Technical Contents

Engineering Guide: Titanium Printer

Engineering Imperatives in Titanium Component Manufacturing for Precision Print Systems

The term “titanium printer” requires immediate technical clarification within industrial manufacturing contexts. Wuxi Lead Precision Machinery specializes not in additive manufacturing machines called “titanium printers,” but in the ultra-precision CNC machining of critical titanium components for high-end printing systems, particularly in aerospace, medical device production, and advanced industrial printing. Titanium alloys like Grade 5 (Ti-6Al-4V) present exceptional strength-to-weight ratios and corrosion resistance, yet demand extraordinary machining precision due to inherent material challenges. Thermal conductivity is low, leading to significant heat buildup during cutting; work hardening occurs rapidly if parameters are suboptimal; and dimensional stability is highly sensitive to residual stresses induced during processing. Neglecting these factors results in part distortion, compromised surface integrity, or premature fatigue failure – catastrophic outcomes in mission-critical printer mechanisms where micron-level accuracy directly impacts print fidelity, component lifespan, and system reliability.

Achieving the required precision necessitates deep metallurgical understanding coupled with advanced process control. We meticulously manage cutting parameters, toolpath strategies, and thermal management to counteract titanium’s tendencies. Stress relief cycles are integrated into the manufacturing sequence, often utilizing specialized ovens with tightly controlled ramp/soak profiles. Fixture design is paramount, ensuring minimal part deflection while accommodating thermal expansion. Surface finish requirements frequently demand Ra values below 0.8μm to prevent stress concentration points, requiring specialized tooling and multi-stage finishing passes. Dimensional tolerances consistently held within ±0.005mm across complex geometries are non-negotiable for components like print head mounts, vacuum chamber fixtures, or high-pressure fluid manifolds where leakage or misalignment destroys functionality.

Wuxi Lead Precision Machinery possesses demonstrable expertise in overcoming these hurdles, proven through rigorous applications. Our processes consistently deliver components meeting the exacting standards required for systems deployed in the Beijing Winter Olympics timing infrastructure and critical subsystems within next-generation military unmanned aerial vehicles. These projects demanded not only extreme dimensional accuracy but also guaranteed performance under severe thermal cycling and vibration – conditions directly analogous to the demanding environments of high-speed industrial printers. Our engineers understand that precision in titanium machining is not merely about hitting a dimension; it is about ensuring the part performs flawlessly throughout its operational lifecycle under real-world stresses.

The following table outlines critical specifications achievable for titanium components destined for precision printing systems:

| Parameter | Typical Capability (Ti-6Al-4V) | Critical for Print Systems Because… |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | Ensures perfect alignment of print heads and media handling |

| Surface Roughness (Ra) | 0.4 – 0.8 μm | Minimizes particle generation and ensures uniform fluid flow |

| Geometric Tolerance (GD&T) | ±0.01 mm (Position, Flatness) | Guarantees sealing integrity and structural stability under load |

| Residual Stress Level | < 50 MPa (Post-Machining) | Prevents in-service distortion affecting print accuracy |

| Thermal Stability | Maintained within spec across -50°C to +200°C | Critical for consistent performance in varying operational environments |

This level of controlled precision manufacturing is the foundation upon which reliable, high-performance printing systems are built. Wuxi Lead Precision Machinery leverages its proven experience in the most demanding sectors to deliver titanium components where failure is not an option.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for mission-critical applications, with a specialized focus on high-performance materials such as titanium. Our expertise in precision engineering ensures that components meet the rigorous demands of aerospace, medical, defense, and high-end industrial sectors. At the core of our production capability is a fully integrated 5-axis CNC machining platform, enabling us to produce complex geometries with exceptional accuracy and surface finish. This technology allows simultaneous multi-directional cutting, minimizing setup changes and ensuring tight tolerances across intricate features—critical when working with challenging materials like titanium alloys.

Our 5-axis CNC systems are operated by certified machinists with over a decade of experience in high-precision manufacturing. Each machine is maintained to OEM standards and equipped with high-resolution probing systems for in-process verification. We utilize advanced CAM software to optimize toolpaths, reduce cycle times, and enhance part consistency. Material utilization is maximized through intelligent nesting and adaptive machining strategies, reducing waste and improving lead time efficiency. Titanium, known for its high strength-to-weight ratio and corrosion resistance, presents unique challenges due to its low thermal conductivity and tendency to work-harden. Our machining protocols are specifically calibrated to manage heat buildup, tool wear, and vibration, ensuring dimensional stability and surface integrity.

