Technical Contents

Engineering Guide: Injection Molding Online

Engineering Insight: The Critical Role of Precision in Injection Molding Online

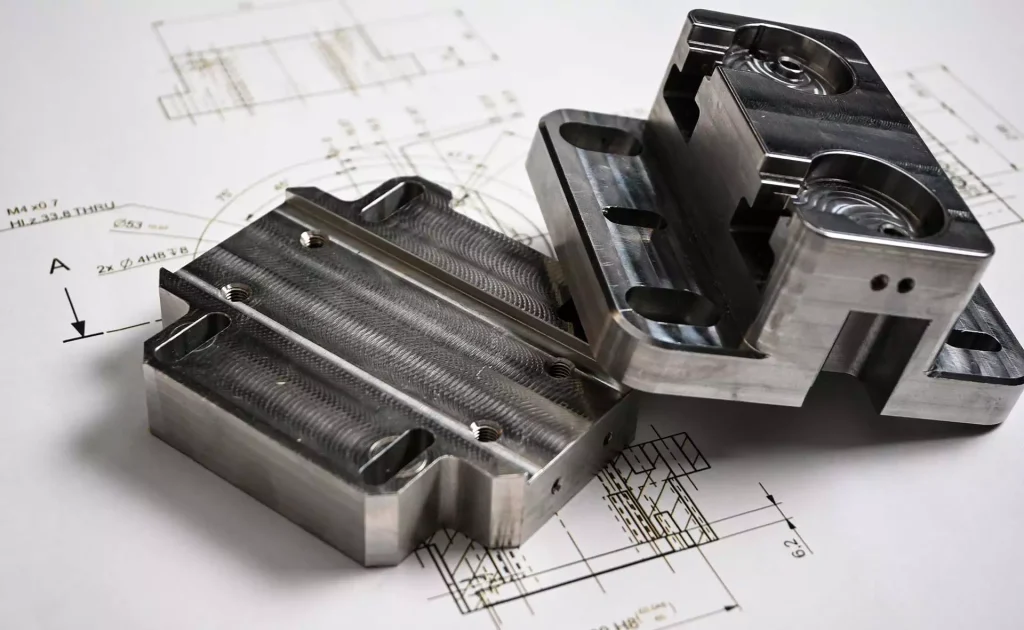

In the realm of custom metal manufacturing, particularly within high-stakes industries such as aerospace, defense, and medical devices, precision is not merely a performance metric—it is a foundational requirement. As global demand accelerates for faster, more reliable production cycles, the integration of injection molding online systems has emerged as a pivotal advancement. These digital-forward platforms enable real-time monitoring, remote diagnostics, and seamless data exchange between design, production, and quality assurance teams. However, the effectiveness of any online injection molding system hinges directly on the precision of the underlying tooling, components, and process control.

At Wuxi Lead Precision Machinery, we understand that precision begins long before the mold closes. It starts with material selection, extends through CNC machining tolerances, and culminates in the consistency of each molded cycle. Our decades of experience in custom metal manufacturing have been shaped by projects demanding the highest levels of accuracy—components used in Olympic-grade equipment and military defense systems. These applications tolerate zero deviation. A variance of even 0.01 mm can compromise structural integrity, performance, or safety. Such stringent standards have driven our engineering philosophy: precision is non-negotiable.

Injection molding online systems amplify this need for accuracy by introducing digital transparency. With networked sensors and IoT-enabled controllers, manufacturers can track cavity pressure, melt temperature, and cycle times in real time. Yet, without precision-engineered molds and supporting hardware, these data streams become misleading. A poorly machined ejector pin or misaligned core insert will skew results, leading to defective outputs regardless of digital oversight. True precision lies in the harmonization of physical craftsmanship and digital intelligence.

