Technical Contents

Engineering Guide: Online Sheet Metal Cutting

Engineering Insight: The Non-Negotiable Imperative of Precision in Online Sheet Metal Cutting

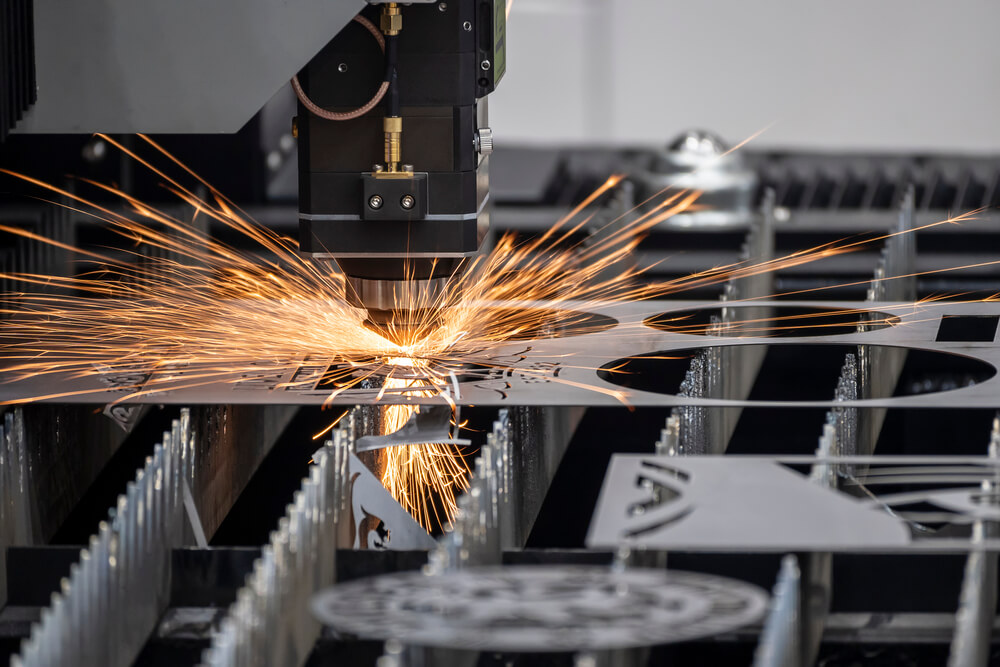

In the high-stakes realm of modern manufacturing, online sheet metal cutting transcends basic material separation. It is the critical foundation upon which complex assemblies, structural integrity, and ultimate product performance are built. Sub-millimeter deviations are not merely tolerable; they are costly failures leading to scrap, rework, delayed shipments, and compromised end-product functionality. Precision is the absolute cornerstone, dictating fit, finish, and the seamless integration of components within larger systems. For industries like aerospace, defense, medical technology, and advanced energy, where tolerances are measured in hundredths of a millimeter, the cutting process must deliver unwavering accuracy consistently, batch after batch, part after part. This level of control is non-negotiable for achieving optimal yield, minimizing waste, and ensuring the final product meets rigorous engineering specifications and safety standards.

Wuxi Lead Precision Machinery operates at this pinnacle of precision sheet metal fabrication. Our core engineering philosophy centers on mastering the variables that impact cut quality: laser beam focus stability, motion control accuracy, material thermal management, and sophisticated process parameter optimization. We leverage state-of-the-art fiber laser systems with dynamic capacitive height control, integrated CAD/CAM nesting software with real-time collision avoidance, and rigorous in-process metrology. This integrated approach ensures geometric fidelity, minimal heat-affected zones, and edge quality suitable for demanding secondary operations like welding or coating – all delivered through a streamlined online quoting and ordering platform designed for engineering rigor, not just convenience.

Our commitment to precision is proven in the most demanding applications. We have successfully executed critical components for major international sporting infrastructure, including structural elements for Olympic venues where dimensional accuracy directly impacted safety and assembly timelines. Furthermore, our processes and quality management systems meet the stringent requirements of military-grade fabrication, producing parts where failure is not an option. This experience underscores our capability to handle projects where precision is mission-critical.

