Technical Contents

Engineering Guide: Good Molding

Engineering Insight: The Precision Behind Good Molding

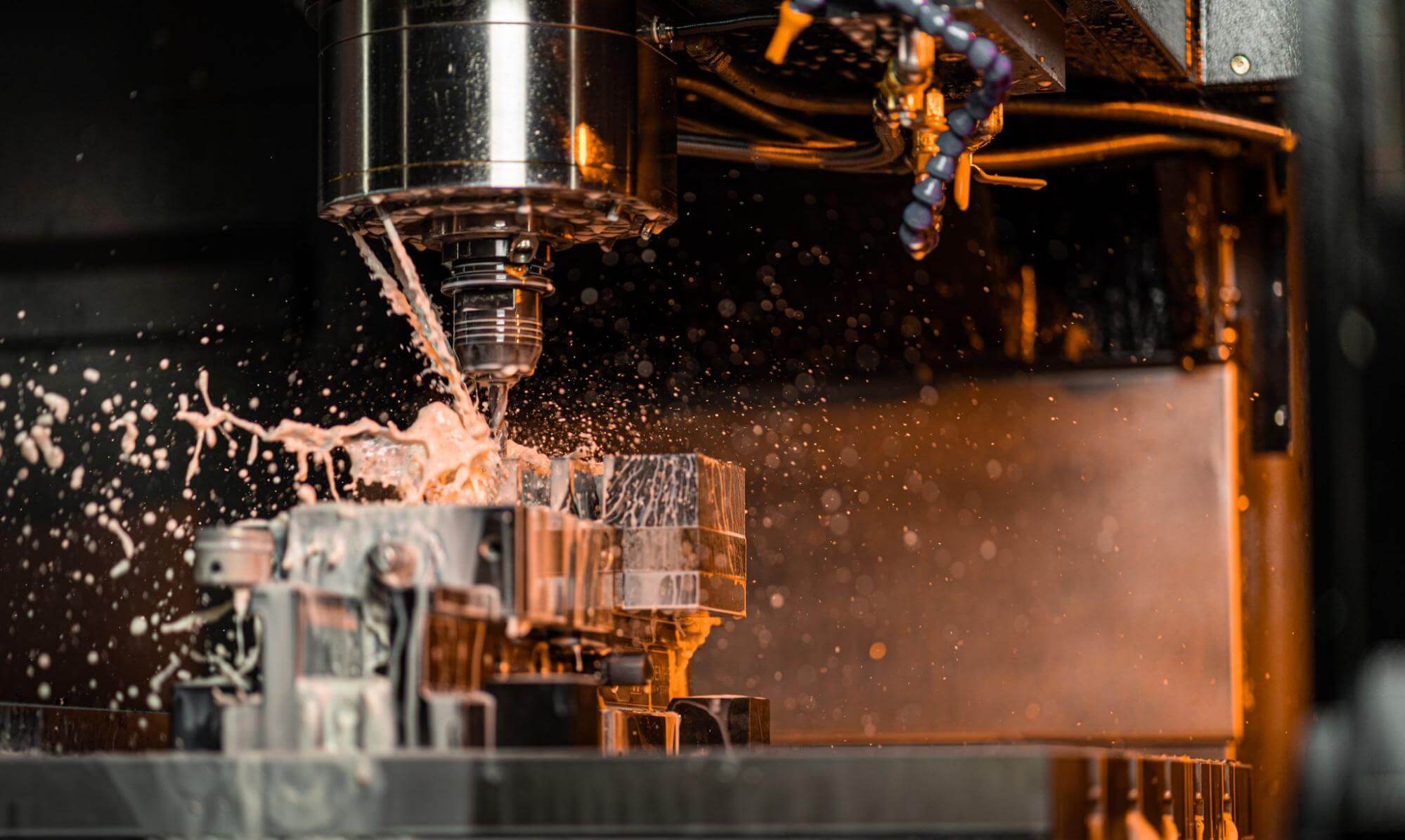

In the realm of custom metal manufacturing, “good molding” transcends aesthetic finish or dimensional conformity—it represents the seamless integration of material science, engineering rigor, and micron-level precision. At Wuxi Lead Precision Machinery, we define good molding not by appearance alone, but by consistency, repeatability, and performance under real-world operational stress. This standard is not accidental; it is engineered through decades of refinement, advanced tooling, and an uncompromising commitment to tolerances that meet the demands of the most critical industries.

