Technical Contents

Engineering Guide: Plastic Molded Products

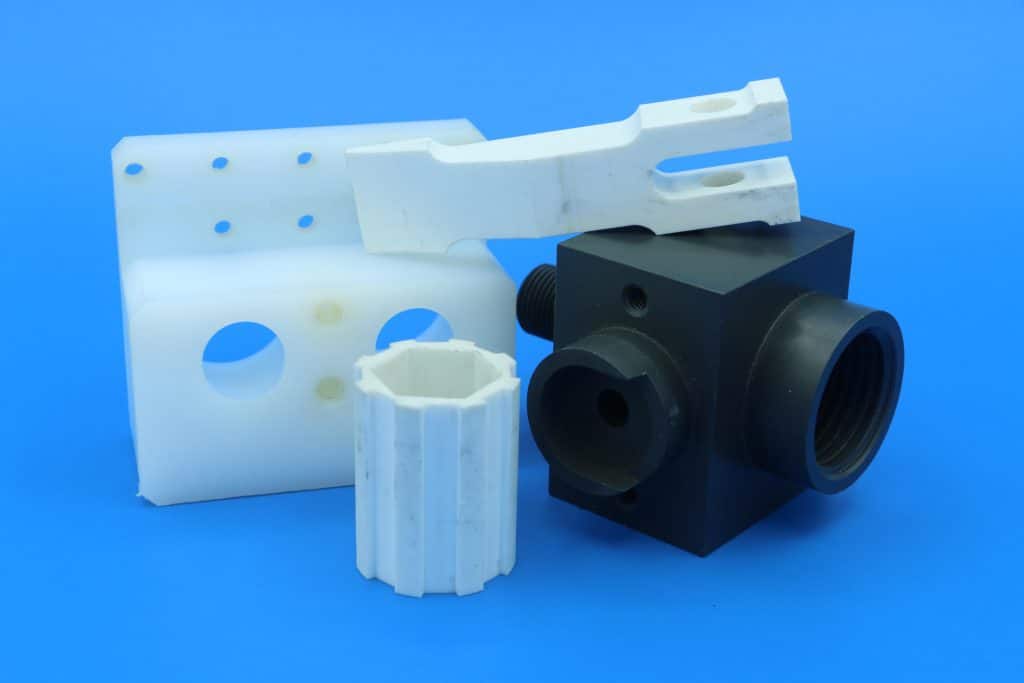

Engineering Insight: The Critical Role of Precision in Plastic Molded Products

In the realm of custom metal manufacturing, the integration of plastic molded components demands an uncompromising commitment to precision. At Wuxi Lead Precision Machinery, we recognize that even the most advanced metal assemblies rely on perfectly engineered plastic elements to deliver optimal performance, longevity, and reliability. Whether in aerospace, defense, or high-performance industrial systems, plastic molded products must meet exacting dimensional tolerances, material specifications, and functional requirements. This level of consistency is not achieved through standard molding practices—it requires advanced tooling, real-time process control, and deep engineering expertise.

Precision in plastic molding begins with mold design. A well-designed mold ensures uniform material flow, minimizes residual stress, and maintains tight tolerances across thousands of cycles. At Lead Precision, our engineering team employs finite element analysis (FEA) and mold-flow simulation to predict and correct potential defects before production begins. This proactive approach reduces trial-and-error, accelerates time-to-market, and ensures first-article compliance with client specifications. Our in-house CNC machining capabilities allow us to fabricate molds with micron-level accuracy, directly translating into superior part consistency and surface finish.

One of the most demanding applications for plastic molded components is in military and Olympic-grade equipment, where failure is not an option. We have supported projects requiring components that operate under extreme thermal cycling, mechanical load, and corrosive environments. For instance, our molded insulators for defense communication systems maintain dielectric integrity at -40°C to +125°C, while our lightweight polymer housings for Olympic timing systems ensure flawless operation under high-speed impact and environmental exposure. These achievements are only possible through rigorous material selection, process validation, and full traceability from raw pellet to finished part.