The following table outlines the core precision capabilities achievable through our online sheet metal cutting services, reflecting the standards demanded by our aerospace, defense, and high-tech industrial clients:

| Capability Parameter | Standard Performance | High-Precision Performance | Key Applications |

|---|---|---|---|

| Linear Cutting Tolerance | ±0.10 mm | ±0.05 mm | Aerospace frames, sensor mounts |

| Hole Position Tolerance | ±0.15 mm | ±0.08 mm | Precision assemblies, tooling |

| Material Thickness Range | 0.5 mm – 25 mm | 0.5 mm – 15 mm | Structural, enclosures, panels |

| Common Processed Materials | Mild Steel, SS, Al | SS 304/316, Al 5052/6061 | Critical components, marine |

| Edge Perpendicularity | < 0.15° | < 0.08° | Weld prep, high-fit assemblies |

This precision is not an isolated feature but the integrated result of our engineering expertise, advanced machinery, and disciplined quality processes – all accessible through a professional online interface. When your design demands micron-level accuracy, Wuxi Lead Precision Machinery delivers the engineered cutting solution, backed by proven experience where performance is paramount. Trust precision. Demand reliability. Choose Lead.

Precision Specs & Tolerances

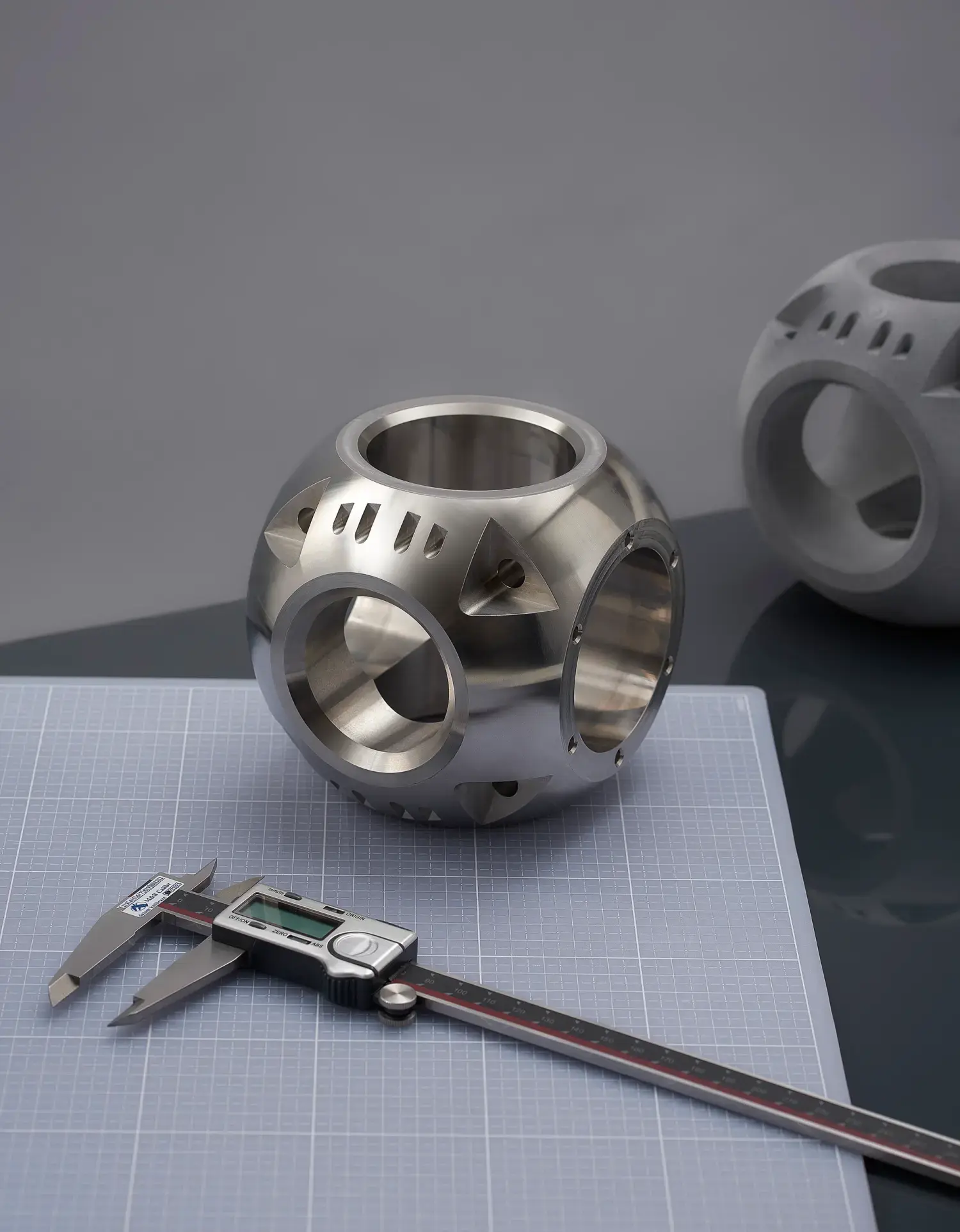

Wuxi Lead Precision Machinery delivers advanced technical capabilities in online sheet metal cutting, engineered for high-precision industrial applications. Our facility integrates state-of-the-art 5-axis CNC machining systems with automated sheet metal processing lines, enabling complex geometries and tight-tolerance components with unmatched repeatability. This level of precision is critical for industries such as aerospace, medical devices, and high-end automation, where dimensional accuracy and surface integrity are non-negotiable.

Our 5-axis CNC cutting platforms provide dynamic multi-directional control, allowing for intricate contours and beveled edges in a single setup. This reduces cumulative error from multiple fixturing stages and enhances throughput without sacrificing quality. The integration of fiber laser and plasma cutting technologies with 5-axis motion systems ensures clean, burr-free edges across a wide range of conductive and non-conductive sheet materials, including stainless steel, aluminum, copper alloys, and titanium. Sheet thicknesses from 0.5 mm to 25 mm are processed with consistent edge squareness and minimal heat-affected zones, thanks to adaptive power modulation and high-speed motion algorithms.

