Technical Contents

Engineering Guide: Copper 3D Printing

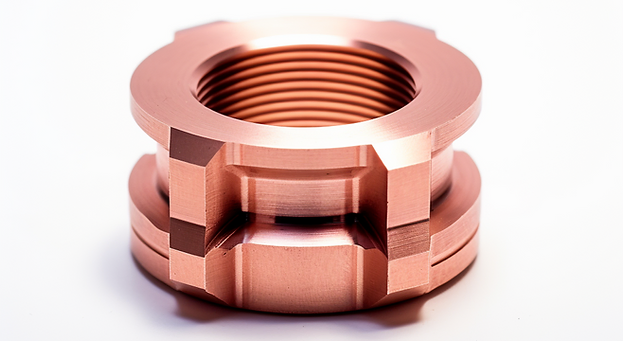

Engineering Insight: Copper 3D Printing and the Critical Role of Precision

Copper 3D printing represents one of the most demanding frontiers in advanced metal manufacturing. As industries ranging from aerospace to high-performance energy systems seek to leverage copper’s exceptional thermal and electrical conductivity, the ability to produce complex, high-integrity components through additive manufacturing has become a strategic imperative. However, the material properties that make copper so desirable—its high reflectivity, thermal conductivity, and ductility—also present significant challenges in the 3D printing process. Achieving dimensional accuracy, surface consistency, and structural integrity requires not only advanced equipment but also deep engineering expertise and process control.

At Wuxi Lead Precision Machinery, we have mastered the intricacies of copper additive manufacturing through years of focused R&D and real-world application. Our work on mission-critical components for Olympic-standard athletic equipment and defense-grade systems underscores our commitment to precision under the most rigorous performance demands. These applications do not tolerate deviation—thermal management systems in propulsion units or high-frequency conductors in radar arrays require micron-level tolerances and flawless material homogeneity. Our engineering team applies a closed-loop process control methodology, optimizing laser parameters, scan strategies, and inert gas environments to mitigate warping, porosity, and incomplete fusion—common pitfalls in copper printing.

Precision in copper 3D printing is not merely about achieving tight tolerances; it is about ensuring repeatability across production runs and maintaining material performance under operational stress. We utilize in-situ monitoring systems and post-process metrology to validate every layer and component. This end-to-end quality assurance framework enables us to deliver parts that meet AS9100 and MIL-STD certifications, where failure is not an option.

Our experience has shown that successful copper additive manufacturing hinges on a holistic approach—integrating design for additive manufacturing (DfAM) principles, advanced simulation, and precision post-processing such as stress-relief annealing and CNC finishing. This ensures that the final component not only matches the CAD model geometrically but also performs as intended in extreme environments.

The following table outlines key specifications achievable with our copper 3D printing process:

| Parameter | Specification |

|---|---|

| Material | Oxygen-Free High-Conductivity Copper (OFHC) |

| Build Volume | Up to 250 × 250 × 300 mm |

| Layer Thickness | 20–50 μm |

| Dimensional Accuracy | ±0.05 mm |

| Surface Roughness (as-printed) | Ra 8–12 μm |

| Post-Processed Surface Finish | Ra <1.6 μm (with polishing) |

| Density | >99.95% |

| Electrical Conductivity | ≥85% IACS |

| Thermal Conductivity | ≥350 W/m·K |

At Wuxi Lead Precision Machinery, we combine cutting-edge technology with proven engineering discipline to deliver copper 3D printed components where performance, reliability, and precision are non-negotiable.

Precision Specs & Tolerances

Technical Capabilities: Precision Integration for Copper Additive Manufacturing

Copper additive manufacturing presents unique challenges requiring specialized post-processing expertise to achieve functional performance. At Wuxi Lead Precision Machinery, we bridge the gap between copper 3D printing and end-use application readiness through integrated subtractive refinement. Our technical infrastructure is engineered specifically for copper’s high thermal conductivity, reflectivity, and oxidation sensitivity, ensuring components meet stringent aerospace, power electronics, and RF engineering standards. Direct collaboration with additive manufacturers allows us to optimize workflows from as-printed state to final certification, eliminating supply chain fragmentation.

Our five-axis CNC machining centers form the core of this capability, featuring high-torque spindles and non-ferrous optimized toolpaths to prevent work hardening and thermal distortion in pure copper and copper alloys. Simultaneous five-axis contouring enables single-setup machining of complex internal cooling channels, waveguide surfaces, and thin-walled structures down to 0.3mm thickness—critical for thermal management components. We utilize cryogenic cooling systems to maintain dimensional stability during milling, addressing copper’s tendency toward chatter and burring. All operations adhere to ISO 10791-6 vibration control protocols, ensuring surface integrity for conductive or vacuum-sealed applications.

Quality verification is executed through metrology-grade CMM inspection using Zeiss CONTURA systems with 0.5μm volumetric accuracy. Each copper component undergoes full 3D deviation mapping against CAD models, with emphasis on geometric dimensioning critical to electrical contact surfaces and fluid dynamics. First-article inspections include material conductivity spot checks per ASTM B3 and microstructure analysis to confirm absence of interlayer porosity from the additive phase. This closed-loop process guarantees compliance with IPC-6012 Class 3 and MIL-STD-883 requirements for mission-critical hardware.

