Technical Contents

Engineering Guide: Fabrication Vs Machining

Engineering Insight Precision in Fabrication Versus Machining

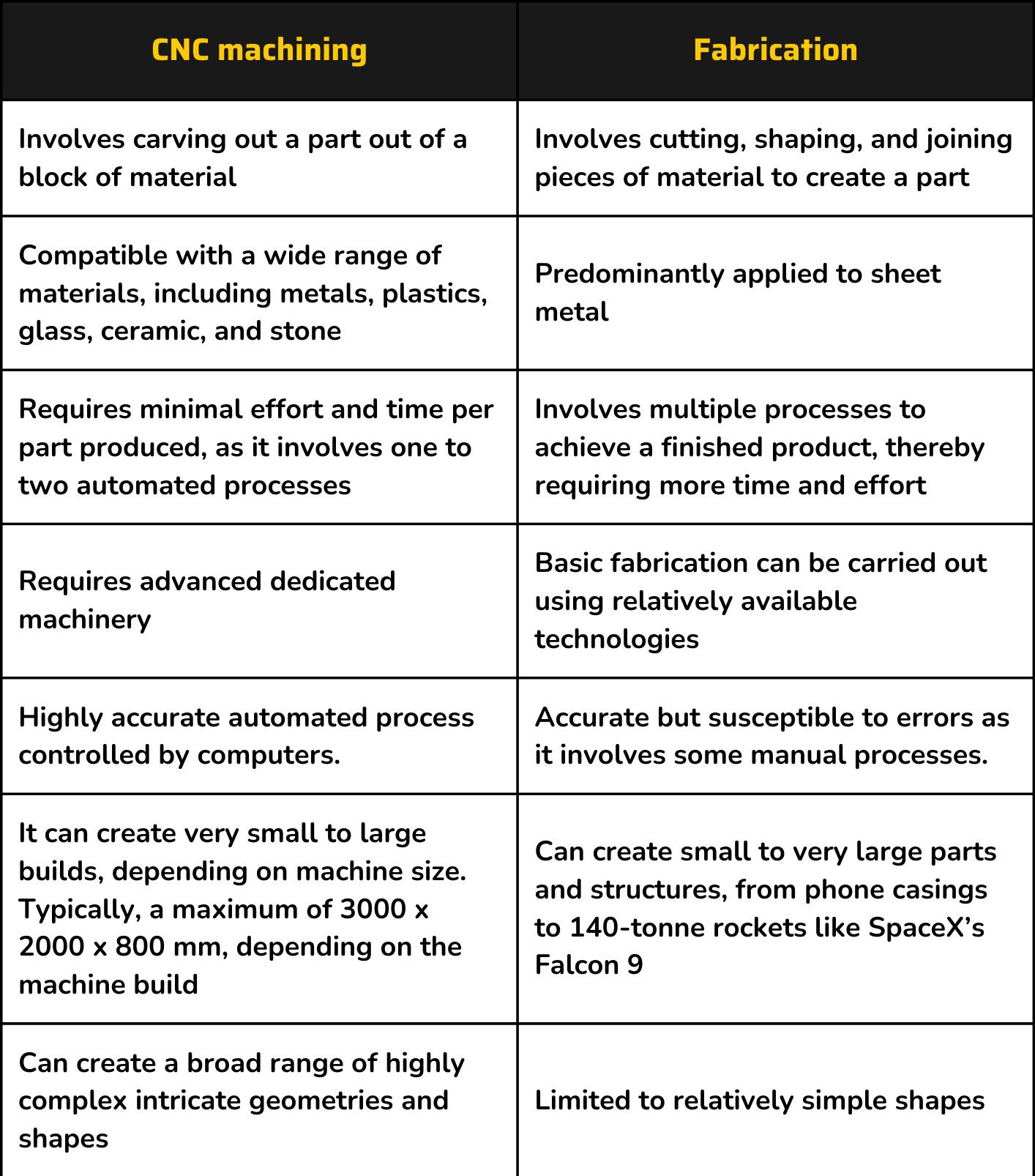

Understanding the distinction between fabrication and machining is fundamental for high-integrity manufacturing, yet the critical factor transcending both methodologies is precision. While machining traditionally dominates discussions on tight tolerances through subtractive processes, advanced sheet metal fabrication has evolved to deliver comparable accuracy for complex geometries. Fabrication—encompassing laser cutting, precision bending, welding, and assembly—excels at transforming flat sheet stock into intricate three-dimensional structures efficiently. Machining, utilizing mills, lathes, and EDM, achieves exceptional detail on solid billets or near-net shapes through controlled material removal. The strategic choice hinges not solely on the process, but on the required precision level for the final component’s function and integration.

