Technical Contents

Engineering Guide: 5X Cnc

Engineering Insight: The Non-Negotiable Imperative of Precision in 5-Axis CNC Machining

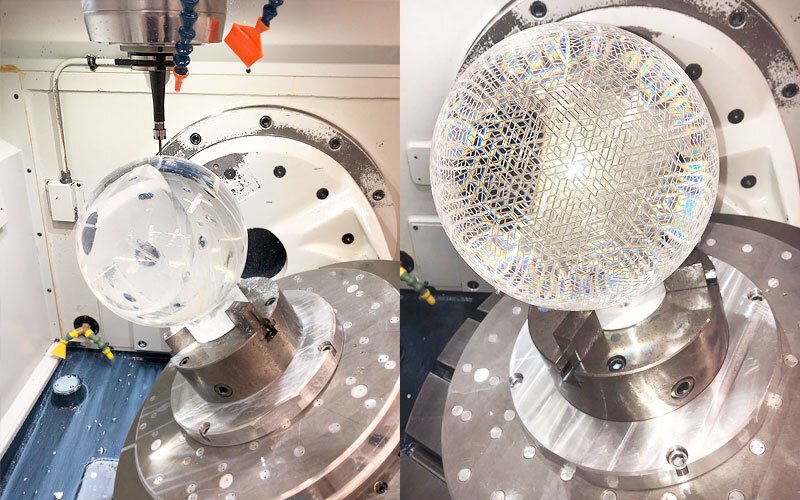

Achieving true geometric complexity in modern manufacturing demands more than multi-directional tool movement; it requires unwavering precision at every rotational and linear axis. Standard 3-axis CNC systems reach inherent limitations when producing intricate contours, deep cavities, or organic forms common in aerospace turbine blades, medical implants, and defense components. 5-axis machining eliminates these barriers by enabling simultaneous movement across X, Y, Z, and two rotary axes (typically A/B or B/C), allowing a single setup to machine complex geometries from nearly any angle. However, the transformative potential of 5-axis technology is entirely contingent upon the machine’s inherent precision and thermal stability. Without micron-level accuracy sustained across all five axes during extended operations, the advantages of reduced setups and complex geometry capability are negated by part inaccuracy, excessive scrap, and costly rework.

Precision in 5-axis machining transcends basic dimensional tolerance. It encompasses the machine’s ability to maintain exact positional repeatability under load, minimize geometric errors (such as squareness, straightness, and angular deviations), and resist thermal growth during prolonged cycles. These factors directly impact surface finish quality, critical feature alignment, and the feasibility of achieving tight tolerances on highly complex surfaces without manual intervention. Sub-micron level control is not merely desirable; it is an absolute requirement for components where failure is not an option. This is where machine tool design, rigorous calibration protocols, and advanced compensation systems become decisive differentiators between capable machines and truly exceptional production assets.

Wuxi Lead Precision Machinery operates at this pinnacle of precision manufacturing. Our engineering heritage is forged in environments demanding the absolute highest standards. We have consistently delivered components meeting the stringent, often classified, tolerances required for critical defense systems, where geometric perfection directly impacts mission success and safety. Similarly, our work supporting Olympic-level sporting equipment manufacturers demanded surface finishes and dimensional accuracies measurable only in microns, directly influencing athlete performance at the world’s most competitive stage. This experience is not anecdotal; it is embedded in our machine calibration processes, environmental controls, and quality assurance systems.

