.005mm CNC standards, ensuring the overmold cavity achieves perfect alignment and consistent wall thickness. This upfront precision prevents common failures like flash, incomplete filling, or delamination.

Prototyping Phase: Validated Process Refinement

Utilizing rapid tooling and our high-precision CNC capabilities, we produce functional prototypes mirroring production intent. Each prototype undergoes comprehensive metrology: CMM verification of metal substrate dimensions, bond strength testing per ASTM D429, and functional validation of sealing or grip performance. Dimensional analysis confirms rubber flow and shrinkage behavior against simulations. Any micro-defects—such as minor sink marks or edge inconsistencies—are traced to root causes in material flow or thermal management. Process parameters are fine-tuned iteratively based on empirical data, not assumptions. This phase delivers not just a physical sample, but a fully documented, validated process window ready for scale-up, significantly de-risking mass production.

Mass Production: Sustained Zero Defects Execution

Transition to volume production leverages the perfected parameters from prototyping within a closed-loop quality system. Our automated overmolding cells integrate real-time monitoring of critical variables. Statistical Process Control (SPC) charts track performance against tight tolerances, triggering immediate intervention if deviations occur. Every metal substrate undergoes 100% visual and dimensional inspection via automated vision systems prior to molding. The table below details our core production control parameters:

| Parameter | Control Range | Monitoring Frequency | Acceptance Criteria |

|---|---|---|---|

| Melt Temperature | ±3°C of setpoint | Continuous | Within compound spec |

| Injection Pressure | ±5 bar | Per cycle | Stable profile, no spikes |

| Mold Temperature | ±1.5°C | Continuous | Uniform across cavity |

| Clamp Force | Verified per shot | Per cycle | No flash, consistent part |

| Cycle Time | ±1.0 second | Per cycle | Stable within 0.5s std dev |

Final inspection combines automated vision for surface defects and dimensional checks with destructive sampling for bond integrity and material properties. This relentless focus on process stability, enabled by our precision metal manufacturing heritage, guarantees consistent output meeting the most stringent zero-defect requirements for medical, automotive, and industrial applications. Wuxi Lead delivers not just parts, but assured performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Rubber Overmolding Solutions

At Wuxi Lead Precision Machinery, we specialize in high-precision custom metal manufacturing with integrated rubber overmolding capabilities, engineered to meet the rigorous demands of industries such as automotive, medical devices, industrial equipment, and consumer electronics. Our expertise lies in merging metal substrates with elastomeric materials to deliver components that combine structural integrity, sealing performance, and ergonomic functionality in a single, durable unit.

