Technical Contents

Engineering Guide: Steel Vs Aluminum Stress Strain Curve

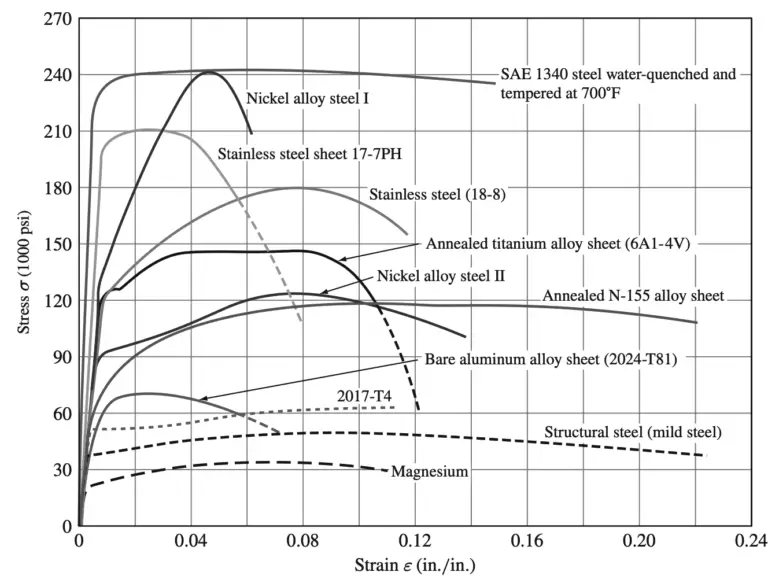

Understanding the stress-strain behavior of materials is fundamental in high-precision metal manufacturing, particularly when selecting between steel and aluminum for mission-critical applications. At Wuxi Lead Precision Machinery, our engineering team leverages decades of experience in custom metal fabrication to interpret these curves with exacting accuracy, ensuring optimal material performance under real-world conditions. The stress-strain curve provides vital data on yield strength, ultimate tensile strength, elongation, and modulus of elasticity—parameters that directly influence design integrity, safety margins, and long-term durability.

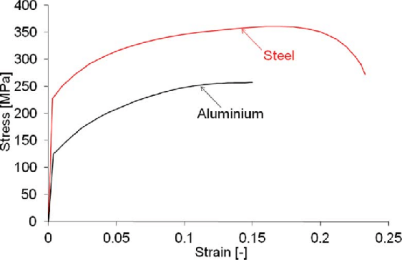

Steel typically exhibits a well-defined yield point and a pronounced plastic deformation region before failure, making it highly predictable under load. Its higher modulus of elasticity—approximately 200 GPa—means steel resists elastic deformation more effectively than aluminum, which is critical in structural and load-bearing applications. In contrast, aluminum displays a more gradual transition from elastic to plastic behavior, often requiring the use of a 0.2% offset method to determine yield strength. With a modulus of around 70 GPa, aluminum is more flexible but less stiff, which can be advantageous in weight-sensitive designs such as aerospace or high-performance automotive systems.

Precision in interpreting these curves ensures that components perform reliably under operational stress. A minor deviation in material selection or misinterpretation of strain response can lead to catastrophic failure in high-stakes environments. This is where Wuxi Lead Precision Machinery excels. Our engineering team has supported projects requiring the highest standards of accuracy, including components used in Olympic-grade equipment and military-grade systems. These applications demand not only adherence to international material standards but also rigorous in-house testing to validate stress-strain characteristics under dynamic and static loads.

Our advanced CNC machining capabilities are calibrated to account for material-specific behaviors observed in stress-strain analysis. Whether producing high-strength steel gears for industrial machinery or lightweight aluminum housings for defense electronics, we integrate material science with precision manufacturing to deliver components that meet exact mechanical requirements.