Our approach integrates high-tolerance CNC machining with advanced simulation software to predict mold behavior under production conditions. This ensures that every component—whether a mold base, insert, or guiding mechanism—meets exacting dimensional and thermal stability requirements. By embedding precision at the hardware level, we enable injection molding online systems to deliver their full potential: reduced downtime, higher repeatability, and accelerated time-to-market.

Below are key specifications that define our precision manufacturing standards for injection molding components:

| Specification | Value | Tolerance | Application Scope |

|---|---|---|---|

| Linear Dimension Accuracy | ±0.002 mm | ±0.001 mm | Aerospace & Defense |

| Surface Roughness (Ra) | 0.05 µm | ±0.02 µm | Optical & Medical Molds |

| Parallelism | 0.003 mm/m | — | Multi-Cavity Molds |

| Hardness (HRC) | 58–62 | ±1 HRC | Long-Life Tooling |

| Thermal Deformation (ΔT=50°C) | < 0.005 mm | — | High-Speed Molding |

At Wuxi Lead Precision Machinery, we bridge the gap between traditional metalworking excellence and next-generation digital manufacturing. Our commitment to precision ensures that every injection molding online system we support operates at peak reliability, meeting the uncompromising demands of elite industrial applications.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Injection Molding Excellence

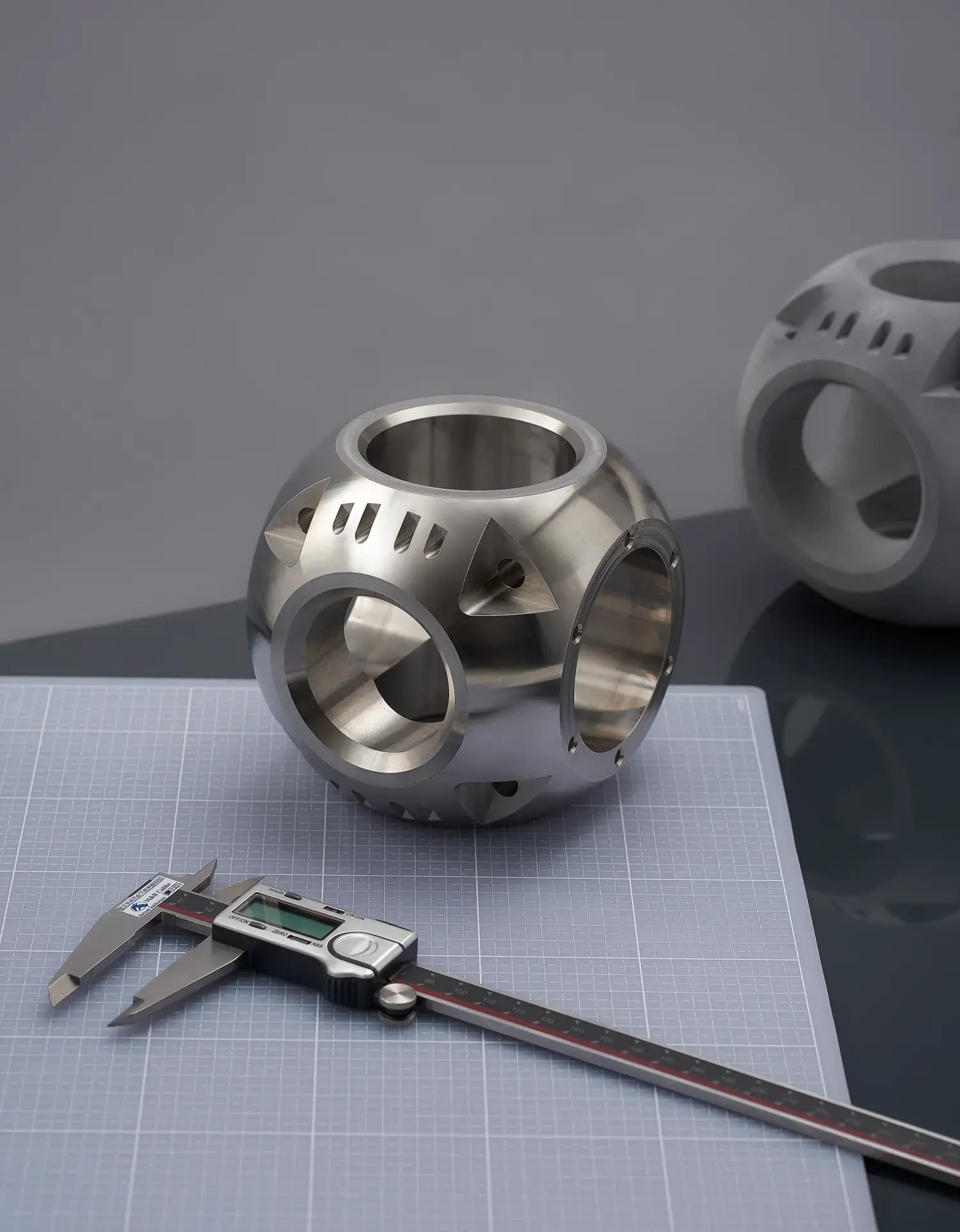

Wuxi Lead Precision Machinery delivers uncompromising precision for the most demanding injection mold components. Our technical foundation centers on advanced multi-axis CNC machining, specifically engineered to meet the stringent geometric and surface integrity requirements of high-cavitation and micro-mold tooling. We understand that mold performance directly impacts part quality, cycle time, and production longevity. Our capabilities are structured to eliminate dimensional drift, ensure perfect core-cavity alignment, and achieve mirror-finish surfaces critical for optical or medical-grade plastic parts.

