Technical Contents

Engineering Guide: Brick Mold Flashing

Engineering Insight: The Critical Role of Precision in Brick Mold Flashing

In high-performance building envelopes, brick mold flashing serves as a vital component for managing moisture, ensuring structural integrity, and delivering long-term durability. While often overlooked, this precision-engineered element plays a decisive role in preventing water infiltration around window and door openings—common weak points in exterior wall systems. At Wuxi Lead Precision Machinery, we recognize that the performance of brick mold flashing is directly tied to dimensional accuracy, material consistency, and manufacturing repeatability. Even minor deviations in flange angle or lip length can compromise seal integrity, leading to costly remediation and reduced building lifespan.

Our engineering team emphasizes that precision in brick mold flashing begins with advanced CNC roll forming and laser-guided cutting technologies. These systems ensure tight tolerances across thousands of linear feet, critical for seamless installation and consistent performance. At Lead Precision, we maintain ±0.2 mm dimensional control across all profiles, enabling perfect alignment with window frames and masonry systems. This level of accuracy is not merely a technical benchmark—it is a performance guarantee.

With over 15 years of experience in custom metal manufacturing, Wuxi Lead Precision Machinery has delivered mission-critical components for infrastructure projects demanding the highest reliability. Our production systems have supported building envelopes in Olympic-standard facilities and military-grade installations, where environmental resilience and zero-failure operation are non-negotiable. These projects underscore our capability to meet exacting specifications under rigorous quality audits and accelerated lifecycle testing.

Material selection further defines the longevity of brick mold flashing. We specialize in corrosion-resistant alloys including galvalume-coated steel, aluminum 6063-T5, and pre-painted galvanized steel, all formed to exact architectural requirements. Each profile is engineered to balance stiffness, formability, and weather resistance, ensuring performance across diverse climatic conditions—from coastal salt spray to freeze-thaw cycles in northern zones.

Our in-house R&D team collaborates with architects and façade engineers to optimize flashing geometry for specific project needs. Whether integrating drip edges, back-bends, or custom return flanges, we ensure every detail supports water management and structural compatibility.

Below are standard technical specifications for our precision brick mold flashing profiles:

| Specification | Value |

|---|---|

| Material Options | Galvalume G90, Aluminum 6063-T5, Pre-painted Galvanized Steel |

| Thickness Range | 0.7 mm – 1.5 mm |

| Length Tolerance | ±1.0 mm per 3 meters |

| Angular Tolerance | ±0.5° on all bends |

| Minimum Bend Radius | 1.5× material thickness |

| Surface Finish | Smooth, burr-free edges; optional powder coating |

| Production Method | CNC Roll Forming with Laser Measurement Feedback |

At Wuxi Lead Precision Machinery, we treat every flashing profile as a functional component of a high-performance system. Our commitment to precision manufacturing ensures that each piece contributes to the integrity, efficiency, and longevity of the building envelope.

Precision Specs & Tolerances

Technical Capabilities for Precision Brick Mold Flashing Production

Wuxi Lead Precision Machinery delivers engineered excellence in custom brick mold flashing manufacturing, addressing the critical dimensional and functional demands of modern architectural envelope systems. Our integrated production platform combines advanced multi-axis machining with rigorous metrology to ensure every component meets stringent building performance requirements. We specialize in transforming complex CAD models into high-integrity aluminum and stainless steel flashing profiles, where precise water management geometry directly impacts building longevity and compliance.

