Technical Contents

Engineering Guide: Cnc Machine’

Engineering Insight The Non-Negotiable Imperative of Precision in CNC Machining

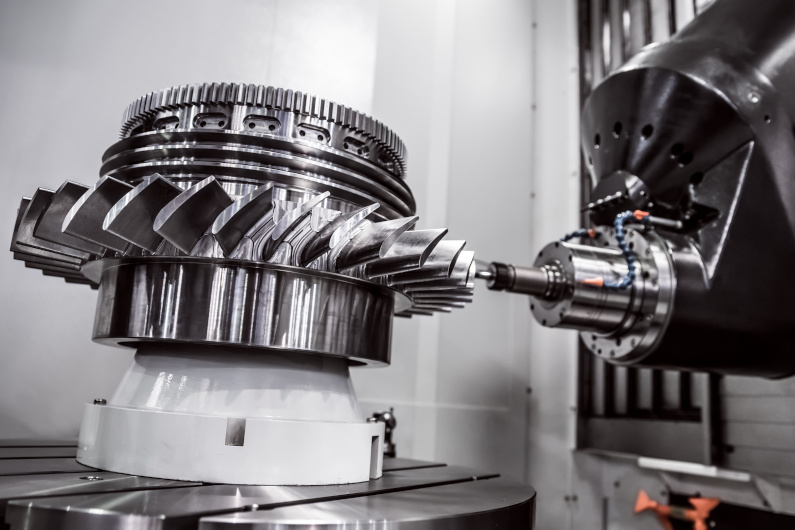

In high-stakes manufacturing sectors aerospace defense energy and advanced medical devices the term “precision” transcends mere specification it defines product viability safety and ultimate market success. Modern CNC machines are the bedrock of this capability yet their true value is realized only when micron-level accuracy is consistently achieved and maintained. Tolerances measured in thousandths of a millimeter are not academic exercises; they directly impact component fatigue life assembly integrity thermal performance and regulatory compliance. A variance of 0.005mm in a turbine blade airfoil can cascade into catastrophic efficiency loss or failure. Similarly in medical implants dimensional drift compromises biocompatibility and patient safety. The economic consequences of inadequate precision are severe: scrap rates soar assembly lines stall recalls devastate reputations and certification is jeopardized. Precision is not a feature—it is the fundamental prerequisite for operational excellence in critical applications.

Wuxi Lead Precision Machinery operates at this demanding frontier. Our engineering philosophy centers on embedding precision into every machine axis control algorithm and thermal management system from initial design through rigorous validation. This commitment is proven in mission-critical projects where failure is inconceivable. We engineered components for Beijing Winter Olympics venue infrastructure demanding seamless structural integration under extreme environmental loads. More significantly our certified facilities consistently deliver parts meeting stringent military specifications where dimensional stability under vibration temperature extremes and decades-long service life are non-negotiable. This experience shapes our entire approach: understanding that precision must be repeatable across batches sustainable over machine lifetime and verifiable to the most exacting audit standards.

Achieving such tolerances requires more than advanced hardware. It demands holistic system integration—high-rigidity cast iron frames with finite element analysis optimization direct-drive spindles with sub-micron runout compensation real-time thermal error correction and closed-loop feedback systems operating at nanometer resolution. Material science expertise is equally vital to predict and counteract internal stresses during machining. Our decades of refinement in these areas ensure clients receive not just a machine but a guaranteed output capability. The table below outlines core precision metrics defining our high-end machining platforms:

| Parameter | Specification | Industry Standard Context |

|---|---|---|

| Positioning Accuracy | ±0.002 mm | Typical high-end: ±0.005 mm |

| Repeatability | ±0.001 mm | Typical high-end: ±0.003 mm |

| Thermal Compensation | < 2μm over 8 hours | Critical for 24/7 production |

| Volumetric Accuracy | < 5μm over 500 mm | Essential for complex 5-axis work |

Precision engineering is the cornerstone of reliable performance and competitive advantage. At Wuxi Lead Precision Machinery we translate Olympic-grade and military-proven expertise into tangible manufacturing outcomes for global industry leaders. Our machines deliver the unwavering accuracy that transforms design intent into flawless physical reality—ensuring your components perform exactly as engineered under the most demanding conditions. This is the standard upon which critical industries depend and the commitment we engineer into every solution.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, engineered to meet the stringent demands of high-performance industries such as aerospace, medical, energy, and advanced automation. At the core of our manufacturing excellence is a fully integrated 5-axis CNC machining platform, enabling the production of complex geometries with superior accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis CNC machines allow simultaneous movement across five planes, significantly reducing setup times and enabling single-operation machining of intricate components. This capability ensures tighter tolerances, improved part consistency, and reduced risk of human error during repositioning.

