Technical Contents

Engineering Guide: Cnc Milling Projects

Engineering Insight: Precision as the Core Value in CNC Milling Projects

In high-stakes CNC milling projects, precision transcends mere specification; it is the fundamental determinant of functional integrity, assembly success, and long-term reliability. For industries where failure is not an option—such as aerospace, medical device manufacturing, and advanced defense systems—micron-level deviations directly impact safety, performance, and regulatory compliance. Achieving true precision demands far more than advanced machinery; it requires an integrated approach encompassing meticulous process engineering, rigorous environmental control, continuous calibration, and deep material science expertise. At Wuxi Lead Precision Machinery, we treat precision not as a target but as a non-negotiable baseline, engineered into every stage of production from initial design consultation through final inspection.

Our commitment to uncompromising precision is validated by demanding applications. We have manufactured critical components for Olympic timing systems, where sub-millisecond accuracy is paramount, and supplied mission-critical parts for military platforms requiring extreme durability and exacting dimensional stability under severe operational stress. These projects demand adherence to the strictest global standards, including AS9100 for aerospace and ITAR-controlled specifications. Our facility operates under ISO 9001 and ISO 13485 certifications, with dedicated climate-controlled metrology labs housing coordinate measuring machines (CMMs) traceable to NIST standards. This environment ensures that thermal drift—a common enemy of micron accuracy—is systematically eliminated.

The engineering challenge lies in translating design intent into physical reality across diverse, often exotic, materials. Complex geometries in hardened tool steels, titanium alloys, or high-temperature superalloys like Inconel introduce unique challenges in managing tool deflection, thermal expansion, and residual stress. Our process engineers employ advanced simulation software to model material behavior and optimize cutting strategies, minimizing distortion while maximizing surface integrity. This proactive approach prevents costly rework and ensures first-article success, even for the most intricate components.

The following table represents our core precision milling capabilities for critical applications:

| Specification Category | Capability Range | Measurement Standard |

|---|---|---|

| Positional Accuracy | ±0.001 mm (0.00004 inches) | ISO 2768-mK |

| Surface Roughness (Ra) | As low as 0.2 µm (8 µin) | ISO 1302 |

| Feature Repeatability | ±0.0005 mm (0.00002 inches) | 6 Sigma Process Control |

| Maximum Work Envelope | 1200 x 800 x 650 mm (47 x 31.5 x 25.6 in) | – |

| Material Compatibility | Aluminum, Titanium, Inconel, Tool Steel, PEEK, Composites | – |

True precision engineering delivers tangible business value: reduced assembly time, extended component lifespan, minimized warranty claims, and accelerated time-to-market for your end product. At Lead Precision, our Olympic and military project heritage instills a culture where tolerances are respected as absolute commitments. We partner with clients not just to machine parts, but to solve the underlying engineering challenges that define project success in the most demanding global markets. Precision, rigorously engineered, is our strategic asset for your competitive advantage.

