Technical Contents

Engineering Guide: Aluminum Injection Machine

Engineering Insight: The Role of Precision in Aluminum Injection Machines

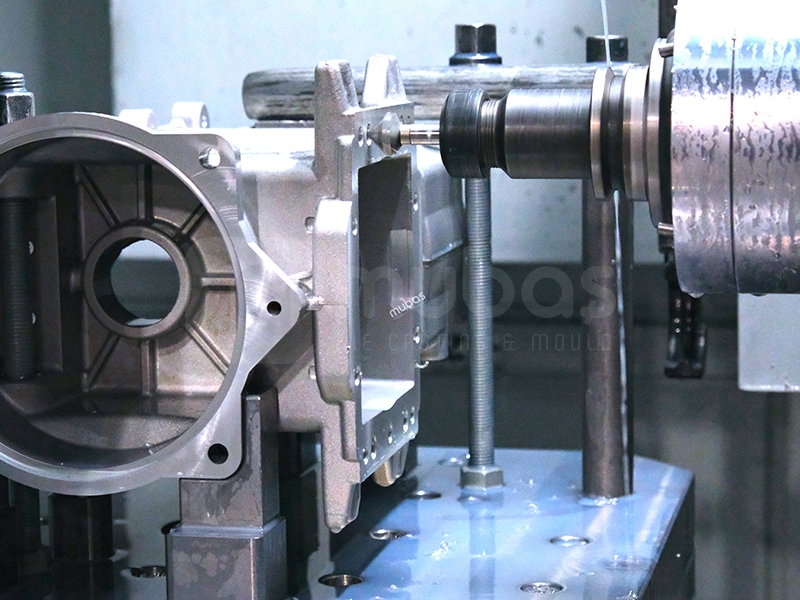

In high-performance manufacturing, the aluminum injection machine stands as a cornerstone of innovation, enabling the production of complex, lightweight, and structurally sound components across aerospace, defense, automotive, and high-end industrial sectors. At Wuxi Lead Precision Machinery, we recognize that the true value of an aluminum injection machine lies not just in its ability to shape molten metal, but in its capacity to do so with uncompromising precision, repeatability, and material integrity.

Aluminum injection molding—often referred to as squeeze casting or high-pressure die casting with controlled solidification—demands exact control over temperature, pressure, and cycle timing. Even minor deviations in injection speed or cavity fill uniformity can result in porosity, incomplete fills, or microstructural inconsistencies that compromise part performance. This is especially critical when producing components for mission-critical applications, where failure is not an option. Our engineering team has leveraged decades of metallurgical and mechanical expertise to refine every phase of the injection process, ensuring that each machine delivers micron-level accuracy and consistent mechanical properties in the final casting.

Wuxi Lead Precision Machinery has been entrusted with manufacturing components for Olympic-grade sporting equipment and military defense systems—applications where precision directly correlates with human safety and operational success. These projects demanded not only superior machine rigidity and thermal stability but also intelligent feedback systems capable of real-time pressure modulation and closed-loop control. Our proprietary control algorithms, developed through rigorous field testing and finite element analysis, allow for adaptive response to material viscosity fluctuations and mold resistance, resulting in near-net-shape parts with minimal post-processing.

Our aluminum injection machines are engineered for scalability and integration within automated production lines, supporting Industry 4.0 standards with IoT-enabled monitoring and predictive maintenance features. From compact 600-ton models for prototyping to 2,500-ton systems for high-volume output, each unit is built to maintain dimensional stability across thousands of cycles, ensuring long-term ROI for our clients.

The following table outlines key technical specifications of our flagship aluminum injection machine series:

| Parameter | Specification |

|---|---|

| Clamping Force Range | 600 – 2,500 tons |

| Injection Pressure | Up to 1,200 bar |

| Shot Speed Control | 0.1 – 5 m/s (adjustable, closed-loop) |

| Temperature Control Accuracy | ±2°C at nozzle and shot sleeve |

| Material Compatibility | A380, A360, ADC12, ZL101, and custom alloys |

| Machine Repeatability (CpK) | ≥1.67 |

| Automation Interface | Siemens S7-1500 PLC with PROFINET support |

| Cooling System | Dual-circuit, closed-loop chiller |

| Safety Compliance | CE, ISO 9001, and GB/T standards |

At Wuxi Lead Precision Machinery, we do not merely build machines—we engineer systems that uphold the highest standards of precision, durability, and performance. Our experience in delivering for elite applications underscores our commitment to excellence in every aluminum injection solution we provide.

