Technical Contents

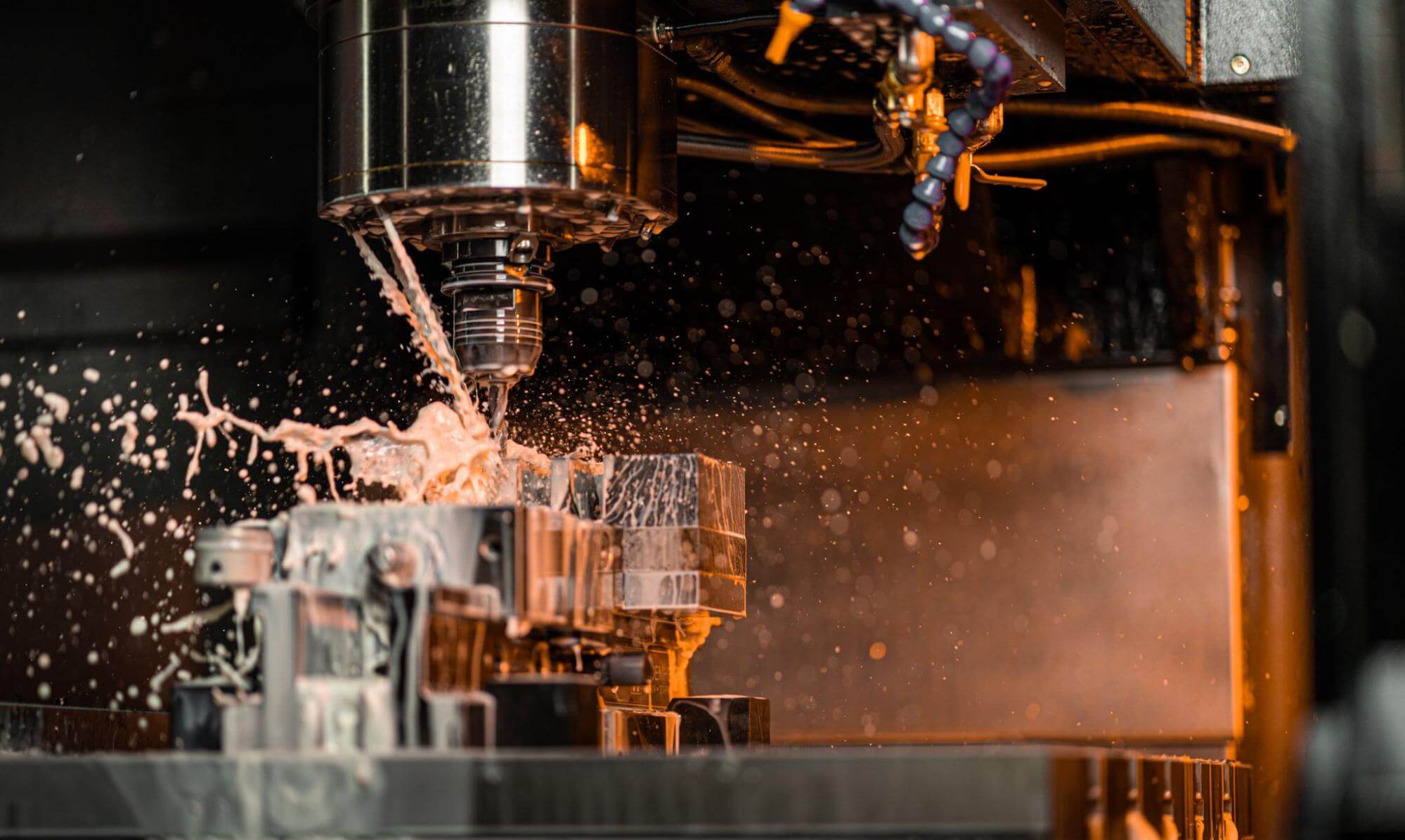

Engineering Guide: Metal Cutting Cnc

Engineering Insight: Precision as the Non-Negotiable Core of Metal Cutting CNC

In high-stakes metal cutting CNC operations, precision transcends mere specification; it is the fundamental determinant of component functionality, system reliability, and ultimate product success. Achieving micron-level tolerances consistently across complex geometries demands far more than advanced machinery alone. It requires an integrated engineering philosophy encompassing thermal stability management, vibration damping, ultra-rigid machine structures, sophisticated motion control algorithms, and rigorous process validation. Sub-micron deviations, imperceptible to the naked eye, can cascade into catastrophic failures in critical applications like aerospace actuators, medical implants, or semiconductor manufacturing equipment. The true measure of a precision CNC capability lies not in isolated peak performance, but in sustained accuracy under production conditions – managing tool wear, material variance, and environmental fluctuations over extended runs. This unwavering consistency separates capable shops from indispensable partners for industries where failure is not an option.

