Technical Contents

Engineering Guide: Plastic Injection Molding Industry

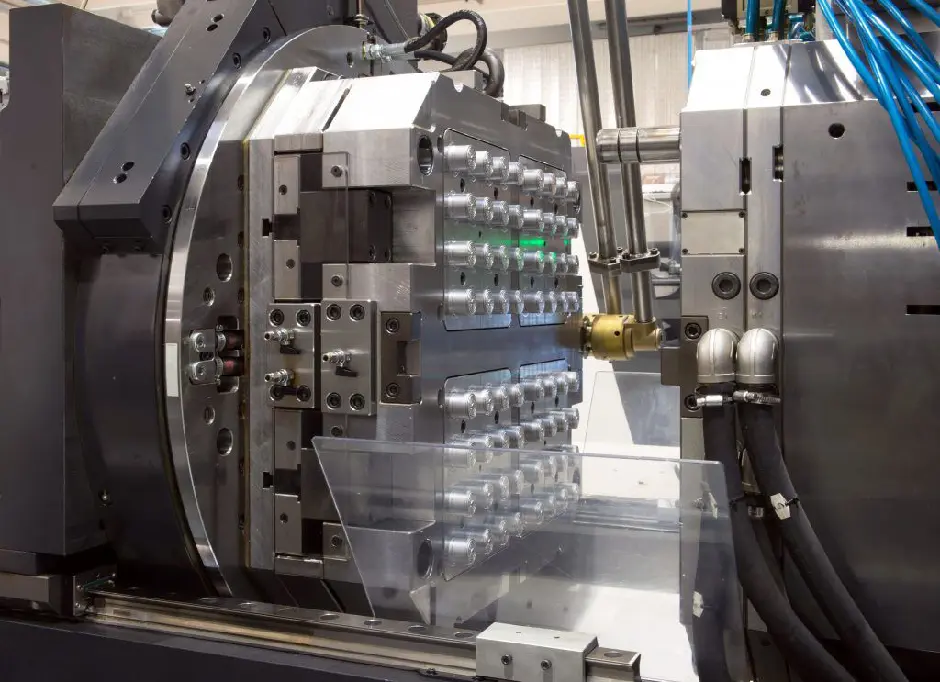

Engineering Insight: The Critical Role of Precision in Plastic Injection Molding

In the plastic injection molding industry, precision is not merely a performance metric—it is the foundation of product integrity, repeatability, and long-term operational efficiency. As components become increasingly complex and tolerances tighter, the demand for ultra-precise metal tooling and supporting machinery has never been greater. At Wuxi Lead Precision Machinery, we understand that even micron-level deviations can compromise the functionality, aesthetics, and safety of molded parts—particularly in high-stakes sectors such as aerospace, medical devices, and defense.

Our engineering philosophy centers on achieving and sustaining dimensional accuracy across every phase of custom metal manufacturing. From initial design to final inspection, we employ advanced CNC machining, coordinate measuring machines (CMM), and real-time process monitoring to ensure consistency. This level of control is essential when producing molds that must withstand thousands of injection cycles while maintaining tight tolerances, surface finish quality, and thermal stability.

Wuxi Lead Precision Machinery brings over a decade of specialized experience to the plastic injection molding industry. Our track record includes delivering mission-critical components for Olympic-standard sports equipment and precision-engineered parts for military applications. These projects demanded not only compliance with stringent international standards but also the ability to innovate under pressure, where failure was not an option. This same rigor is applied to every custom mold and component we manufacture for injection molding clients.

Precision in tooling directly influences cycle time, part quality, and overall production cost. A poorly machined mold can lead to flash, warpage, or inconsistent wall thickness—resulting in rejected batches and costly downtime. Conversely, a high-precision mold ensures optimal material flow, uniform cooling, and repeatable ejection, all of which contribute to higher yields and lower total cost of ownership.

