Technical Contents

Engineering Guide: Cnc Machine Website

Engineering Insight: The Uncompromising Standard of Precision in CNC Machining

In the realm of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, safety, and innovation are built. At Wuxi Lead Precision Machinery, we operate under the principle that every micron matters. Our decades-long commitment to engineering excellence has positioned us as a trusted partner in industries where failure is not an option: aerospace, defense, medical technology, and high-performance industrial systems.

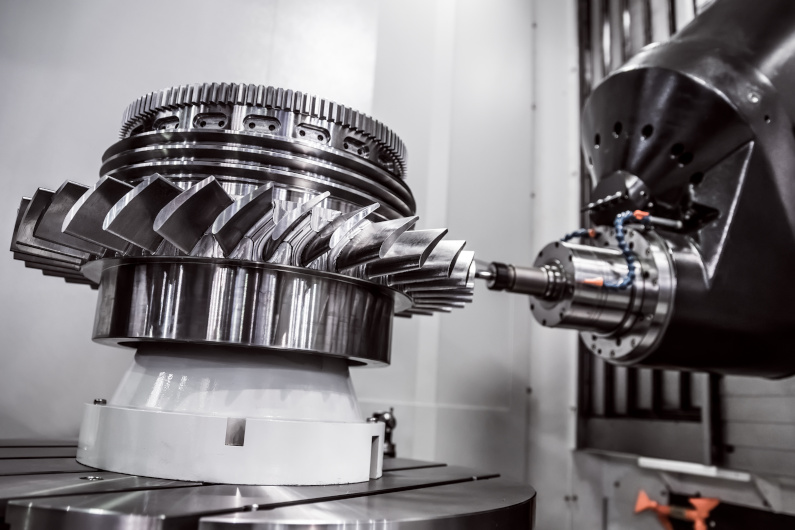

Precision in CNC machining transcends tight tolerances. It encompasses repeatability, thermal stability, dynamic rigidity, and the seamless integration of hardware and software to deliver consistent, high-integrity components. In applications such as aerospace turbine assemblies or military-grade guidance systems, deviations of even a few micrometers can lead to catastrophic system failures. This is why our engineering philosophy centers on deterministic manufacturing—ensuring that every machining cycle produces results within spec, every time.

Our involvement in mission-critical projects—including components for Olympic-standard timing systems and precision subsystems used in military reconnaissance equipment—has reinforced our understanding of what true precision entails. These applications demand not only exceptional machine performance but also rigorous process validation, material traceability, and environmental control. At Lead Precision, we design and build our CNC systems to meet these exacting standards, integrating proprietary motion control algorithms, high-stiffness castings, and real-time error compensation technologies.

We believe that precision begins at the design stage. Our machines are engineered using finite element analysis (FEA) and modal testing to optimize structural dynamics. Linear guideways, preloaded ball screws, and direct-drive spindles are selected based on long-term performance data, not just initial accuracy. Thermal growth is actively managed through symmetrical design and coolant conditioning systems, ensuring dimensional stability across extended production runs.

The result is a machine that does not just claim high precision, but sustains it under real-world conditions.

Below are key performance specifications representative of our flagship 5-axis CNC machining centers, engineered for the most demanding applications:

| Specification | Performance Value |

|---|---|

| Positioning Accuracy (X/Y/Z) | ±0.003 mm |

| Repeatability (X/Y/Z) | ±0.002 mm |

| Spindle Speed (Standard) | 24,000 rpm |

| Surface Finish Capability | Ra ≤ 0.4 µm |

| Thermal Compensation System | Full-axis, real-time |

| Control System | Siemens 840D Solution Line |

| Tool-to-Tool Exchange Time | ≤ 1.8 seconds |

These figures reflect not just machine capability, but our unwavering commitment to delivering systems that perform at the edge of technological possibility. At Wuxi Lead Precision Machinery, we do not manufacture CNC machines—we engineer confidence.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers uncompromising accuracy for mission-critical components across aerospace, medical, and energy sectors. Our technical infrastructure centers on advanced 5-axis CNC machining and rigorous metrology, enabling single-setup production of intricate geometries that eliminate secondary operations and reduce assembly complexity. This integrated approach ensures dimensional stability while accelerating time-to-market for high-value parts.

Our 5-axis machining capacity leverages state-of-the-art DMG MORI and Hermle equipment with simultaneous 5-axis contouring. These platforms feature high-torque spindles (up to 30,000 RPM) and thermal compensation systems, maintaining precision during extended production runs. We machine complex organic shapes, deep cavities, and undercuts in materials ranging from titanium and Inconel to aluminum alloys and engineering plastics. The elimination of repositioning errors achieves geometric tolerances unattainable with 3-axis systems, directly enhancing part functionality and longevity. Critical applications include turbine blades, orthopedic implants, and fluid dynamics components where surface integrity dictates performance.