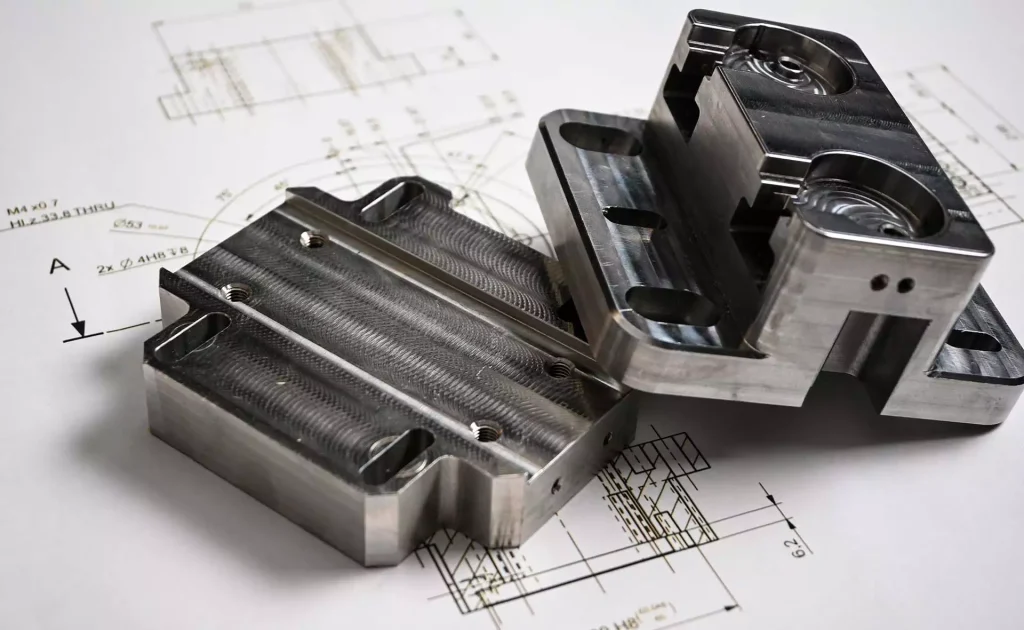

Precision in molding begins long before the first billet is cut. It starts with material selection, mold design simulation, and finite element analysis to predict deformation, stress concentration, and thermal behavior during the forming process. At Lead Precision, our engineering team leverages proprietary algorithms and 3D modeling software to simulate thousands of molding cycles, ensuring that every cavity, core, and ejection mechanism performs as intended. This predictive capability minimizes trial-and-error, reduces waste, and accelerates time-to-market—critical advantages in high-stakes sectors such as aerospace, defense, and advanced medical systems.

Our track record in delivering precision-molded components for Olympic-grade equipment and military applications underscores our mastery of the craft. These projects demand parts that perform flawlessly under extreme conditions—whether exposed to cryogenic temperatures, high-impact loads, or corrosive environments. For instance, components used in precision-guided systems require tolerances within ±0.002 mm and surface finishes under Ra 0.4 µm, specifications we consistently achieve through closed-loop CNC monitoring and in-process metrology.

Good molding also hinges on process control. At our Wuxi facility, every molding operation is governed by real-time sensors that monitor pressure, temperature, and cycle time. Deviations beyond predefined thresholds trigger immediate corrective actions, ensuring batch-to-batch uniformity. Our quality management system is ISO 9001:2015 certified, with additional compliance for AS9100D in aerospace and ITAR for defense contracts.

We understand that precision is not a one-time achievement but a sustained discipline. Our engineers conduct post-molding failure mode analysis on every critical component, feeding insights back into design and process optimization. This continuous improvement cycle has enabled us to maintain a defect rate below 25 PPM across high-volume production runs.