Precision is non-negotiable in sectors like aerospace, defense, and high-end industrial equipment. A tolerance deviation of mere tenths of a millimeter can compromise structural integrity, assembly fit, or functional performance in critical applications. Modern fabrication leverages sophisticated CNC controls, advanced forming techniques like coining or air bending with real-time feedback, and stringent in-process metrology to achieve tolerances once exclusive to machining. This capability shift means fabrication is no longer limited to “rough” structures but is a primary solution for precision-critical assemblies where material efficiency, weight savings, and structural rigidity from formed features are paramount.

The following table highlights key precision characteristics differentiating advanced fabrication from traditional machining approaches for context:

| Parameter | Advanced Sheet Metal Fabrication | Traditional Machining |

|---|---|---|

| Typical Tolerances | ±0.1 mm to ±0.2 mm (bending/cut) | ±0.01 mm to ±0.05 mm |

| Material Removal | Minimal (primarily cutting) | Significant (subtraction) |

| Key Strength | Complex 3D structures from sheet | High-detail features on solids |

| Optimal Application | Enclosures, brackets, chassis | Shafts, housings, intricate parts |

At Wuxi Lead Precision Machinery, we operate at this precision frontier daily. Our engineering team possesses deep expertise in pushing fabrication tolerances to their absolute limits, consistently achieving sub-0.1mm repeatability in critical bending and assembly operations. This capability is rigorously validated through our work on projects demanding flawless execution under intense scrutiny. We have supplied mission-critical fabricated components for Olympic venue infrastructure, where structural perfection and on-time delivery were mandatory, and for specialized military applications requiring adherence to stringent MIL-STD specifications. These engagements are not merely contracts; they are proof points of our process control, material science understanding, and unwavering commitment to dimensional accuracy.

Precision in fabrication is not an aspiration—it is the engineered outcome of calibrated machinery, expert programming, and disciplined quality systems. For OEMs requiring components where form, fit, and function are inseparable from the manufacturing process, advanced sheet metal fabrication delivers the precision, efficiency, and structural advantages that machining alone cannot replicate. Partnering with a fabricator proven in the most demanding environments ensures your design intent translates into a flawless physical reality. At Lead Precision, we engineer precision into every bend and weld.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for precision, repeatability, and performance in high-demand industrial environments. Our technical capabilities integrate state-of-the-art 5-axis CNC machining with comprehensive sheet metal processing, enabling us to support complex geometries, tight tolerances, and mission-critical components across aerospace, medical, energy, and automation sectors. By combining multi-axis CNC technology with deep expertise in metal forming, cutting, and assembly, we provide end-to-end manufacturing services that bridge the gap between design intent and physical reality.

At the core of our machining capability is a fleet of 5-axis CNC centers equipped with high-speed spindles, automated tool changers, and real-time monitoring systems. These machines allow for simultaneous multi-directional cutting, reducing the need for part repositioning and minimizing cumulative error. This results in superior surface finishes, tighter tolerances, and the ability to produce highly intricate features in a single setup. Materials such as aluminum alloys, stainless steel, titanium, and specialty alloys are routinely processed with consistency and accuracy, supporting both prototype development and high-volume production runs.

Complementing our machining strength is a full suite of sheet metal fabrication services, including laser cutting, precision bending, welding, and assembly. Our Trumpf and Amada laser systems achieve kerf widths as narrow as 0.1 mm, enabling detailed contour cutting in materials up to 25 mm thick. CNC press brakes with automated backgauging ensure angular accuracy within ±0.2°, while robotic welding systems maintain consistent weld integrity across batches. All processes are supported by digital work instructions and in-process checks to ensure compliance with customer specifications.

Quality assurance is integral to our operations. Every critical dimension is verified using coordinate measuring machines (CMM) calibrated to ISO 17025 standards. Our CMM inspection protocols cover geometric dimensioning and tolerancing (GD&T), surface profile analysis, and first-article inspection reports (FAIR). Data from inspections is documented and traceable, providing full transparency for audit and compliance purposes.

The following table outlines key technical specifications and achievable tolerances across our core processes:

| Process | Material Thickness Range | Typical Tolerance | Positional Accuracy | Surface Finish (Ra) |

|---|---|---|---|---|

| 5-Axis CNC Machining | Up to 500 mm (work envelope) | ±0.005 mm | ±0.01 mm | 0.8 – 3.2 µm |

| Fiber Laser Cutting | 0.5 – 25 mm | ±0.1 mm | ±0.05 mm | 3.2 – 6.3 µm |

| CNC Press Brake Forming | 0.5 – 12 mm | ±0.2° angular | ±0.1 mm linear | N/A |

| MIG/TIG Welding | 1.0 – 15 mm | ±0.5 mm distortion control | Full weld mapping | As-welded or ground |

| CMM Inspection | N/A | Measurement uncertainty: 1.5 + L/300 µm | ISO 10360-2 compliant | N/A |

Our integrated approach to fabrication and machining ensures that components meet the highest standards of dimensional accuracy, structural integrity, and functional performance. Wuxi Lead Precision Machinery is committed to delivering precision-engineered solutions that exceed the expectations of global OEMs and advanced manufacturing partners.