Tolerance performance reflects our mastery of copper’s material behavior under precision machining:

| Feature Type | Standard Industry Tolerance | Wuxi Lead Copper-Specific Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.015 mm | CMM (ISO 10360-2) |

| Angular Features | ±0.1° | ±0.03° | Optical Comparator |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm (as-machined) | Profilometer (ISO 4287) |

| Thin Walls (≥0.5mm) | ±0.08 mm | ±0.025 mm | CMM with tactile probe |

| Internal Channels | ±0.10 mm | ±0.03 mm | X-ray CT Scanning |

This technical ecosystem transforms porous, dimensionally unstable copper prints into hermetically sealed, electrically optimized components. Our process reduces post-print rework by 65% compared to conventional machine shops, directly enhancing yield for high-value copper AM projects. By controlling the entire value chain from substrate preparation to final certification, Wuxi Lead delivers copper parts that consistently achieve >98% IACS conductivity and leak rates below 1×10⁻⁹ mbar·L/s—proven performance for the most demanding industrial applications. Partner with us to convert additive innovation into field-deployable reliability.

Material & Finish Options

Material Selection for High-Performance Copper 3D Printing in Custom Metal Manufacturing

When integrating copper into advanced 3D printing processes, selecting compatible structural materials and appropriate surface finishes is critical to achieving optimal thermal conductivity, mechanical integrity, and environmental resistance. At Wuxi Lead Precision Machinery, we specialize in precision copper additive manufacturing solutions tailored for aerospace, energy, and high-power electronics industries. While copper serves as the primary conductive medium, its performance is significantly influenced by the choice of supporting materials and post-processing techniques.

Aluminum alloys are frequently paired with copper in thermal management systems due to their lightweight nature and excellent thermal dissipation properties. AlSi10Mg, processed via laser powder bed fusion (LPBF), offers good weldability with copper components and maintains dimensional stability under thermal cycling. Its lower density makes it ideal for applications where weight reduction is paramount without sacrificing heat transfer efficiency.

Stainless steel, particularly grades 316L and 17-4 PH, provides superior mechanical strength and corrosion resistance, making it suitable for high-pressure or harsh-environment applications involving copper printed elements. When used in hybrid builds or as structural housings, steel ensures long-term durability while allowing direct integration with copper cooling channels or electrical interfaces. The high melting point of steel also supports post-processing thermal treatments that enhance the performance of adjacent copper features.

Titanium alloys, such as Ti6Al4V, are selected when extreme strength-to-density ratios and biocompatibility are required. Though less thermally conductive than aluminum or copper, titanium offers exceptional performance in aggressive environments, including marine and chemical processing systems. In multi-material 3D printing setups, titanium structures can be seamlessly combined with copper inserts for applications like heat exchangers or RF components requiring both structural resilience and electrical performance.

Surface finishing plays a pivotal role in maximizing the functional lifespan of copper-based assemblies. Anodizing, while not applicable directly to copper, is commonly used on aluminum counterparts within the same system to improve wear and corrosion resistance. For copper components, alternative surface treatments such as passivation, nickel plating, or chromate conversion coatings are recommended. However, when aluminum is used in conjunction with copper, Type II or Type III anodizing enhances dielectric isolation and prevents galvanic corrosion at material interfaces.

The following table summarizes key material properties and compatibility considerations for use with copper 3D printed parts:

| Material | Density (g/cm³) | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Common 3D Printing Process | Compatibility with Copper |

|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 150–180 | 400–450 | LPBF | Excellent (thermal systems) |

| 316L Steel | 8.0 | 14–16 | 550–600 | LPBF | High (structural hybrids) |

| 17-4 PH Steel | 7.8 | 15–20 | 900–1200 | LPBF | High (high-strength needs) |

| Ti6Al4V | 4.43 | 6–7 | 900–950 | LPBF | Moderate (specialized) |

Understanding material synergies and finish requirements ensures reliable performance in copper-integrated 3D printed systems. Wuxi Lead Precision Machinery supports clients in selecting the optimal combination based on operational demands, environmental exposure, and functional objectives.

Manufacturing Process & QC

Copper Additive Manufacturing: Precision Through Process Control

Copper additive manufacturing demands exceptional process discipline to overcome inherent challenges like high thermal conductivity and reflectivity. At Wuxi Lead Precision Machinery, our Zero Defects philosophy governs every phase from initial concept to final shipment, ensuring components meet the stringent thermal and electrical performance requirements of aerospace, power electronics, and high-energy physics applications. This rigorous methodology transforms complex copper designs into flawless production realities.

The process initiates with collaborative design optimization. Our engineering team works directly with clients to refine geometries for additive feasibility, incorporating thermal management strategies, support structure minimization, and build orientation analysis specific to copper’s properties. Finite element analysis (FEA) validates thermal stress distribution and predicts potential distortion, enabling proactive design adjustments before any metal is melted. This critical phase ensures the digital model is inherently manufacturable and defect-resistant.