Wuxi Lead Precision Machinery has engineered its entire operational framework around this uncompromising precision mandate. Our foundation rests on state-of-the-art CNC platforms meticulously selected and enhanced for dimensional integrity. We implement multi-point laser calibration systems adhering to ISO 230-2 standards, active thermal compensation networks monitoring hundreds of data points, and proprietary fixturing solutions minimizing workpiece deflection. This technical infrastructure is guided by deep process knowledge honed through demanding projects. Our precision protocols were rigorously proven in supplying mission-critical components for the Beijing 2022 Winter Olympics infrastructure, where environmental extremes demanded flawless sensor and structural part performance. Similarly, our adherence to MIL-STD-810 and ITAR-compliant processes for classified military subsystems underscores our capability to deliver zero-defect components under the most stringent quality and security requirements. Precision here is not theoretical; it is validated daily in components enabling global events and national security.

The engineering specifications below reflect the tangible capabilities underpinning this precision commitment across our core 5-axis machining centers:

| Performance Parameter | Specification | Engineering Significance |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ±1.5 µm (ISO 230-2) | Ensures feature location integrity across large work envelopes |

| Repeatability (X/Y/Z) | ±0.8 µm (ISO 230-2) | Guarantees consistent part-to-part conformity in production |

| Volumetric Accuracy | ±3.0 µm (100x100x100mm) | Critical for complex 3D contours and tight assembly fits |

| Spindle Runout (TIR) | ≤0.5 µm | Directly impacts surface finish and micro-geometry fidelity |

| Thermal Drift Compensation | <1.0 µm/°C (Active) | Maintains accuracy during extended machining cycles |

This level of controlled performance is the non-negotiable baseline for industries where component integrity defines system success. At Wuxi Lead, precision is the engineered outcome of relentless attention to machine capability, environmental control, and proven process discipline – a commitment forged in the crucible of Olympic and military-grade manufacturing demands. It is the cornerstone upon which we build client trust and deliver components that perform flawlessly in the world’s most demanding applications.

