Technical Contents

Engineering Guide: Surface Quality Precision Cnc Turning

Engineering Insight: Surface Quality in Precision CNC Turning

In high-performance manufacturing, surface quality is not merely an aesthetic concern—it is a critical engineering parameter that directly influences the functionality, durability, and reliability of precision components. At Wuxi Lead Precision Machinery, we understand that achieving superior surface finish in CNC turning is essential for applications where friction, wear resistance, sealing performance, and fatigue life are paramount. Our expertise in surface quality precision CNC turning has been rigorously tested in sectors where failure is not an option—such as aerospace, defense, and Olympic-grade sports technology.

Precision CNC turning achieves optimal surface quality through a combination of advanced machine rigidity, ultra-stable tooling systems, high-frequency spindle control, and meticulously optimized cutting parameters. At Lead Precision, we employ state-of-the-art CNC lathes with sub-micron positioning accuracy and real-time vibration damping to minimize surface imperfections. Our process engineering team fine-tunes feed rates, cutting speeds, and tool nose radii to produce finishes that consistently meet or exceed industry benchmarks—down to Ra 0.2 µm and below when required.

Material selection and workpiece preparation also play a vital role. We implement strict incoming material inspection protocols and pre-machining stress-relief procedures to prevent distortion and ensure uniform surface integrity. Additionally, our use of coated carbide and polycrystalline diamond (PCD) tooling enables consistent surface replication across high-volume production runs, especially with challenging materials such as titanium alloys, Inconel, and hardened steels.

Our commitment to excellence has been validated through demanding projects. Components manufactured by Wuxi Lead have been integrated into Olympic-level athletic equipment, where nanoscale surface consistency directly impacts performance. Similarly, our parts meet stringent military specifications (MIL-STD) for use in guidance systems and tactical hardware, where surface defects could compromise mission-critical operations.

We adhere to international surface measurement standards, utilizing non-contact profilometry and 3D surface mapping to verify topography, waviness, and roughness. This data-driven approach ensures traceability and repeatability across batches, providing our clients with confidence in every turned component.

Below is a summary of our typical surface quality capabilities in precision CNC turning:

| Parameter | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Surface Roughness (Ra) | Ra 1.6 – 3.2 µm | Ra 0.2 – 0.8 µm | Contact profilometer, Class I |

| Surface Waviness (Wt) | ≤ 5 µm | ≤ 1.5 µm | 3D optical interferometry |

| Tooling Precision | ±0.001 mm | ±0.0005 mm | Laser tool presetting systems |

| Spindle Runout | ≤ 2 µm | ≤ 1 µm | Capacitive displacement sensors |

| Material Compatibility | Steel, Aluminum, Brass, Stainless, Titanium, Inconel | Same + PEEK, Ceramics (with coating) | N/A |

At Wuxi Lead Precision Machinery, surface quality is not an afterthought—it is engineered into every rotation, every cut, and every component we produce.

Precision Specs & Tolerances

Surface Quality Precision in CNC Turning: Technical Capabilities

Achieving exceptional surface quality in CNC turning is non-negotiable for critical components in aerospace, medical, and semiconductor applications. At Wuxi Lead Precision Machinery, we integrate advanced multi-axis machining with rigorous metrology to deliver surface finishes and geometric accuracy that meet the most stringent international specifications. Our process control philosophy ensures consistency from prototype to high-volume production, directly impacting part functionality, longevity, and assembly performance.