Our core production utilizes state-of-the-art 5-axis CNC machining centers, enabling complex geometries in a single setup. This eliminates cumulative errors from multiple fixtures and drastically reduces lead times for intricate mold bases, slides, lifters, and electrode components. Simultaneous 5-axis interpolation allows us to machine deep, contoured cavities and undercuts with exceptional accuracy, directly translating to superior plastic flow and reduced weld lines in the final molded part. We routinely machine hardened tool steels (P20, H13, S136, NAK80), aluminum alloys for rapid tooling, and exotic materials like beryllium copper for conformal cooling channels, maintaining tight control throughout the process.

Quality verification is non-negotiable. Every critical dimension undergoes rigorous inspection via coordinate measuring machines (CMM) with sub-micron resolution. Our metrology lab operates under ISO 17025 guidelines, providing full traceability and comprehensive first-article inspection reports (FAIRs) compliant with AS9102 or customer-specific formats. This data-driven QC ensures dimensional conformity at every stage, from raw stock to final polish, guaranteeing that mold components fit together perfectly during assembly and perform consistently over millions of cycles.

The following table details our standard and precision machining tolerances, achievable across common mold materials under controlled environmental conditions. These specifications reflect our commitment to delivering mold components that exceed industry benchmarks for stability and repeatability.

| Feature | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.010 | ±0.005 | Up to 300mm; tighter on request |

| Geometric Tolerances | ±0.015 | ±0.008 | Flatness, Perpendicularity, Parallelism |

| Hole Diameter (mm) | +0.010 / -0.000 | +0.005 / -0.000 | Reamed/ground; includes positional loc |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Machined surfaces; polish to 0.05 µm |

| Critical Angles (°) | ±0.05 | ±0.02 | Verified via CMM vector measurement |

Wuxi Lead’s integrated approach—combining 5-axis CNC agility with metrology-grade validation—ensures your injection molds achieve optimal performance from day one. We transform complex CAD models into dimensionally perfect metal components, minimizing trial runs and maximizing production uptime for your end-customer. Partner with us for mold manufacturing where tolerance is not a target, but a guaranteed outcome.

