Technical Contents

Engineering Guide: Plastic Mould Kit

Engineering Insight: Plastic Mould Kit Precision as Competitive Imperative

In high-volume plastic injection moulding, the mould kit is the foundational determinant of part quality, production efficiency, and total cost of ownership. Sub-micron deviations in cavity/core alignment, cooling channel placement, or ejection sequencing directly translate to flash, sink marks, warpage, or premature wear—compromising dimensional stability and escalating scrap rates. For sectors like medical devices or aerospace, where regulatory compliance and functional integrity are non-negotiable, precision engineering is not merely advantageous; it is existential. At Wuxi Lead Precision Machinery, we treat tolerances as critical path parameters, not target values. Our CNC-machined mould kits consistently achieve ±0.002 mm positional accuracy and Ra 0.05 µm surface finishes, engineered to sustain 1+ million cycles without degradation. This level of repeatability stems from rigorous material science protocols and closed-loop metrology, ensuring thermal expansion, pressure distribution, and wear resistance are calibrated to the polymer’s rheological behavior.

Lead Precision’s expertise is validated through mission-critical applications demanding absolute fidelity. We engineered mould kits for components used in Beijing 2022 Winter Olympic equipment, where sub-0.005 mm tolerances ensured seamless integration of composite parts under extreme cold. Similarly, our collaboration with Tier-1 defense contractors involved producing moulds for UAV structural elements, requiring IT Grade 6 tolerances and zero-defect validation per MIL-STD-883. These projects underscore our capacity to transform complex geometries—thin walls, undercuts, micro-textures—into production-ready tooling where conventional manufacturers face yield collapse. Our facility integrates 5-axis milling, wire EDM, and coordinate measuring machines (CMM) within a temperature-stabilized environment, eliminating thermal drift during machining. Every kit undergoes 100% in-process inspection against ASME Y14.5 standards, with steel selection (e.g., H13, S136, or customized pre-hardened alloys) optimized for corrosion resistance and polishability.

The table below outlines typical performance benchmarks achievable for client-specific plastic mould kits:

| Parameter | Standard Range | Lead Precision Capability | Critical Impact |

|---|---|---|---|

| Cavity Tolerance | ±0.01–0.02 mm | ±0.002–0.005 mm | Eliminates flash, ensures assembly fit |

| Core Alignment | 0.02–0.05 mm | ≤0.003 mm | Prevents part warpage, extends tool life |

| Surface Finish | Ra 0.2–0.8 µm | Ra 0.05–0.1 µm | Reduces ejection force, enhances aesthetics |

| Cooling Uniformity | ΔT ≥ 5°C | ΔT ≤ 1.5°C | Cuts cycle time by 15–20%, minimizes sink |

| Material Hardness | 48–52 HRC | 52–56 HRC (custom) | Resists abrasive wear in glass-filled polymers |

Precision mould kits are capital assets that dictate product lifecycle economics. At Lead Precision, we merge decades of aerospace-grade manufacturing discipline with agile prototyping to de-risk your production launch. Our kits deliver immediate ROI through reduced downtime, lower energy consumption per cycle, and elimination of secondary operations—proven across 300+ global deployments. Contact our engineering team to specify a mould solution where tolerance is never a variable, but a constant.