Quality assurance is anchored by Zeiss and Hexagon CMM systems operating in a climate-controlled metrology lab (20°C ±0.5°C). Every critical feature undergoes full 3D scanning against CAD models, with first-article inspection reports (FAIR) and PPAP documentation provided per AS9102 or client-specific standards. Statistical process control (SPC) monitors capability indices (Cp/Cpk) in real time, ensuring consistency across batches. Dimensional validation extends beyond linear measurements to include form, position, and surface roughness analysis, guaranteeing compliance with GD&T callouts.

The following table details achievable tolerance benchmarks under optimal machining conditions. Actual specifications are validated per project requirements and material properties.

| Parameter | Standard Tolerance | Tight Tolerance | Units |

|---|---|---|---|

| Linear Dimensions | ±0.010 | ±0.005 | mm |

| Angular Features | ±0.05 | ±0.02 | degrees |

| Positional Tolerance | ±0.012 | ±0.008 | mm |

| Surface Roughness (Ra) | 1.6 | 0.8 | μm |

Wuxi Lead’s capabilities translate technical specifications into reliable outcomes. By consolidating multi-axis machining and metrology under one roof, we mitigate supply chain risks while delivering components that meet the most stringent industry certifications. Partner with us to transform complex designs into precision-engineered realities with documented quality at every stage.

Material & Finish Options

Material selection is a critical phase in precision CNC machining, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in machining high-integrity parts from aluminum, steel, and titanium—each offering distinct mechanical properties and application advantages. Understanding the characteristics of these materials allows engineers and procurement teams to make informed decisions aligned with functional requirements and environmental conditions.

Aluminum is widely favored in aerospace, automotive, and consumer electronics due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is particularly popular for prototyping and structural applications, offering good weldability and corrosion resistance. Its low density reduces component weight without sacrificing performance, making it ideal for dynamic systems where inertia and fuel efficiency are critical.

Steel, particularly alloy and stainless variants such as 4140 and 304/316, delivers superior strength, wear resistance, and structural stability under high loads and elevated temperatures. Stainless steel is preferred in medical, food processing, and marine environments due to its exceptional corrosion resistance and compliance with stringent hygiene standards. While heavier than aluminum, steel provides unmatched durability in demanding industrial applications.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for high-performance sectors such as aerospace, defense, and biomedical implants. It offers an outstanding strength-to-density ratio, excellent resistance to extreme temperatures, and unparalleled corrosion resistance—even in saline and chemically aggressive environments. Though more challenging to machine due to its low thermal conductivity and tendency to work-harden, titanium’s longevity and performance under stress justify its use in mission-critical components.

Surface finishing further enhances material performance. Anodizing is a key post-machining process for aluminum, creating a durable, corrosion-resistant oxide layer that can be dyed for identification or aesthetic purposes. Type II (sulfuric acid) anodizing is commonly used for general protection, while Type III (hardcoat anodizing) provides thicker, harder surfaces suitable for high-wear environments. Anodized layers are electrically insulating and improve adhesion for paint and primers.

Below is a comparative overview of key material properties relevant to CNC machining:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Typical Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 310 | 2.7 | 6061-T6, 7075-T6 | Aerospace, Electronics, Automotive | Excellent |

| Stainless Steel | 505–860 | 7.9 | 304, 316, 17-4PH | Medical, Marine, Industrial | Moderate |

| Alloy Steel | 655–900 | 7.8 | 4140, 4340 | Tooling, Heavy Machinery | Fair |

| Titanium | 900–1000 | 4.5 | Ti-6Al-4V (Gr 5) | Aerospace, Defense, Implants | Poor to Moderate |

At Wuxi Lead Precision Machinery, we combine advanced CNC capabilities with material science expertise to deliver precision-machined components tailored to your operational demands. Our engineering team supports material and finish selection to optimize performance, longevity, and cost across your production lifecycle.

Manufacturing Process & QC

Precision CNC Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process is engineered for uncompromising quality and repeatability, transforming client specifications into mission-critical components. We enforce a rigorously controlled sequence spanning design validation, physical prototyping, and high-volume manufacturing, all governed by our Zero Defects mandate. This systematic approach eliminates costly errors and ensures every part meets exacting aerospace, medical, and industrial standards from the first production run.

The process begins with intensive Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with clients to scrutinize 3D CAD models, identifying potential machining constraints, material inefficiencies, or geometric instabilities before metal is cut. Advanced simulation software validates toolpaths, predicts thermal deformation, and optimizes fixture strategies under virtual conditions mirroring our actual machine capabilities. This phase ensures the design is not only feasible but optimized for maximum precision and minimal cycle time, directly preventing defects rooted in flawed geometry or impractical manufacturing assumptions. Only upon final DFM sign-off does the project advance.