To maintain the integrity of every component, all production runs are supported by comprehensive quality control protocols. Each batch undergoes rigorous inspection using a Zeiss DuraMax and Wenzel LH87 coordinate measuring machine (CMM), ensuring full compliance with ISO 10360 standards. Our CMM system performs 3D geometric dimensioning and tolerance (GD&T) verification, surface profile analysis, and positional accuracy checks on critical features. Data from each inspection is archived for full traceability, supporting AS9100 and ISO 13485 compliance for regulated sectors.

The following table outlines the standard and precision tolerances achievable across our sheet metal cutting operations:

| Feature | Standard Tolerance | Precision Tolerance (CMM-Validated) |

|---|---|---|

| Linear Dimensions (up to 300 mm) | ±0.1 mm | ±0.05 mm |

| Linear Dimensions (300–1000 mm) | ±0.15 mm | ±0.08 mm |

| Hole Diameter | ±0.1 mm | ±0.05 mm |

| Hole Position | ±0.15 mm | ±0.07 mm |

| Edge Perpendicularity | 0.15 mm/100 mm | 0.08 mm/100 mm |

| Bevel Angle (5-axis cut) | ±1.5° | ±0.5° |

| Surface Roughness (Ra) | 6.3 µm | 3.2 µm (polished finish available) |

All tolerances are validated under controlled environmental conditions (20±1°C) and are subject to material grade, thickness, and part geometry. Custom process plans are developed for high-mix, low-volume runs, ensuring optimal setup and inspection routing. With full digital integration from CAD/CAM to CMM reporting, Wuxi Lead Precision Machinery ensures that every online sheet metal cutting job meets the highest benchmarks in accuracy, consistency, and industrial reliability.

Material & Finish Options

Material Selection for Precision Sheet Metal Cutting

Selecting the optimal material is a critical consideration in sheet metal fabrication, directly impacting manufacturability, cost, performance, and final part functionality. At Wuxi Lead Precision Machinery, our advanced CNC cutting systems handle a wide range of metals, but understanding the specific properties of Aluminum, Steel, and Titanium ensures the best outcome for your high-tolerance components. Material choice must align with the part’s operational environment, mechanical requirements, and post-processing needs, particularly when utilizing online cutting services where upfront specification accuracy is paramount.

Aluminum alloys, especially 6061-T6, are a premier choice for lightweight structural applications demanding good strength-to-weight ratio, excellent corrosion resistance, and high thermal/electrical conductivity. Its relative softness facilitates faster cutting speeds with minimal tool wear on our fiber laser systems, making it cost-effective for complex geometries. However, aluminum’s high thermal conductivity requires precise parameter control to prevent dross formation or edge melting during laser cutting. It is ideal for aerospace components, enclosures, and heat sinks where weight savings are critical.

