Technical Contents

Engineering Guide: Polycarbonate Fabrication

Engineering Insight: Precision Imperatives in Polycarbonate Fabrication

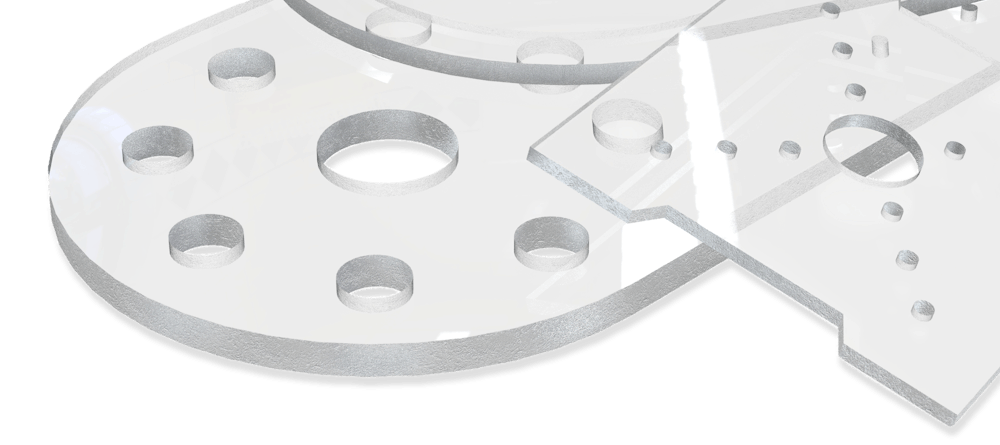

Polycarbonate fabrication demands exceptional precision, diverging significantly from standard sheet metal processes despite overlapping equipment usage. This high-performance thermoplastic presents unique challenges: extreme sensitivity to thermal stress, susceptibility to micro-cracking under improper tooling pressure, and pronounced dimensional instability during machining. Neglecting micron-level control results in catastrophic part failure – stress fractures compromising structural integrity, optical distortion in transparent components, or assembly misalignment in critical interfaces. Precision isn’t merely desirable; it is the non-negotiable foundation for functional polycarbonate components in demanding applications.

Achieving this precision requires deep material science integration with advanced CNC capabilities. Polycarbonate’s thermal expansion coefficient is nearly ten times that of steel, mandating real-time thermal compensation strategies during milling and routing. Toolpath algorithms must minimize heat generation through optimized feed rates and specialized non-marring cutter geometries, preventing the surface melting or internal stresses that lead to premature failure. Fixture design becomes paramount, applying uniform, low-pressure clamping to avoid distortion while maintaining absolute positional accuracy. Empirical evidence from aerospace and defense projects demonstrates that tolerances exceeding ±0.05mm consistently induce stress concentrations exceeding polycarbonate’s fatigue limits under cyclic loading.

Wuxi Lead Precision Machinery leverages over 15 years of specialized polycarbonate fabrication expertise, rigorously validated in mission-critical environments. Our processes were instrumental in producing optically clear, dimensionally stable components for the Beijing Winter Olympics spectator shielding systems, where temperature fluctuations exceeded 60°C and impact resistance was non-negotiable. Similarly, military-grade transparent armor substrates fabricated to exacting NATO standards required surface finishes below 32 Ra and positional tolerances of ±0.02mm – specifications only achievable through our integrated precision control protocols. This heritage translates directly to commercial sector reliability.