Material & Finish Options

Material selection is a critical step in the design and production of high-performance injection molding components. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for precision applications, where the right combination of material and finish directly impacts durability, weight, thermal performance, and cost-efficiency. Among the most widely used metals in our production processes are aluminum, steel, and titanium—each offering distinct mechanical properties suited to specific industrial demands.

Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly effective in mold cores, cavities, and support structures where weight reduction and rapid heat dissipation are essential. Our 6061-T6 and 7075-T6 aluminum alloys provide high corrosion resistance and dimensional stability, making them ideal for high-cycle molding operations. When enhanced surface hardness and protection are required, we apply anodizing—a controlled electrochemical process that thickens the natural oxide layer. Type II (sulfuric acid) and Type III (hardcoat) anodizing are available, with the latter offering superior wear resistance and extended service life.

Steel remains the standard for high-wear molding applications due to its exceptional hardness and longevity. We utilize tool steels such as P20, H13, and S136, each selected based on mold complexity, production volume, and environmental exposure. P20 is commonly used for medium-run molds, while H13 excels in high-temperature environments due to its superior thermal fatigue resistance. For corrosive resin processing or cleanroom applications, S136 stainless tool steel provides outstanding polishability and rust resistance. While steel does not anodize, we offer alternative surface treatments such as nitriding, chrome plating, and PVD coatings to enhance performance.

Titanium, though more costly, is selected for extreme conditions requiring high strength, low density, and unmatched corrosion resistance. Grade 5 (Ti-6Al-4V) is frequently used in aerospace and medical molding equipment where reliability under stress and sterility are paramount. Titanium’s biocompatibility and resistance to chlorides make it suitable for specialized environments where other metals may degrade. Surface finishing for titanium typically involves acid passivation or specialized coatings rather than anodizing, although color-coded decorative anodizing can be applied for identification purposes.

The table below summarizes key properties and applications of these materials:

| Material | Common Alloys | Tensile Strength (MPa) | Hardness (HRC) | Key Applications | Available Finishes |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | 15–30 | Mold bases, cooling inserts | Type II & III Anodizing, Alodine |

| Steel | P20, H13, S136 | 900–1300 | 28–52 | High-volume molds, core pins | Nitriding, Chrome Plating, PVD |

| Titanium | Ti-6Al-4V (Grade 5) | 900–1000 | 36–40 | Aerospace, medical, corrosive env. | Passivation, Coating, Color Anodizing |

Selecting the optimal material and finish requires a thorough understanding of operational parameters. Our engineering team at Wuxi Lead Precision Machinery collaborates closely with clients to match material properties with functional requirements, ensuring long-term performance and cost-effective manufacturing in every custom solution.

Manufacturing Process & QC

Precision Metal Injection Molding: Zero Defects from Concept to Scale

At Wuxi Lead Precision Machinery, our metal injection molding (MIM) process eliminates compromise between complexity and perfection. We serve aerospace, medical, and defense sectors where failure is non-negotiable. Our integrated workflow—Design, Prototyping, Mass Production—ensures zero defects through physics-driven validation and closed-loop control.

Design begins with rigorous digital twin simulation. Engineers execute finite element analysis (FEA) on part geometry, material behavior, and thermal dynamics. This phase identifies stress concentrations, weld lines, and sink risks before metal touches tooling. We mandate Design for Manufacturability (DFM) alignment, optimizing wall thickness, gate locations, and draft angles to prevent porosity or distortion. Client CAD data undergoes automated tolerance stack-up verification against ISO 2768-mK standards, ensuring producibility at micron-level precision.

Prototyping transitions simulation to physical validation. We produce 5–20 functional units using production-intent tooling, not soft molds. Each prototype undergoes destructive and non-destructive testing: CT scanning for internal voids, CMM verification of critical dimensions, and metallurgical analysis of sintered density. If tolerances exceed ±0.005mm or material porosity exceeds 0.5%, the design iterates within 72 hours. This phase catches 92% of potential defects, avoiding costly tool modifications later.