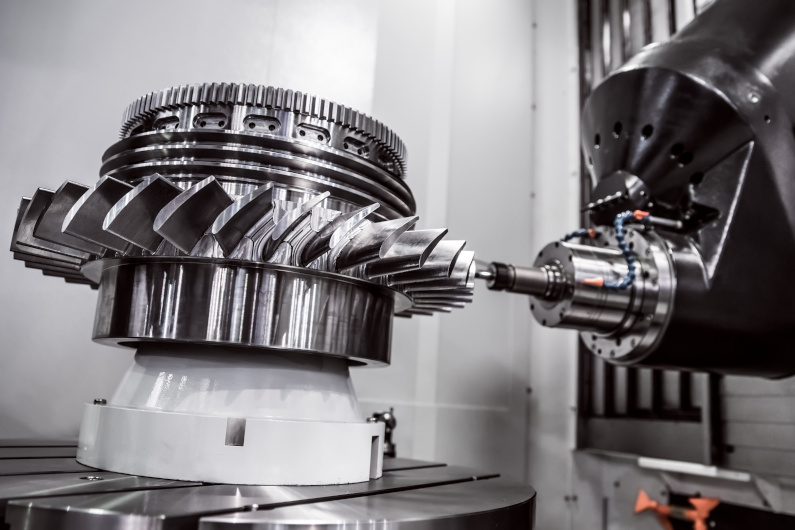

Our core capability centers on state-of-the-art 5-axis CNC turning centers. These machines enable complex geometries to be machined in a single setup, eliminating cumulative errors inherent in multi-setup processes. High-precision spindles with thermal compensation systems maintain stability during extended operations, while advanced toolpath strategies minimize tool deflection and vibration – key factors influencing surface integrity. We utilize premium carbide and CBN tooling optimized for specific materials, coupled with real-time process monitoring to detect and correct deviations before they affect surface finish. This integrated approach ensures superior Ra values and critical form tolerances across challenging alloys like Inconel, titanium, and medical-grade stainless steels.

Quality verification is embedded at every stage, not merely as a final check. Our dedicated Coordinate Measuring Machine (CMM) laboratory operates under ISO 17025 guidelines. Each critical feature undergoes comprehensive inspection using calibrated蔡司 CONTURA and Wenzel LH systems. We perform full geometric dimensioning and tolerancing (GD&T) analysis, including profile, flatness, roundness, and surface roughness measurements traceable to NIST standards. This data-driven QC process provides objective evidence of conformance and enables continuous process refinement. Statistical process control (SPC) charts are maintained for high-volume runs, ensuring long-term capability and early detection of any process drift affecting surface quality.

The following table details our standard and enhanced surface quality capabilities for precision CNC turning operations. All tolerances are achievable on production parts under controlled process conditions with appropriate material selection and part geometry.

| Parameter | Standard Capability | Enhanced Capability | Measurement Method |

|---|---|---|---|

| Geometric Tolerances | ±0.005 mm | ±0.001 mm to ±0.002 mm | CMM (Zeiss, Wenzel) |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm to 0.4 µm | Profilometer (Mitutoyo) |

| Roundness | 2.5 µm | 0.5 µm to 1.0 µm | Roundness Tester |

| Cylindricity | 5.0 µm | 1.0 µm to 2.0 µm | CMM |

| Runout (Total) | 0.010 mm | 0.003 mm to 0.005 mm | CMM / Dial Indicator |

| Material Finish Range | Aluminum, Steel, Stainless Steel, Titanium, Inconel | Exotic Alloys, Plastics | Visual / Microscopy |

This capability set, combined with our engineering expertise in material science and machining dynamics, allows Wuxi Lead to solve complex surface quality challenges. We partner with clients during the design phase to optimize manufacturability, ensuring the final turned component not only meets but exceeds functional surface requirements critical for performance in demanding operational environments. Consistent sub-micron repeatability is our benchmark.

Material & Finish Options

Material Selection for Surface Quality in Precision CNC Turning

Achieving superior surface quality in precision CNC turning begins with intelligent material selection. At Wuxi Lead Precision Machinery, we emphasize that the interplay between material properties and machining parameters directly influences the final surface finish, dimensional accuracy, and functional performance of turned components. Among the most widely used materials in high-end manufacturing—aluminum, steel, and titanium—each presents unique challenges and advantages in surface quality control.

