Technical Contents

Engineering Guide: Anodising Service

Engineering Insight Precision Anodising for Mission Critical Applications

Precision anodising transcends basic surface treatment in high-performance manufacturing. It is an engineered process where microscopic control over oxide layer formation directly impacts component longevity, corrosion resistance, and functional reliability. At Wuxi Lead Precision Machinery, we recognize that dimensional stability during anodising is non-negotiable for aerospace, defense, and elite infrastructure components. Variations in temperature, electrolyte concentration, or current density as small as 0.5°C or 0.1 A/dm² can induce warpage in thin-walled geometries or compromise sealing integrity—failures unacceptable in systems operating under extreme stress.

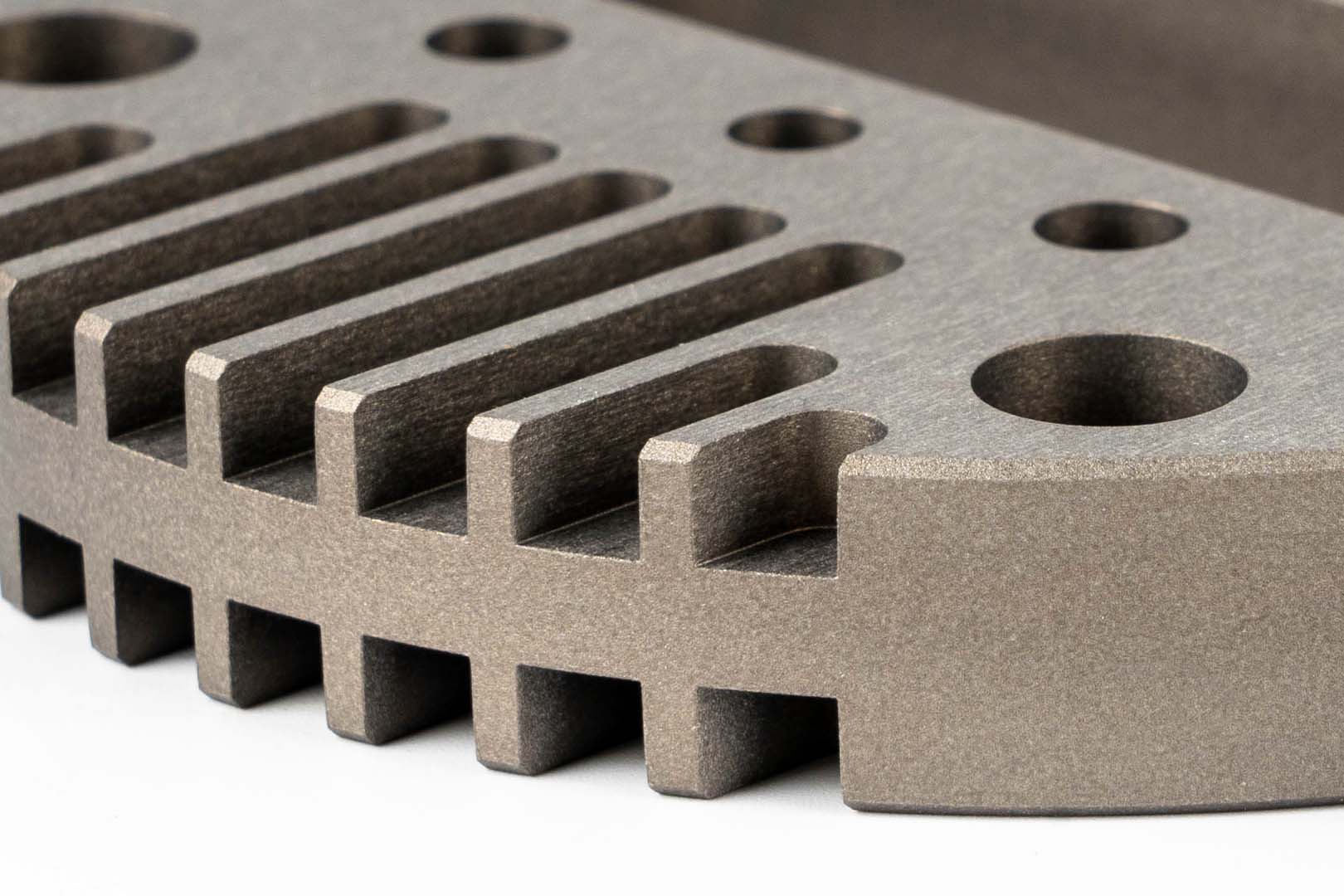

The challenge intensifies with complex geometries common in hydraulic manifolds, optical mounts, and structural brackets. Uniform current distribution across intricate features demands advanced racking techniques and real-time process monitoring. Without millimeter-level precision in fixture design and voltage sequencing, critical surfaces suffer from uneven coating thickness or dielectric breakdown. Our proprietary multi-stage anodising protocol addresses this through closed-loop control systems that dynamically adjust parameters based on real-time conductivity feedback, ensuring ±2μm thickness consistency even on parts with 10:1 aspect ratios.

