Technical Contents

Engineering Guide: Quality Injection Mold

Engineering Insight: The Critical Role of Precision in Quality Injection Molds

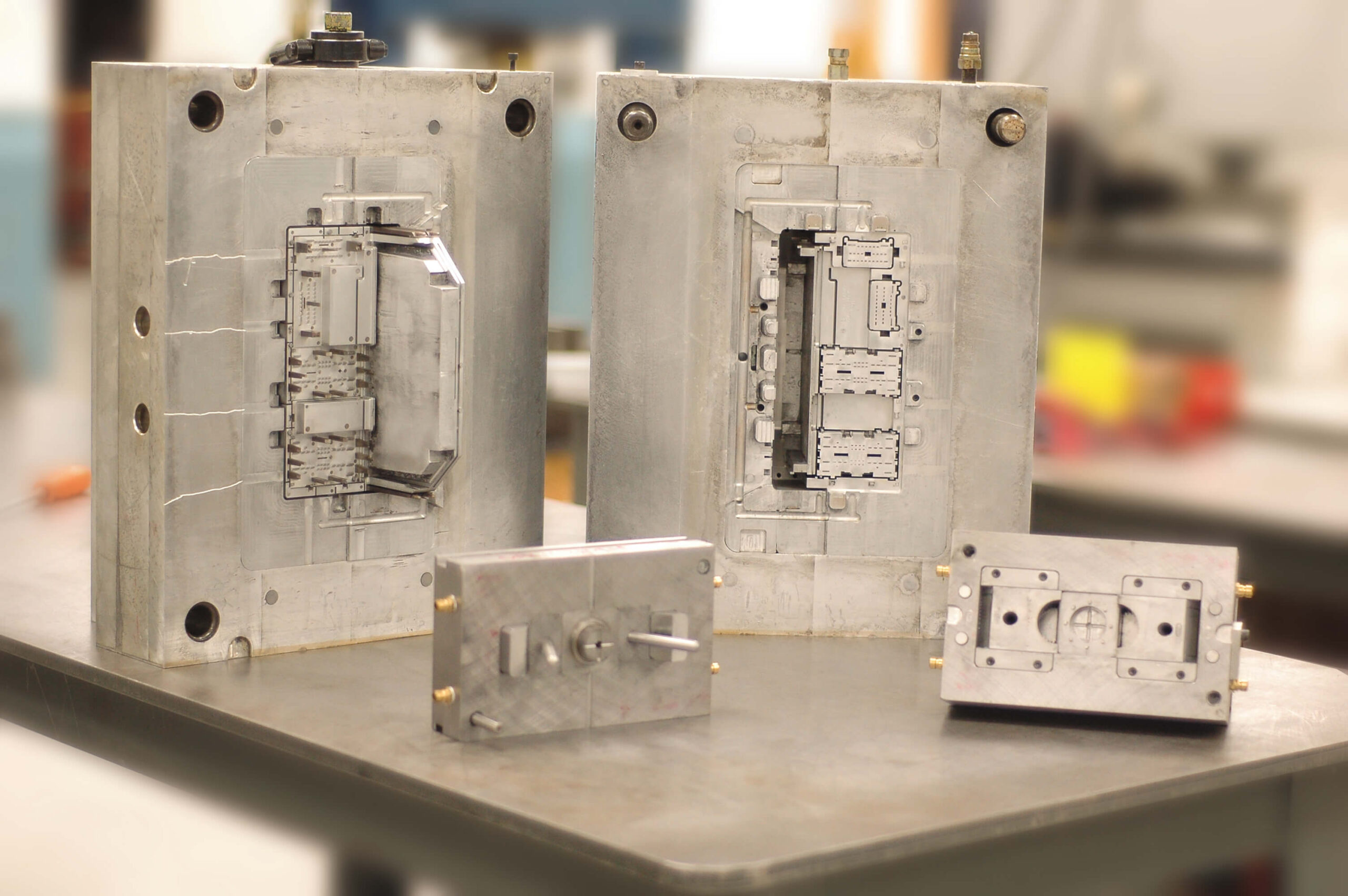

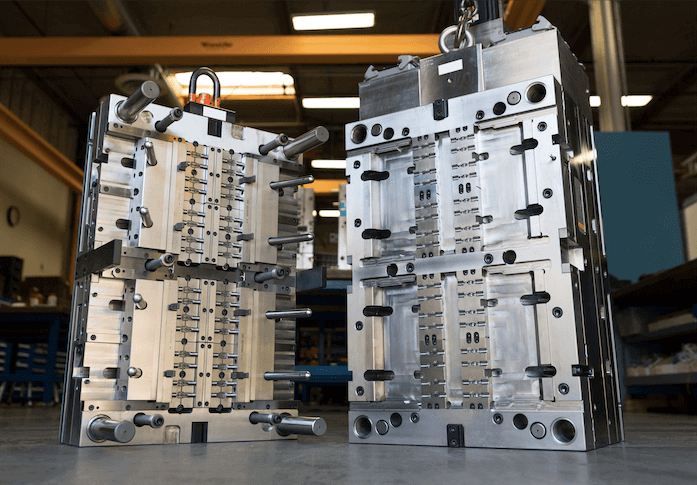

In the realm of custom metal manufacturing, the injection molding process serves as a cornerstone for high-volume, repeatable production of complex components. However, the success of any injection molding operation hinges on one foundational element: precision. At Wuxi Lead Precision Machinery, we understand that a quality injection mold is not merely a tool—it is an engineered system where micron-level tolerances directly influence part consistency, material performance, and production efficiency. Even minor deviations in mold geometry can propagate into significant defects such as flash, warpage, or dimensional instability, leading to costly rework and downtime.

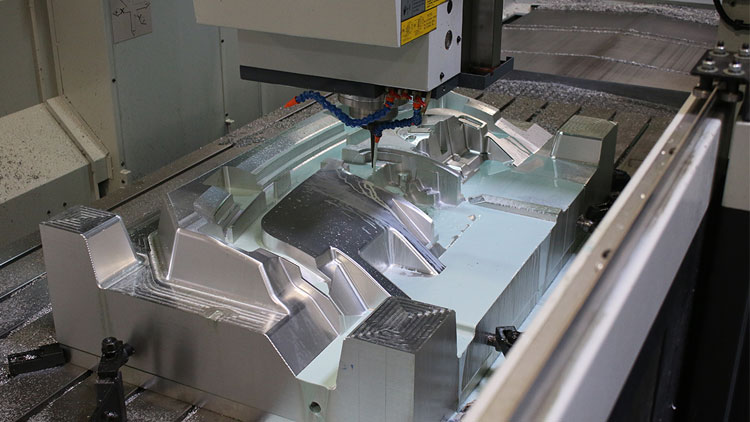

Precision in mold manufacturing begins with advanced CNC machining, supported by rigorous metrology and thermal stability control. Our facility in Wuxi integrates 5-axis milling, electrical discharge machining (EDM), and high-speed finishing techniques to achieve surface finishes below Ra 0.2 µm and tolerances within ±0.002 mm. This level of accuracy ensures uniform cavity filling, optimal gate performance, and minimal cycle time variability—critical factors in industries where reliability is non-negotiable.

Our expertise in precision engineering has been validated through mission-critical applications. Wuxi Lead has contributed to components used in Olympic-grade sporting equipment, where material integrity and dimensional repeatability directly impact athletic performance. Additionally, our molds have supported defense-sector projects requiring compliance with MIL-STD specifications, underscoring our capability to meet the most stringent quality and durability standards. These experiences reinforce our philosophy: a quality injection mold must perform consistently across thousands, if not millions, of cycles without degradation.

Material selection and thermal management further define mold longevity and output quality. We employ high-grade tool steels such as H13, S136, and NAK80, chosen based on corrosion resistance, hardness, and thermal conductivity requirements. Integrated conformal cooling channels—designed using mold flow simulation—are machined with precision to ensure uniform heat extraction, reducing cycle times by up to 30% while minimizing internal stresses in the final part.