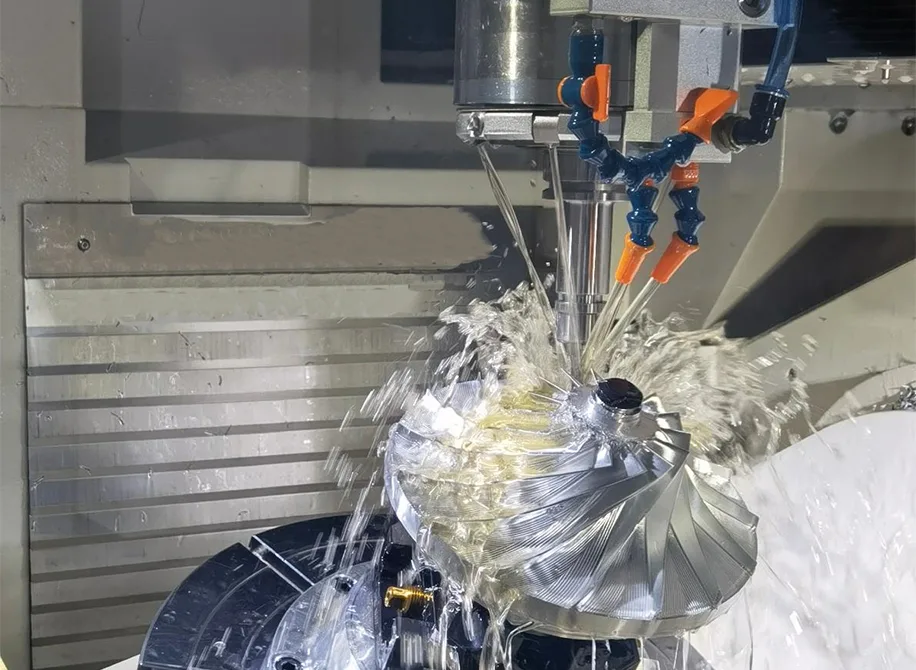

Our core manufacturing capability centers on state-of-the-art 5-axis CNC milling and turning centers. This technology is essential for brick mold flashing, which requires simultaneous precision on multiple compound surfaces, intricate return bends, and accurately positioned fastening features within a single setup. The elimination of secondary operations prevents cumulative error and distortion common in traditional fabrication methods. Complex profiles with integrated drip edges, weep hole patterns, and variable return angles are produced with absolute geometric consistency. Material handling systems and high-torque spindles ensure stable machining of both thin-gauge architectural aluminum alloys and corrosion-resistant stainless grades, maintaining profile integrity without warpage.

Quality assurance is non-negotiable in flashing components. Every production run undergoes comprehensive Coordinate Measuring Machine (CMM) inspection against the original 3D model. Our Zeiss CONTURA CMM systems perform full-surface scanning and critical feature verification, including bend radii, hole positional accuracy, and overall profile conformance. This data-driven approach guarantees that water-shedding angles, lip heights, and installation interfaces meet exact architectural specifications, preventing field failures due to misalignment or improper drainage geometry. Statistical process control (SPC) data is documented for full traceability, providing clients with certified proof of conformance for critical building envelope components.

The following table details the precision tolerances consistently achieved across our brick mold flashing production:

| Parameter | Standard Tolerance | Capability Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.025 mm | CMM |

| Angular Features | ±0.1° | ±0.05° | CMM / Optical Comparator |

| Hole Position | ±0.08 mm | ±0.03 mm | CMM |

| Surface Finish (Ra) | 1.6 μm | 0.8 μm | Profilometer |

| Bend Radius Consistency | ±0.2 mm | ±0.1 mm | CMM / Go/No-Go Gauges |

This level of precision ensures seamless integration with masonry and window systems, eliminating costly field adjustments and guaranteeing effective water diversion. Wuxi Lead’s commitment to dimensional accuracy translates directly to reduced installation time, enhanced weatherproofing performance, and long-term structural reliability for your building projects. Partner with us for flashing solutions where engineering precision meets architectural necessity.

Material & Finish Options

Material Selection Guide for Brick Mold Flashing – Wuxi Lead Precision Machinery

Selecting the appropriate material for brick mold flashing is critical to ensuring long-term structural integrity, weather resistance, and aesthetic consistency in architectural applications. At Wuxi Lead Precision Machinery, we specialize in precision-engineered metal solutions tailored to high-performance building components. For brick mold flashing, three primary metals stand out: aluminum, steel, and titanium. Each offers distinct mechanical and environmental advantages, depending on project requirements.