This rigor stems from direct experience delivering anodised components for Olympic venue infrastructure and Tier-1 military suppliers. For Beijing 2022’s cable-suspended roof structures, we achieved color consistency within ΔE 0.3 across 12,000 m² of architectural aluminum—meeting ISO 28340 Class A standards under sub-zero installation conditions. Similarly, our MIL-A-8625 Type III hard anodising for defense-grade actuators maintains 500+ HV hardness with zero micro-cracking at 50μm thickness, validated through NADCAP-accredited testing. Such projects cement our understanding that precision anodising is a systems engineering discipline, not merely a finishing step.

Key performance metrics for mission-critical anodising are non-negotiable. The following specifications represent our baseline capabilities for high-integrity applications:

| Parameter | Standard Specification | Precision Capability (Wuxi Lead) | Test Standard |

|---|---|---|---|

| Coating Thickness | ±10% | ±4% (25-100μm range) | ASTM B244 |

| Surface Hardness | 300-400 HV | 480-520 HV (Type III) | ASTM E384 |

| Color Consistency (ΔE) | ≤1.5 | ≤0.4 | ISO 12647-7 |

| Pore Sealing Quality | 20 mg/dm² loss max | <5 mg/dm² loss | ASTM B137 |

| Dimensional Stability | ±0.05mm | ±0.01mm (critical axes) | ISO 2768-mK |

For manufacturers where component failure equates to operational catastrophe, anodising precision defines system resilience. Wuxi Lead Precision Machinery integrates metrology-grade process control with aerospace-proven validation protocols, transforming surface engineering into a strategic advantage. Our China-based facility operates under AS9100 and ISO 13485 frameworks, ensuring every anodised part meets the silent specifications of extreme environments—where tolerance isn’t measured in microns alone, but in mission success.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced anodising services integrated within a comprehensive custom metal manufacturing ecosystem. Our technical capabilities are engineered to meet the stringent demands of aerospace, medical, automotive, and industrial equipment sectors, where precision, durability, and surface integrity are non-negotiable. As a vertically integrated manufacturer based in Wuxi, China, we combine state-of-the-art 5-axis CNC machining with in-house anodising and certified quality control to ensure seamless production from raw material to finished component.

Our 5-axis CNC machining centers provide unparalleled geometric flexibility, enabling the production of complex, net-shape parts with minimal setup and exceptional repeatability. This precision foundation ensures that components are optimally prepared for anodising, with tightly controlled surface finishes and dimensional accuracy. The integration of multi-axis machining prior to surface treatment reduces cumulative tolerances and eliminates inter-facility variances often seen in outsourced workflows.

All anodising processes are conducted under controlled environmental and chemical conditions to achieve consistent coating thickness, hardness, and corrosion resistance. We specialize in Type II (sulfuric acid anodising) and Type III (hard coat anodising) processes, catering to both decorative and high-performance engineering applications. Our anodising lines are calibrated to accommodate a wide range of aluminum alloys, including 2024, 6061, 7075, and specialty grades, with options for dyeing, sealing, and post-treatment enhancements such as lubricity or wear resistance.

Quality assurance is embedded at every stage. Each component undergoes rigorous CMM (Coordinate Measuring Machine) inspection before and after anodising to verify dimensional stability and coating conformity. Our Zeiss and Hexagon CMM systems provide micron-level verification across complex geometries, ensuring that final parts meet or exceed customer-specified tolerances. Full inspection reports, including first-article and batch certifications, are available upon request, supporting compliance with ISO 9001:2015 and AS9100 standards.

The following table outlines our standard technical specifications and achievable tolerances for machined and anodised aluminum components:

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Machining Tolerance (Linear) | ±0.025 mm | ±0.010 mm |

| Positional Tolerance | ±0.02 mm | ±0.008 mm |

| Surface Finish (as-machined) | Ra 3.2 µm | Ra 0.8 µm (polished) |

| Anodising Type II Thickness | 8–15 µm | Up to 25 µm |

| Anodising Type III Thickness | 25–50 µm | Up to 75 µm (custom) |

| Hardness (Type III) | ≥500 HV | ≥600 HV |

| CMM Inspection Accuracy | ±2.5 µm + L/300 mm | Full 3D GD&T reporting |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Available on request |

By combining 5-axis precision, controlled anodising, and metrology-grade inspection, Wuxi Lead Precision Machinery ensures that every component meets the highest standards of performance and reliability. Our technical team collaborates directly with engineering partners to optimize designs for manufacturability, coating adhesion, and long-term service life.