Precision Specs & Tolerances

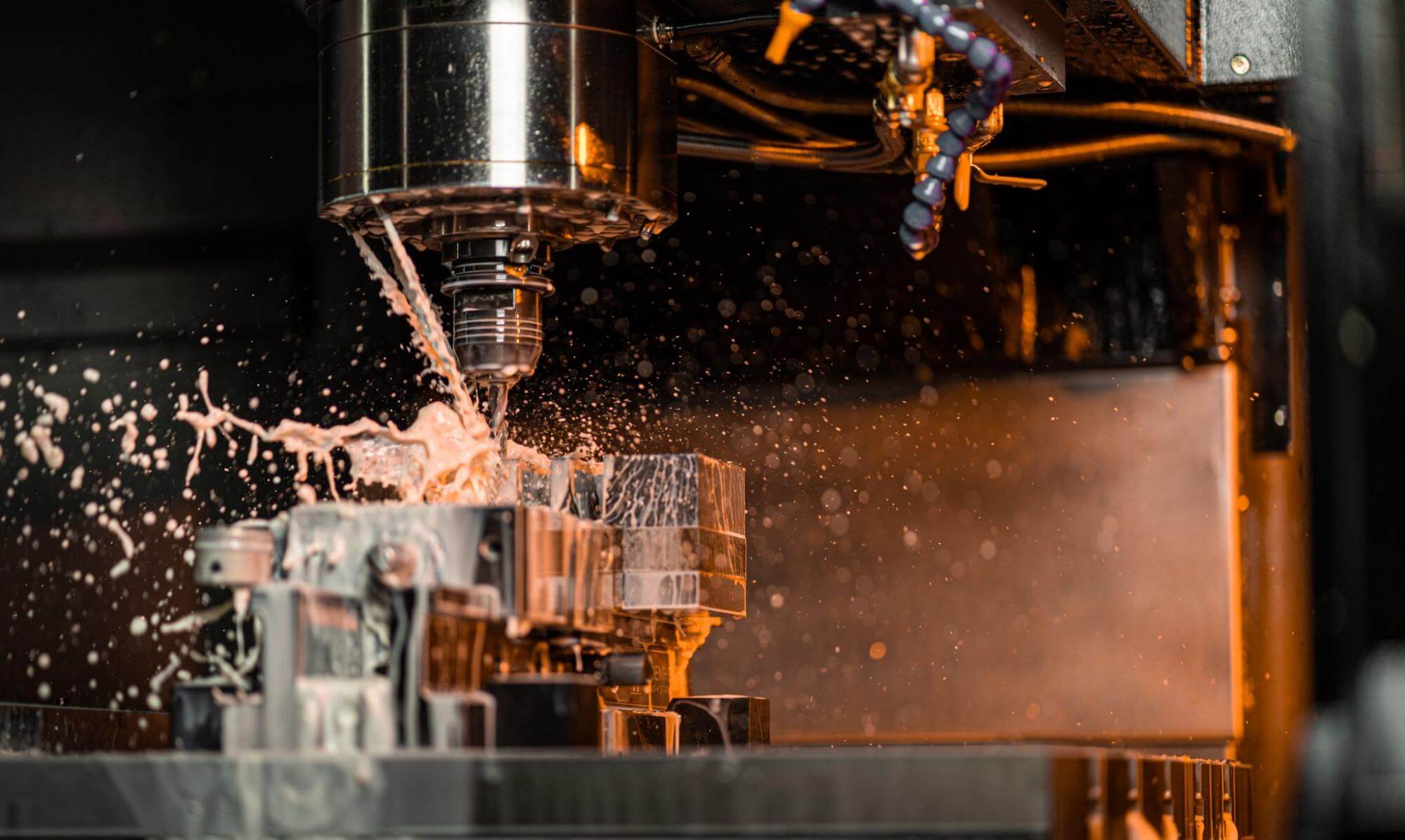

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, engineered to meet the demanding requirements of high-performance industries such as aerospace, medical, energy, and industrial automation. At the core of our manufacturing excellence is our fleet of state-of-the-art 5-axis CNC machining centers, which enable complex geometries, tighter tolerances, and superior surface finishes. These machines integrate simultaneous multi-axis motion, allowing for the precise machining of intricate 3D contours and deep cavities without the need for multiple setups. This not only enhances dimensional accuracy but also significantly reduces lead times and potential for human error.

Our 5-axis CNC systems are equipped with high-speed spindles, advanced tool management, and real-time monitoring systems to ensure consistent performance across both prototyping and high-volume production runs. By leveraging adaptive toolpath strategies and high-precision kinematics, we achieve exceptional part integrity and repeatability. Materials commonly processed include aerospace-grade aluminum alloys, titanium, stainless steel, Inconel, and engineering plastics such as PEEK and ULTEM, all machined under strict environmental controls to minimize thermal distortion.

Quality is inseparable from capability at Wuxi Lead. Every component undergoes a comprehensive quality control protocol anchored by Coordinate Measuring Machine (CMM) inspection. Our CMM systems provide full 3D metrology validation, ensuring that each part conforms precisely to CAD-defined specifications. These inspections are supplemented with first-article inspection reports (FAIR), process capability (Cp/Cpk) analysis, and full traceability documentation, meeting ISO 9001 and AS9100 standards. In-process checks and final audits are conducted at defined control points to guarantee consistency across batches.

We maintain a climate-controlled metrology lab to eliminate measurement drift, and our quality engineers are certified to interpret GD&T (Geometric Dimensioning and Tolerancing) to the highest ASME and ISO standards. This rigorous approach ensures that components not only meet but exceed the functional requirements of mission-critical applications.