We specialize in producing hardened and pre-hardened steel molds, aluminum rapid tooling, and insert molds tailored to specific resin behaviors and production volumes. Our in-house capabilities allow us to control metallurgical properties, surface coatings, and geometric accuracy, ensuring that each mold meets the exact requirements of the application.

Below are key specifications that define our precision manufacturing capabilities:

| Specification | Capability |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Surface Roughness (Ra) | 0.05 µm (polished) |

| Maximum Machining Size | 1200 x 800 x 600 mm |

| Tolerance Range | ±0.005 mm (standard), ±0.001 mm (high-precision) |

| Materials Supported | P20, 718, H13, S136, Aluminum 7075, Titanium alloys |

| Quality Standards | ISO 9001:2015, MIL-STD-810G (for defense projects) |

| Lead Time (Average) | 15–25 days, depending on complexity |

At Wuxi Lead Precision Machinery, we do not view ourselves merely as suppliers—but as engineering partners. Our work in elite-tier manufacturing environments has sharpened our ability to deliver precision where it matters most. For the plastic injection molding industry, that means molds that perform consistently, last longer, and produce flawless parts, cycle after cycle.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Injection Molding Excellence

Wuxi Lead Precision Machinery delivers uncompromising precision for the plastic injection molding industry through advanced custom metal manufacturing. Our core strength lies in producing critical mold components where dimensional accuracy directly impacts part quality, cycle time, and tool longevity. We specialize in complex geometries inherent to modern molds, including conformal cooling channels, intricate cavities, and tight-tolerance core pins. This precision engineering foundation ensures molds perform reliably under high-pressure, high-cycle production environments, minimizing flash, sink marks, and premature wear.