The following specifications represent the baseline precision performance achievable on our flagship 5-axis machining centers under controlled conditions, verified per ISO 10791-6 standards:

| Specification Parameter | Performance Value | Measurement Standard |

|---|---|---|

| Linear Axis Positioning Accuracy (X/Y/Z) | ±0.003 mm | ISO 230-2:2014 |

| Rotary Axis Positioning Accuracy (B/C) | ±5 arc-seconds | ISO 230-2:2014 |

| Volumetric Accuracy (Working Volume) | ±0.005 mm | ISO 230-6:2021 |

| Repeatability (All Axes) | ±0.0015 mm | ISO 230-2:2014 |

| Thermal Growth Compensation | < 0.002 mm/°C | Internal Protocol |

This level of precision is not accidental. It results from decades of focused engineering, investment in metrology-grade components, and an uncompromising commitment to stability. For manufacturers venturing into advanced 5-axis applications, the machine tool’s foundational accuracy is the critical enabler. It dictates yield rates, secondary operation requirements, and ultimately, the ability to produce components that meet the evolving demands of high-stakes industries. At Wuxi Lead, we understand that precision is the currency of trust in precision machining, and our Olympic and defense-grade production history proves our capability to deliver it consistently.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced precision CNC machining services engineered for high-complexity, mission-critical components across aerospace, medical, energy, and industrial automation sectors. At the core of our technical capabilities is our fleet of state-of-the-art 5-axis CNC machining centers, which enable us to produce intricate geometries with exceptional accuracy and surface finish. These machines integrate simultaneous multi-axis motion, allowing for complex contours, deep cavities, and compound angles to be machined in a single setup. This reduces cumulative error, improves part consistency, and significantly shortens lead times compared to traditional 3-axis methods.

Our 5-axis platforms are equipped with high-precision spindles, thermal compensation systems, and advanced tool monitoring to maintain dimensional stability across extended production runs. We support a broad range of materials, including aerospace-grade aluminum alloys, titanium, Inconel, stainless steels, and engineering plastics, ensuring compatibility with demanding performance environments. Each machine operates under strict environmental controls, and our programming team utilizes industry-leading CAM software to optimize toolpaths, minimize cycle times, and extend tool life.

To ensure every component meets the most exacting standards, we implement a comprehensive quality control protocol anchored by Coordinate Measuring Machine (CMM) inspection. Our CMM systems provide full 3D verification of critical features with micron-level resolution, generating detailed inspection reports traceable to international standards. These reports include geometric dimensioning and tolerancing (GD&T) analysis, surface profile validation, and positional accuracy assessments. All measurements are documented and archived for full production traceability, supporting compliance with ISO 9001 and customer-specific quality requirements.

Our machining capabilities are further reinforced by in-house design for manufacturability (DFM) analysis, fixture design, and first-article inspection (FAI) services. We collaborate closely with engineering teams to optimize part design for precision manufacturing, reducing cost and improving yield without sacrificing performance. From prototype to high-volume production, our technical infrastructure ensures repeatability, reliability, and compliance with the tightest tolerances.

The following table outlines our standard machining tolerances and inspection capabilities:

| Feature | Standard Tolerance | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers, Calipers |

| Geometric Tolerances (GD&T) | ±0.02 mm | ±0.008 mm | CMM with PC-DMIS software |

| Surface Roughness | Ra 3.2 μm | Ra 0.4 μm | Surface Roughness Tester |

| Hole Position Accuracy | ±0.02 mm | ±0.005 mm | CMM, Optical Comparator |

| Angular Accuracy | ±0.05° | ±0.01° | CMM, Precision Angle Blocks |

| Repeatability (Batch) | ±0.015 mm | ±0.003 mm | Statistical Process Control |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with rigorous metrology to deliver precision-engineered components that meet the highest standards of performance and reliability.

Material & Finish Options

Precision Material Selection for 5-Axis CNC Machining

Material selection is a critical engineering decision directly impacting the performance, cost, and manufacturability of precision 5-axis CNC components. At Wuxi Lead Precision Machinery, we understand that optimal material choice balances mechanical requirements, thermal behavior during complex multi-axis cutting, and final application demands. Suboptimal selection leads to excessive tool wear, dimensional instability, or compromised part function, particularly in intricate geometries achievable with 5-axis technology. This guide focuses on three core aerospace and industrial materials: Aluminum, Steel, and Titanium, alongside essential anodizing finishes.