Prototyping serves as the critical physical validation stage. We produce initial components using the exact materials, tooling, and CNC programs designated for mass production. Each prototype undergoes comprehensive metrology, including full CMM inspection against nominal CAD data and functional gauging. Dimensional accuracy, surface finish, and material properties are verified against client specifications. Any deviations trigger immediate root-cause analysis and process refinement. This stage is non-negotiable for defect elimination; it proves the process capability and secures client approval on tangible parts, not just simulations. Only prototypes achieving 100% conformance unlock the path to volume production.

Mass production leverages our validated process within a closed-loop quality ecosystem. Components undergo real-time Statistical Process Control (SPC) monitoring on the shop floor, with critical dimensions measured at defined intervals using automated probes and vision systems. Our integrated quality management system tracks every parameter – spindle load, tool wear, coolant pressure – correlating machine data with inspection results. Any trend approaching tolerance limits triggers automatic process correction before non-conformance occurs. Final inspection employs multi-sensor CMMs and optical comparators for 100% verification of critical features on high-risk components, ensuring absolute adherence to the Zero Defects standard. Traceability from raw material to finished part is maintained throughout.

Wuxi Lead Precision Production Capabilities

| Parameter | Capability | Equipment/Technology Used | Quality Standard |

|---|---|---|---|

| Positional Accuracy | ±0.002 mm (±0.00008″) | 5-Axis DMG MORI, Makino, Okuma | ISO 2768-mK |

| Surface Finish | Ra 0.2 µm (8 µin) achievable | High-Speed Spindles (30,000 RPM) | ASME B46.1 |

| Max Work Envelope | 1200 x 800 x 650 mm | Multi-Pallet Systems | Per Client Drawing |

| Material Range | Titanium, Inconel, PEEK, Steel | Swiss-Type Lathes, Mill-Turn | AMS, ASTM, ISO Certified |

| In-Process Control | Real-time SPC, Tool Breakage | Renishaw Probing, MES Integration | PPAP Level 3 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Your Trusted Source for Advanced CNC Machining Solutions

At Wuxi Lead Precision Machinery, we don’t just manufacture precision components—we engineer long-term partnerships built on reliability, technical excellence, and unwavering commitment to quality. As a leading provider of high-precision CNC machining services in China, we specialize in delivering custom-engineered solutions for industries where performance and consistency are non-negotiable. From aerospace and medical devices to automation and energy systems, our clients trust us to meet the most demanding specifications with zero compromise.

Our CNC machining capabilities are powered by state-of-the-art equipment, including 3-axis, 4-axis, and 5-axis machining centers, ensuring we can handle complex geometries with micron-level accuracy. Combined with our ISO 9001-certified quality management system and a team of seasoned engineers, we deliver parts that meet or exceed global standards. But what truly sets us apart is our partnership approach. We work closely with your engineering and procurement teams from concept to completion—offering design for manufacturability (DFM) feedback, rapid prototyping, and scalable production runs—all with transparent communication and on-time delivery.

We understand that in high-end manufacturing, every detail matters. That’s why our facility in Wuxi is equipped with advanced metrology tools such as CMMs, optical comparators, and surface roughness testers to ensure every component is verified before shipment. Whether you require low-volume prototypes or high-volume production, our agile manufacturing system adapts to your timeline, volume, and quality requirements.

For global OEMs and tier-one suppliers, choosing the right manufacturing partner is a strategic decision. At Lead Precision, we align our capabilities with your business goals—offering competitive pricing without sacrificing precision, responsiveness, or technical support. Our track record includes successful collaborations with clients across North America, Europe, and Asia, where repeat orders and long-term contracts are the norm.

If you’re looking for a CNC machining partner that combines technical mastery with operational reliability, we invite you to start a conversation today. Let us demonstrate how we can support your next project with precision, professionalism, and performance.

Contact us at [email protected] to discuss your requirements, request a quote, or schedule a virtual tour of our facility.

| Specification | Detail |

|---|---|

| Machine Types | 3-axis, 4-axis, 5-axis CNC Machining Centers |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Brass, Plastics (PEEK, Delrin, etc.) |

| Tolerance Capability | ±0.005 mm (±0.0002″) |

| Max Work Envelope | 1200 x 800 x 600 mm (47″ x 31.5″ x 23.6″) |

| Surface Finish | As low as Ra 0.4 µm (16 µin) |

| Quality Standards | ISO 9001:2015 Certified, Full First Article Inspection (FAI) Reports |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

| Secondary Operations | Deburring, Anodizing, Plating, Passivation, Laser Marking |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.