Material & Finish Options

Material Selection Fundamentals for Precision Anodizing Services

Selecting the appropriate base material is the critical first step in achieving optimal anodized finishes for demanding industrial applications. At Wuxi Lead Precision Machinery, our extensive production experience confirms that aluminum stands as the sole primary candidate for conventional sulfuric acid anodizing processes. This electrochemical conversion coating fundamentally relies on the metal’s ability to form a stable, adherent oxide layer integral to the substrate. Aluminum alloys readily support this reaction, creating the porous structure essential for dye absorption and subsequent sealing, resulting in enhanced corrosion resistance, wear properties, and aesthetic control. Steel and titanium, while vital engineering materials, lack this inherent compatibility with standard anodizing chemistry.

Steel cannot undergo true anodizing. Attempts to apply sulfuric acid anodizing to steel result in rapid, uncontrolled etching and hydrogen evolution, destroying the surface integrity. Achieving corrosion resistance or decorative finishes on steel requires alternative processes such as zinc or cadmium plating, followed by chromate conversion coatings, or specialized powder coating systems. Titanium, while forming a naturally occurring oxide layer, does not develop the characteristic porous morphology required for classical anodizing dyeing and sealing through sulfuric acid electrolysis. Titanium surfaces can be colored via electrolytic coloring in specific electrolytes, but this is a distinct process yielding different performance characteristics compared to aluminum anodizing; it does not provide the same level of wear resistance or corrosion barrier properties inherent in a properly sealed anodized aluminum layer.

Therefore, for high-performance anodized components, aluminum alloys are exclusively recommended. The specific alloy grade significantly impacts the final finish quality, color consistency, and mechanical properties. Wrought alloys like 6061-T6 offer excellent balance for structural parts, while 7075-T73 provides superior strength for aerospace applications, though may exhibit slightly darker base colors. Cast alloys such as A380 require careful process parameter control due to higher silicon content affecting appearance. Surface preparation quality before anodizing is equally crucial; tight tolerances on machined surfaces directly translate to uniform coating thickness and appearance. Specify alloys known for anodizing compatibility and ensure stringent pre-treatment standards for optimal results.

The following table summarizes key material considerations for anodizing services:

| Material | Primary Anodizing Compatibility | Common Alloys for Anodizing | Typical Finish Outcomes |

|---|---|---|---|

| Aluminum | Excellent (Standard Process) | 6061-T6, 7075-T73, 2024-T3, 5052, A356, A380 | Hard, wear-resistant coatings; Excellent corrosion barrier when sealed; Wide color range via dyeing; Precise dimensional control; Enhanced electrical insulation |

| Steel | Not Applicable | 304, 316, 4140, 1018 | True anodizing impossible. Requires plating (e.g., zinc/nickel) + chromating or painting for corrosion/decorative finishes. |

| Titanium | Not Applicable (for standard anodizing) | Grade 2, Grade 5 (Ti-6Al-4V) | Electrolytic coloring possible for decoration only; Does not yield hard, sealed corrosion/wear resistant layer like aluminum anodizing. |

Partnering with an experienced anodizing provider like Wuxi Lead ensures precise material assessment and process execution. We rigorously validate alloy composition and surface condition prior to processing, applying tailored anodizing parameters to meet stringent aerospace, medical, and industrial specifications. Consult our engineering team early in the design phase to select the optimal aluminum alloy and define achievable finish requirements for your critical application.

Manufacturing Process & QC

Design Phase: Precision Engineering for Anodising Compatibility

At Wuxi Lead Precision Machinery, the anodising production process begins with meticulous design engineering. Our technical team collaborates closely with clients to analyze part geometry, material selection, and functional requirements. Given that anodising is an electrochemical process that builds a controlled oxide layer on aluminum surfaces, design integrity directly impacts coating uniformity, adhesion, and corrosion resistance. We assess wall thickness, corner radii, and tolerance zones to prevent stress concentrations and ensure even current distribution during anodising. Critical features such as masking areas, fixturing points, and electrical contact zones are integrated into the CAD model. Using advanced simulation software, we predict thermal expansion and dimensional shifts during processing, ensuring the final part meets tight tolerance specifications post-treatment. All designs undergo a Design for Manufacturability (DFM) review, specifically tailored for anodising compatibility, to eliminate potential defects before prototyping.