The table below outlines key specifications achievable at Wuxi Lead Precision Machinery for custom injection molds:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish (Cavity/Core) | Ra 0.05 – 0.4 µm |

| Maximum Mold Weight | 15,000 kg |

| Mold Base Materials | LKM, FUTABA, DAIDO, or customer-specified |

| Lead Time (Average) | 4–8 weeks, depending on complexity |

| Compatible Plastics | PEEK, PC, ABS, POM, PP, PA6/66, and engineered composites |

At Wuxi Lead Precision Machinery, we combine decades of technical experience with state-of-the-art manufacturing systems to deliver injection molds that exceed industry benchmarks. Precision is not an outcome—it is our standard.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Injection Mold Excellence

Wuxi Lead Precision Machinery delivers uncompromising quality in custom metal manufacturing for high-performance injection molds. Our integrated technical capabilities combine advanced machinery, rigorous process control, and deep engineering expertise to meet the most demanding specifications of global automotive, medical, and consumer electronics clients. We specialize in transforming complex designs into production-ready mold components where dimensional accuracy, surface integrity, and material performance are non-negotiable.

Precision Machining Capabilities

Central to our operation is a dedicated fleet of state-of-the-art 5-axis CNC machining centers, including DMG MORI CTX beta 1250 and Hermle C400 U milling machines. These platforms enable the efficient production of intricate mold bases, cavities, cores, sliders, and lifters in a single setup, eliminating cumulative errors from multiple fixtures. Our programming leverages Siemens NX CAM for optimized toolpaths, achieving complex undercuts and organic contours with exceptional surface finishes down to Ra 0.2 µm. This capability significantly reduces lead times while ensuring geometric precision critical for part ejection, venting, and weld line control in the final molded product. All machining processes adhere to strict environmental controls within our temperature-stabilized facility, maintaining consistent thermal conditions for micron-level repeatability.

Comprehensive Quality Control Framework

Every component undergoes a multi-stage quality verification protocol anchored by Zeiss CONTURA G3 and Wenzel LH877 coordinate measuring machines (CMM). Our AS9100 and ISO 17025 accredited metrology lab performs full 3D dimensional analysis against CAD models, verifying critical features such as parting line alignment, cooling channel positioning, and tolerance zones. CMM inspection reports provide traceable, GD&T-compliant data with uncertainty budgets documented per ISO/IEC 17025. Beyond dimensional checks, we implement in-process laser scanning for first-article validation and final hardness testing using Wilson Rockwell testers to confirm material properties meet specification. This systematic approach ensures 100% of delivered mold components conform to print requirements before assembly.

The following table details our standard and achievable tolerance capabilities for critical mold features across common tool steel grades:

| Feature Category | Material | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|---|

| Core/Cavity Dimensions | P20, H13, S7 | ±0.010 mm | ±0.003 mm |

| Slider/Insert Fit | Pre-hardened Steels | ±0.005 mm | ±0.0015 mm |

| Cooling Channel Location | All Mold Steels | ±0.05 mm | ±0.02 mm |

| Parting Line Flatness | Mold Bases | 0.02 mm/m | 0.005 mm/m |

| Ejector Pin Holes | Hardened Steels | H7 (±0.007 mm) | F7 (±0.003 mm) |

Our technical capabilities are not merely about equipment specs; they represent a commitment to solving your toughest molding challenges. By integrating 5-axis precision with metrology-grade verification, Wuxi Lead ensures your injection molds achieve superior longevity, reduced cycle times, and zero-defect production from day one. Partner with us for mold components where every micron contributes to your manufacturing success. Precision engineered for performance.

Material & Finish Options

Material Selection for High-Precision Injection Molds

Selecting the appropriate material for injection molds is critical to ensuring longevity, dimensional accuracy, and surface quality in high-volume production environments. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for precision injection molds, leveraging advanced metallurgical expertise to match material properties with application demands. The most commonly used materials—aluminum, steel, and titanium—each offer distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum alloys, particularly 7075 and 6061, are favored for prototype and low-to-medium volume production due to their excellent machinability and thermal conductivity. These properties allow faster cycle times and reduced wear during initial production runs. While aluminum lacks the hardness of steel, modern anodizing techniques significantly enhance surface durability and corrosion resistance. For applications requiring rapid turnaround and cost efficiency, aluminum remains a strategic choice.