Aluminum alloys dominate where weight reduction and thermal conductivity are paramount. Grades like 6061-T6 offer excellent machinability and weldability for structural housings, while 7075-T6 provides superior strength for high-stress components like aircraft fittings. Aluminum’s low density minimizes inertial forces during rapid 5-axis contouring, enhancing surface finish. However, its lower stiffness requires careful fixturing to prevent chatter in thin-wall features. Thermal management is generally favorable due to high conductivity, reducing heat buildup during extended milling cycles.

Carbon and alloy steels, such as 4140 and 17-4 PH stainless, deliver exceptional strength, wear resistance, and dimensional stability for demanding applications like hydraulic manifolds or tooling. These materials present higher cutting forces and generate significant heat during 5-axis operations, necessitating rigid machine setups and optimized coolant strategies. Machinability varies widely; free-machining steels like 12L14 improve chip control but sacrifice some strength. Steel’s lower thermal conductivity compared to aluminum demands precise speed/feed adjustments to avoid work hardening, especially in deep cavities.

Titanium alloys, primarily Ti-6Al-4V, are indispensable for high strength-to-weight ratio and corrosion resistance in aerospace and medical implants. Titanium’s low thermal conductivity is a major machining challenge in 5-axis work, causing intense localized heat at the tool tip that accelerates wear and risks material contamination. Rigorous chip evacuation and lower surface speeds are mandatory. Its high chemical reactivity requires dedicated tooling and coolants to prevent galling. While costly, titanium’s performance justifies its use in critical, load-bearing components where weight savings are non-negotiable.

Anodizing is the primary surface enhancement for aluminum parts, significantly improving corrosion resistance and wear properties. Type II (Sulfuric Acid) anodizing provides a standard decorative and protective layer, while Type III (Hardcoat) anodizing delivers a much thicker, harder, and more abrasion-resistant finish essential for functional surfaces. Note that anodizing is not applicable to steel or titanium in the same manner; steel typically uses plating or passivation, and titanium employs specialized anodizing for color coding or minor corrosion resistance, not hardness.

Key material properties for precision 5-axis machining are summarized below:

| Material Type | Common Grades | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Machinability Rating |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310, 570 | 150-180 | 85-100 |

| Steel | 4140, 17-4 PH SS | 655, 1000 | 40-45 | 65-75 |

| Titanium | Ti-6Al-4V | 900 | 7 | 25-35 |

Selecting the right material requires analyzing the entire lifecycle cost, not just raw material price. Consider the machining time, tooling expenses, and secondary operations like anodizing. Wuxi Lead Precision Machinery leverages extensive 5-axis expertise and verified domestic supply chains to optimize this selection process, ensuring your components meet stringent performance criteria while maximizing production efficiency. Partner with us early in design to avoid costly material-related rework.

Manufacturing Process & QC

From Concept to Consistency: The 5-Axis CNC Production Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we engineer precision into every phase of manufacturing. Our 5-axis CNC machining process is built on a seamless progression from design to prototyping and into high-volume production, all governed by a zero-defect philosophy. This structured workflow ensures that every component meets the exacting standards demanded by aerospace, medical, and advanced industrial applications.

The process begins with collaborative design engineering. Our team works closely with clients to analyze CAD models, assess material suitability, and optimize part geometry for manufacturability. Utilizing advanced simulation software, we perform toolpath verification and interference checks to eliminate potential errors before any metal is cut. This digital validation phase is critical in preventing rework and ensuring dimensional accuracy from the outset.

Once the design is finalized, we move into precision prototyping. Using our state-of-the-art 5-axis CNC machines, we produce initial sample parts under full production conditions. This allows us to validate tolerances, surface finishes, and functional performance. Clients receive fully documented prototypes with first-article inspection reports, including GD&T analysis and material certifications. Feedback from this stage is incorporated swiftly, ensuring that the transition to mass production is both seamless and risk-free.