Aluminum alloys, particularly 6061 and 7075, are favored for their excellent machinability, low density, and high thermal conductivity. These properties allow for high-speed cutting with minimal tool wear, resulting in smooth surface finishes often below 0.8 µm Ra without secondary operations. Aluminum’s softness enables fine detail reproduction, making it ideal for aerospace enclosures, heat sinks, and optical mounts. However, its low hardness necessitates careful handling post-machining to avoid surface marring.

Steel, especially in grades such as 303, 304, and 4140, offers superior strength, durability, and wear resistance. While more abrasive to cutting tools than aluminum, modern carbide inserts and optimized feed rates enable consistent surface finishes down to 1.6 µm Ra. The higher modulus of elasticity in steel ensures dimensional stability under load, critical for shafts, fittings, and industrial tooling. Nonetheless, achieving mirror-like finishes typically requires post-process polishing or grinding due to steel’s tendency to produce micro-burrs and tool marks.

Titanium alloys, notably Ti-6Al-4V, are selected for extreme environments where strength-to-density ratio and corrosion resistance are paramount. Despite their challenging machinability—due to low thermal conductivity and high chemical reactivity with cutting tools—titanium components can achieve surface finishes of 1.6–3.2 µm Ra under controlled conditions. Excessive heat buildup during turning can lead to surface oxidation or microcracking, so Wuxi Lead employs strict coolant management and low-cutting-speed strategies to preserve surface integrity.

Post-machining surface enhancement further elevates quality, especially anodizing for aluminum. Anodizing creates a hard, corrosion-resistant oxide layer that improves wear performance and allows for color coding. Type II (sulfuric acid) anodizing is standard for general applications, while Type III (hardcoat) anodizing delivers thicker, more durable coatings suitable for high-stress environments. Importantly, anodizing amplifies surface texture—imperfections are not hidden but accentuated—so achieving a high-quality anodized finish begins with precision turning to tight surface roughness tolerances.

Below is a comparative summary of key material properties and achievable surface finishes in CNC turning:

| Material | Typical Alloys | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Surface Finish (Ra, µm) | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061, 7075 | 310–570 | 150–200 | 0.4–0.8 | Aerospace, Electronics, Optics |

| Steel | 303, 304, 4140 | 500–1000 | 15–50 | 1.6–3.2 | Industrial Components, Shafts |

| Titanium | Ti-6Al-4V | 900–1000 | 6–7 | 1.6–3.2 | Medical Implants, Jet Engines |

Selecting the optimal material requires balancing mechanical requirements, environmental exposure, and surface quality targets. At Wuxi Lead Precision Machinery, our process-driven approach ensures that material choice and finishing methods are aligned to deliver components that meet the highest standards of precision and reliability.

Manufacturing Process & QC

Achieving Zero Defects in Surface Quality Precision CNC Turning

At Wuxi Lead Precision Machinery, surface quality is non-negotiable. Our Zero Defects philosophy governs every stage from initial concept to final shipment, ensuring components meet the most stringent aerospace, medical, and semiconductor specifications. This rigor begins in the Design Phase. Our engineering team conducts comprehensive Design for Manufacturability (DFM) analysis, scrutinizing geometries for optimal tool access, minimizing deflection risks, and selecting materials compatible with sub-micron surface finish requirements. Critical surface zones are explicitly defined, and toolpath strategies are simulated using advanced CAM software to predict and eliminate potential chatter marks or feed striations before metal is cut. Material certifications and thermal stability data are verified to prevent post-machining distortion affecting surface integrity.

The Prototyping Phase is where theoretical precision becomes tangible reality. Utilizing our high-rigidity turning centers equipped with sub-micron linear scales and proprietary vibration damping systems, we produce initial prototypes under production-intent conditions. Each prototype undergoes rigorous metrology: surface roughness (Ra, Rz) is measured via calibrated profilometers at multiple points, roundness and cylindricity are verified on high-precision CMMs, and visual inspection under controlled lighting identifies micro-burrs or anomalies. Data from this phase directly refines cutting parameters—optimizing spindle speed, feed rate, depth of cut, and coolant pressure—specifically targeting surface finish consistency. Only when prototypes consistently achieve the target specifications, validated against client benchmarks, does the process advance.