Tool steels such as P20, H13, and S136 are the standard for high-volume injection molding. These steels offer superior hardness, wear resistance, and thermal stability, ensuring mold integrity over hundreds of thousands of cycles. P20 is commonly used for general-purpose molds, while H13 excels in applications involving high thermal cycling due to its exceptional toughness. Stainless variants like S136 provide added corrosion resistance, making them ideal for molds exposed to abrasive or chemically aggressive materials. Steel molds, though more expensive and time-consuming to machine, deliver unmatched longevity and precision in demanding industrial settings.

Titanium and its alloys, while less common in standard mold construction, are gaining traction in specialized aerospace and medical applications. Titanium offers an exceptional strength-to-density ratio and outstanding resistance to corrosion and thermal deformation. However, its high cost and challenging machinability limit its use to niche applications where weight reduction and extreme environmental resilience are paramount.

Surface finishing, particularly anodizing, plays a vital role in enhancing mold performance. Anodizing aluminum increases surface hardness, improves wear resistance, and allows for color coding through dye integration. Hard anodizing, in particular, can produce a ceramic-like surface layer capable of withstanding significant mechanical stress. For steel molds, alternative finishes such as chrome plating or nitriding are typically preferred, though anodizing may be applied in hybrid systems where aluminum components interface with steel cores.

Below is a comparative overview of key material properties relevant to injection mold performance.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 130 | Moderate (improved with anodizing) | Prototypes, low-volume runs |

| P20 Steel | 28–32 | 30 | Low to moderate | Medium-to-high volume molds |

| H13 Steel | 48–52 | 35 | Moderate | High-temperature molding |

| S136 Steel | 50–54 | 25 | High (stainless) | Corrosive environments |

| Titanium Ti-6Al-4V | 35–40 | 7 | Excellent | Aerospace, medical molds |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on production goals, budget, and environmental factors, ensuring optimal performance and return on investment.

Manufacturing Process & QC

Precision Injection Mold Production: The Zero Defects Pathway

Achieving true quality in injection molding demands an integrated, non-negotiable commitment to zero defects from initial concept through high-volume output. At Wuxi Lead Precision Machinery, our production process is engineered as a closed-loop system where Design, Prototyping, and Mass Production phases are intrinsically linked by rigorous validation and continuous data feedback, eliminating tolerance stack-up and process drift before they impact your parts.

The foundation is our advanced Design phase. We move beyond basic CAD modeling, employing comprehensive Mold Flow Analysis (MFA) and Finite Element Analysis (FEA) to simulate material behavior, cooling dynamics, and structural stresses under actual production conditions. This virtual validation identifies potential weaknesses like weld lines, sink marks, or ejection issues before metal is cut. Crucially, our Design for Manufacturability (DFM) review involves direct collaboration between your engineering team and our mold designers, ensuring cavity/core geometry, gating strategy, and material selection align precisely with your part’s functional requirements and dimensional tolerances. This upfront investment prevents costly revisions later and establishes the blueprint for defect elimination.

Prototyping is not merely a formality; it is the critical stress test of our design integrity. Utilizing high-speed CNC machining and precision EDM, we produce functional prototype molds in hardened tool steel, mirroring the final production tool’s material and construction. These prototypes undergo rigorous trial runs on production-specification injection molding presses. Every parameter – melt temperature, injection speed, packing pressure, cooling time – is meticulously logged and correlated against the MFA predictions. Dimensional inspection of prototype parts uses CMM and optical comparators against your GD&T drawings, validating critical features. Any deviation triggers immediate root cause analysis and mold adjustment, refining the process window before committing to mass production tooling. This phase ensures the mold geometry and process parameters are proven for repeatability.