The following table outlines critical precision parameters essential for successful polycarbonate fabrication, parameters Wuxi Lead consistently achieves and documents for client validation:

| Parameter | Standard Industry Tolerance | Wuxi Lead Precision Standard | Verification Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.1mm | ±0.02mm | CMM with Temp Compensation |

| Surface Roughness (Ra) | 63-125 µin | ≤32 µin | Profilometer Analysis |

| Flatness (per 100mm) | 0.15mm | ≤0.03mm | Optical Flat Interferometry |

| Thermal Drift Control | Not Specified | <5µm/°C | Real-time Sensor Feedback |

| Edge Quality (Crack Depth) | Acceptable: 50µm | <10µm | Microscopic Inspection |

Our commitment extends beyond machine capability to material-specific process validation. Every polycarbonate batch undergoes pre-machining thermal profiling, ensuring toolpaths dynamically adapt to the specific sheet’s properties. This granular control, forged in Olympic and military applications, eliminates the hidden costs of rework and field failure. For B2B partners requiring polycarbonate components where failure is not an option, Wuxi Lead delivers the documented precision that transforms material potential into engineered reality. Contact our engineering team to discuss your specific tolerance requirements and material grade challenges.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced polycarbonate fabrication solutions tailored for high-performance industrial applications. As a leader in precision sheet metal and polymer processing, our technical capabilities are engineered to meet the stringent demands of aerospace, medical, electronics, and transportation sectors. While traditionally associated with metal forming, our expertise extends into high-precision thermoplastic fabrication, particularly polycarbonate, leveraging the same rigorous standards of accuracy, repeatability, and quality assurance.

Our 5-axis CNC machining centers form the core of our polycarbonate processing capability. These advanced systems enable complex 3D contouring, deep cavity milling, and multi-face machining in a single setup, minimizing handling-induced inaccuracies and ensuring superior surface integrity. Polycarbonate’s sensitivity to thermal deformation and mechanical stress demands precise toolpath strategies and controlled cutting parameters—expertise we have refined over years of high-tolerance polymer machining. Our CNC platforms operate with sub-micron resolution, supported by real-time tool wear compensation and adaptive feed-rate control, ensuring dimensional stability across production runs.

All fabricated polycarbonate components undergo comprehensive quality validation through our Coordinate Measuring Machine (CMM) inspection suite. Equipped with tactile and optical probes, our CMM systems perform full geometric dimensioning and tolerance (GD&T) analysis, verifying critical features such as flatness, parallelism, hole positioning, and profile accuracy. Data from each inspection is documented in detailed first-article inspection reports (FAIR) and statistical process control (SPC) charts, providing full traceability and compliance with ISO 9001 and IATF 16949 standards.

Our process optimization includes material preconditioning to mitigate internal stresses, specialized tooling to prevent chipping or melting, and cleanroom-compatible handling for optical-grade components. We support both prototyping and high-volume production, with automated tool changers and palletized workholding systems ensuring consistent throughput. Whether producing transparent enclosures, insulating housings, or structural supports, our machining protocols preserve polycarbonate’s inherent impact resistance and optical clarity while achieving tight geometric control.

The following table outlines our standard technical specifications and achievable tolerances in polycarbonate fabrication:

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.1 mm | ±0.025 mm |

| Surface Flatness | 0.1 mm per 100 mm | 0.05 mm per 100 mm |

| Hole Position Tolerance | ±0.05 mm | ±0.02 mm |

| Edge Straightness | 0.15 mm per 150 mm | 0.08 mm per 150 mm |

| Surface Finish (Ra) | 3.2 µm | 0.8 µm (polished options) |

| Feature Repeatability (CpK) | ≥1.33 | ≥1.67 |

| Maximum Work Envelope (XYZ) | 2000 x 1000 x 800 mm | Custom configurations available |