The following table outlines our standard and precision tolerance capabilities across key machining parameters:

| Feature | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | Up to 500 mm |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Reamed/precision bored |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | Relative to datum |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | As machined, optional polishing |

| Angular Tolerance | ±0.1° | ±0.05° | Between features |

| Flatness | 0.05 mm | 0.02 mm | Over 100 mm span |

| Runout (Concentricity) | 0.05 mm | 0.01 mm | Critical for rotating parts |

These specifications reflect our commitment to precision, repeatability, and technical leadership in CNC milling projects. Wuxi Lead Precision Machinery is equipped and certified to support the most challenging engineering requirements with confidence and consistency.

Material & Finish Options

Material Selection for Precision CNC Milling Projects

Material choice directly impacts performance, cost, and manufacturability in precision CNC milling. At Wuxi Lead Precision Machinery, we prioritize aligning material properties with your functional requirements, environmental conditions, and production efficiency. Aluminum, steel, and titanium dominate high-end applications, each offering distinct advantages for aerospace, medical, and automotive sectors.

Aluminum alloys like 6061-T6 and 7075-T6 provide an optimal strength-to-weight ratio, excellent thermal conductivity, and superior machinability. They are ideal for lightweight structural components, heat sinks, and enclosures where corrosion resistance and ease of fabrication are critical. Steel variants such as 4140 and 303 stainless balance strength, durability, and cost-effectiveness. 4140 excels in high-stress applications like shafts and gears due to its hardenability, while 303 stainless offers enhanced corrosion resistance for medical instruments and marine hardware. Titanium Grade 5 (Ti-6Al-4V) delivers exceptional strength at elevated temperatures, biocompatibility, and resistance to extreme environments, making it indispensable for aerospace landing gear and surgical implants despite higher machining costs.

Key mechanical properties guide optimal selection. The table below summarizes critical specifications for common materials:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Machinability Rating | Primary Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 276 | 95 | Excellent (65) | Enclosures, brackets, heat sinks |

| Steel 4140 | 655 | 415 | 197 | Good (60) | Shafts, gears, tooling |

| Steel 303 Stainless | 586 | 241 | 149 | Fair (50) | Valves, fasteners, medical |

| Titanium Ti-6Al-4V | 900 | 830 | 360 | Poor (30) | Aerospace, implants, marine |

Surface finish selection must complement material choice to ensure longevity and performance. Anodizing is the industry-standard electrochemical process for aluminum components, enhancing corrosion and wear resistance while allowing color coding for identification. Type II (sulfuric acid) anodizing provides a versatile, economical finish for general use, while Type III (hardcoat) anodizing delivers thicker, harder layers (50–100 µm) for severe abrasion resistance in hydraulic systems or automotive parts. Crucially, anodizing thickness must be factored into tight-tolerance designs, as it adds dimensional build-up. For steel, consider passivation or zinc plating; titanium typically requires specialized treatments like nitriding for extreme wear scenarios.

At Wuxi Lead, our engineering team collaborates early in your design phase to validate material-process synergy. We leverage advanced CNC milling capabilities and strict process controls to mitigate challenges like titanium’s low thermal conductivity or steel’s work hardening. Partner with us to transform material potential into precision-engineered reality—ensuring your components meet exacting performance and compliance standards.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our CNC milling projects follow a rigorously structured production process designed to deliver precision-engineered components with zero defects. This systematic approach spans three critical phases: Design, Prototyping, and Mass Production. Each stage is engineered for accuracy, repeatability, and compliance with the highest international quality standards.

The process begins with Design, where our engineering team collaborates closely with clients to translate conceptual requirements into detailed 3D CAD models. Utilizing advanced software such as Siemens NX and SolidWorks, we ensure geometric accuracy, material suitability, and manufacturability. Design for Manufacturability (DFM) analysis is performed early to identify potential issues, optimize tool paths, and minimize waste. This phase sets the foundation for dimensional integrity and long-term production efficiency.

Following design finalization, we proceed to Prototyping. A limited batch of parts is produced using the same CNC milling machines and materials intended for full-scale production. This allows us to validate form, fit, and function under real manufacturing conditions. Our prototyping phase includes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Any deviations are addressed through iterative refinement, ensuring the design meets all technical and performance criteria before scaling.