Mass production is executed on our automated 5-axis machining cells, which combine high-speed cutting with continuous in-process inspection. Our machines operate with sub-micron repeatability, supported by automated tool monitoring and thermal compensation systems. Each production run is governed by a comprehensive quality plan, including SPC (Statistical Process Control) and 100% critical dimension checks where required. Our ISO 9001-certified quality management system ensures full traceability, from raw material batch numbers to final inspection data.

Zero defects is not a slogan—it is a measurable outcome of our integrated process controls, skilled workforce, and investment in cutting-edge technology. By aligning design intent with manufacturing capability and enforcing rigorous quality protocols, we deliver components that perform flawlessly in the most demanding environments.

Key 5-Axis CNC Production Specifications

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1,200 × 800 × 750 mm |

| Spindle Speed | Up to 24,000 rpm |

| Tool Changer Capacity | 30T / 60T (optional) |

| Supported Materials | Aluminum, Titanium, Inconel, Steel, PEEK |

| Surface Finish (Typical) | Ra 0.4 µm (as machined), down to Ra 0.1 µm |

| Tolerance Range | ±0.005 mm (standard), ±0.001 mm (tight) |

| In-Process Measurement | On-machine probing with Renishaw systems |

| Quality Certification | ISO 9001:2015, Full FAI and PPAP reporting |

Why Choose Wuxi Lead Precision

Elevate Your Precision Manufacturing Partnership

Wuxi Lead Precision Machinery stands as your definitive engineering ally for mission-critical CNC components. With ISO 9001:2015 certification and German-engineered HAAS, DMG MORI, and MAZAK platforms, we deliver uncompromising accuracy for aerospace, medical, and energy sectors. Our 15,000 m² facility integrates 5-axis simultaneous machining, high-speed milling, and multi-tasking turning centers—operating under stringent environmental controls to maintain tolerances down to ±0.001mm. This is not merely production; it is the convergence of metrology-grade validation and repeatable process excellence.

Our technical capacity spans complex geometries in challenging materials, from Inconel 718 and titanium Grade 5 to medical-grade PEEK and hardened tool steels. Every component undergoes rigorous inspection via Zeiss CONTURA CMMs and optical comparators, ensuring compliance with AS9100, ISO 13485, and customer-specific PPAP protocols. Below details our core production specifications:

| Capability | Specification Range |

|---|---|

| Machine Types | 5-Axis Milling, Mill-Turn, High-Speed Vertical Machining |

| Tolerance Range | ±0.001 mm to ±0.005 mm (feature-dependent) |

| Material Expertise | Titanium, Inconel, Hastelloy, Aluminum 7075-T6, Stainless 17-4PH, PEEK |

| Max Work Envelope | 1,200 x 800 x 650 mm (5-axis) |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm (as machined) |

Partnering with Lead Precision means eliminating supply chain vulnerabilities. We deploy real-time production tracking via our proprietary MES platform, granting clients live access to work-in-progress status, first-article inspection reports, and thermal compensation data. Our engineering team collaborates at the RFQ stage to optimize designs for manufacturability—reducing lead times by 22% on average while enhancing structural integrity. This proactive approach prevents costly iterations, ensuring your project transitions seamlessly from CAD model to certified component.

The cost of precision extends beyond machining—it encompasses risk mitigation, regulatory adherence, and on-time delivery certainty. We absorb this burden through dedicated project cells, in-house heat treatment coordination, and NADCAP-accredited finishing partnerships. When your application demands zero-defect output under compressed timelines, our integrated workflow becomes your competitive advantage.

Initiate Your Precision Project

Contact our engineering team directly to discuss your technical requirements. Submit your 3D model or drawing package to [email protected] for a comprehensive feasibility analysis and quotation within 24 business hours. Our CNC specialists will outline process validation steps, material sourcing strategy, and delivery milestones tailored to your production schedule. For urgent RFQs, reference “Priority 5X” in your email subject line to expedite review.

Wuxi Lead Precision Machinery operates where engineering ambition meets executional certainty. We do not manufacture parts—we deliver certified solutions that power innovation at the highest levels of global industry. Your next breakthrough component begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.