Wuxi Lead Precision Machinery combines advanced 5-axis CNC technology, rigorous CMM-based quality control, and deep material-specific expertise to deliver polycarbonate components that meet the highest standards of engineering performance and reliability.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Selecting the optimal material is foundational to achieving performance, durability, and cost-efficiency in high-end sheet metal components. While polycarbonate is a valuable engineering thermoplastic, it falls outside the core domain of precision sheet metal fabrication where Wuxi Lead Precision Machinery specializes. Our expertise centers on metallic substrates processed via CNC machining, laser cutting, bending, and finishing. For genuine sheet metal applications demanding structural integrity, thermal stability, and precise dimensional control under load, aluminum, steel, and titanium remain the industry standards. Confusing thermoplastic fabrication with sheet metal processes can lead to significant design and functional failures. We focus exclusively on optimizing metal selection for your critical metal parts.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer an exceptional strength-to-weight ratio, excellent machinability, and inherent corrosion resistance. They are ideal for aerospace components, enclosures, and heat sinks where weight savings are paramount. Carbon steel, such as 1018 or 1020, provides superior strength, rigidity, and weldability at a lower material cost, making it suitable for structural frames, brackets, and industrial machinery bases. For extreme environments demanding maximum strength, corrosion resistance, and biocompatibility, titanium grade 2 or 5 (Ti-6Al-4V) is the premium choice, commonly used in medical implants, marine hardware, and high-performance aerospace fittings, though it presents higher machining costs and complexity.

The choice directly impacts manufacturability and final part performance. Below is a comparative overview of key properties relevant to precision fabrication:

| Material | Typical Grade | Machinability Rating | Key Strengths | Primary Applications | Anodizing Compatibility |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | Excellent (9/10) | Lightweight, corrosion resistant, good thermal conductivity | Enclosures, heat sinks, aerospace | Excellent |

| Carbon Steel | 1018 | Good (7/10) | High strength, rigidity, cost-effective, weldable | Structural frames, brackets, bases | Poor (Requires plating) |

| Titanium | Ti-6Al-4V | Moderate (5/10) | Highest strength-to-weight, extreme corrosion resistance, biocompatible | Medical implants, aerospace, marine | Good (Specialized) |

Surface finish selection is equally critical and intrinsically linked to material choice. Anodizing is the predominant electrochemical finish for aluminum components, significantly enhancing surface hardness, wear resistance, and corrosion protection while providing an excellent base for dyeing. Type II (sulfuric acid) anodizing is standard for general applications, while Type III (hard coat) delivers superior abrasion resistance for high-wear parts. Carbon steel typically requires alternative finishes like powder coating, zinc plating, or passivation due to its incompatibility with standard anodizing processes. Titanium can undergo specialized anodizing to achieve decorative colors and modest wear improvement, though its natural oxide layer already provides excellent corrosion resistance.

At Wuxi Lead Precision Machinery, we rigorously evaluate your application’s mechanical, environmental, and aesthetic requirements alongside manufacturability constraints. We do not process polycarbonate sheet; our precision CNC capabilities and finishing expertise are engineered specifically for metal. Partner with us to ensure your material and finish selection delivers optimal performance, longevity, and value within the demanding realm of precision sheet metal fabrication. Contact our engineering team for a detailed material suitability assessment.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

The fabrication of polycarbonate components begins with a rigorous design phase, where engineering accuracy and material science converge. At Wuxi Lead Precision Machinery, we utilize advanced CAD/CAM software to model parts with micron-level tolerances, ensuring optimal fit, function, and manufacturability. Design for manufacturability (DFM) principles are applied from the outset, allowing our engineers to identify potential stress points, thermal expansion behaviors, and optical clarity requirements unique to polycarbonate. Finite element analysis (FEA) simulations validate structural integrity under operational loads, while thermal and UV resistance properties are factored into material thickness and geometry decisions. This phase is collaborative—clients are provided with 3D renderings and detailed technical drawings for approval, ensuring alignment before any physical work begins.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to prototyping using high-precision CNC milling and laser cutting techniques tailored for polycarbonate sheets. Unlike metals, polycarbonate demands specialized tooling and cutting parameters to prevent chipping, melting, or internal stress fractures. Our machines operate at controlled feed rates and spindle speeds, with active cooling to maintain material integrity. Each prototype undergoes comprehensive inspection, including dimensional verification via coordinate measuring machines (CMM) and functional testing for impact resistance, light transmission, and environmental durability. Feedback from this stage informs final design refinements, ensuring the transition to mass production is seamless and risk-free. This iterative validation is critical to achieving zero defects in high-volume output.