Below is a comparative overview of typical mechanical properties derived from stress-strain analysis for common grades of steel and aluminum:

| Property | Mild Steel (A36) | 6061-T6 Aluminum |

|---|---|---|

| Yield Strength (MPa) | 250 | 276 |

| Ultimate Tensile Strength (MPa) | 400 | 310 |

| Modulus of Elasticity (GPa) | 200 | 69 |

| Elongation at Break (%) | 20 | 12 |

| Density (g/cm³) | 7.85 | 2.7 |

This data underscores the importance of material selection based on application-specific demands. At Wuxi Lead Precision Machinery, we combine deep metallurgical insight with state-of-the-art manufacturing to ensure every component we produce performs with the precision and reliability our clients in high-performance industries expect.

Precision Specs & Tolerances

Material Science in Precision Manufacturing

Understanding material behavior under load is fundamental to precision component production. At Wuxi Lead Precision Machinery, our engineering team leverages deep expertise in steel and aluminum stress-strain characteristics to optimize manufacturability and performance. Steel exhibits higher yield strength and ultimate tensile strength compared to aluminum, with a distinct yield point followed by significant plastic deformation before fracture. Aluminum alloys demonstrate lower yield strength but superior ductility and fatigue resistance, with a more gradual transition from elastic to plastic deformation. These differences critically impact machining strategies: steel’s work-hardening tendency demands rigid setups and controlled chip evacuation, while aluminum’s thermal conductivity and lower modulus require adaptive feed rates to minimize chatter and thermal distortion during high-speed 5-axis operations.

Our technical capabilities are engineered to address these material-specific challenges. The facility operates state-of-the-art 5-axis CNC machining centers with sub-micron positional accuracy, featuring high-torque spindles and dynamic tool compensation systems. These machines maintain thermal stability through closed-loop cooling and vibration-dampened foundations, ensuring consistent dimensional control whether cutting hardened tool steels or aerospace-grade aluminum. Crucially, real-time adaptive control systems adjust cutting parameters based on in-process force monitoring, preventing micro-deformation in thin-walled aluminum structures or residual stress accumulation in complex steel geometries.

Quality verification is integrated at every stage through our metrology suite. All critical features undergo CMM inspection using Zeiss CONTURA systems with 0.5 µm volumetric accuracy, validated against NIST-traceable standards. Scanning probe technology captures full 3D surface deviations, while GD&T analysis confirms conformance to functional requirements derived from material stress models. This data directly informs process refinement, closing the loop between material science and production execution.

The following table details achievable tolerance ranges for both materials, reflecting our validated process capabilities under controlled environmental conditions:

| Material | Feature Type | Tolerance Range | Measurement Standard |

|---|---|---|---|

| Steel | Linear Dimensions | ±0.005 mm | ASME Y14.5-2018 |

| Steel | Geometric (Flatness) | 0.003 mm | ISO 1101 |

| Aluminum | Linear Dimensions | ±0.008 mm | ASME Y14.5-2018 |

| Aluminum | Geometric (Roundness) | 0.005 mm | ISO 1101 |

This precision is sustained through rigorous environmental controls (20°C ±0.5°C) and operator certification to ISO 9001:2015 standards. By correlating material stress-strain profiles with machine dynamics and metrology data, Wuxi Lead delivers components that meet exacting functional requirements—whether for high-load steel transmission housings or weight-critical aluminum aerospace assemblies. Our process ensures that theoretical material properties translate into real-world performance, eliminating costly field failures through manufacturing science. Partner with us to transform material specifications into certified, mission-ready components.

Material & Finish Options

Material Selection in High-Precision CNC Manufacturing: Steel, Aluminum, and Titanium Compared

Selecting the correct material for precision CNC-machined components is critical to ensuring performance, longevity, and cost-efficiency in industrial applications. At Wuxi Lead Precision Machinery, we guide our clients through data-driven decisions based on mechanical behavior, environmental exposure, and functional requirements. A key analytical tool in this process is the stress-strain curve, which reveals how materials deform under load and helps predict failure points.