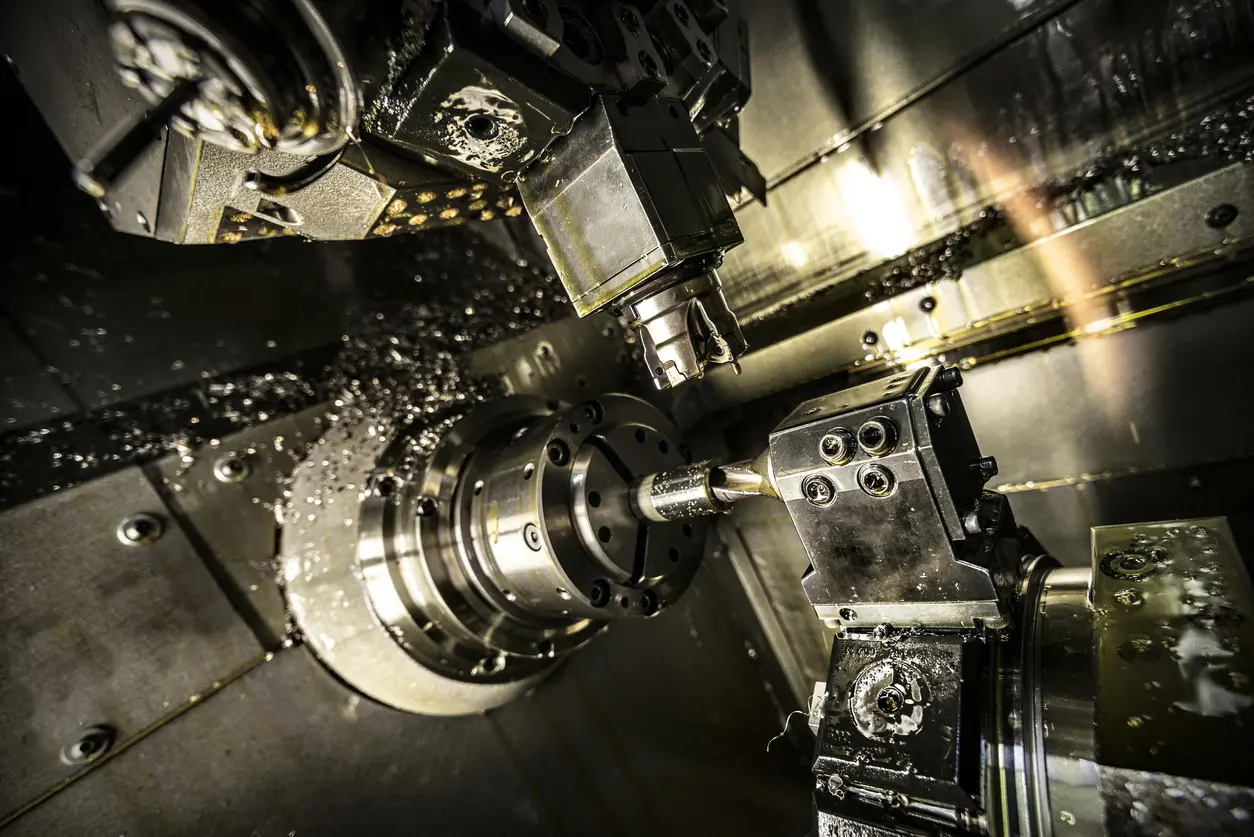

Our machining centers are equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation systems, ensuring optimal cutting performance across a broad range of materials—including titanium, Inconel, aluminum alloys, stainless steel, and engineering plastics. Advanced CNC controls with predictive maintenance algorithms allow for continuous operation with minimal downtime, supporting both prototype development and high-volume production runs. All machines are maintained under strict environmental controls to minimize thermal drift and ensure dimensional stability throughout the machining process.

Quality assurance is embedded at every stage of production. Each machined component undergoes comprehensive inspection using a Zeiss coordinate measuring machine (CMM), providing metrology-grade verification of geometric dimensions and surface characteristics. The CMM system is calibrated to international standards (ISO 17025) and operates in a temperature-controlled inspection lab to ensure measurement repeatability within sub-micron accuracy. This level of inspection supports full traceability, with detailed inspection reports available for every production lot.

In addition to CMM validation, in-process probing and laser scanning are employed to monitor critical dimensions during machining, enabling immediate correction and minimizing scrap. All inspection data is stored digitally for long-term quality tracking and compliance with industry-specific regulatory requirements, including AS9100 and ISO 13485.