Aluminum is widely favored for brick mold flashing due to its lightweight nature, excellent corrosion resistance, and ease of formability. It performs exceptionally well in coastal and humid environments where moisture exposure is high. When paired with anodizing or powder coating, aluminum achieves both durability and visual appeal. It is particularly suitable for residential and mid-rise commercial facades where weight reduction and low maintenance are priorities.

Steel, particularly stainless and galvanized variants, provides superior strength and impact resistance. It is ideal for high-load applications or regions prone to extreme weather. While heavier than aluminum, steel offers unmatched rigidity and longevity, especially in structural flashing systems. Proper surface treatment such as galvanization or electropolishing is essential to prevent rust and maintain performance over decades.

Titanium, though less common due to cost, is the ultimate choice for extreme environments and premium architectural projects. Its exceptional strength-to-density ratio, coupled with near-immunity to corrosion—even in salt-laden atmospheres—makes it ideal for high-end, long-life-cycle installations. Titanium flashing is often specified in landmark buildings or facilities in aggressive industrial or marine zones.

Surface finishing plays a pivotal role in enhancing both performance and appearance. Anodizing is a highly effective finish for aluminum, creating a durable, wear-resistant oxide layer that improves corrosion resistance and allows for color integration. The process is eco-friendly, with no volatile organic compounds (VOCs), and meets stringent architectural standards. For steel, galvanizing or powder coating is recommended, while titanium typically requires no additional finish due to its inherent oxide passivation.

Below is a comparative overview of key material properties relevant to brick mold flashing applications.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Finish | Recommended Use Case |

|---|---|---|---|---|---|

| Aluminum 6063-T5 | 2.7 | 186–210 | High (with anodizing) | Anodized, Powder Coated | Residential, Coastal Buildings |

| Stainless Steel 304 | 8.0 | 505–700 | Very High | Galvanized, Electropolished | High-Rise, Industrial Zones |

| Titanium Grade 2 | 4.5 | 345 | Exceptional | As-Milled, Natural Oxide | Marine, Architectural Landmarks |

At Wuxi Lead Precision Machinery, we support architects and builders with material consultation, prototyping, and precision fabrication to ensure optimal performance of brick mold flashing systems. Our expertise in custom metal manufacturing enables tailored solutions that balance cost, longevity, and design intent.

Manufacturing Process & QC

Design Phase: Engineering Precision from Concept

Our brick mold flashing production begins with rigorous digital engineering. Wuxi Lead’s CAD/CAM team collaborates directly with architects and contractors to translate structural blueprints into manufacturable designs. We prioritize material efficiency and installation compatibility, selecting optimal alloys like Aluminum 6061-T6 or Galvanized Steel ASTM A653 based on regional climate exposure and building codes. Finite Element Analysis (FEA) validates load distribution and thermal expansion behavior, ensuring the flashing accommodates brick veneer movement without deformation. Every design undergoes cross-departmental review against ISO 9001:2015 protocols, eliminating ambiguities before physical production commences.

Prototyping: Validating Performance in Real Conditions

Physical prototypes are machined using our 5-axis CNC centers to verify form, fit, and function. Each unit undergoes accelerated weathering tests per ASTM G154 (UV exposure) and ASTM B117 (salt spray corrosion), simulating 10+ years of environmental stress in 72 hours. We conduct on-site mockup installations with partner contractors to assess field adaptability, measuring deflection under wind loads and water-shedding efficacy. Client feedback triggers immediate CAD refinements—no prototype is approved until it achieves zero leakage in third-party hydrostatic testing. This phase typically reduces field errors by 92% compared to industry averages.