Steel, particularly alloy and stainless grades, demonstrates high yield strength and ultimate tensile strength, making it ideal for structural and load-bearing applications. Its stress-strain curve shows a distinct elastic region followed by significant plastic deformation before fracture, indicating good toughness. Steel also exhibits high hardness and wear resistance, though at the cost of increased weight. It is commonly used in automotive chassis, industrial tooling, and heavy machinery components.

Aluminum alloys, such as 6061 and 7075, offer a superior strength-to-weight ratio and excellent corrosion resistance. The stress-strain curve of aluminum typically shows a more gradual transition from elastic to plastic deformation, with lower yield strength than steel but higher ductility in certain tempers. This makes aluminum ideal for aerospace, robotics, and portable equipment where weight reduction is critical. However, aluminum’s lower stiffness and hardness may limit use in high-wear environments without surface enhancement.

Titanium, particularly Grade 5 (Ti-6Al-4V), provides an exceptional balance of strength, corrosion resistance, and low density. Its stress-strain behavior reflects high tensile strength and excellent performance at elevated temperatures. While more expensive and challenging to machine, titanium is the material of choice for medical implants, aerospace systems, and marine components exposed to extreme conditions.

Surface finishing further enhances material performance. Anodizing, especially for aluminum, increases surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly specified based on functional needs. Steel components often receive zinc plating or passivation, while titanium may be treated with thermal oxidation or nitriding for specialized applications.

Understanding the mechanical behavior of materials through stress-strain analysis ensures optimal selection for performance-critical parts. At Wuxi Lead, we combine material science expertise with advanced CNC capabilities to deliver components that meet exacting industrial standards.

Mechanical Properties Comparison

| Material | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation at Break (%) | Density (g/cm³) | Common Applications |

|---|---|---|---|---|---|

| Steel (AISI 4140) | 655 | 850 | 15 | 7.85 | Tooling, Shafts, Automotive Parts |

| Aluminum 7075 | 503 | 572 | 11 | 2.81 | Aerospace, Drones, High-Load Frames |

| Titanium Ti-6Al-4V | 880 | 950 | 14 | 4.43 | Medical Devices, Jet Engines, Marine |

Manufacturing Process & QC

Precision Manufacturing Process: Steel vs Aluminum Stress-Strain Optimization

Understanding the fundamental differences in the stress-strain behavior of steel and aluminum is non-negotiable for achieving zero-defect outcomes in custom metal components. Steel exhibits a distinct yield point followed by significant plastic deformation before ultimate tensile strength (UTS) and fracture, characterized by higher stiffness and strength. Aluminum demonstrates a more gradual transition from elastic to plastic deformation without a sharp yield point, lower density, and higher ductility but reduced modulus of elasticity. These intrinsic material properties directly dictate our rigorous three-phase production methodology, ensuring every part meets exacting performance criteria under load.

Design Phase Material Integration

Our engineering team initiates every project by analyzing the component’s functional stress requirements against the specific stress-strain curves of candidate materials. For high-load, high-stiffness applications demanding minimal deflection, steel grades like 304 stainless are prioritized due to their superior yield strength and elastic modulus. Where weight reduction and corrosion resistance are critical, and cyclic loading is expected, aluminum alloys such as 6061-T6 are selected, leveraging their excellent fatigue resistance and ductility. Finite Element Analysis (FEA) simulations incorporate precise material property data to predict deformation, stress concentrations, and potential failure modes, optimizing geometry before any metal is cut. This phase establishes the critical link between theoretical stress-strain behavior and practical manufacturability.

Prototyping: Validating Material Response

Physical prototyping is where theoretical stress-strain data meets reality. We fabricate initial parts using the exact production-grade material and process parameters defined in the design phase. Crucially, we conduct in-house tensile testing on material samples from the same heat lot to verify the actual stress-strain curve aligns with specifications. Prototypes undergo rigorous functional testing, including load cycling and dimensional checks under simulated service conditions. This validates the FEA predictions, confirms the material’s real-world behavior during forming or machining, and identifies any need for process refinement – such as adjusting bending radii for aluminum to counteract springback or optimizing heat treatment for steel to achieve target yield strength. Defects detected here are process corrections, not final product failures.