Carbon steel and stainless steel variants like 304 offer superior strength, durability, and cost efficiency for structural and industrial applications. 304 stainless steel provides excellent corrosion resistance and weldability, suitable for food processing, medical equipment, and architectural elements. While generally more economical than aluminum or titanium, steel requires higher laser power settings due to its higher melting point and thermal conductivity compared to aluminum. Careful attention to assist gas selection (typically nitrogen for clean edges on stainless, oxygen for carbon steel) is essential to achieve the required edge quality and minimize oxidation.

Titanium Grade 2 stands out for extreme environments demanding exceptional strength-to-weight ratio, outstanding corrosion resistance (especially to chlorides), and biocompatibility. Its high melting point and chemical reactivity necessitate specialized cutting parameters and stringent inert gas shielding (argon) during laser processing to prevent oxidation and contamination, significantly impacting cycle time and cost. Titanium is reserved for critical aerospace, medical implant, and high-performance marine applications where its unique properties justify the fabrication complexity.

Anodizing is the dominant finish for aluminum components, enhancing surface hardness, wear resistance, and corrosion protection while providing an excellent base for dyeing. Type II (sulfuric acid) anodizing offers a standard decorative and protective layer, while Type III (hardcoat) anodizing delivers significantly thicker, harder, and more abrasion-resistant surfaces suitable for demanding engineering applications. Note that anodizing requires precise dimensional allowances as the process builds oxide layer thickness both inward and outward from the base metal surface. Material selection must account for this final dimension change.

The following table summarizes key properties relevant to CNC cutting feasibility and application suitability:

| Material | Key Properties for Cutting | Max Thickness (mm) | Primary Applications |

|---|---|---|---|

| Aluminum 6061-T6 | High thermal conductivity, lower melting point | 25 | Aerospace frames, enclosures, heat sinks |

| Stainless Steel 304 | High corrosion resistance, moderate strength | 30 | Medical devices, food processing, marine |

| Titanium Grade 2 | Extremely high strength-to-weight, reactive | 12 | Aircraft components, medical implants |

Choosing the right material involves balancing performance requirements against fabrication constraints inherent in precision sheet metal cutting processes. Wuxi Lead Precision Machinery leverages decades of expertise to advise clients on optimal material and finish selection, ensuring your online cutting order translates seamlessly into high-quality, functional parts meeting exact specifications. Consult our engineering team early in the design phase for material-specific guidance.

Manufacturing Process & QC

Design: The Foundation of Precision Manufacturing

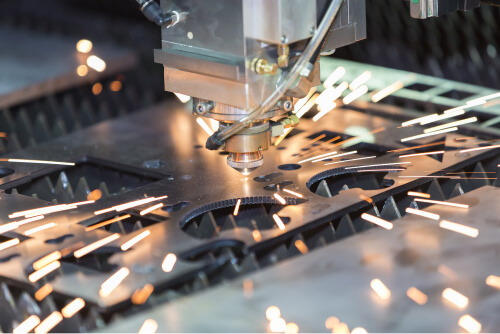

At Wuxi Lead Precision Machinery, the production process for online sheet metal cutting begins with meticulous design engineering. Every component is developed using advanced 3D CAD software, ensuring dimensional accuracy and structural integrity from the earliest stage. Our design team collaborates closely with clients to interpret technical drawings, refine geometries, and optimize for manufacturability. This phase includes material selection, thickness analysis, and feature validation to ensure compatibility with high-speed cutting technologies such as fiber laser, CNC punching, and plasma systems. Design for Assembly (DFA) and Design for Manufacturing (DFM) principles are rigorously applied to minimize waste, reduce cycle times, and eliminate potential failure points before any metal is cut.

Prototyping: Validating Performance and Fit

Once the digital model is finalized, we proceed to prototyping—a critical checkpoint in our zero-defect strategy. A physical prototype is produced using the same industrial-grade equipment intended for mass production, guaranteeing consistent process parameters. This allows us to verify form, fit, and function under real-world conditions. Dimensional inspection is conducted using coordinate measuring machines (CMM) and laser scanning to confirm tolerances within ±0.1 mm. Any deviations are traced back to the design or setup phase and corrected immediately. Client feedback is integrated at this stage, enabling final adjustments before committing to full-scale manufacturing. Prototyping not only mitigates risk but also accelerates time-to-market by identifying issues early.