Precision Specs & Tolerances

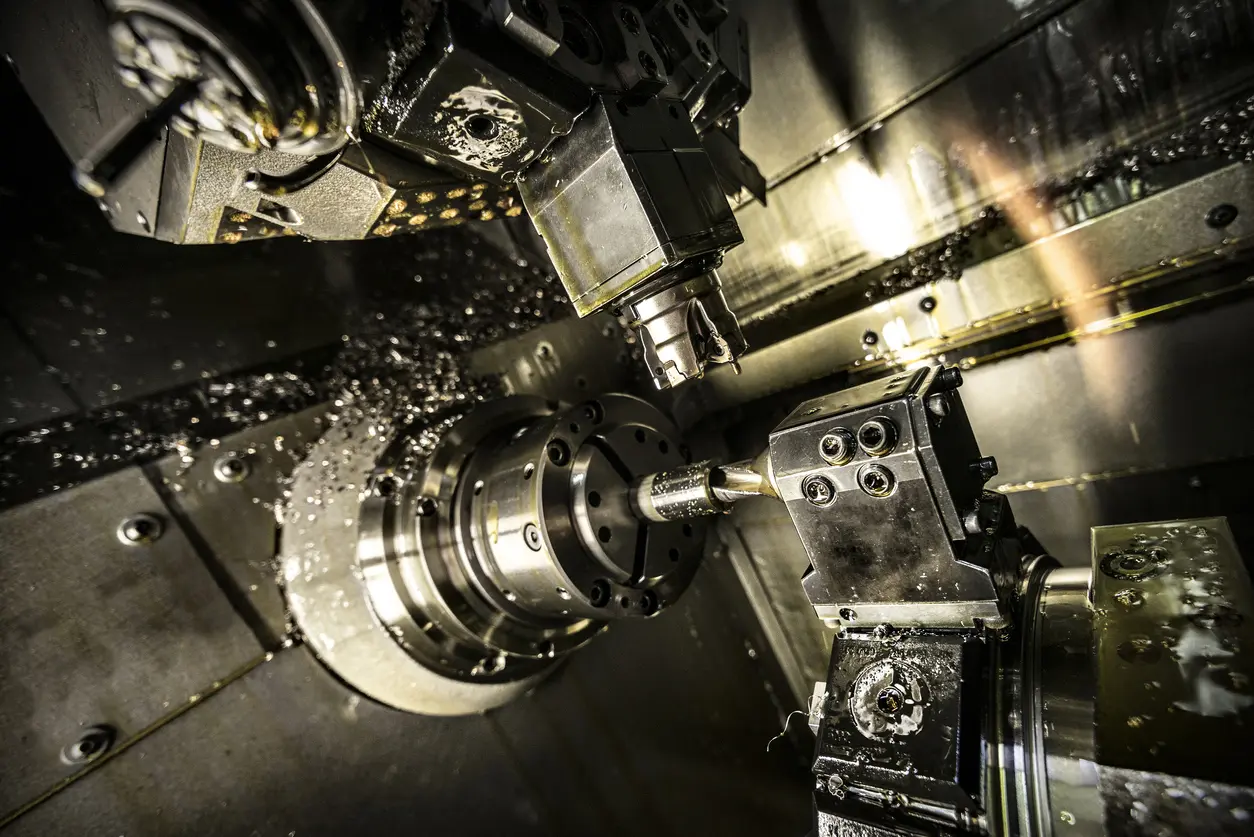

Wuxi Lead Precision Machinery delivers advanced metal cutting CNC solutions engineered for high-precision industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly enhancing machining efficiency and part integrity. By eliminating the need for multiple setups, we reduce human error, improve repeatability, and maintain tight tolerances across intricate components used in aerospace, medical, automotive, and energy sectors.

Our 5-axis CNC platforms are equipped with high-speed spindles, automatic tool changers, and real-time monitoring systems that ensure optimal cutting conditions and tool life. This advanced configuration supports a wide range of metals, including aluminum alloys, titanium, stainless steel, and hardened tool steels. Whether producing low-volume prototypes or high-volume production runs, our machines deliver consistent performance, minimizing cycle times while maximizing dimensional accuracy.

To guarantee the highest quality standards, every machined component undergoes rigorous inspection using Coordinate Measuring Machine (CMM) technology. Our CMM systems provide full 3D metrology verification, capturing thousands of data points to validate geometric dimensions and tolerances per ISO 1101 and ASME Y14.5 standards. This closed-loop quality control process ensures that each part conforms precisely to customer specifications and engineering drawings. Additionally, inspection reports are generated for full traceability, supporting compliance with industry-specific regulatory requirements.

Material utilization, toolpath optimization, and thermal compensation algorithms are integrated into our CNC programming workflow, further enhancing precision and process stability. Our engineering team employs advanced CAM software to simulate machining operations prior to production, identifying potential interference or deflection issues before any material is cut. This proactive approach reduces waste, accelerates time-to-market, and ensures first-time-right outcomes.

The combination of advanced machinery, skilled programming, and comprehensive quality assurance enables Wuxi Lead Precision Machinery to meet the most demanding technical challenges in precision metal cutting. We are committed to delivering components that not only meet but exceed expectations in performance, reliability, and consistency.

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Machining Centers |

| Spindle Speed | Up to 24,000 RPM |

| Travel Range (X/Y/Z) | 1,200 mm × 800 mm × 750 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Maximum Workpiece Weight | 1,500 kg |

| Typical Surface Finish | Ra 0.8 μm (as machined), down to Ra 0.2 μm with finishing |

| Standard Tolerances | ±0.01 mm (general), down to ±0.005 mm (precision) |

| Geometric Tolerances | ±0.01 mm (flatness, perpendicularity, true position) |

| Inspection System | Bridge-Type CMM with 0.5 + L/600 μm accuracy |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Tool Steel, Brass |