Precision Specs & Tolerances

Technical Capabilities for Aluminum Die Casting Components

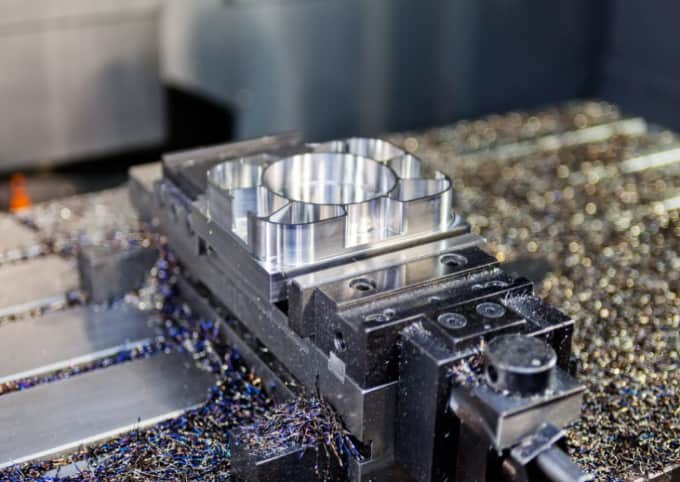

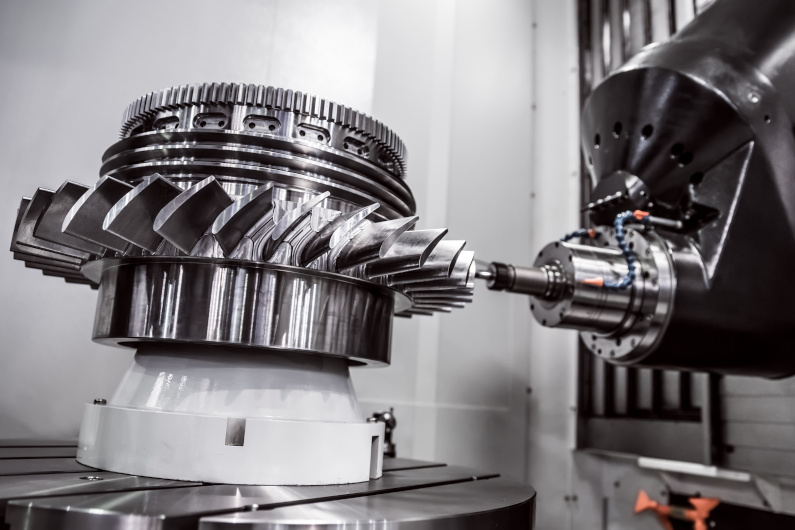

Wuxi Lead Precision Machinery delivers mission-critical aluminum die casting components through integrated advanced manufacturing and metrology systems. Our facility specializes in high-integrity parts for aerospace, medical, and automotive sectors where geometric complexity and dimensional stability are non-negotiable. Central to our capability is a full suite of 5-axis CNC machining centers, enabling single-setup processing of intricate castings that would require multiple operations on conventional 3-axis equipment. This eliminates cumulative alignment errors and significantly reduces lead times while achieving superior surface finishes down to Ra 0.8 µm. Our DMG MORI and MAZAK platforms handle aluminum alloys including A380, A360, and ADC12 with rapid tool-change systems and high-precision spindles operating at 24,000 RPM, ensuring optimal material removal rates without compromising part integrity.

Quality assurance is engineered into every process stage. All critical features undergo 100% inspection via Zeiss CONTURA and GLOBAL S CMM systems, operating in a temperature-controlled metrology lab (20±0.5°C). Our inspection protocols follow AS9102 and PPAP standards, with real-time SPC data analysis feeding back into machine parameter adjustments. This closed-loop system guarantees consistent conformance to extreme tolerance requirements, even for thin-walled structures under 1.5mm thickness. Our engineers utilize CALYPSO and PC-DMIS software for GD&T validation, including complex profile tolerances and position callouts relative to primary datums established during casting.

The table below defines our standard and precision capability ranges for machined aluminum die casting components:

| Feature | Standard Capability | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.012 mm | CMM / Optical Comparator |

| Hole Diameter | ±0.03 mm | ±0.008 mm | Air Gauge / CMM |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | CMM (GD&T Analysis) |

| Surface Profile | 0.10 mm | 0.03 mm | CMM / Laser Scanner |

| Flatness | 0.05 mm / 100 mm | 0.015 mm / 100 mm | CMM / Surface Plate |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Profilometer |

This precision foundation supports complex secondary operations including micro-milling of cooling channels, tight-tolerance bore finishing for hydraulic components, and multi-face sealing surface machining. We routinely produce parts with aspect ratios exceeding 15:1 and integrate tapped holes as small as M2 within cast geometries. Our process control extends to post-machining treatments like anodizing and chromate conversion, with pre-treatment dimensional verification ensuring final assembly fit. For mission-critical applications, we provide full traceability from raw material certs through in-process inspection to final first-article reports, delivering components that perform reliably in extreme operational environments. Partner with Wuxi Lead to transform aluminum die casting designs into dimensionally perfect, functionally validated products.