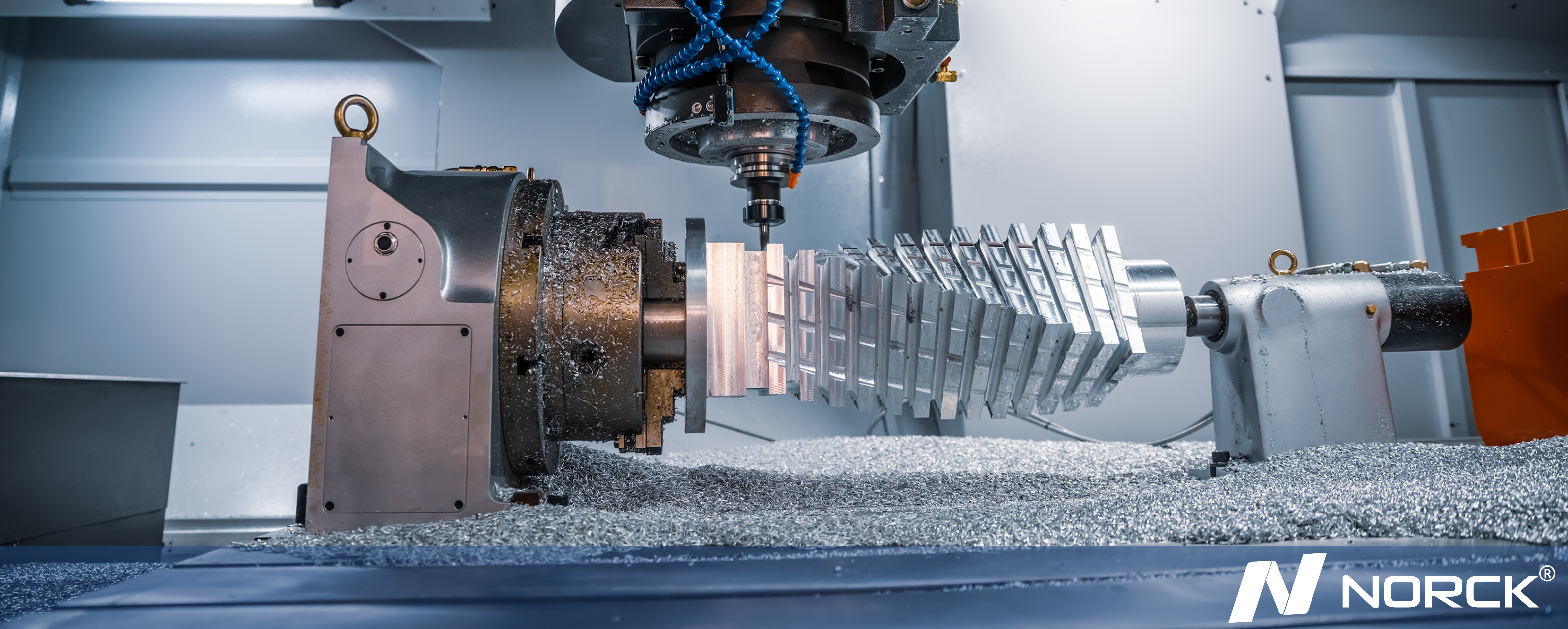

Our 5-axis CNC machining centers represent the pinnacle of metal fabrication capability for mold manufacturing. These systems enable simultaneous multi-directional tool movement, eliminating the need for multiple setups and preserving critical datum integrity. This capability is essential for machining complex 3D surfaces found in family molds, multi-cavity layouts, and molds requiring undercuts or deep ribs. Advanced high-speed machining (HSM) strategies achieve superior surface finishes on hardened tool steels (up to HRC 58), reducing or eliminating secondary hand polishing. Material removal efficiency is optimized for hardened P20, H13, S7, and stainless steels, ensuring geometric accuracy while maintaining thermal stability during prolonged runs. The result is mold components with perfect parting line registration, consistent wall thickness control, and seamless integration of cooling circuits—critical factors for dimensional stability in precision plastic parts.

Quality validation is non-negotiable. Every critical feature undergoes rigorous inspection using state-of-the-art Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMMs provide traceable, sub-micron verification against CAD models, confirming positional accuracy, form tolerances, and surface relationships. This metrology-driven approach validates that mold components meet the exacting demands of high-cavitation or micro-molding applications. Full inspection reports, including GD&T analysis, are standard deliverables, providing clients with documented proof of conformance before mold assembly begins.

The following table details our standard achievable tolerances for critical mold features, reflecting our commitment to dimensional integrity:

| Feature Type | Standard Tolerance | Critical Application Example |

|---|---|---|

| Linear Dimensions | ±0.005 mm | Core pin diameters, ejector pin bores |

| Angular Features | ±0.005° | Slide angles, lifters, cam profiles |

| Positional Tolerance | ±0.003 mm | Multi-cavity alignment, cooling port locations |

| Surface Roughness (Ra) | 0.4 µm (machined) | Cavity/core sealing surfaces |

| Flatness | 0.002 mm per 100 mm | Parting line surfaces, mold base plates |

These tolerances are consistently achieved on components up to 1,200 x 800 x 600 mm and are validated per ISO 10360 standards. Material selection and hardening processes are optimized to maintain these specifications under operational thermal cycling. This level of precision directly translates to reduced mold tryout time, lower scrap rates, and extended tool life for our clients—transforming engineering specifications into measurable production efficiency. Wuxi Lead’s integrated manufacturing and metrology capability ensures your mold investment delivers consistent, high-quality plastic parts from the first shot.

Material & Finish Options

Material Selection for Precision Components in Plastic Injection Molding

In the plastic injection molding industry, the performance and longevity of mold components depend heavily on the selection of base materials and surface treatments. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-demand molding applications, where material integrity directly impacts cycle life, dimensional accuracy, and resistance to wear and corrosion. Among the most widely used metals are aluminum, steel, and titanium—each offering distinct mechanical and thermal properties suited to specific production environments.

Aluminum is often selected for prototype molds and low-volume production due to its excellent thermal conductivity and machinability. It enables rapid heat dissipation, reducing cycle times during testing phases. While aluminum lacks the hardness of steel, modern alloys such as 7075-T6 provide enhanced strength and are ideal for applications where weight reduction and quick turnaround are critical. However, aluminum’s lower wear resistance makes it less suitable for long production runs.