Prototyping: Validating Performance and Surface Integrity

Once the design is finalized, we proceed to low-volume prototyping. This phase is essential for verifying both mechanical function and surface treatment performance. Prototypes are machined from the same aluminum alloy—typically 6061, 7075, or 5052—intended for mass production. Each part undergoes precision CNC machining, deburring, and alkaline cleaning to prepare the surface for anodising. We then apply the specified anodising process, whether Type II (sulfuric acid anodising for decorative and moderate corrosion resistance) or Type III (hard anodising for extreme wear resistance). Coating thickness, hardness, and pore structure are rigorously tested using calibrated eddy current gauges, microhardness testers, and metallurgical microscopy. Salt spray testing (per ASTM B117) evaluates corrosion resistance, while CMM inspection confirms dimensional stability. Any deviations are traced back to design or process parameters, allowing corrective action before scaling to full production.

Mass Production: Zero-Defect Manufacturing with Full Traceability

With prototype validation complete, we transition to high-volume manufacturing under a zero-defect protocol. Our production line integrates automated handling, in-process inspection, and real-time process monitoring to maintain consistency. Each batch is tracked through a digital quality management system, ensuring full material and process traceability. Anodising parameters—bath composition, temperature, voltage, and dwell time—are continuously logged and controlled to ±2% of setpoints. Post-anodising, parts undergo 100% visual inspection under standardized lighting and magnification, with automated optical scanning for critical aerospace or medical components. Final QA includes adhesion tests (tape test per ASTM D3359), dimensional recheck, and batch sampling for salt spray and wear resistance. All documentation, including material certs, process logs, and inspection reports, is compiled for client review.

Typical Anodising Specifications at Wuxi Lead Precision Machinery

| Parameter | Type II (Standard) | Type III (Hard Anodising) | Standards Met |

|---|---|---|---|

| Coating Thickness | 5–25 µm | 25–100 µm | AMS 2471, MIL-A-8625 |

| Surface Hardness | 200–300 HV | 500–800 HV | ASTM E384 |

| Corrosion Resistance | 96–240 hrs (5% NaCl) | 500+ hrs (5% NaCl) | ASTM B117 |

| Tolerance Control | ±0.01 mm (post-treatment) | ±0.015 mm (post-treatment) | ISO 2768, GD&T |

| Color Options | Clear, Bronze, Black | Clear, Black | Custom color matching (RAL) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Anodising Solutions

When component performance hinges on surface integrity, corrosion resistance, and dimensional stability, your anodising partner must deliver uncompromising precision. At Wuxi Lead Precision Machinery, we engineer anodising services as an integrated extension of your manufacturing workflow—not as a standalone process. Our ISO 9001-certified facility combines aerospace-grade quality systems with deep expertise in CNC-machined part preparation, ensuring every anodised component meets exacting global standards. We eliminate the risk of adhesion failure, color inconsistency, or tolerance drift that plagues generic surface treatment providers. For industries where failure is not an option—medical devices, semiconductor tooling, or defense systems—our process control guarantees repeatability down to sub-micron tolerances.

Our technical capability spans Type II (sulfuric acid) and Type III (hardcoat) anodising, with rigorous control over critical parameters. Below are core specifications defining our production envelope:

| Parameter | Type II Standard | Type III Hardcoat | Tolerance Control |

|---|---|---|---|

| Coating Thickness | 5–25 μm | 25–100 μm | ±2 μm |

| Surface Hardness | 200–300 HK | 500–700 HK | ±15 HK |

| Color Range | Clear, Black, Bronze, Gold, Red, Blue | Black, Grey, Olive Drab | ΔE < 0.5 (vs. standard) |

| Dimensional Impact | < 0.002 mm per surface | < 0.005 mm per surface | Verified via CMM pre/post-process |

| Salt Spray Resistance | 336+ hours (ASTM B117) | 1000+ hours (ASTM B117) | Certified test reports provided |

Unlike commodity anodisers, we begin with your CAD model and material certification. Our engineers collaborate during the design phase to optimize part geometry for uniform current distribution, preventing edge buildup or shadowing defects. All batches undergo 100% thickness verification via eddy current and cross-section microscopy, with full traceability from raw material lot to finished component. This integration with your CNC machining workflow—executed within our 12,000m² facility—slashes lead times by eliminating third-party logistics and quality handoffs.

Partnering with Lead Precision means accessing a single point of accountability for complex metal finishing. Our technical sales team includes degreed metallurgists who speak your engineering language, providing data-driven solutions—not generic quotations. We support global supply chains with EXW, FOB, and DDP shipping, compliant with REACH, RoHS, and ITAR frameworks. When your project demands zero-defect surface engineering, our closed-loop process ensures every anodised part performs exactly as designed, in every environment.

Initiate your precision anodising project with engineering rigor, not guesswork. Contact our technical sales team at Contact [email protected] to schedule a confidential consultation. Include your component specifications, target volumes, and performance requirements. We will respond within 4 business hours with a tailored process validation plan—including sample production timelines and first-article inspection protocols. Trust Wuxi Lead to transform your surface treatment from a cost center into a competitive advantage. Your next breakthrough component starts here.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.