Material & Finish Options

Strategic Material Selection in Precision Sheet Metal Fabrication

Material choice fundamentally dictates performance, manufacturability, and total cost in high-precision sheet metal fabrication. At Wuxi Lead Precision Machinery, our engineering team emphasizes selecting the optimal base material early in the design phase to avoid costly rework and ensure component reliability under operational stress. This decision directly impacts CNC machining parameters, forming capabilities, weld integrity, and final finish adhesion. Understanding the core properties and limitations of aluminum, steel, and titanium is non-negotiable for demanding industrial applications.

Aluminum alloys dominate aerospace, electronics, and transportation sectors due to their exceptional strength-to-weight ratio and natural corrosion resistance. Grade 6061-T6 offers excellent weldability and moderate strength for structural frames, while 5052-H32 provides superior workability for complex deep draws and marine environments. Its lower density reduces shipping costs and inertia in moving assemblies. Crucially, aluminum is the primary candidate for anodizing – an electrochemical process creating a dense, wear-resistant oxide layer that enhances corrosion protection and allows for durable color coding. Avoid anodizing near weld zones or on parts requiring tight electrical conductivity.

Carbon and stainless steels deliver unmatched strength and durability for heavy machinery, enclosures, and structural components. Low-carbon steel (e.g., A36) is highly formable and cost-effective for brackets and chassis but requires protective finishes like powder coating. Austenitic stainless steels, particularly 304/304L and 316/316L, provide inherent corrosion and heat resistance essential for food processing, medical, and chemical equipment. Their higher hardness increases tool wear during CNC milling and punching compared to aluminum, necessitating optimized feed rates and tooling. Stainless grades generally do not accept standard anodizing; passivation or electropolishing are preferred surface treatments.

Titanium alloys, primarily Grade 2 and 5 (Ti-6Al-4V), are reserved for extreme environments demanding the highest strength-to-weight ratio, exceptional corrosion resistance (especially to chlorides), and biocompatibility. Common in aerospace critical components and high-end medical implants, titanium presents significant fabrication challenges. Its low thermal conductivity causes rapid heat buildup during machining, requiring specialized toolpaths, rigid setups, and lower cutting speeds. Forming titanium sheet demands higher forces and careful springback compensation. Anodizing titanium is possible but serves primarily for color coding in medical devices, not wear enhancement like aluminum.

Material selection must align with functional requirements, production volume, and total lifecycle cost. Below is a comparative overview of key properties:

| Material Family | Key Grades | Density (g/cm³) | Tensile Strength (MPa) | Primary Fabrication Advantages | Common High-End Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 5052-H32 | 2.7 | 124-310 | Lightweight, excellent corrosion resistance, ideal for anodizing | Aerospace panels, electronic housings |

| Steel | A36, 304L, 316L | 7.8 | 400-690 | High strength, structural rigidity, cost-effective (carbon) | Machinery bases, medical enclosures |

| Titanium | Gr 2, Gr 5 | 4.5 | 345-900 | Extreme strength/weight, superior corrosion resistance | Aircraft engine components, surgical implants |

Partnering with an experienced fabricator like Wuxi Lead ensures material properties are fully leveraged within manufacturing constraints. We provide detailed DFM analysis to confirm your material choice supports precision tolerances, minimizes waste, and achieves the required surface finish – whether leveraging anodizing for aluminum aesthetics/protection or selecting the optimal steel grade for structural integrity. Your material decision is the foundation of success.

Manufacturing Process & QC

Design: The Foundation of Precision Manufacturing

At Wuxi Lead Precision Machinery, the fabrication process begins with an engineering-first approach to design. Every component is conceived using advanced CAD/CAM software, ensuring geometric accuracy, material efficiency, and manufacturability. Our design engineers collaborate closely with clients to interpret technical drawings, validate tolerances, and optimize part geometry for sheet metal characteristics such as bend allowances, grain direction, and spring-back effects. Finite element analysis (FEA) and design for manufacturability (DFM) reviews are standard practice, minimizing risks before physical production begins. This phase establishes the blueprint for zero-defect manufacturing, where precision is not achieved through correction—but through foresight.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to prototyping using high-accuracy CNC punching, laser cutting, and press braking systems. Prototypes are produced on the same class of equipment used in mass production, ensuring consistency in material behavior and dimensional outcomes. This phase allows functional testing, fit checks, and assembly validation under real-world conditions. At Wuxi Lead, every prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and laser scanning to verify conformance to ISO 2768-mK and client-specific tolerances. Feedback from this stage informs any necessary design or process adjustments, closing the loop between virtual design and physical reality. Our goal is not just to produce a sample—but to certify a repeatable, defect-free process.