Below are representative specifications achievable through our precision molding processes:

| Parameter | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.01 mm | ±0.002 mm | CMM (ZEISS DuraMax) |

| Surface Roughness (Ra) | 1.6 µm | 0.2 µm | Profilometer (Mitutoyo SJ-410) |

| Material Compatibility | Aluminum, Steel, Titanium, Inconel | Specialty Alloys (e.g., MP35N) | Spectrometry (Bruker Q4) |

| Maximum Part Weight | 50 kg | 25 kg (for tight tolerances) | Load Cell Calibration |

| Production Volume | 1 – 100,000+ units/year | 1,000 – 50,000 units/year | Automated Cell Monitoring |

At Wuxi Lead Precision Machinery, we believe that good molding is the foundation of reliable performance. It is the difference between a component that functions and one that excels. With our heritage in mission-critical manufacturing, we bring Olympic and military-grade precision to every custom metal molding project we undertake.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering for Superior Molding Performance

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to deliver the foundational precision required for high-performance molding applications. We specialize in custom metal manufacturing where dimensional accuracy, surface integrity, and thermal stability directly dictate mold longevity, part consistency, and production efficiency. Our integrated approach ensures every component meets the rigorous demands of advanced molding processes, minimizing downtime and scrap rates for our clients.

Central to our operation is a dedicated fleet of 5-axis CNC machining centers, featuring FANUC and Siemens controls with sub-micron positioning accuracy. These systems enable complex geometries in a single setup—critical for mold cores, cavities, and inserts—eliminating cumulative errors from multiple fixtures. Our machines incorporate thermal compensation systems and rigid cast-iron structures to maintain stability during extended production runs, ensuring repeatability under varying thermal loads. Material compatibility spans hardened tool steels (H13, S7), aluminum alloys, copper-beryllium, and exotic superalloys, all machined with optimized toolpaths that preserve material grain structure and minimize residual stress.

Quality control is non-negotiable. Every component undergoes comprehensive metrology using Zeiss CONTURA and Hexagon GLOBAL CMMs, programmed to ASME Y14.5 and ISO 1101 standards. Our inspection protocol covers full geometric dimensioning and tolerancing (GD&T), including form, profile, and positional checks across critical features. Surface roughness is verified via Mitutoyo SJ-410 profilometers, ensuring finishes meet Ra 0.4 µm or finer where required for release properties and aesthetic molding. Statistical process control (SPC) data is documented per lot, providing traceability from raw material to final shipment.

The following table details our standard achievable tolerances for molding-critical features, reflecting our commitment to exceeding industry benchmarks:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.002 mm | CMM |

| Hole Diameter | ±0.008 mm | ±0.001 mm | CMM / Air Gage |

| Flatness | 0.005 mm | 0.001 mm | CMM |

| Parallelism | 0.008 mm | 0.002 mm | CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Profilometer |

| Angular Features | ±0.005° | ±0.001° | CMM |

These capabilities translate directly into molding excellence: precise cavity/core matching prevents flash, controlled draft angles ensure part ejection, and uniform thermal channels optimize cycle times. We collaborate closely with clients during design for manufacturability (DFM) reviews, identifying potential molding risks early—such as stress concentrations or cooling inefficiencies—and refining geometries for optimal CNC execution. Our process guarantees that every mold base, insert, or electrode arrives with geometric integrity that maximizes tool life and part quality.

For mission-critical molding applications, precision is not a specification—it is the foundation of your production success. Wuxi Lead Precision Machinery delivers the technical rigor to make it achievable.

Material & Finish Options

Material Selection for Precision Metal Components: A Guide by Wuxi Lead Precision Machinery

Selecting the appropriate material and finish is critical in achieving optimal performance, durability, and cost-efficiency in custom metal manufacturing. At Wuxi Lead Precision Machinery, we specialize in high-precision components for industries ranging from aerospace to medical devices, where material integrity directly impacts product success. This guide outlines the key characteristics of aluminum, steel, and titanium, along with the benefits of anodizing as a surface treatment.