Mass Production executes the perfected process with unwavering control. Our CNC turning cells operate under strict environmental controls to minimize thermal drift. In-process probing verifies critical dimensions and surface location between operations, while real-time spindle power monitoring detects tool wear anomalies before they impact surface quality. Statistical Process Control (SPC) charts track key surface parameters from every batch, enabling immediate corrective action if trends approach tolerance limits. Every component undergoes 100% visual inspection under magnification and spot-check surface roughness verification against the master standard. This closed-loop system, combined with our ISO 9001-certified procedures and operator expertise, guarantees batch-to-batch repeatability and absolute adherence to the Zero Defects mandate. Surface excellence is not an outcome; it is engineered into every rotation of the spindle.

Critical Surface Quality Specifications Achieved

| Parameter | Target Value | Measurement Method | Tolerance Range |

|---|---|---|---|

| Ra (Arithmetic Avg) | 0.2 – 0.8 μm | ISO 4287 Calibrated Profilometer | ±0.05 μm |

| Rz (Max Height) | 1.0 – 3.2 μm | ISO 4287 Calibrated Profilometer | ±0.2 μm |

| Waviness (Wa) | < 0.5 μm | Filtered Profilometry | N/A |

| Visual Defects | None Acceptable | 10x Magnification, ISO 1302 | Zero Burrs, Scratches |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Surface Quality in CNC Turning

At Wuxi Lead Precision Machinery, we understand that surface quality is not just a specification—it’s a standard. In high-performance industries such as aerospace, medical device manufacturing, and advanced automation, the finish of a machined component directly impacts functionality, longevity, and compliance. That’s why our precision CNC turning processes are engineered to deliver surface finishes that consistently meet and exceed the most stringent industry requirements.

Our expertise lies in transforming raw materials into high-tolerance components with surface roughness values as low as Ra 0.2 µm. This level of precision is achieved through a combination of state-of-the-art CNC turning centers, advanced tooling technologies, and a rigorous quality control framework. Every spindle rotation, tool path, and coolant application is optimized to minimize vibration, reduce tool wear, and ensure uniform surface integrity.

What sets Wuxi Lead apart is our end-to-end control over the manufacturing process. From material selection and CNC programming to in-process inspection and final finishing, our team of certified engineers oversees every detail. We utilize real-time monitoring systems and non-contact profilometers to validate surface quality at multiple stages, ensuring traceability and consistency across production runs—whether you require a single prototype or high-volume batches.

We specialize in machining a wide range of materials, including stainless steel, titanium alloys, aluminum, and engineering plastics, all while maintaining micron-level tolerances and superior surface finishes. Our facility is ISO 9001:2015 certified, and we adhere to international standards such as AS9100 for aerospace and ISO 13485 for medical components.

When you partner with Wuxi Lead Precision Machinery, you’re not just outsourcing a machining task—you’re gaining a strategic manufacturing ally committed to excellence, reliability, and technical innovation.

Key Surface Quality and Precision Specifications

| Parameter | Specification |

|---|---|

| Surface Roughness (Ra) | As low as 0.2 µm (Ra), down to mirror finish |

| Dimensional Tolerance | ±0.001 mm |

| Roundness | ≤ 0.002 mm |

| Concentricity | ≤ 0.003 mm |

| Maximum Turning Diameter | 320 mm |

| Maximum Turning Length | 500 mm |

| Materials Supported | Stainless Steel, Titanium, Aluminum, Brass, Engineering Plastics |

| Quality Standards | ISO 9001:2015, AS9100 (aerospace), ISO 13485 (medical) |

Contact us today to discuss your precision CNC turning requirements. Let Wuxi Lead Precision Machinery elevate your component quality, reduce lead times, and support your engineering goals with unmatched surface finish consistency. For technical inquiries or project consultation, email us at [email protected]. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.