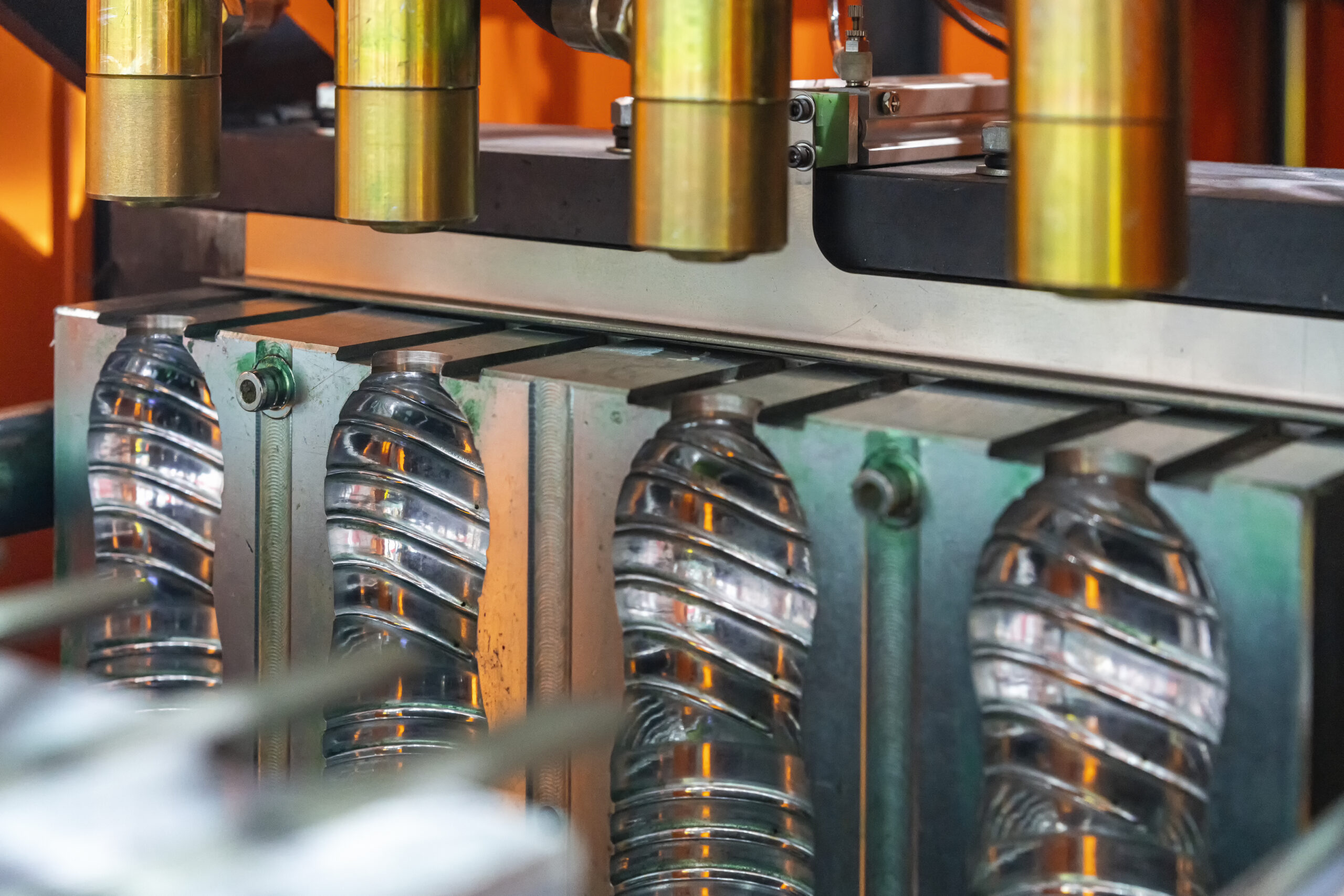

Rubber overmolding is more than a production process—it’s a strategic advantage. By permanently bonding rubber to metal, we enhance product longevity, reduce assembly steps, improve grip and noise dampening, and ensure reliable sealing against moisture, dust, and vibration. At Lead Precision, we leverage state-of-the-art injection molding machines, precision tooling, and advanced material science to achieve tight tolerances and consistent repeatability across both low-volume prototypes and high-volume production runs.

Our engineering team works collaboratively with clients from concept to completion, offering design for manufacturability (DFM) analysis, material selection guidance, and rapid prototyping to accelerate time-to-market. Whether you’re overmolding silicone onto stainless steel for medical instruments or bonding thermoplastic rubber to aluminum housings for automotive controls, we ensure every component meets exact performance and regulatory standards.

We maintain full in-house control over the manufacturing process, including CNC machining, mold design, surface treatment, and cleanroom assembly where required. This vertical integration enables faster iteration, superior quality control, and traceability across every production batch. Our facility is ISO 9001:2015 certified, and we comply with RoHS, REACH, and other international compliance frameworks.

Below are key technical specifications for our rubber overmolding services:

| Specification | Capability |

|---|---|

| Material Compatibility | Silicone, NBR, EPDM, TPE, TPU, FKM (Viton®), and custom compounds |

| Metal Substrates | Stainless steel, aluminum, brass, carbon steel, and specialty alloys |

| Tolerances | ±0.05 mm for metal components; ±0.1 mm for overmolded dimensions |

| Part Size Range | Up to 300 mm x 200 mm x 150 mm |

| Production Volume | Prototypes to 500,000+ units annually |

| Tooling | Hardened steel molds with multi-cavity options |

| Secondary Operations | CNC finishing, polishing, plating, laser marking, ultrasonic welding |

| Quality Control | In-process inspection, CMM, optical measurement, pull testing, environmental aging |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally committed to innovation, precision, and long-term collaboration. We don’t just produce parts—we deliver engineered solutions that enhance your product performance and reduce total cost of ownership.

For expert support on your next rubber overmolding project, contact us today at [email protected]. Let our team help you transform your design challenges into high-performance realities.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.