Aluminum is widely favored for applications requiring a high strength-to-weight ratio, excellent thermal conductivity, and corrosion resistance. It is particularly suitable for lightweight structural components, enclosures, and heat sinks. The 6061 and 7075 aluminum alloys offer enhanced mechanical properties and weldability, making them ideal for complex machined parts. When paired with anodizing, aluminum gains a durable oxide layer that improves wear resistance, enhances aesthetic appeal, and allows for color coding in assembly lines.

Steel remains the material of choice for high-strength, high-wear applications. Alloys such as 4140 and 1045 provide exceptional toughness and can be heat-treated to meet stringent mechanical requirements. Stainless steel grades like 304 and 316 offer superior corrosion resistance, making them suitable for medical instruments and food processing equipment. While steel does not anodize, it can be treated with passivation, plating, or powder coating to enhance surface properties.

Titanium, particularly Grade 5 (Ti-6Al-4V), delivers an unmatched combination of strength, light weight, and resistance to extreme environments. It is frequently used in aerospace, defense, and biomedical implants due to its biocompatibility and performance under high stress and temperature. Although more challenging to machine, titanium’s long-term reliability justifies its use in mission-critical applications.

Anodizing is a key surface treatment for aluminum components. This electrochemical process thickens the natural oxide layer, significantly improving corrosion and abrasion resistance. Type II (sulfuric acid) anodizing is commonly used for decorative and moderate-duty applications, while Type III (hardcoat) anodizing provides a thicker, harder surface for industrial and military-grade parts. Anodized layers are integral to the base metal, ensuring they do not peel or flake under stress.

The table below summarizes key mechanical and surface treatment properties of the materials discussed.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Suitable Finishes |

|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | Good | Anodizing (Type II, Type III) |

| Steel 4140 | 655 | 7.85 | Moderate | Passivation, Zinc Plating |

| Stainless 316 | 570 | 8.0 | Excellent | Electropolishing, Passivation |

| Titanium Ti-6Al-4V | 900 | 4.43 | Excellent | Anodizing (Color), Passivation |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish combination based on functional requirements, environmental exposure, and lifecycle demands. Our engineering team provides consultation from design to delivery, ensuring every component meets exacting standards.

Manufacturing Process & QC

Precision Metal Manufacturing: The Zero Defects Production Process

Achieving true ‘good molding’ in custom metal components demands an uncompromising, integrated production process. At Wuxi Lead Precision Machinery, we engineer perfection through three rigorously controlled phases: Design, Prototyping, and Mass Production. This systematic approach ensures zero defects are not merely aspirational but contractually guaranteed deliverables for demanding industries like aerospace, medical, and semiconductor.

The foundation is meticulous Design engineering. Our senior CNC engineers collaborate directly with your team to translate concepts into manufacturable realities. We conduct exhaustive Design for Manufacturability (DFM) and Design for Assembly (DFA) analyses, identifying potential stress points, material limitations, and geometric complexities before metal is cut. Finite Element Analysis (FEA) validates structural integrity under operational loads, while thermal modeling predicts behavior during molding and service. This phase eliminates approximately 80% of potential defects at the source, optimizing tool paths and material selection for inherent quality. Material certifications and traceability protocols are established here, ensuring compliance with ASTM, ISO, or client-specific standards from day one.

Prototyping transitions validated designs into physical validation. We produce functional prototypes using the same hardened tooling and CNC processes destined for mass production, not soft tooling substitutes. Each prototype undergoes rigorous metrology: Coordinate Measuring Machine (CMM) verification against 3D CAD models, surface roughness testing, dimensional stability checks under thermal cycling, and non-destructive testing (NDT) like X-ray or ultrasonic inspection where critical. This is not a single iteration but a closed-loop process. Any deviation triggers immediate root cause analysis and design or process refinement. Only when the prototype consistently meets all specifications – dimensional, mechanical, and cosmetic – does it receive formal approval for scale-up.