Mass Production: Precision at Scale with Zero Defects

With design and prototype approval, we transition seamlessly into high-volume manufacturing. Our automated production lines integrate fiber laser cutting, automated bending cells, and robotic welding stations, all governed by real-time quality monitoring systems. Each stage incorporates in-process inspections and statistical process control (SPC) to detect deviations instantly. Traceability is maintained through barcode tracking, linking every component to its material batch, machine settings, and inspection records. Our quality management system is certified to ISO 9001:2015, with additional adherence to IATF 16949 standards for automotive clients. The result is a production flow where consistency is engineered in, not inspected in—enabling true zero-defect output across thousands of parts.

Key Production Specifications

| Parameter | Capability | Standard Tolerance |

|---|---|---|

| Material Thickness | 0.5 mm – 25 mm | ±0.1 mm |

| Laser Cutting Accuracy | ±0.05 mm | ISO 2768-mK |

| Punching Tolerance | ±0.1 mm | ISO 2768-mK |

| Bending Angle Tolerance | ±0.5° | Per drawing specification |

| Hole Position Tolerance | ±0.15 mm | ISO 2768-mK |

| Surface Roughness (Ra) | As low as 0.8 µm (machined surfaces) | Ra ≤ 3.2 µm (standard) |

| Welding Standards | ISO 15614-1, AWS D1.1 | Full or spot weld per spec |

| Quality Certification | ISO 9001:2015, IATF 16949 (automotive) | Full inspection reports |

At Wuxi Lead Precision Machinery, we treat fabrication not as a sequence of operations—but as a unified system where design integrity, process validation, and disciplined execution converge to deliver perfection at scale.

Why Choose Wuxi Lead Precision

Elevate Your Production Strategy Through Precision Partnership

In today’s volatile manufacturing landscape, selecting the right partner transcends cost considerations—it demands unwavering precision, technical agility, and supply chain resilience. Wuxi Lead Precision Machinery delivers engineered solutions where sheet metal fabrication and CNC machining converge to solve complex production challenges. We eliminate the guesswork in process selection, ensuring your components meet exact functional and geometric requirements while optimizing lead times and total cost of ownership. Our ISO 9001-certified facility in Wuxi integrates advanced automation with rigorous quality control protocols, providing Western manufacturers a strategically located Asian partner that operates to global standards without compromise.

Understanding the technical boundaries between fabrication and machining is critical for project success. Below we clarify core capabilities to guide your decision-making:

| Parameter | Sheet Metal Fabrication | CNC Machining |

|---|---|---|

| Material Thickness | 0.5mm – 12mm | No inherent thickness limit |

| Tolerance Range | ±0.1mm (bending/welding) | ±0.005mm – ±0.02mm |

| Primary Processes | Laser cutting, bending, welding | Milling, turning, grinding |

| Ideal Applications | Enclosures, brackets, chassis | Precision shafts, housings, aerospace components |

| Surface Finish Options | Anodizing, powder coating | Bead blasting, plating, polishing |

Why Partner With Lead Precision

We engineer partnerships, not transactions. Our team collaborates from design inception through volume production, offering DFM analysis that identifies cost-saving opportunities without sacrificing integrity. Unlike commodity-focused suppliers, we deploy in-process inspections at critical control points—ensuring dimensional accuracy via CMM, vision systems, and metallurgical testing. This proactive quality framework reduces scrap rates by up to 35% while guaranteeing on-time delivery for Tier 1 automotive, medical device, and industrial equipment clients. Our Wuxi facility operates 24/7 with redundant capacity, mitigating geopolitical and logistical disruptions that plague fragmented supply chains.

Your Next Step Toward Manufacturing Excellence

Stop negotiating trade-offs between precision and scalability. Submit your technical drawings or project specifications to our engineering team for a no-obligation process analysis. We will identify the optimal fabrication or machining pathway—including hybrid solutions—while providing a validated timeline and cost breakdown within 72 hours. For urgent RFQs or to schedule a virtual facility audit, contact us directly at [email protected]. Our sales engineers respond within one business day with actionable insights tailored to your production goals.

Connect with Precision Leadership

Email [email protected] with subject line “Fabrication vs Machining Strategy Review” to initiate a technical consultation. Include your component requirements, volume needs, and quality standards for immediate prioritization. Wuxi Lead Precision Machinery—where global engineering standards meet Chinese manufacturing efficiency. Let us prove why industry leaders trust our processes to secure their supply chains.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.