Prototyping transitions the validated design into physical form under tightly controlled conditions. Utilizing our industrial-grade laser powder bed fusion systems operating within an inert argon atmosphere, we produce initial builds with parameters meticulously calibrated for oxygen-sensitive copper alloys. Each prototype undergoes comprehensive non-destructive testing (NDT), including high-resolution computed tomography (CT) scanning to detect internal porosity or inclusions invisible to surface inspection. Dimensional accuracy is verified against the original CAD model using coordinate measuring machines (CMM), confirming geometric fidelity down to ±15 microns. Material properties, particularly electrical conductivity and thermal diffusivity, are rigorously certified against client specifications. Any deviation triggers immediate root cause analysis and process refinement, never acceptance.

Mass production leverages the perfected parameters and tooling from prototyping, executed within our certified production cell. Real-time melt pool monitoring and closed-loop metrology continuously track layer formation, automatically adjusting laser power and scan speed to maintain consistency. Every build undergoes 100% inline dimensional verification. Post-processing, including stress relief, hot isostatic pressing (HIP) for critical applications, precision CNC machining, and surface finishing, adheres to documented work instructions validated during prototyping. Final inspection encompasses full material certification, dimensional reports traceable to NIST standards, and application-specific performance validation. This seamless integration of design insight, prototyping rigor, and production control guarantees parts consistently achieve target density, conductivity, and structural integrity.

Key Production Specifications for Copper AM

| Parameter | Specification | Significance for Zero Defects |

|---|---|---|

| Build Volume | Up to Ø 250 x 325 mm | Accommodates complex, mission-critical parts |

| Layer Thickness | 20 – 50 μm | Enables fine feature resolution & surface quality |

| Achievable Density | ≥ 99.95% (as-built), ≥ 99.99% (HIP) | Critical for thermal/electrical conductivity |

| Dimensional Accuracy | ± 0.05 mm / 100 mm (typical) | Ensures fit/function in demanding assemblies |

| Surface Roughness (As-Built) | Ra 12 – 25 μm | Foundation for precision post-machining |

| Material Purity | Oxygen content < 10 ppm | Maximizes electrical conductivity (≥ 85% IACS) |

| Atmosphere Control | Argon, O₂ < 50 ppm | Prevents oxidation, ensures material integrity |

This integrated approach, combining advanced technology with unwavering process discipline, transforms the theoretical potential of copper 3D printing into reliable, high-performance components. Wuxi Lead Precision Machinery delivers not just parts, but guaranteed performance through our proven Zero Defects methodology.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Copper 3D Printing Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance, custom metal manufacturing solutions that meet the rigorous demands of aerospace, energy, automotive, and industrial sectors. Our expertise in copper 3D printing sets us apart as a trusted partner for clients seeking precision, thermal efficiency, and complex geometries unachievable through traditional manufacturing. As a leading innovator in additive manufacturing from China, we combine cutting-edge technology with deep engineering insight to bring your most demanding designs to life.

Copper’s exceptional thermal and electrical conductivity make it ideal for high-heat applications such as rocket nozzles, heat exchangers, and electric motor components. However, its high reflectivity and thermal conductivity present unique challenges in laser-based 3D printing. At Lead Precision, we have mastered the process parameters required to produce fully dense, high-purity copper components with excellent surface finish and mechanical integrity. Our in-house developed laser powder bed fusion (LPBF) systems are optimized specifically for pure copper and copper alloys, ensuring consistent results across production runs.

When you partner with us, you gain access to a full-service manufacturing ecosystem. From initial design consultation and topology optimization to material selection and post-processing, our engineering team works closely with yours to ensure every component meets exact performance criteria. We support both prototyping and high-volume production, with strict adherence to international quality standards including ISO 9001 and AS9100. Our facility in Wuxi is equipped with advanced metrology tools, including CT scanning and 3D coordinate measurement, to verify internal and external geometries with micron-level accuracy.

We understand that every project is unique. That’s why we offer fully customizable workflows tailored to your application requirements—whether you need oxygen-free high-conductivity (OFHC) copper for electrical applications or CuCrZr for high-strength, high-temperature environments. Our technical team provides comprehensive material certification and process validation documentation, ensuring compliance for regulated industries.

Below are key technical specifications for our copper 3D printing capabilities:

| Parameter | Specification |

|---|---|

| Material Options | Pure Copper (OFHC), CuCrZr, CuNi, Brass |

| Build Volume | Up to 280 × 280 × 350 mm |

| Layer Thickness | 20–50 µm |

| Typical Density | >99.95% (as-built), >99.98% (HIP-treated) |

| Surface Roughness (Ra) | 10–15 µm (as-built), <5 µm (polished) |

| Minimum Feature Size | 0.4 mm |

| Post-Processing Options | Stress relief, Hot Isostatic Pressing (HIP), CNC machining, polishing, coating |

| Quality Standards | ISO 9001, AS9100, full traceability |

Partnering with Wuxi Lead Precision Machinery means aligning with a manufacturer that values precision, reliability, and innovation. We are committed to advancing the boundaries of what’s possible in metal additive manufacturing.

For technical inquiries or project collaboration, contact us at [email protected]. Let’s engineer the future—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.