Steel, particularly tool steels like P20, H13, and S136, remains the standard for high-volume injection molds. These steels offer superior hardness, wear resistance, and dimensional stability under repeated thermal cycling. P20 steel is commonly used for general-purpose molds, while H13 excels in hot-runner systems due to its thermal fatigue resistance. For corrosive environments or medical-grade plastics, stainless variants such as S136 provide excellent resistance to rust and pitting. The trade-off lies in longer machining times and higher tooling costs, but the extended service life justifies the investment in mass production.

Titanium is increasingly adopted in specialized molding applications where high strength-to-density ratio and corrosion resistance are paramount. Though not typically used for full mold bases, titanium alloys are ideal for ejector pins, inserts, and other wear-prone components. Its biocompatibility and resistance to chloride-based environments make it especially valuable in medical and marine-grade polymer processing. However, titanium’s high reactivity during machining and cost limit its use to targeted, high-performance parts.

Surface finishing further enhances material performance. Anodizing, particularly Type II and Type III (hard anodizing), is a critical treatment for aluminum components. It creates a durable, corrosion-resistant oxide layer that improves surface hardness and wear resistance. Hard anodizing can achieve surface hardness up to 600 HV, making treated aluminum suitable for extended use in abrasive molding conditions. For steel and titanium, alternative coatings such as nitriding or PVD may be preferred, though anodizing remains exclusive to aluminum.

The table below summarizes key mechanical and thermal properties of these materials:

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Common Applications |

|---|---|---|---|---|

| Aluminum 7075-T6 | 570 | 15–20 (HB) | 130 | Prototype molds, low-volume runs |

| P20 Steel | 900–1100 | 28–32 | 30 | General production molds |

| H13 Steel | 1500 | 45–50 | 35 | Hot-runner systems, high heat |

| S136 Steel | 1000 | 48–52 | 25 | Corrosion-resistant molds |

| Titanium Ti-6Al-4V | 950 | 36 | 7 | Ejector pins, medical inserts |

Selecting the optimal material and finish requires balancing performance requirements with production economics. Wuxi Lead Precision Machinery supports clients in making informed decisions based on application demands, ensuring reliability and precision in every component.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Zero-Defect Production Process for Injection Molds

Achieving true zero defects in plastic injection molding begins not with the press, but with the precision metal mold. At Wuxi Lead Precision Machinery, our integrated production process rigorously controls every phase from initial concept to high-volume output, ensuring molds deliver consistent part quality and maximize client profitability. We understand that mold performance directly dictates production yield, scrap rates, and ultimately, your bottom line.

The foundation is meticulous Design Engineering. Our senior engineers collaborate closely with client technical teams during the initial phase, conducting comprehensive Design for Manufacturability (DFM) analysis. This is not a cursory review; we utilize advanced 3D simulation software to predict material flow, cooling efficiency, and potential stress points within the cavity and core. Critical factors like gate location, venting strategy, and ejection mechanics are optimized virtually, preventing common defects such as sink marks, weld lines, or short shots before metal is cut. This proactive engineering phase eliminates 80% of potential mold-related failures at the source.

Precision Prototyping follows, utilizing our rapid tooling capabilities. We manufacture functional prototype molds from high-grade tool steels using multi-axis CNC machining and wire EDM, mirroring the exact geometry and critical tolerances of the final production tool. These prototypes undergo rigorous validation testing on client-specification injection molding machines. We perform detailed dimensional analysis of molded parts using calibrated Coordinate Measuring Machines (CMM), conduct gate seal studies, and validate cooling circuit performance. Any discrepancies identified trigger immediate design refinements. This iterative validation, conducted under real production conditions, guarantees the final mold design is flawless and process-ready.