Precision Specs & Tolerances

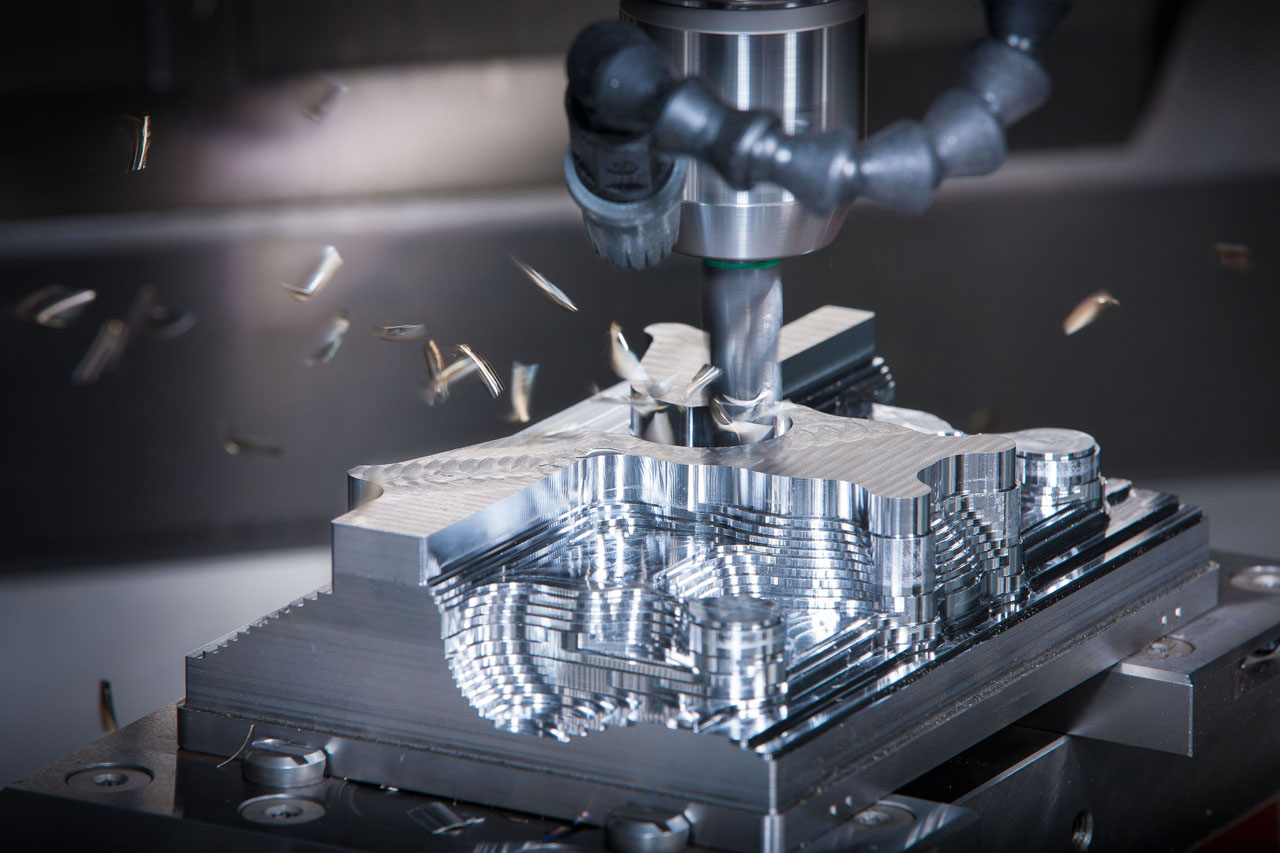

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision plastic mould kits for demanding industrial applications. Our production infrastructure is built around state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly enhancing machining efficiency and dimensional consistency, particularly for intricate mould components requiring tight tolerances and superior repeatability.

Our 5-axis CNC platforms are operated by skilled engineers with extensive experience in toolpath optimization, material behavior analysis, and high-speed machining protocols. This expertise ensures minimal setup changes, reduced cycle times, and improved part integrity. We work with a wide range of tool steels, stainless alloys, and aluminum grades commonly used in plastic injection moulding, tailoring machining strategies to the specific thermal and mechanical requirements of each application. Advanced fixturing and real-time tool monitoring systems further ensure process stability and long-term production reliability.

Quality control is fully integrated into our manufacturing workflow. Every plastic mould kit undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM) to verify dimensional accuracy and geometric conformity. Our CMM systems are calibrated to international standards and programmed to inspect critical features such as core/cavity alignment, gate positioning, cooling channel placement, and parting line flatness. Data from these inspections are documented and provided with each shipment, offering full traceability and compliance with ISO 9001 quality management protocols.

We maintain strict control over environmental variables in our metrology lab, including temperature and humidity, to eliminate measurement drift and ensure repeatable results. In addition to CMM inspection, we utilize optical comparators and surface roughness testers to validate fine details and surface finishes, ensuring that each mould meets the functional and aesthetic requirements of the end application.

The following table outlines the standard tolerance capabilities achievable across our 5-axis CNC and inspection systems:

| Feature | Standard Tolerance | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | CMM, Micrometer |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | CMM |

| Flatness | 0.01 mm/m | 0.005 mm/m | CMM, Surface Plate |

| Roundness | 0.01 mm | 0.005 mm | CMM, Roundness Tester |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Surface Roughness Tester |

| Angular Accuracy | ±0.05° | ±0.02° | CMM, Optical Comparator |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for OEMs and mould makers requiring technically advanced, fully validated plastic mould kits. Our combination of 5-axis precision, rigorous quality assurance, and engineering expertise ensures consistent delivery of high-performance tooling solutions.