Material & Finish Options

Material Selection for Precision CNC Metal Cutting

Selecting the optimal material is foundational to achieving performance, cost efficiency, and longevity in precision CNC machined components. At Wuxi Lead Precision Machinery, our engineering team prioritizes matching material properties to your specific application demands, machining constraints, and finish requirements. Understanding the core characteristics of common aerospace, automotive, and industrial materials ensures the final part meets stringent functional and dimensional specifications. Aluminum, steel, and titanium represent the primary structural alloys, each offering distinct advantages and machining considerations that directly impact production time, tooling strategy, and final part cost.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate where high strength-to-weight ratio and excellent machinability are critical. 6061-T6 offers good corrosion resistance and weldability, machining efficiently at high speeds with sharp carbide tools, making it ideal for prototypes and structural housings. 7075-T6 provides superior strength for demanding applications like aerospace fittings but requires slower feed rates and meticulous chip control due to its higher hardness and tendency for built-up edge. Both alloys readily accept anodizing for enhanced surface durability and aesthetics. Steel variants, such as 4140 and 17-4 PH stainless, deliver exceptional strength, hardness, and wear resistance essential for high-stress components like shafts, gears, and tooling. Machining steel demands robust tooling, lower spindle speeds compared to aluminum, and precise coolant management to manage heat and prevent work hardening. Pre-hardened steels reduce post-machining distortion but increase tool wear rates significantly. Titanium alloys, notably Grade 5 (Ti-6Al-4V), are indispensable in extreme environments requiring unparalleled strength-to-weight ratio, corrosion resistance, and biocompatibility, such as medical implants and critical aerospace structures. However, titanium’s low thermal conductivity and high chemical reactivity necessitate specialized cutting strategies: very low speeds, high-pressure coolant, rigid setups, and specific tool geometries to avoid galling and excessive tool wear, directly influencing machining time and cost.

Surface finishing, particularly anodizing, is integral to aluminum component performance. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and dyeing capability for cosmetic or moderate-wear applications. For critical wear resistance, electrical insulation, or severe environmental exposure, Type III (Hardcoat) anodizing is essential. This process creates a significantly thicker, harder ceramic layer (typically 25-50 µm), dramatically improving surface durability while maintaining precise dimensional control – a capability Wuxi Lead Precision Machinery rigorously controls through in-house process validation. Selecting the correct anodizing type and thickness specification is as crucial as the base material choice.

Key Material Properties for CNC Machining

| Material | Density (g/cm³) | Tensile Strength (Min, ksi) | Typical Machinability Rating | Key Machining Considerations |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 45 | Excellent (100%) | High speeds, sharp tools, excellent chip control |

| Aluminum 7075-T6 | 2.8 | 83 | Good (70%) | Slower feeds, high coolant pressure, chip control |

| Steel 4140 (Annealed) | 7.85 | 95 | Moderate (65%) | Lower speeds, rigid setup, effective coolant |

| Steel 17-4 PH | 7.75 | 150 | Fair (50%) | Low speeds, high coolant, prone to work hardening |

| Titanium Ti-6Al-4V | 4.43 | 130 | Poor (20-30%) | Very low speeds, high coolant pressure, specialized tooling |

Partnering with Wuxi Lead ensures your material and finish selection leverages deep machining expertise. We analyze your functional requirements, production volume, and geometric complexity to recommend the optimal alloy and surface treatment, minimizing total cost while maximizing part performance and manufacturability from the initial design phase through final inspection.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our metal cutting CNC production process is engineered for precision, consistency, and zero-defect output. We adhere to a rigorous three-phase workflow—Design, Prototyping, and Mass Production—ensuring every component meets the highest standards of quality and performance expected in advanced manufacturing sectors such as aerospace, medical devices, and high-performance automation.

The process begins with Design, where our engineering team collaborates closely with clients to translate technical requirements into manufacturable solutions. Utilizing advanced CAD/CAM software, we develop detailed 3D models and generate optimized toolpaths tailored to the specific material and geometry of the part. Finite element analysis (FEA) and tolerance stack-up simulations are performed to anticipate stress points and ensure dimensional stability. This digital-first approach allows us to refine designs before any metal is cut, minimizing risk and maximizing efficiency.