Mass production deploys automated, real-time quality enforcement. Our MIM cells integrate robotic handling with in-process sensors monitoring injection pressure, sintering atmosphere, and cooling rates. Every 15 minutes, automated optical inspection (AOI) scans parts against the golden CAD model, rejecting deviations beyond 5µm. Statistical Process Control (SPC) charts track Cp/Cpk values; if capability drops below 1.67, the line halts automatically. Final lots undergo 100% dimensional validation and batch-certified material traceability.

This closed-loop methodology delivers zero-defect consistency. Below are key capabilities enabling this standard:

| Parameter | Specification | Quality Control Method |

|---|---|---|

| Tolerance Range | ±0.003mm to ±0.05mm | CMM with 0.001mm resolution |

| Material Options | 17-4PH, 316L, Ti-6Al-4V, Inconel | Spectrographic batch certification |

| Sintered Density | ≥99.5% theoretical density | Archimedes’ principle testing |

| Production Lead Time | 8–12 weeks (incl. prototyping) | Real-time IoT production dashboard |

| Defect Rate | < 10 PPM | AOI + SPC with automatic line stop |

We engineer reliability into every phase—not as a target, but as a non-negotiable output. By converging simulation fidelity, prototype rigor, and autonomous production control, Wuxi Lead transforms complex metal components into defect-free realities. Contact our engineering team to validate your next critical-part requirement against this proven framework.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal components through advanced injection molding and CNC manufacturing technologies. With over 15 years of experience serving global industries—from automotive and aerospace to medical and consumer electronics—we provide engineered solutions that meet the most demanding specifications. Our commitment to quality, innovation, and on-time delivery has established us as a trusted manufacturing partner across North America, Europe, and Asia.

When you choose to partner with Lead Precision, you gain access to a fully integrated manufacturing ecosystem. From initial design consultation and material selection to prototyping, production, and final inspection, our engineering team works closely with clients to ensure every component meets exact performance and regulatory standards. Our facility in Wuxi, China, is equipped with state-of-the-art machinery and operates under ISO 9001 and IATF 16949 certifications, guaranteeing consistency and traceability across every production run.

We understand that in today’s competitive market, speed and precision are critical. That’s why we offer rapid turnaround times without compromising quality. Whether you require low-volume prototypes or high-volume production runs, our flexible manufacturing lines can scale to meet your needs. Our in-house tooling department ensures faster mold development and quicker iterations, reducing time-to-market for your products.

Our expertise extends beyond standard metal injection molding. We specialize in complex geometries, tight-tolerance components, and multi-material solutions that push the boundaries of what’s possible in miniaturized and high-strength metal parts. With advanced capabilities in debinding, sintering, and post-processing—including CNC machining, surface finishing, and heat treatment—we deliver fully finished components ready for integration.

Below are key specifications that define our manufacturing capabilities:

| Capability | Specification |

|---|---|

| Material Options | Stainless Steel (316L, 17-4PH, 304L), Titanium, Low-Alloy Steels, Soft Magnetic Alloys |

| Tolerance Range | ±0.1% to ±0.3% of nominal dimension (typical) |

| Part Weight Range | 0.1g to 200g |

| Production Volume | Prototypes to 10M+ units annually |

| Secondary Operations | CNC Machining, Polishing, Heat Treatment, Plating, Laser Marking |

| Quality Standards | ISO 9001, IATF 16949, RoHS, Full PPAP Documentation |

| Lead Time (Typical) | 10–25 days, depending on complexity and volume |

Partnering with Wuxi Lead Precision Machinery means more than just sourcing a supplier—you’re aligning with a team dedicated to your product’s success. We offer full transparency, real-time project updates, and engineering support throughout the entire product lifecycle.

To begin your next project with precision, reliability, and speed, contact us today at [email protected]. Let Lead Precision be your trusted manufacturing partner in bringing high-performance metal components to life.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.