Our experience in high-stakes industries has reinforced a fundamental truth: precision is not a feature—it is the foundation. Variations of even a few microns can lead to assembly misalignment, sealing failure, or performance degradation in dynamic systems. This is especially critical when plastic components interface with machined metal parts, where thermal expansion coefficients and surface geometries must be perfectly synchronized.

To ensure consistency, we maintain ISO 9001-certified processes, including automated in-line inspection using coordinate measuring machines (CMM) and optical comparators. Every batch is subject to dimensional verification, material certification, and functional testing as required by the application.

Below are representative specifications for our precision plastic molding capabilities:

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Mold Material | H13, S136, 2738, 718H (hardened & pre-hardened) |

| Clamping Force Range | 50 to 1,200 tons |

| Shot Weight Range | 1g to 2,500g |

| Common Materials | PEEK, PPS, PC, ABS, POM, PP, PE, PMMA |

| Secondary Operations | Ultrasonic welding, insert molding, plating |

| Quality Standards | ISO 9001, RoHS, full traceability documentation |

At Wuxi Lead Precision Machinery, we combine advanced manufacturing technology with proven engineering discipline to deliver plastic molded products that meet the highest standards of performance and reliability. Our work with Olympic and military-grade systems is not merely a credential—it is a testament to our capability and commitment.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Tooling for Plastic Molding Excellence

At Wuxi Lead Precision Machinery, our core strength lies in transforming complex plastic molded product concepts into reality through ultra-precise metal tooling. We recognize that the dimensional integrity and surface fidelity of plastic components are fundamentally dictated by the quality of the metal molds and inserts used in production. Our dedicated focus on custom metal manufacturing for mold fabrication ensures the critical interface between metal tooling and plastic flow achieves uncompromising repeatability and performance.

Central to our capability is a modern fleet of 5-axis CNC machining centers, operating under stringent environmental controls to minimize thermal drift. These systems enable us to machine intricate mold cavities, cores, slides, and lifters in a single setup, eliminating cumulative errors inherent in multi-axis repositioning. We routinely handle challenging geometries—including deep ribs, undercuts, and organic contours—in hardened tool steels (P20, H13, S136) and aluminum alloys, achieving surface finishes down to Ra 0.2 µm directly from the machine. This capability is essential for producing plastic parts with tight aesthetic requirements, zero knit lines, and seamless assembly interfaces, particularly in medical, automotive, and consumer electronics applications.

Every component undergoes rigorous validation through our metrology lab, anchored by Zeiss and Hexagon CMMs with sub-micron probe resolution. Inspection routines are fully programmed from client CAD models, ensuring comprehensive verification of critical dimensions, geometric tolerances, and contour deviations against nominal data. We implement first-article inspection (FAI) protocols per AS9102 standards and conduct in-process checks during long-run production to guarantee stability. This closed-loop quality process provides documented evidence that mold components meet specifications before assembly, directly reducing scrap rates and cycle time inefficiencies for our clients’ plastic molding operations.

Our commitment to precision is quantifiable through the following achievable tolerances for mold components, which directly translate to consistent plastic part quality:

| Feature | Capability | Application Context |

|---|---|---|

| Linear Dimensions | ±0.005 mm | Core/cavity matching, slide fits |

| Geometric Tolerances | 0.01 mm (GD&T) | Positional accuracy for inserts, pins |

| Surface Finish (Ra) | 0.2 µm – 0.8 µm | Optical surfaces, cosmetic parts |

| Hole Concentricity | 0.008 mm | Ejector pin alignment, bushings |

| Flatness | 0.005 mm per 100 mm | Parting line sealing surfaces |

These specifications are not theoretical limits but routinely achieved production standards, validated across thousands of mold sets annually. By mastering the metal foundation of plastic molding, Wuxi Lead ensures your final plastic products exhibit minimal warpage, consistent wall thickness, and flawless demolding—critical for high-volume, zero-defect manufacturing. Our technical partnership extends beyond machining; we collaborate early in design to optimize tool steel selection, cooling channel layout, and ejection strategies, directly enhancing the manufacturability and performance of your plastic molded products. This integrated approach to precision metal tooling delivers tangible reductions in total cost of ownership for your production lifecycle.