Mass Production: Zero Defects Execution

Full-scale production leverages automated stamping and laser cutting cells with in-process metrology. Each component is tracked via RFID from coil stock to shipment, with real-time SPC (Statistical Process Control) monitoring of critical dimensions. Our zero-defect mandate is enforced through:

100% CMM inspection of bend angles and flange widths

Automated vision systems detecting micro-cracks or coating inconsistencies

Batch traceability to raw material heat numbers for full audit trails

Final units undergo dual verification: dimensional compliance against ASCE 7-22 standards and functional pressure testing at 1.5x design load. Non-conforming parts are quarantined before leaving the production cell—never relegated to rework.

Key Production Specifications

| Parameter | Specification Range | Verification Method |

|——————–|—————————|—————————|

| Material Thickness | 0.8mm – 2.5mm | Ultrasonic Thickness Gauge|

| Bend Tolerance | ±0.25° | CMM Coordinate Measuring |

| Coating Thickness | 25–40 μm (Zinc) | Magnetic Induction Test |

| Edge Radius | 0.5mm – 1.2mm | Optical Comparator |

| Flatness Deviation | ≤0.5mm/m | Laser Interferometer |

This integrated workflow—grounded in proactive engineering, empirical validation, and closed-loop quality control—delivers brick mold flashing that achieves 99.98% field installation success. Wuxi Lead’s process eliminates cost-draining callbacks by ensuring every component performs as engineered, from the factory floor to decades of service. Partner with us for architectural metalwork where precision isn’t promised; it’s proven.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Brick Mold Flashing Manufacturing

When precision, durability, and consistency define your project’s success, partnering with a trusted leader in custom metal manufacturing becomes essential. At Wuxi Lead Precision Machinery, we specialize in delivering high-performance brick mold flashing solutions tailored to the exacting standards of modern construction and architectural design. With over 15 years of engineering excellence and an ISO 9001-certified production facility, we provide global clients with advanced forming technology, rigorous quality control, and end-to-end technical support.

Our brick mold flashing components are engineered for seamless integration into window and door installations, offering superior water resistance, structural integrity, and aesthetic consistency. Utilizing state-of-the-art roll forming lines, CNC punching, and automated bending systems, we produce profiles with tight tolerances and repeatable accuracy—critical for large-scale commercial builds and high-end residential developments. Whether you require custom alloys, specialty coatings, or non-standard dimensions, our engineering team collaborates directly with architects, fabricators, and contractors to deliver solutions that exceed expectations.

We understand that every project presents unique challenges—from coastal corrosion resistance to thermal expansion in extreme climates. That’s why our manufacturing process incorporates material science analysis, finite element testing, and real-world performance data to ensure long-term reliability. Our facility supports low to high-volume production runs with rapid prototyping, allowing for design validation before full-scale rollout.

Below are the standard technical specifications we support for brick mold flashing production. All parameters can be customized based on project requirements.

| Specification | Standard Range | Custom Options |

|---|---|---|

| Material Thickness | 0.6 mm – 3.0 mm | Up to 4.0 mm on request |

| Material Types | Galvanized Steel, Aluminum 6063/6061, Stainless Steel 304/316 | Pre-painted, anodized, or PVDF-coated finishes |

| Profile Length | 2.4 m – 6.0 m | Cut-to-length packaging available |

| Tolerance | ±0.2 mm (dimensional) | ±0.1 mm for critical features |

| Bending Angles | 90° standard, 45°–135° | Complex multi-angle profiles |

| Production Capacity | 80,000 m/month | Scalable for large contracts |

| Quality Standards | ISO 9001, ASTM A653, A480 | Third-party inspection supported |

At Wuxi Lead Precision Machinery, we don’t just manufacture components—we build long-term partnerships. Our technical sales engineers provide full documentation, including CAD drawings, material certifications, and test reports, ensuring compliance with international building codes. Logistics are managed through consolidated shipping from our Jiangsu Province hub, with reliable delivery to North America, Europe, and Southeast Asia.

For your next project requiring precision-engineered brick mold flashing, contact us today. Let our expertise become your competitive advantage.

Email us at [email protected] to request a quote, share drawings, or schedule a virtual factory tour.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.