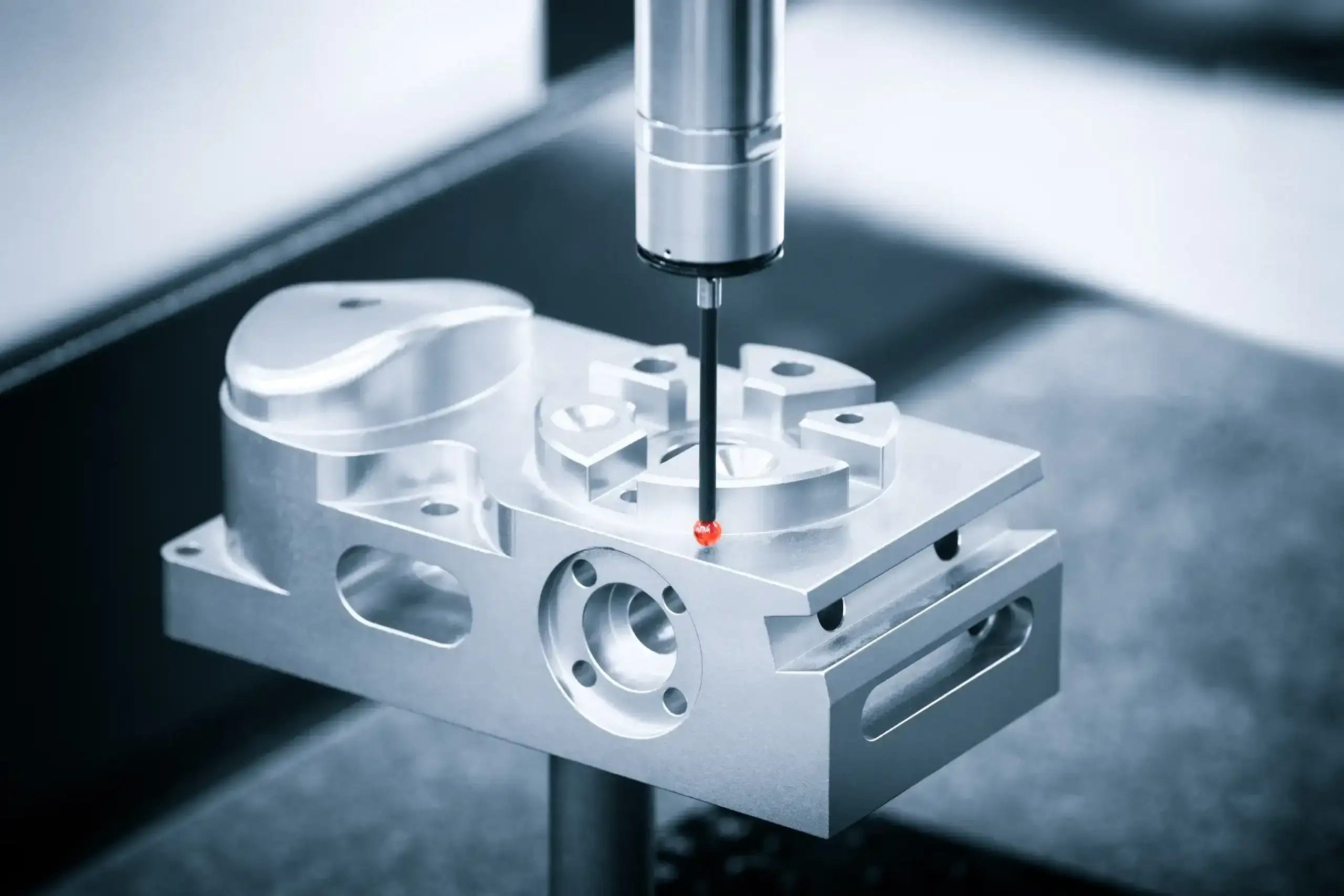

Quality control is integral to every stage of production. All titanium components undergo comprehensive inspection using our state-of-the-art Coordinate Measuring Machine (CMM) system, which provides micron-level verification of geometric dimensions and tolerances. The CMM is programmed to follow ISO 10360 standards and supports full first-article inspection (FAI) reporting and production batch validation. Data from inspections is documented and traceable, providing full transparency for audit and compliance purposes. In addition to CMM analysis, we perform surface roughness testing, hardness verification, and visual inspection under magnification to ensure compliance with customer specifications and industry standards.