The following table outlines the standard technical specifications and achievable tolerances across our 5-axis CNC machining services:

| Parameter | Specification |

|---|---|

| Positional Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.4 µm (polished finish available) |

| Maximum Work Envelope | 1,200 x 800 x 600 mm |

| Minimum Feature Size | 0.5 mm (internal radii) |

| Standard Tolerance (±) | ±0.01 mm (machined) |

| Tight Tolerance (optional) | ±0.005 mm (with inspection) |

| Angular Tolerance | ±0.05° |

| Material Compatibility | Metals, alloys, engineering plastics |

| Inspection Equipment | Zeiss CMM, laser scanners, optical comparators |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis technology with metrology-grade quality control to deliver precision components that meet the highest standards of performance and reliability.

Material & Finish Options

Material Selection for Precision CNC Machining: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal material is foundational to achieving performance, longevity, and cost-efficiency in precision CNC machined components. At Wuxi Lead Precision Machinery, our engineering team emphasizes that material choice directly impacts machinability, final part properties, secondary processing requirements, and overall project economics. This guide outlines critical considerations for three core aerospace, medical, and industrial materials: Aluminum, Steel, and Titanium, alongside essential anodizing finishes.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate applications demanding high strength-to-weight ratios, excellent thermal conductivity, and inherent corrosion resistance. 6061 offers superior weldability and moderate strength, ideal for structural frames and marine fittings. 7075 provides near-steel strength, crucial for high-stress aerospace components, though with reduced corrosion resistance requiring protective finishes. Aluminum machines rapidly with sharp tools, minimizing cycle times and tool wear, making it highly cost-effective for complex geometries. Its lower density significantly reduces part weight, a critical factor in transportation and portable equipment.

Carbon and alloy steels, including 4140, 4340, and 17-4 PH stainless, are selected when maximum strength, wear resistance, and structural integrity under heavy loads are paramount. Steel excels in high-temperature environments and applications requiring precise dimensional stability. Machining steel demands robust tooling, controlled feed rates, and effective coolant strategies due to work hardening and higher cutting forces compared to aluminum. While cycle times may be longer, steel delivers unmatched durability for gears, shafts, hydraulic manifolds, and critical structural elements where failure is not an option.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), are indispensable for extreme strength-to-weight ratios, exceptional corrosion resistance in harsh environments (e.g., seawater, chemicals), and biocompatibility. Its low thermal conductivity poses significant machining challenges, generating intense localized heat that accelerates tool wear and risks part distortion. Success requires rigid setups, specialized carbide tooling, precise speed/feed optimization, and ample coolant. Despite higher material and machining costs, titanium is non-negotiable for critical aerospace components, medical implants, and deep-sea equipment where performance justifies the investment.

Anodizing is the predominant surface finish for aluminum parts, enhancing corrosion resistance, wear properties, and providing an excellent base for adhesives or paints. Type II (Sulfuric Acid) anodizing offers good general-purpose protection and dyeing capability for identification. Type III (Hardcoat) anodizing creates a significantly thicker, harder, and more wear-resistant ceramic layer, essential for high-abrasion applications like hydraulic pistons or aerospace fittings. Proper anodizing specification, including thickness and sealing, is critical to meet functional and aesthetic requirements without compromising tight tolerances.

The comparative specifications below highlight key properties influencing CNC machining decisions:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Common Grades | Key Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 (6061-T6) | Excellent (A) | 6061-T6, 7075-T6 | Aerospace frames, heat sinks, marine |

| Steel | 7.8 | 655 (4140) | Moderate (C) | 4140, 4340, 17-4 PH | Gears, shafts, hydraulic components |

| Titanium | 4.5 | 900 (Ti-6Al-4V) | Poor (D) | Ti-6Al-4V (Gr5) | Aircraft structures, medical implants |

Partnering with Wuxi Lead ensures your material and finish selection leverages decades of precision machining expertise. We rigorously analyze your application’s thermal, mechanical, and environmental demands to recommend the optimal material-grade-finish combination, maximizing part performance while optimizing your manufacturing investment. Contact our engineering team for a tailored material assessment.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our CNC machining production process is engineered for precision, consistency, and zero-defect outcomes. We follow a disciplined progression from design to prototyping and into mass production, ensuring every component meets the highest standards of quality and performance. This structured approach enables us to deliver complex, high-tolerance parts for aerospace, medical, automotive, and industrial equipment sectors with unmatched reliability.