Next comes Prototyping, a critical validation phase. Using our high-precision 5-axis CNC machining centers, we produce initial sample parts under actual production conditions. These prototypes undergo comprehensive metrological inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. We verify conformity to GD&T specifications, material integrity, and functional fit. Client feedback is integrated at this stage, and design adjustments are made if necessary. Only after full approval do we proceed to mass production.

Mass Production is executed on our automated CNC production lines, where process stability is maintained through real-time monitoring and statistical process control (SPC). Each machining station is equipped with tool wear sensors, coolant pressure regulation, and in-process gauging to detect deviations instantly. Our quality management system is ISO 9001-certified, and we enforce a zero-defect policy through 100% critical dimension inspection on key features and random sampling for secondary features per ANSI/ASQ Z1.4 standards.

All operators are trained in lean manufacturing principles and perform regular machine calibration checks. Barcoding and traceability systems ensure full part genealogy, from raw material batch to final inspection report. This closed-loop production model enables rapid corrective action and continuous improvement.

The following table outlines key specifications of our CNC metal cutting capabilities:

| Parameter | Specification |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC machining centers |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 1200 x 800 x 750 mm |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Engineering Plastics |

| Tolerance Range | ±0.01 mm (standard), down to ±0.003 mm (tight) |

| Surface Finish | Ra 0.4 µm to Ra 1.6 µm (as specified) |

| Production Capacity | 1 to 10,000+ units per order |

| Quality Standards | ISO 9001, ISO 13485 (medical), RoHS compliant |

Through disciplined execution and advanced technology, Wuxi Lead Precision Machinery delivers flawless CNC-machined components, on time and to exacting specifications.

Why Choose Wuxi Lead Precision

Elevate Your Precision Manufacturing Partnership

For global enterprises demanding uncompromising quality in metal cutting CNC solutions, Wuxi Lead Precision Machinery stands as your strategic manufacturing ally. With over 15 years of specialized expertise in high-tolerance CNC milling, turning, and multi-axis machining, we transform complex engineering challenges into flawless production realities. Our ISO 9001:2015 and AS9100D-certified facility in Wuxi, China, operates at the forefront of precision engineering, serving Tier-1 aerospace, medical device, and automotive innovators worldwide. Partnering with Lead Precision means eliminating supply chain vulnerabilities while achieving repeatable accuracy down to ±0.001mm—critical for components where failure is not an option.

We understand that your success hinges on more than just machinery; it requires a partner who anticipates technical roadblocks and delivers proactive engineering collaboration. Our team of degreed CNC engineers works directly with your design and production staff from prototyping through volume manufacturing, ensuring seamless integration of GD&T standards, material science expertise, and process validation. Unlike transactional suppliers, we implement rigorous First Article Inspection (FAI) protocols and real-time SPC data sharing, giving you full transparency into every micron of dimensional conformity. This commitment to collaborative precision has enabled clients to reduce scrap rates by 37% and accelerate time-to-market by 22% on average.

Technical Capabilities at a Glance

| Parameter | Specification | Industry Relevance |

|---|---|---|

| Positional Accuracy | ±0.001 mm | Critical for aerospace hydraulic manifolds |

| Surface Finish | Ra 0.2 µm (mirror-grade) | Medical implant biocompatibility |

| Max Work Envelope | 1,200 x 800 x 650 mm | Complex automotive powertrain housings |

| Material Range | Titanium, Inconel, PEEK, 4340 Steel | Extreme-environment applications |

| Process Control | Real-time CMM + SPC integration | Zero-defect batch validation |

Your next-generation components deserve manufacturing excellence rooted in empirical rigor, not promises. We invest in cutting-edge DMG MORI and Makino platforms with sub-micron repeatability because your reputation depends on parts that perform identically across 10,000 units. When competitors cut corners on secondary operations, our integrated deburring, passivation, and metrology suites ensure end-to-end quality control—delivering fully finished components ready for assembly.

Initiate your precision partnership today by contacting our engineering team directly at [email protected]. Include your technical drawings and production requirements for a customized capability assessment within 24 hours. Specify your target tolerance class and volume needs to receive a detailed process flow analysis with yield projections. For urgent RFQs, reference code LEAD-CNC24 to expedite technical review.

Wuxi Lead Precision Machinery doesn’t just meet specifications—we redefine what’s achievable in metal cutting CNC. Let our precision become your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.