Material & Finish Options

Material selection plays a critical role in the performance, durability, and cost-efficiency of custom metal components used in plastic molded products. At Wuxi Lead Precision Machinery, we specialize in precision manufacturing where material properties directly influence mold life, surface finish, and production throughput. Aluminum, steel, and titanium each offer distinct advantages depending on application requirements such as thermal conductivity, wear resistance, and mechanical strength.

Aluminum alloys are widely used in mold manufacturing due to their excellent thermal conductivity and machinability. These properties allow for faster cooling cycles, increasing production efficiency in high-volume plastic molding operations. Aluminum is particularly suitable for prototypes and low-to-medium volume production runs where rapid turnaround and cost savings are priorities. While not as wear-resistant as steel, modern aluminum alloys with enhanced hardness can support extended service life under proper conditions.

Steel remains the dominant choice for high-volume plastic molding applications. Tool steels such as P20, H13, and S136 offer superior hardness, wear resistance, and polishability—essential traits for maintaining dimensional accuracy and surface quality over millions of cycles. Stainless and hardened steels also provide excellent corrosion resistance, especially when molding abrasive or chemically aggressive resins. The initial machining time and cost are higher than aluminum, but the extended tool life justifies the investment in large-scale manufacturing.

Titanium is less common but increasingly considered for specialized components within mold assemblies where extreme strength-to-density ratio and corrosion resistance are paramount. While not typically used for full mold bases or cavities due to cost and machining complexity, titanium finds application in ejector pins, inserts, and support structures exposed to high stress or corrosive environments. Its biocompatibility also makes it suitable for medical-grade plastic molding systems.

Surface finishing, particularly anodizing, significantly enhances aluminum’s functional properties. Anodizing creates a hard, wear-resistant oxide layer that improves corrosion resistance and allows for color coding through dye integration. Type II (sulfuric acid) and Type III (hard coat) anodizing are commonly applied based on required coating thickness and performance needs. While anodizing is specific to aluminum, steel components benefit from alternative treatments such as nitriding, chrome plating, or PVD coatings to achieve similar improvements in surface hardness and release properties.

Below is a comparative overview of key material specifications relevant to plastic mold manufacturing.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Applications |

|---|---|---|---|---|

| Aluminum 7075 | 570 | 15–20 (HB) | 130 | Prototypes, low-volume molds |

| P20 Steel | 900–1100 | 28–32 | 30 | High-volume mold bases, cavities |

| H13 Steel | 1500 | 45–52 | 25 | Hot-runner systems, core inserts |

| Titanium Grade 5 | 900–1000 | 35–40 | 7 | Ejector components, medical tools |

Selecting the optimal material and finish requires a thorough understanding of production volume, resin type, part geometry, and environmental exposure. Wuxi Lead Precision Machinery supports clients in making data-driven decisions to ensure long-term reliability and performance of their plastic molding systems.

Manufacturing Process & QC

Precision Plastic Molded Products: The Zero Defects Manufacturing Process

At Wuxi Lead Precision Machinery, we deliver plastic molded components meeting the exacting demands of high-end industrial applications. Our integrated approach ensures seamless compatibility with precision metal assemblies, eliminating interface failures. The journey from concept to flawless mass production follows a rigorously controlled sequence designed for zero defects.

The process begins with collaborative design engineering. Our team conducts in-depth Design for Manufacturability (DFM) analysis, focusing on material flow, gate placement, cooling efficiency, and critical tolerance zones where plastic parts interface with metal components. We identify potential stress points, sink marks, or warpage risks early, ensuring the design inherently supports dimensional stability and structural integrity required in demanding environments. This phase utilizes advanced simulation software to predict molding behavior under precise pressure and temperature profiles, optimizing the design before tooling commences. Close coordination with the client’s engineering team is mandatory to align on functional requirements and interface specifications.

Prototyping transitions the validated design into physical reality. We employ rapid tooling techniques using hardened steel inserts for critical features, producing functional prototypes that accurately represent final part characteristics. These prototypes undergo comprehensive metrology against CAD models and rigorous functional testing within simulated assembly environments. Crucially, we verify dimensional conformity at all metal-plastic contact points using coordinate measuring machines. Any deviation triggers immediate design or process parameter refinement. This stage is not merely form validation; it is a stress test for the entire production system under near-actual conditions.