The following table outlines the standard technical tolerances we consistently achieve in titanium machining operations:

| Parameter | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.025 mm | ±0.010 mm |

| Angular Dimensions | ±0.1° | ±0.05° |

| Positional Tolerance | ±0.020 mm | ±0.010 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.8 µm (polished available) |

| Geometric Tolerances (GD&T) | ±0.025 mm | ±0.010 mm |

| Feature Repeatability | ±0.015 mm | ±0.008 mm |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with rigorous quality assurance to deliver titanium components that meet the highest standards of performance and reliability. Our technical capabilities are designed to support low-volume prototyping and high-repeatability production runs with equal precision.

Material & Finish Options

Material Selection for High-Performance Titanium Applications

Wuxi Lead Precision Machinery clarifies that “titanium printer” refers to precision components for additive manufacturing systems handling titanium, not the printer itself. Selecting optimal materials for these critical parts demands rigorous analysis of mechanical properties, environmental resistance, and manufacturability. Aluminum, steel, and titanium each serve distinct roles in titanium processing equipment, where thermal stability and corrosion resistance are non-negotiable.

Aluminum alloys like 6061-T6 offer exceptional strength-to-weight ratios and thermal conductivity, ideal for non-load-bearing structural frames and heat sinks. However, their lower hardness limits use in high-wear zones. Steel variants, particularly 17-4 PH stainless, provide superior tensile strength and wear resistance for shafts and fasteners but require meticulous passivation to withstand titanium powder’s reactive environment. Titanium Grade 5 (Ti-6Al-4V) excels in vacuum chamber components and powder delivery systems due to its unparalleled corrosion resistance, biocompatibility, and performance at elevated temperatures—though its low thermal conductivity and galling tendency necessitate specialized CNC tooling and slower machining feeds.

Below is a comparative specification table for key materials in titanium processing equipment:

| Property | Aluminum 6061-T6 | Steel 17-4 PH | Titanium Ti-6Al-4V |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 7.8 | 4.4 |

| Tensile Strength (MPa) | 310 | 1300 | 900 |

| Corrosion Resistance | Moderate | High (with passivation) | Exceptional |

| Machinability Rating | Excellent | Good | Poor |

| Relative Cost | Low | Medium | High |

Anodizing is exclusively applicable to aluminum components, enhancing surface durability and electrical insulation. Type II (sulfuric acid) anodizing provides standard wear resistance for enclosures, while Type III (hardcoat) anodizing achieves 50–70 µm thickness for high-abrasion areas like powder containment trays. Critical note: anodizing cannot be applied to titanium or steel; titanium requires plasma electrolytic oxidation (PEO) for similar benefits, and steel relies on nitriding or specialized coatings.

At Wuxi Lead, we mitigate titanium’s machining complexities through proprietary toolpath strategies and in-process monitoring, ensuring dimensional accuracy within ±0.005 mm. Our engineers collaborate to match material properties with your operational demands—whether prioritizing weight reduction (aluminum), structural rigidity (steel), or extreme corrosion resilience (titanium). This precision prevents premature wear in oxygen-sensitive titanium processing environments, directly impacting your system’s uptime and total cost of ownership. Partner with us to transform material science into manufacturing advantage.

Manufacturing Process & QC

The production process for titanium printer components at Wuxi Lead Precision Machinery is engineered for uncompromising precision, structural integrity, and zero-defect delivery. As a leading custom metal manufacturing partner in China, we integrate advanced CNC machining, metallurgical expertise, and rigorous quality assurance to transform conceptual designs into high-performance titanium parts suitable for aerospace, medical, and industrial 3D printing applications.

The process begins with Design Engineering, where our team collaborates closely with clients to evaluate technical drawings, material specifications, and functional requirements. Utilizing CAD/CAM software and finite element analysis (FEA), we optimize geometries for manufacturability, thermal stability, and mechanical load resistance. Special attention is given to minimizing stress concentrations and ensuring compatibility with additive manufacturing systems. Design for Manufacturability (DFM) reviews are conducted to preempt potential production issues, ensuring seamless progression into prototyping.