Material & Finish Options

Material Selection for High-Performance Aluminum Injection Components

When engineering precision components via aluminum injection molding—or more accurately, high-pressure die casting—material selection is critical to achieving optimal mechanical performance, thermal stability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that leverage advanced aluminum alloys, complemented by selective use of steel and titanium for specialized applications. Each material brings distinct advantages depending on the operational demands of the final product.

Aluminum remains the dominant choice for lightweight, high-strength applications requiring excellent thermal and electrical conductivity. Alloys such as A380, A360, and ADC12 are widely used due to their superior castability, corrosion resistance, and dimensional stability. These alloys are ideal for automotive housings, powertrain components, and heat sinks in electronics. Aluminum’s low density reduces part weight significantly, making it indispensable in industries where fuel efficiency and energy savings are paramount.

Steel, though heavier, offers unmatched tensile strength and wear resistance. It is typically used in tooling, dies, and structural inserts within aluminum injection systems rather than as a primary cast material. Tool steels like H13 are standard for die molds due to their ability to withstand high thermal cycling and mechanical stress. In hybrid designs, steel inserts can be overmolded with aluminum to enhance durability in high-load zones.

Titanium is reserved for extreme environments requiring exceptional strength-to-density ratios and corrosion resistance at elevated temperatures. While not commonly processed via aluminum injection methods due to incompatibility in melting and casting parameters, titanium components may be integrated into assemblies where lightweight performance under stress—such as in aerospace or medical devices—is non-negotiable. Our engineering team supports multi-material integration strategies to combine titanium subcomponents with aluminum cast structures.

Surface finishing is equally vital in determining end-part performance. Anodizing is the most effective post-processing technique for aluminum, enhancing surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing provides a decorative and protective layer, while Type III (hardcoat anodizing) delivers a thicker, denser oxide layer suitable for industrial and military applications. We offer precision anodizing services with tight control over coating thickness (5–100 µm) and color consistency, meeting ASTM B580 and MIL-A-8625 standards.

Below is a comparative overview of key material properties relevant to aluminum injection and associated applications.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Common Applications | Suitable for Anodizing |

|---|---|---|---|---|---|

| A380 Aluminum | 2.7 | 320–380 | 96–100 | Automotive, Electronics | Yes |

| ADC12 Aluminum | 2.7 | 280–330 | 90–95 | Motor Housings, Brackets | Yes |

| H13 Steel | 7.8 | 1,200–1,400 | 30–35 | Die Casting Molds, Inserts | No |

| Ti-6Al-4V | 4.4 | 900–1,100 | 6–7 | Aerospace, Medical | Limited |

Material and finish selection must align with functional requirements, production volume, and environmental exposure. Wuxi Lead Precision Machinery provides full engineering consultation to ensure optimal material pairing and surface treatment for your custom aluminum injection projects.

Manufacturing Process & QC

Aluminum Injection Machine Production Process: Achieving Zero Defects

The aluminum injection molding process at Wuxi Lead Precision Machinery is engineered for uncompromising quality, transitioning seamlessly from concept to high-volume output through a rigorously controlled workflow. Our integrated approach ensures every component meets the most demanding aerospace, automotive, and medical specifications, eliminating defects before they occur. This disciplined methodology forms the cornerstone of our Zero Defects commitment.

Design Phase: Precision Engineered from Inception

Initial design leverages advanced CAD/CAM systems coupled with sophisticated MoldFlow simulation software. This critical stage analyzes molten aluminum flow, cooling dynamics, and potential stress points within the virtual mold cavity. Engineers optimize gate locations, runner systems, and cooling channel layouts to prevent common defects like porosity, shrinkage, or warpage. Material science expertise ensures compatibility between the specific aluminum alloy (e.g., A380, ADC12) and the part geometry. Client collaboration is paramount; we validate thermal management strategies and structural integrity simulations against functional requirements before any metal is cut, establishing a defect-proof foundation.