The process begins with design collaboration. Our engineering team works closely with clients to review CAD models, perform Design for Manufacturability (DFM) analysis, and optimize geometries for CNC machining. We assess material selection, tolerances, surface finishes, and assembly requirements to eliminate potential issues before production. Using advanced simulation software, we validate toolpaths and detect interference or deformation risks, ensuring the design is both functional and manufacturable.

Once the design is finalized, we move into the prototyping phase. This critical stage allows us to produce a small batch of parts—typically 1 to 10 units—for functional testing and client approval. Prototyping is conducted on the same high-precision CNC machines used in full-scale production, ensuring consistency in quality and performance. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and 3D scanning to verify dimensional accuracy and surface integrity. Feedback from this stage is incorporated into final adjustments, minimizing risk during mass production.

Mass production is initiated only after prototype validation and client sign-off. Our facility utilizes a fleet of multi-axis CNC machining centers, including 3-axis, 4-axis, and 5-axis systems, to handle complex geometries with micron-level precision. Automated tool monitoring, in-process gauging, and real-time quality control systems ensure that each part conforms to specifications throughout the production run. Every operation is documented, and statistical process control (SPC) is employed to detect trends and prevent deviations before they occur.

Our zero-defect philosophy is supported by a comprehensive quality management system compliant with ISO 9001:2015 standards. From raw material certification to final packaging, every step is traceable. First-article inspections, batch sampling, and 100% critical dimension checks are standard practice. This end-to-end control ensures that clients receive parts that are not only precise but also consistent across production cycles.

The following table outlines key capabilities of our CNC machining process:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Maximum Work Envelope | 1200 × 800 × 600 mm (5-axis) |

| Tolerance Range | ±0.01 mm standard, ±0.005 mm tight |

| Surface Finish | Ra 0.8 μm standard, down to Ra 0.2 μm |

| Materials Supported | Aluminum, Stainless Steel, Titanium, PEEK, Brass, Carbon Steel |

| Lead Time (Prototype) | 5–7 days |

| Lead Time (Mass Production) | 10–20 days (volume-dependent) |

By integrating precision engineering, advanced technology, and strict quality protocols, Wuxi Lead Precision Machinery ensures that every product transition—from concept to mass production—is seamless, scalable, and defect-free.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Engineered for Your Competitive Edge

When microns determine market position and uptime dictates profitability, your CNC machining partner must deliver uncompromising precision and reliability. At Wuxi Lead Precision Machinery, we engineer solutions for manufacturers who refuse to compromise on quality, efficiency, or technical support. With over 15 years of specialization in high-end CNC machining for aerospace, medical, and automotive sectors, we transform complex component challenges into competitive advantages. Our ISO 9001-certified processes and German-engineered machine platforms ensure every part meets the strictest global tolerances, while our proactive maintenance protocols minimize unplanned downtime.

Our flagship 5-axis CNC machining centers integrate cutting-edge technology with operational robustness. The specifications below reflect the foundation of our partnership promise:

| Specification | Value | Industry Benchmark |

|---|---|---|

| Positioning Accuracy | ±0.001 mm | ±0.003 mm |

| Repeatability | ±0.0005 mm | ±0.0015 mm |

| Max Spindle Speed | 24,000 RPM | 18,000 RPM |

| Axis Travel (X/Y/Z) | 1,200 x 800 x 600 mm | 1,000 x 700 x 500 mm |

| Surface Finish (Ra) | 0.2 µm | 0.8 µm |

This performance is sustained through our global technical ecosystem. Every machine ships with LeadSmart IoT monitoring, enabling real-time diagnostics and predictive maintenance. Our engineering team provides 24/7 multilingual support, reducing resolution time by 65% compared to industry averages. We don’t just supply equipment—we integrate with your production workflow through customized training, process validation, and lifecycle optimization services. Clients consistently achieve 30% faster time-to-part and 22% lower total cost of ownership within the first year of partnership.

The true value of precision engineering lies in partnership continuity. We commit to your long-term success through dedicated account engineering, rapid spare parts logistics from our EU and APAC hubs, and iterative technology upgrades aligned with your roadmap. When your project demands micron-level consistency in titanium, Inconel, or composites, our machines deliver repeatable excellence under the most demanding conditions.

Initiate your precision transformation today. Contact our engineering team directly at [email protected] to schedule a technical consultation and receive a customized capability audit. Specify your material, tolerance, and volume requirements to receive machine configuration recommendations within 24 hours. For urgent project timelines, reference code LEAD-CTA2024 to expedite our response protocol. Your next breakthrough component begins with a conversation—let us prove why global innovators trust Lead Precision as their manufacturing extension.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.