Mass production leverages our certified ISO 9001:2015 manufacturing cell with closed-loop process control. Each molding cycle is monitored in real-time for pressure, temperature, and fill time deviations exceeding predefined statistical control limits. Our zero defects mandate is enforced through Statistical Process Control (SPC) with continuous data logging and automated alerts. Every batch undergoes 100% critical dimension verification at defined checkpoints using calibrated optical and tactile measurement systems. Non-conforming parts are physically isolated before they progress. Process capability indices (Cp/Cpk) are maintained above 1.67 for all critical features through proactive machine calibration and environmental controls.

Critical Metrology Capabilities Ensuring Zero Defects

| Measurement System | Accuracy Range | Key Application for Plastic-Metal Integration |

|---|---|---|

| Coordinate Measuring Machine (CMM) | ± 0.0001 inch (2.5 µm) | Verifying interface geometry, positional tolerances, and GD&T callouts on molded parts mating with precision metal components |

| Optical Comparator | ± 0.0002 inch (5 µm) | Rapid inspection of complex contours, radii, and critical wall thicknesses affecting assembly fit |

| Laser Scanning | ± 0.0004 inch (10 µm) | Full-field surface analysis to detect warpage or sink incompatible with metal housing tolerances |

| In-Process Vision System | ± 0.0005 inch (12.5 µm) | Real-time verification of part presence, orientation, and gross defects before secondary operations |

This disciplined progression—grounded in predictive design, validated prototyping, and statistically controlled mass production—guarantees plastic molded products that integrate flawlessly with precision metal assemblies. Wuxi Lead Precision Machinery delivers not just parts, but guaranteed performance and zero assembly-line disruptions.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision Metal Components in Plastic Molded Product Applications

When manufacturing high-performance plastic molded products, the precision and reliability of metal components are critical to mold integrity, production efficiency, and final part quality. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing engineered to support advanced molding operations. Our expertise lies in delivering high-tolerance, durable metal parts that integrate seamlessly into mold assemblies, from core pins and ejector systems to custom inserts and support structures.

We understand that plastic molding demands materials and components that can withstand repeated thermal cycling, mechanical stress, and corrosive environments. That’s why every component we produce is crafted using premium-grade tool steels, stainless alloys, and specialized surface treatments designed to extend service life and reduce downtime. Our manufacturing capabilities include CNC milling, turning, wire EDM, grinding, and laser texturing, all performed under strict ISO 9001-certified quality controls.

Our engineering team works closely with clients to interpret design requirements, optimize manufacturability, and ensure dimensional accuracy down to ±0.002 mm. Whether you require a single prototype or high-volume production runs, we maintain consistent quality and on-time delivery through scalable processes and real-time production monitoring.

Below are key technical specifications reflecting our manufacturing capabilities:

| Specification | Capability |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.05 µm to Ra 1.6 µm (custom finishes available) |

| Materials | P20, 718H, S136, NAK80, H13, Stainless Steel (304, 316), Aluminum (7075, 6061), Titanium |

| Heat Treatment | Up to 58 HRC (quenching, tempering, nitriding) |

| Coating & Surface Treatments | TiN, TiCN, DLC, PVD, Electroless Nickel, Hard Chrome |

| Maximum Part Size | 800 mm × 600 mm × 500 mm |

| Production Capacity | Prototype to 50,000+ units annually |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), CMM Reporting |

We serve clients across the automotive, medical device, consumer electronics, and industrial equipment sectors—industries where precision directly impacts product performance and regulatory compliance. Our track record includes long-term partnerships with Tier 1 mold makers and OEMs who rely on our components for mission-critical applications.

Choosing the right manufacturing partner is not just about capability—it’s about collaboration, responsiveness, and technical insight. At Wuxi Lead Precision Machinery, we align our engineering expertise with your product goals to deliver metal components that enhance the performance and longevity of your plastic molding systems.

For engineering inquiries or to request a quote, contact us today at [email protected]. Let us become an extension of your technical team and support your next generation of precision plastic molded products.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.