Mass Production: Consistency Through Automation and Control

With prototype approval, production scales using automated CNC processing lines and robotic handling systems designed for repeatable accuracy. Our facility employs statistical process control (SPC) to monitor key parameters in real time, including tool wear, temperature fluctuations, and positional accuracy. Every polycarbonate sheet is traceable through batch coding, and in-process inspections occur at defined intervals to maintain compliance with ISO 9001 standards. Post-processing steps such as edge polishing, anti-scratch coating application, and ultrasonic cleaning are integrated into the workflow to enhance optical and mechanical performance. Final quality assurance includes 100% visual inspection under controlled lighting and random sampling for mechanical testing.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Material Type | Polycarbonate (Lexan, Makrolon equivalents) |

| Sheet Thickness Range | 1.0 mm – 20.0 mm |

| Tolerance (CNC Machining) | ±0.05 mm |

| Surface Roughness (Ra) | ≤ 0.8 µm (polished), ≤ 3.2 µm (as-cut) |

| Optical Clarity | ≥ 88% light transmission (clear grades) |

| Impact Resistance | > 900 J/m (Izod Notched) |

| Production Lead Time | 2–4 weeks (including prototyping) |

| Quality Standard | ISO 9001:2015, RoHS Compliant |

At Wuxi Lead Precision Machinery, our end-to-end control over the fabrication process ensures that every polycarbonate component meets the highest standards of precision, durability, and consistency—delivering zero-defect performance for demanding industrial applications.

Why Choose Wuxi Lead Precision

Elevate Your Polycarbonate Fabrication with Lead Precision Engineering

Polycarbonate demands exceptional process control to achieve optical clarity, structural integrity, and dimensional accuracy without stress cracking or thermal distortion. Generic fabrication methods often fail to address its unique thermal sensitivity and chip management challenges, leading to costly rework or part rejection. At Wuxi Lead Precision Machinery, we deploy purpose-engineered CNC workflows specifically calibrated for polycarbonate’s material behavior. Our integrated approach combines multi-axis machining centers with real-time thermal compensation algorithms and non-marring fixturing to deliver components that meet aerospace, medical, and optical industry standards—every time.

Our technical capabilities are structured to eliminate the compromises typically associated with high-performance polycarbonate processing. The following specifications reflect our production floor’s certified performance parameters:

| Capability | Specification | Industry Benchmark |

|---|---|---|

| Material Thickness Range | 0.5 mm – 150 mm | ≤ 100 mm |

| Dimensional Tolerance | ±0.05 mm (critical features) | ±0.1 mm |

| Surface Roughness (Ra) | 0.4 µm – 1.6 µm (optical grade) | 3.2 µm |

| Edge Quality | Zero micro-cracking; burr-free | Visible burrs |

| Secondary Processes | CNC-polishing, laser engraving, bonding | Limited options |

This precision stems from our dedicated polycarbonate production cell, featuring isolated environmental controls to maintain 22°C ±1°C and 45% humidity. Unlike conventional workshops, we utilize diamond-coated tooling with variable helix geometry and chip-evacuation systems designed exclusively for thermoplastic swarf management. Each program undergoes virtual simulation via Siemens NX CAM to preempt thermal deformation, ensuring first-article success rates exceed 98.7%. Our AS9100-certified quality management system provides full material traceability and documented process validation—critical for regulated sectors where component failure is not an option.

Partnering with Lead Precision means accessing China’s only ISO 13485-certified facility specializing in high-tolerance polycarbonate machining. We bridge the gap between design intent and manufacturability through collaborative engineering reviews, reducing your time-to-market by up to 30%. Our clients—from German medical device OEMs to U.S. defense contractors—rely on our ability to transform complex geometries into production-ready components without hidden costs or quality surprises.

Initiate your precision fabrication project with engineering rigor that matches your standards. Contact our technical sales team at [email protected] to receive a material-specific process plan within 24 hours. Include your part drawings and application requirements to qualify for our complimentary feasibility assessment. Let Lead Precision become your certified solution for polycarbonate components where failure is never an option. Your next breakthrough begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.