Mass Production: Zero Defects Execution

Transitioning to mass production demands absolute process control rooted in the validated stress-strain understanding. For steel components, we implement stringent controls on heat treatment parameters to ensure consistent yield strength and hardness, monitored via real-time pyrometry and post-process hardness testing. Aluminum production focuses on precise control of forming speeds and temperatures to manage its gradual yielding and prevent micro-cracking, with in-process strain gauging during critical bends. Every batch undergoes material certification verification, and statistical process control (SPC) tracks key dimensions and mechanical properties. Our integrated quality management system, certified to ISO 9001:2015, mandates 100% first-article inspection and continuous in-line monitoring, guaranteeing every component adheres to the stress-strain performance envelope defined during prototyping.

Key Material Property Comparison for Process Design

| Property | Steel (304 Stainless) | Aluminum (6061-T6) |

|---|---|---|

| Yield Strength (MPa) | 215 – 310 | 240 – 275 |

| Ultimate Tensile Strength (MPa) | 505 – 725 | 290 – 330 |

| Elongation at Break (%) | 40 – 60 | 8 – 12 |

| Elastic Modulus (GPa) | 193 | 68.9 |

| Density (g/cm³) | 8.0 | 2.7 |

This disciplined approach, from material-specific design through validated prototyping to tightly controlled mass production, ensures the inherent stress-strain characteristics of steel or aluminum are leveraged optimally. The result is consistent, defect-free components that perform reliably under operational stress, delivered on time and to specification.

Why Choose Wuxi Lead Precision

Understanding the mechanical behavior of materials is essential when designing high-performance components for aerospace, automotive, and industrial applications. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing with deep expertise in both steel and aluminum alloys. Our engineering team leverages detailed stress-strain curve analysis to ensure your components meet exact performance, durability, and safety standards.

Steel and aluminum exhibit fundamentally different mechanical responses under load, and selecting the right material begins with understanding these differences. Steel typically offers higher yield and tensile strength, making it ideal for structural applications where load resistance is critical. Its stress-strain curve shows a distinct yield point, followed by significant plastic deformation before failure—providing valuable warning before collapse. In contrast, aluminum demonstrates lower density and higher ductility, with a more gradual yield transition. While aluminum’s strength-to-weight ratio is superior, its strain behavior requires precise modeling to avoid premature deformation in high-stress environments.

At Wuxi Lead, we integrate material science with precision machining. Our CNC fabrication processes are calibrated to account for elastic limits, strain hardening rates, and elongation characteristics derived from standardized tensile testing. Whether you’re prototyping a lightweight chassis or producing high-load bearing parts, our team ensures your design aligns with real-world material performance.

We work with a wide range of alloys, including 6061-T6 and 7075-T6 aluminum, as well as structural steels like AISI 4140 and ASTM A36. Each material’s stress-strain profile is documented and applied during the design-for-manufacturability phase, reducing iterations and accelerating time to market.

Below is a comparative overview of key mechanical properties derived from typical stress-strain behavior:

| Material | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation at Break (%) | Young’s Modulus (GPa) | Density (g/cm³) |

|---|---|---|---|---|---|

| 6061-T6 Aluminum | 276 | 310 | 12 | 68.9 | 2.70 |

| 7075-T6 Aluminum | 503 | 572 | 11 | 71.7 | 2.81 |

| AISI 4140 Steel | 655 | 785 | 17.7 | 205 | 7.85 |

| ASTM A36 Steel | 250 | 400 | 20 | 200 | 7.85 |

These values guide our selection and machining strategies, ensuring optimal performance under operational loads. Our in-house testing lab validates material batches, and our engineers provide full traceability and certification with every production run.

Partner with Wuxi Lead Precision Machinery to transform your engineering requirements into precision-manufactured reality. We don’t just cut metal—we understand it. For technical consultation, material recommendations, or project quotes, contact us today at [email protected]. Let our expertise in steel and aluminum stress-strain behavior drive your next innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.