Mass Production: Scalable Precision with Zero Defects

With prototype approval, we transition seamlessly into mass production. Our automated production lines leverage integrated CNC controls, robotic material handling, and real-time monitoring systems to maintain consistency across thousands of parts. Each batch undergoes in-process quality checks at defined intervals, including edge quality assessment, burr detection, and geometric verification. Statistical Process Control (SPC) data is logged and analyzed to detect trends that could indicate tool wear or alignment drift, enabling predictive maintenance and instant correction. All finished components are cleaned, deburred, and inspected according to ISO 9001 standards before packaging.

Throughout the entire workflow—from design to delivery—traceability is maintained via a digital manufacturing execution system (MES), ensuring full accountability and enabling rapid root-cause analysis if required. This closed-loop approach is central to our zero-defect philosophy.

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 – 25 mm |

| Cutting Tolerance | ±0.1 mm |

| Positional Accuracy | ±0.05 mm/m |

| Surface Roughness (Ra) | ≤ 3.2 μm |

| Maximum Workpiece Size | 4000 x 15000 mm |

| Supported File Formats | STEP, IGES, DXF, DWG, PDF |

| Quality Standard | ISO 9001:2015 |

This disciplined progression ensures that every part produced meets the highest standards of precision, reliability, and repeatability—defining the Wuxi Lead Precision Machinery advantage in global sheet metal fabrication.

Why Choose Wuxi Lead Precision

Elevate Your Production with Precision Engineering Partnerships

In the demanding landscape of modern manufacturing, inconsistent sheet metal fabrication partners directly impact your production timelines, quality control, and bottom line. Wuxi Lead Precision Machinery exists to eliminate these critical bottlenecks. We are not merely a vendor; we are a strategic engineering extension of your team, dedicated to transforming your most complex sheet metal cutting requirements into flawlessly executed components. Our advanced online sheet metal cutting platform integrates seamlessly with your procurement workflow, providing real-time quoting, order tracking, and technical collaboration, all while adhering to the stringent tolerances demanded by aerospace, medical device, and high-end industrial sectors. Partnering with Lead Precision means accessing a foundation built on German-engineered CNC laser and turret punch technology, operated by certified technicians with over 15 years of precision sheet metal expertise.

Our commitment transcends standard fabrication. We implement rigorous material traceability protocols and in-process quality verification at every stage, ensuring compliance with ISO 9001:2015 standards and your specific engineering documentation. Whether you require prototyping in thin-gauge stainless steel or high-volume production of structural aluminum components, our optimized processes deliver unmatched repeatability and surface finish. The result is reduced scrap rates, minimized assembly rework, and accelerated time-to-market for your finished products. We understand that your reputation hinges on component integrity; ours is built on guaranteeing it.

The technical capabilities underpinning this reliability are quantifiable. Our core sheet metal cutting specifications consistently meet the highest industry benchmarks:

| Capability | Specification | Advantage for Your Project |

|---|---|---|

| Material Thickness Range | 0.5mm – 6.0mm (Stainless, Carbon Steel, Aluminum) | Versatility for intricate prototypes to robust production parts |

| Cutting Tolerance | ±0.05mm (Laser), ±0.1mm (Punch) | Ensures perfect fit in critical assemblies |

| Max. Working Area | 1500mm x 3000mm | Accommodates large panels without seams |

| Lead Time (Standard) | 5-7 Working Days (From PO) | Predictable scheduling for JIT manufacturing |

| Surface Finish (Ra) | ≤ 1.6µm (Laser Cut Edges) | Reduces or eliminates secondary finishing needs |

This precision is sustained through our online portal, which provides immediate access to detailed manufacturing feedback, dimensional reports, and material certifications, fostering transparent collaboration. When component failure is not an option, your choice of fabrication partner becomes paramount. Wuxi Lead Precision Machinery delivers the engineering rigor, technical capacity, and responsive partnership essential for success in high-stakes manufacturing environments.

Initiate a partnership built on precision and performance. Contact our engineering sales team directly at [email protected] to discuss your specific sheet metal cutting requirements. Provide your project drawings or specifications, and we will deliver a comprehensive technical assessment and competitive quotation within 24 business hours. Let Lead Precision become the reliable, high-precision manufacturing solution your production workflow demands. Your next breakthrough component starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.