Zero-Defect Mass Production leverages our fully integrated manufacturing facility and stringent quality management system. Every production mold component is machined on state-of-the-art CNC grinders and milling centers with sub-micron repeatability. In-process inspections at critical stages verify dimensions and surface integrity. Final assembly occurs in a climate-controlled environment, followed by comprehensive functional testing simulating actual molding cycles. Only molds passing our 100% inspection protocol, exceeding standard industry specifications, are shipped. Continuous feedback from client production floors informs our process refinement, closing the loop on defect prevention.

Our commitment to zero defects is measurable through the precision and reliability of the molds we deliver. The table below outlines key specifications achievable through our controlled process:

| Parameter | Wuxi Lead Precision Standard | Measurement Method |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | CMM (Zeiss CONTURA) |

| Cavity Surface Finish | Ra 0.05 µm (Mirror Polish) | Profilometer (Mitutoyo) |

| Core Pin Straightness | ≤ 0.001 mm over 50 mm | Optical Comparator |

| Hardness Uniformity | ±1 HRC across component | Rockwell Hardness Tester |

| Runout (Critical Axes) | ≤ 0.003 mm | Dial Indicator (0.001mm) |

This systematic approach – rigorous design validation, real-world prototyping, and statistically controlled mass production – transforms the theoretical goal of zero defects into an operational reality. Partner with Wuxi Lead to eliminate mold-induced scrap, reduce your total cost of ownership, and achieve unmatched consistency in your plastic injection molding operations.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing for the Plastic Injection Molding Industry

At Wuxi Lead Precision Machinery, we understand that precision, durability, and consistency are non-negotiable in the plastic injection molding industry. As a leading provider of custom metal manufacturing solutions based in China, we specialize in delivering high-performance components engineered to meet the rigorous demands of modern molding operations. Our advanced CNC machining capabilities, combined with decades of industrial experience, position us as the strategic partner of choice for global OEMs and Tier-1 suppliers.

When you partner with Lead Precision, you gain access to a fully integrated manufacturing ecosystem. From initial design consultation and material selection to precision machining, heat treatment, and final inspection, every stage of production is executed under strict ISO 9001-certified quality protocols. Our facility is equipped with state-of-the-art multi-axis CNC centers, wire EDM, grinding systems, and 3D metrology equipment, ensuring micron-level accuracy and repeatability across all components.

We focus exclusively on mission-critical parts used in injection molds—such as mold bases, cavities, cores, ejector systems, and precision guide components—manufactured from high-grade tool steels, pre-hardened steels, and specialty alloys. Whether your application requires wear resistance, thermal stability, or corrosion protection, our engineering team works closely with you to optimize material properties and geometries for maximum performance and extended service life.

Our commitment to on-time delivery and technical agility allows us to support rapid prototyping, low-volume customization, and high-volume production runs with equal proficiency. With seamless English communication, real-time project tracking, and comprehensive documentation including material certifications and inspection reports, we ensure complete transparency and traceability throughout the supply chain.

Below are key technical specifications that define our manufacturing capabilities:

| Specification | Capability |

|---|---|

| Maximum Machining Size | 1200 mm × 800 mm × 600 mm |

| Tolerance Control | ±0.005 mm |

| Surface Finish | Ra 0.2 – 1.6 μm (polishable to mirror finish) |

| Materials Processed | P20, 718, S136, H13, 420SS, Aluminum 7075, Brass, Titanium |

| CNC Equipment | 3-axis, 4-axis, 5-axis machining centers |

| Secondary Processes | Heat treatment, nitriding, deep hole drilling, tapping |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), CMM reporting |

Choosing the right manufacturing partner is critical to maintaining competitive advantage in today’s fast-moving markets. At Wuxi Lead Precision Machinery, we don’t just produce parts—we deliver precision-engineered solutions that enhance mold reliability, reduce downtime, and improve overall production efficiency.

Contact us today at [email protected] to discuss your next project. Let Lead Precision be your trusted partner in achieving excellence in custom metal manufacturing for the plastic injection molding industry.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.