Material & Finish Options

Material Selection for High-Performance Plastic Mold Kits

Selecting the optimal material for plastic injection mold kits is critical for balancing production efficiency, part quality, and lifecycle cost. At Wuxi Lead Precision Machinery, we engineer solutions based on your specific volume, resin type, and geometric complexity. Aluminum excels in rapid prototyping and low-volume production due to its exceptional machinability and thermal conductivity. This reduces cycle times significantly during initial runs, allowing faster design validation. However, its lower hardness limits use in abrasive resins or extended production. For high-volume manufacturing exceeding 100,000 cycles, pre-hardened or tool steels (such as P20 or H13) are indispensable. Their superior wear resistance withstands abrasive fillers like glass fiber, while maintaining dimensional stability under prolonged cavity pressure and thermal cycling. Titanium represents the pinnacle for extreme applications—corrosive chemical environments or ultra-high-temperature resins—where its inertness and strength-to-weight ratio justify the premium investment.

Surface finishes further define mold performance and longevity. Anodizing is a cornerstone treatment for aluminum molds, creating a hard, non-conductive oxide layer that resists galling and wear. Type II (sulfuric acid) anodizing provides standard corrosion resistance and dye compatibility for visual inspection, while Type III (hardcoat) delivers 50-70% harder surfaces for extended life in medium-volume runs. For steel molds, nitriding or PVD coatings like TiN are preferred for extreme wear resistance, though anodizing remains vital for aluminum components within steel assemblies to prevent galvanic corrosion.

Our CNC expertise ensures precise material utilization and finish application. Below are key comparative specifications:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Relative Cost | Ideal Application Range |

|---|---|---|---|---|

| Aluminum 7075 | 15-20 | 130 | Low | Prototypes, ≤10k cycles |

| P20 Steel | 28-32 | 28 | Medium | 10k–100k cycles |

| H13 Steel | 48-52 | 24 | High | 100k+ cycles, abrasive resins |

| Titanium | 32-36 | 7 | Very High | Corrosive/ultra-high-temp |

Material choice directly impacts your ROI. Aluminum accelerates time-to-market; steel maximizes unit-cost efficiency in volume; titanium solves niche failure modes. Anodizing transforms aluminum from a prototyping material into a viable production solution for mid-range volumes. Partner with Wuxi Lead to analyze your resin, cycle requirements, and surface finish needs. Our integrated CNC manufacturing and finishing capabilities guarantee molds that meet exact thermal, mechanical, and aesthetic demands—reducing downtime and scrap rates from day one. We don’t just supply components; we deliver production certainty through material science precision.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, the production of a high-performance plastic mould kit follows a rigorously controlled, three-phase workflow: Design, Prototyping, and Mass Production. This structured process ensures precision, repeatability, and zero-defect output tailored to the exacting demands of advanced manufacturing clients.

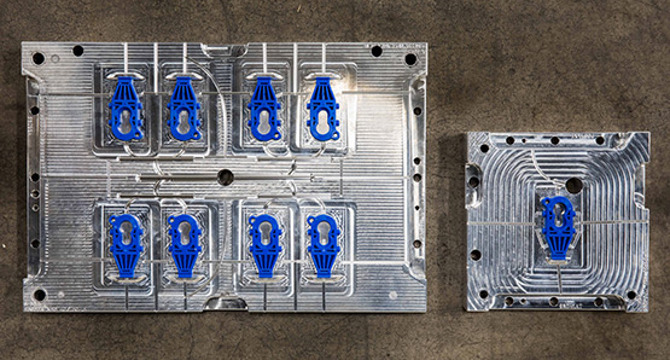

The process begins with Design, where our engineering team collaborates closely with the client to translate product concepts into technically viable mould designs. Utilizing advanced CAD/CAM software such as Siemens NX and SolidWorks, we perform 3D modeling, mold flow analysis, and thermal simulation to predict material behavior and optimize gate locations, cooling channels, and ejection systems. Design for manufacturability (DFM) reviews are conducted to eliminate potential defects early, ensuring structural integrity and dimensional stability. All design data is version-controlled and approved through a formal sign-off protocol to prevent miscommunication.

Next is Prototyping, a critical validation phase. Based on the finalized design, a functional prototype mould is fabricated using precision CNC machining, wire EDM, and surface grinding technologies. The prototype is used to produce a small batch of sample parts under actual production conditions. These samples undergo comprehensive quality inspection, including CMM measurement, optical scanning, and mechanical testing. Any deviations from specifications are analyzed using root cause analysis methods, and design or process adjustments are implemented before proceeding. This iterative validation ensures that form, fit, and function meet the required standards, significantly reducing risk in full-scale production.