Once prototype approval is obtained, we transition seamlessly into Mass Production. Our facility in Wuxi operates a fleet of multi-axis CNC milling centers, including 5-axis machines with high-speed spindles and automated tool changers. Production is monitored in real time using IoT-enabled systems that track machine performance, tool wear, and environmental conditions. Every component undergoes 100% in-process inspection at critical stages, with final quality verification conducted under ISO 9001-certified protocols. Statistical Process Control (SPC) ensures consistency across batches, maintaining tolerances as tight as ±0.005 mm.

Our zero-defect philosophy is enforced through full traceability. Each part is serialized, and machining data—including tooling parameters, inspection reports, and operator logs—is digitally archived for full lifecycle tracking. This level of transparency supports rapid root-cause analysis and continuous improvement.

The following table outlines key specifications achievable across our CNC milling projects:

| Specification | Capability |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Positional Accuracy | ±0.005 mm |

| Surface Roughness (Ra) | 0.4 – 3.2 µm |

| Spindle Speed | Up to 24,000 rpm |

| Materials Supported | Aluminum Alloys, Stainless Steel, Titanium, PEEK, Brass, Engineering Plastics |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), IATF 16949 (automotive) |

By integrating precision engineering with disciplined process control, Wuxi Lead ensures every CNC milling project achieves flawless execution from concept to volume delivery.

Why Choose Wuxi Lead Precision

Elevate Your CNC Milling Projects Through Strategic Partnership

Precision manufacturing demands more than advanced machinery—it requires a partner who anticipates engineering complexities and mitigates production risks before they impact your timeline or quality standards. At Wuxi Lead Precision Machinery, we engineer partnerships grounded in technical rigor and operational transparency. Our 15-year specialization in high-tolerance CNC milling for aerospace, medical, and energy sectors ensures your critical components meet exacting global specifications without compromise. We understand that a single micron deviation can cascade into project delays or compliance failures; thus, our entire workflow prioritizes predictive quality control and proactive communication.

Technical Capabilities That Define Reliability

Our facility operates under ISO 9001:2015 and IATF 16949 standards, deploying a meticulously calibrated infrastructure to transform complex designs into flawless physical outputs. Below are core specifications underpinning our service delivery:

| Specification | Capability Range | Industry Relevance |

|---|---|---|

| Tolerance Control | ±0.001 mm to ±0.005 mm | Critical for aerospace hydraulic manifolds and medical implants |

| Max Work Envelope | 1,200 x 800 x 650 mm | Accommodates large-scale industrial components |

| Material Expertise | Titanium, Inconel, PEEK, 7075-T6 Aluminum | Supports extreme-environment applications |

| Lead Time Reduction | 25–40% vs. industry average | Accelerates time-to-market for urgent projects |

| In-Process Inspection | On-machine probing + CMM validation | Eliminates post-machining rework cycles |

This technical foundation enables us to de-risk your supply chain. Unlike transactional vendors, we integrate early in your design phase via DFM analysis, identifying potential manufacturability hurdles before toolpaths are generated. Our engineers collaborate directly with your R&D team to optimize part geometry for cost efficiency without sacrificing performance—a practice that has reduced client prototyping iterations by 60% in recent engagements.

Your Project, Our Accountability

We recognize that CNC milling projects hinge on predictability. Therefore, we implement real-time production tracking accessible via secure client portals, providing live updates on machining status, quality checkpoints, and logistics. Should deviations arise, our corrective action protocols activate within 2 hours—documented, resolved, and communicated transparently. This operational discipline has sustained a 99.2% on-time delivery rate across 1,200+ annual projects, even amid volatile material markets.

Partnering with Wuxi Lead Precision Machinery means aligning with a team that treats your specifications as non-negotiable commitments. We do not merely fulfill purchase orders; we safeguard your engineering integrity through every spindle rotation. For projects demanding uncompromised precision and partnership accountability, initiate a technical consultation today. Contact our engineering team directly at [email protected] to discuss your requirements, material certifications, or tolerance validation protocols. Let us demonstrate how precision machining, executed with purpose, becomes your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.