Mass Production leverages the validated process parameters and refined tooling. Our production cells operate under stringent Statistical Process Control (SPC), with real-time monitoring of cavity pressure, temperature profiles, and cycle times. Automated vision systems perform 100% in-process inspection on critical dimensions for high-risk features. The mold itself incorporates advanced sensor technology for predictive maintenance, monitoring wear on critical components like ejector pins and sliders. Continuous data streams feed into our central quality management system, enabling immediate corrective action if any parameter approaches its control limit, guaranteeing every part meets specification. This closed-loop control, built on the foundation of validated design and prototyping, is the essence of our zero defects commitment.

The following specifications define the precision achievable within our controlled production environment:

| Critical Parameter | Production Standard | Measurement Method | Control Limit (SPC) |

|---|---|---|---|

| Cavity Dimensional Accuracy | ±0.005 mm (±0.0002″) | CMM (Calibrated to ISO 17025) | ±0.008 mm |

| Mold Temperature Uniformity | ≤ ±1.5°C (±2.7°F) across cavity surface | Embedded Thermocouples / IR Scan | ≤ ±2.5°C |

| Cavity Pressure Monitoring | Real-time per cavity (0.1% resolution) | Piezoelectric Sensors | ±3% of setpoint |

| Part Dimensional Repeatability | Cp/Cpk ≥ 1.67 on critical features | Automated Vision / CMM Sampling | Cp/Cpk ≥ 1.33 |

This integrated approach transforms quality from an inspection outcome into an inherent characteristic of the manufacturing process. By rigorously validating at each stage and leveraging real-time data for proactive control, Wuxi Lead ensures your injection molded components deliver consistent performance, minimize scrap, and maximize your operational ROI. The path to zero defects begins with precise design and unwavering process discipline.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Quality in Injection Mold Manufacturing

When precision, durability, and consistency define your production requirements, partnering with a trusted leader in custom metal manufacturing becomes essential. At Wuxi Lead Precision Machinery, we specialize in delivering high-performance injection molds engineered to meet the exacting standards of global industries, including automotive, medical, electronics, and consumer goods. Our commitment to excellence is reflected in every phase of development—from initial design and material selection to final inspection and delivery.

With over 15 years of experience in CNC machining, mold fabrication, and precision engineering, we bring deep technical expertise to every custom project. Our in-house team of engineers and technicians works closely with clients to optimize mold design for manufacturability, longevity, and cost-efficiency. Utilizing advanced CAD/CAM software and state-of-the-art CNC machining centers, we ensure micron-level accuracy and repeatability across all production runs.

We understand that a high-quality injection mold is not just a tool—it is a long-term investment in product consistency and production efficiency. That’s why we use premium-grade tool steels such as P20, 718H, NAK80, and H13, selected based on your application’s thermal, wear, and corrosion resistance needs. Each mold undergoes rigorous quality control, including hardness testing, surface finish verification, and trial molding, to guarantee flawless performance on your production floor.

Our manufacturing capabilities are supported by a fully integrated quality management system certified to ISO 9001:2015 standards. From prototype development to high-volume production tooling, we maintain strict process controls and documentation to ensure full traceability and compliance.

Below are key technical specifications that define our injection mold manufacturing capabilities:

| Specification | Capability |

|---|---|

| Maximum Mold Size | 1200 mm × 800 mm × 900 mm |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.05 µm to Ra 1.6 µm (polished, textured, or as-machined) |

| Materials | P20, 718H, NAK80, H13, S136, 420SS, and custom alloys |

| Machining Equipment | 3-axis, 4-axis, and 5-axis CNC, EDM, Wire-Cutting, Grinding |

| Lead Time | 4–8 weeks (depending on complexity) |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP available |

At Wuxi Lead Precision Machinery, we don’t just manufacture molds—we build long-term partnerships grounded in reliability, transparency, and technical excellence. Whether you require a single-cavity prototype mold or a multi-cavity production system, we deliver solutions that enhance your operational efficiency and product quality.

Contact us today to discuss your next injection mold project. Our engineering team is ready to support you with technical consultation, design feedback, and a competitive quotation tailored to your specifications.

Email us at [email protected] and discover how Wuxi Lead Precision Machinery can become your strategic manufacturing partner in China.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.