Prototyping follows the finalized design phase, serving as a critical validation step. Using 5-axis CNC milling and wire EDM, we fabricate initial titanium (Grade 2, Grade 5, or custom alloy) components with tolerances as tight as ±0.005 mm. These prototypes undergo comprehensive metrology testing via CMM (Coordinate Measuring Machine), surface roughness analysis, and non-destructive testing (NDT) such as X-ray and ultrasonic inspection. Functional testing within simulated printer environments verifies thermal performance, dimensional stability, and interface compatibility. Client feedback is incorporated at this stage to refine design features before committing to full-scale production.

Mass Production is executed under a zero-defect framework governed by ISO 9001 and IATF 16949 standards. Each titanium component is machined using high-rigidity CNC platforms with in-process probing to ensure real-time dimensional accuracy. Our cleanroom-compatible production lines minimize particulate contamination, essential for parts used in precision printer systems. Automated optical inspection (AOI) and batch traceability systems track every component from raw material to final packaging. All finished parts are passivated and ultrasonically cleaned to remove residual contaminants and enhance corrosion resistance.

Throughout the entire process, quality is not a checkpoint but a continuous protocol. Statistical Process Control (SPC) monitors key parameters, while First Article Inspection Reports (FAIR) and Production Part Approval Processes (PPAP) provide full documentation transparency. This disciplined approach ensures every titanium printer component meets the highest standards of reliability and performance.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Material Options | Ti-6Al-4V (Grade 5), CP Ti (Grade 2), Custom Alloys |

| Tolerance Control | ±0.005 mm |

| Surface Roughness (Ra) | As low as 0.4 µm (polished), 1.6 µm (machined) |

| Max Workpiece Dimensions | 800 mm × 600 mm × 500 mm |

| Machining Methods | 5-Axis CNC, Wire EDM, Mill-Turn |

| Quality Standards | ISO 9001, IATF 16949, AS9100 (aerospace) |

| Inspection Tools | CMM, OGP SmartScope, Ultrasonic Testing, X-ray |

| Lead Time (Prototype) | 7–10 working days |

| Lead Time (Mass Production) | 15–25 working days (volume-dependent) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Titanium Manufacturing Authority

Titanium’s exceptional strength-to-weight ratio and corrosion resistance make it indispensable for aerospace, medical, and high-performance industrial applications. Yet its reactivity, thermal conductivity challenges, and stringent quality requirements demand more than standard additive capabilities. At Wuxi Lead Precision Machinery, we specialize in transforming titanium’s complexities into your competitive advantage through engineered precision and process mastery. Our end-to-end titanium manufacturing ecosystem—spanning laser powder bed fusion, electron beam melting, and hybrid CNC post-processing—ensures components meet AS9100 and ISO 13485 standards while minimizing waste and cycle time. We do not merely operate machines; we solve metallurgical and geometric constraints inherent to titanium through proprietary parameter libraries and in-situ monitoring systems.

Our commitment extends beyond equipment to collaborative engineering. When you partner with Lead Precision, our application engineers engage during your design phase to optimize part geometry for additive manufacturability, reducing support structures and mitigating thermal distortion risks unique to titanium alloys like Ti-6Al-4V and CP Grade 5. This proactive approach cuts lead times by up to 40% and elevates first-pass yield rates above industry averages. Below outlines our titanium-specific production capabilities:

| Parameter | Specification | Industry Standard |

|---|---|---|

| Build Volume | Up to Ø500 x 1000 mm | Ø350 x 400 mm |

| Layer Thickness | 20–60 μm (adaptive) | 30–50 μm |

| Dimensional Accuracy | ±0.025 mm per 100 mm | ±0.1 mm |

| Surface Roughness (as-printed) | Ra 8–12 μm | Ra 15–25 μm |

| Chamber Atmosphere | Argon < 50 ppm O₂ | < 100 ppm O₂ |

| Post-Processing Integration | In-house HIP, stress-relief, 5-axis milling | External only |

This technical foundation enables us to deliver mission-critical components with certified material properties, repeatable microstructure control, and full traceability—from prototype to serial production. We understand that titanium projects carry high stakes; a single failed build can disrupt supply chains and inflate costs. Our zero-defect culture, backed by real-time melt pool analytics and NDT validation, ensures your specifications become reality.

Initiate a partnership where engineering rigor meets responsive execution. Contact our technical sales team to discuss your titanium project’s specific requirements, material certifications, or DFAM consultation. We will provide a detailed capability assessment and timeline within 24 hours of receiving your CAD files and specifications.

Contact [email protected] to secure your titanium manufacturing advantage. Let Lead Precision become the extension of your engineering team—delivering precision you can measure and trust.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.