Prototyping: Validating the Virtual to Physical

Physical validation begins with precision-machined prototype molds using hardened tool steels. Short-run production under actual machine parameters generates initial parts for exhaustive metrology. Components undergo comprehensive inspection via Coordinate Measuring Machines (CMM), optical comparators, and destructive/non-destructive testing (including X-ray for internal integrity). Dimensional accuracy, surface finish, and mechanical properties are meticulously compared against the simulated model and client specifications. Any micro-deviation triggers immediate design or process parameter refinement. This iterative loop, typically completed within 10-15 days, guarantees the production mold design is flawless and process-stable before scale-up.

Mass Production: Sustained Zero Defects Execution

Full-scale production utilizes our high-precision aluminum injection machines operating within a controlled environment. Real-time monitoring systems track critical parameters—pressure, temperature, shot speed, and cooling time—with sub-millisecond accuracy. Statistical Process Control (SPC) charts continuously analyze data streams, enabling predictive adjustments before deviations exceed tolerance bands. Automated in-line vision systems perform 100% surface defect inspection, while integrated material handling ensures consistent shot integrity. Every machine cycle is documented, creating a full traceability record. This closed-loop system, combined with rigorous operator training and preventive maintenance protocols, ensures sustained output where non-conforming parts are statistically improbable, not merely inspected out.

Key machine specifications enabling this precision are detailed below. Our integrated workflow transforms design intent into flawless physical reality, delivering consistent quality that minimizes total cost of ownership for our clients.

| Parameter | Specification | Significance for Zero Defects |

|---|---|---|

| Clamping Force | 800 – 2200 kN | Ensures mold integrity under high injection pressure, preventing flash |

| Shot Speed | 0 – 8 m/s (Adjustable) | Controls metal flow to eliminate turbulence and air entrapment |

| Injection Pressure | Up to 180 MPa | Achieves complete cavity fill for complex geometries |

| Temperature Control | ±1°C Accuracy | Maintains optimal metal fluidity and solidification |

| Repeatability (Shot) | ±0.15% | Guarantees consistent part density and dimensions |

| Cycle Time Monitoring | Real-time SPC | Enables immediate correction of process drift |

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Advanced Aluminum Injection Solutions

When it comes to high-performance aluminum injection machines, precision, reliability, and long-term efficiency define success. At Wuxi Lead Precision Machinery, we specialize in delivering custom-engineered aluminum injection systems designed for high-end industrial applications. Our machines are built to meet the evolving demands of aerospace, automotive, electronics, and medical device manufacturing, where dimensional accuracy and material integrity are non-negotiable.

As a trusted name in custom metal manufacturing, we integrate cutting-edge control systems, robust hydraulic performance, and intelligent monitoring technology into every aluminum injection machine we produce. Our engineering team works closely with clients to tailor solutions that align with specific production volumes, part complexity, and automation requirements. Whether you’re scaling up production or entering a new market segment, our machines deliver consistent cycle times, minimal scrap rates, and exceptional surface finish quality.

Our commitment extends beyond equipment supply. We provide full technical support, from initial feasibility analysis and mold design validation to on-site installation and operator training. Our service network ensures rapid response times and continuous optimization, minimizing downtime and maximizing return on investment. With CE certification and compliance with international safety standards, our machines are trusted by manufacturers across North America, Europe, and Southeast Asia.

Choosing the right manufacturing partner is critical. Wuxi Lead Precision Machinery offers more than advanced hardware — we deliver a collaborative engineering relationship focused on your long-term success. Our facility in Wuxi, Jiangsu Province, operates under strict ISO 9001 quality management protocols, ensuring every component meets the highest standards of durability and performance.

We invite global manufacturers to contact us and explore how our aluminum injection machines can elevate your production capabilities. Let our team of CNC engineers and application specialists help you configure the ideal system for your operational goals.

For technical inquiries, project consultations, or pricing details, reach out to us directly at [email protected]. Our engineering department responds within 24 hours to all qualified requests.

Key Technical Specifications

| Model Series | Clamping Force (kN) | Shot Weight (Al, g) | Injection Pressure (MPa) | Machine Dimensions (L×W×H, mm) | Control System |

|---|---|---|---|---|---|

| LP-800AI | 800 | 450 | 120 | 4200×1800×2400 | Siemens S7-1500 |

| LP-1200AI | 1200 | 800 | 120 | 4800×2000×2500 | Siemens S7-1500 |

| LP-2000AI | 2000 | 1500 | 120 | 6200×2400×2800 | Siemens S7-1500 |

| LP-3500AI | 3500 | 2800 | 120 | 7800×3000×3200 | Siemens S7-1500 |

All models feature servo-hydraulic drive systems, real-time pressure monitoring, and optional integration with robotic handling systems. Custom configurations are available upon request.

Contact Wuxi Lead Precision Machinery today at [email protected] and take the next step toward precision-driven manufacturing excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.