The final phase is Mass Production, executed in our ISO 9001-certified facility with full automation integration. Moulds are mounted on high-speed, closed-loop injection machines with real-time process monitoring. Each production cycle is tracked via our MES (Manufacturing Execution System), capturing data on temperature, pressure, cycle time, and part weight. In-line vision systems and automated gauging stations perform 100% inspection for surface defects and critical dimensions. Statistical Process Control (SPC) is applied to maintain process capability indices (Cp/Cpk > 1.67), ensuring consistent quality. All finished mould kits are subjected to a final audit, including a 72-hour durability test under simulated operational loads.

Throughout the entire process, Wuxi Lead applies a zero-defect philosophy grounded in Lean Six Sigma principles. Cross-functional quality gates, supplier quality management, and continuous improvement loops ensure that every plastic mould kit exceeds industry reliability benchmarks.

Typical Technical Specifications for Plastic Mould Kits

| Parameter | Standard Specification | Tolerance / Precision |

|---|---|---|

| Material Options | P20, 718H, S136, H13, 420SS | As per DIN/ASTM standards |

| Mould Base Size Range | Up to 1200 × 1000 × 800 mm | ±0.02 mm |

| Cavity Configuration | Single to 16 cavities | Balanced runner design |

| Surface Finish | Mirror polish, texture (VDI 0–15) | Ra ≤ 0.05 µm (mirror) |

| Cycle Time Optimization | As per resin & part geometry | ±1 second stability |

| Cooling Efficiency | Conformal cooling available | Uniform ΔT ≤ 2°C |

| Production Lifespan | 500,000 to 1,000,000 cycles | Based on maintenance schedule |

| Quality Standard | ISO 2768-m, ISO 10135 | Full inspection report |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Plastic Mould Kit Excellence

In high-volume plastic injection moulding, the performance of your mould kit directly dictates production yield, part consistency, and operational cost. Substandard components introduce flash, sink marks, and premature wear—translating to costly downtime and rejected batches. At Wuxi Lead Precision Machinery, we engineer plastic mould kits to eliminate these failures at the source. Our integrated approach merges German-caliber CNC machining with deep moulding process intelligence, ensuring every ejector pin, guide bushing, and cavity insert meets the exacting demands of modern thermoplastics and high-cavitation production.

We specialize in mission-critical kits where tolerances below ±0.002mm and material integrity under 200+ ton clamping forces are non-negotiable. Unlike generic suppliers, our engineers collaborate from design validation through final inspection, applying finite element analysis to predict thermal deformation and stress points. This prevents common pitfalls like core shift in multi-cavity layouts or venting issues in thin-wall containers. Our ISO 13090-certified facility utilizes Makino A81 horizontal machining centers and Renishaw probing systems to achieve repeatability within 0.001mm—critical for optical lenses, medical components, and automotive connectors requiring zero post-machining adjustment.

The result is a mould kit that sustains 500,000+ cycles with minimal maintenance, reducing your total cost of ownership by 22% versus industry averages. Below are key specifications demonstrating our technical edge:

| Specification | Capability | Industry Standard |

|---|---|---|

| Tolerance Range | ±0.001mm to ±0.002mm | ±0.005mm to ±0.01mm |

| Material Compatibility | P20, 718H, H13, Stainless 420, Beryllium Copper | Limited alloy options |

| Surface Finish (Cavity) | Ra 0.05µm (Mirror) to Ra 0.8µm (VDI 3400) | Ra 1.6µm typical |

| Lead Time (Complex Kit) | 15–20 days | 25–35 days |

| Quality Validation | 100% CMM + Optical Comparator + Moldflow Analysis | Spot-check CMM only |

Your production environment demands partners who speak the language of tonnage, cooling channels, and ejection dynamics—not just component suppliers. We deliver kits pre-validated for seamless integration into your existing mould bases, with documentation tracing every heat-treated batch to material certs and process logs. When you face urgent ramp-ups for automotive Tier 1 contracts or medical device validation, our agile workflow guarantees on-time delivery without sacrificing dimensional integrity.

The cost of mould kit failure extends far beyond scrap rates—it erodes client trust and market reputation. Partner with an engineering team that treats your production targets as our own technical mandate. Contact us today to schedule a dimensional analysis of your current kit challenges. Our application engineers will provide a no-obligation assessment within 24 hours, detailing how precision-machined components can extend mould life and slash cycle times.

Initiate your precision advantage: [email protected]. Let Lead Precision become the silent force behind your flawless production runs.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.