Mass Production executes the perfected process with relentless statistical control. Every CNC machine operates under real-time monitoring of critical parameters: spindle load, tool wear, coolant pressure, and environmental conditions. Automated in-process gauging at defined intervals verifies dimensions mid-run, preventing drift. Full First Article Inspection (FAI) reports per AS9102 are standard. Crucially, our traceability system logs every component’s journey – specific machine, operator, tooling batch, raw material lot, and inspection data – enabling instant recall if ever needed. Final inspection employs 100% visual checks and randomized high-precision CMM verification against tightened internal tolerances exceeding typical customer requirements. This multi-layered defense system ensures every shipped part meets the Zero Defects mandate.

Wuxi Lead Precision Machinery Core Production Specifications

| Parameter | Capability | Quality Control Method | Tolerance/Standard |

|---|---|---|---|

| Dimensional Accuracy | Complex Geometries (5-Axis CNC) | Real-time In-Process Gauging + CMM | ±0.005 mm (Standard) |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm | Profilometer + Visual Inspection | Per ISO 1302 |

| Material Compliance | Aerospace Alloys, Medical Stainless | Mill Certificates + PMI Verification | ASTM/AMS/ISO Certified |

| Traceability | Full Component Lifecycle | Digital Lot Tracking System | Unique Serial per Batch |

| Process Control | Statistical Process Control (SPC) | Real-time Parameter Monitoring | CpK ≥ 1.67 (Target) |

This integrated Design-Prototype-Production framework, underpinned by advanced metrology and absolute traceability, transforms ‘good molding’ from an outcome into a predictable, repeatable engineering discipline. Partner with Wuxi Lead for components where failure is never an option. Zero defects is not our goal; it is our baseline standard.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Custom Metal Manufacturing

In the world of high-performance industrial components, precision is not just a requirement—it is the foundation of reliability, efficiency, and long-term value. At Wuxi Lead Precision Machinery, we specialize in delivering custom metal manufacturing solutions engineered to meet the exacting standards of global industries, from aerospace and automotive to medical and energy. Our commitment to quality, innovation, and technical mastery positions us as the strategic partner of choice for organizations demanding superior molding performance and dimensional accuracy.

When you partner with Lead Precision, you gain access to a fully integrated manufacturing ecosystem. Our advanced CNC machining centers, automated inspection systems, and in-house tooling design capabilities ensure that every component is produced with micron-level consistency. We understand that “good molding” goes beyond surface finish—it encompasses material integrity, structural repeatability, thermal stability, and long-term durability under operational stress. Our engineering team collaborates closely with clients from concept through production, applying Design for Manufacturing (DFM) principles to optimize performance while reducing lead times and total cost of ownership.

Our facility in Wuxi, China, operates under strict ISO 9001 and IATF 16949 quality management systems, ensuring every process is traceable, auditable, and aligned with international standards. Whether you require low-volume prototyping or high-volume production runs, our scalable infrastructure supports rapid deployment without compromising precision.

Below are key technical capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| CNC Machining Accuracy | ±0.002 mm |

| Maximum Work Envelope | 2,200 mm × 1,200 mm × 1,000 mm |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Tool Steels, Copper Alloys |

| Surface Finish (Typical) | Ra 0.4 µm to Ra 1.6 µm |

| Tolerance Control | IT6 to IT8 per ISO 286 |

| Production Capacity | Up to 500,000 units/year (automated lines) |

| Quality Assurance | CMM, 3D Scanning, Optical Measurement, Hardness Testing |

We don’t just manufacture parts—we engineer performance. Our solutions are built on decades of experience in solving complex metal forming challenges, where thermal expansion, residual stress, and mold flow dynamics directly impact final product quality. With real-time process monitoring and adaptive machining strategies, we ensure that every batch meets the highest benchmark for consistency and reliability.

For global OEMs and Tier-1 suppliers, the choice of a manufacturing partner is a strategic decision that affects product lifecycle, compliance, and market competitiveness. At Lead Precision, we combine Chinese manufacturing efficiency with European-level precision standards, offering a unique value proposition that bridges cost and quality.

To begin your next project with confidence, contact us today at [email protected]. Let our engineering team help you transform design intent into precision reality. Partner with Wuxi Lead Precision Machinery—where exacting standards meet industrial innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.